LED-UV light curing solventless varnish

A solvent-free, light-curing technology, applied in anti-corrosion coatings, coatings, etc., to achieve the effects of improving corrosion resistance, eliminating pinholes in coatings, and excellent physical and chemical properties

Inactive Publication Date: 2019-06-07

上海君子兰新材料股份有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide a LED-UV light-curing solvent-free varnish, which solves the problem of curing the surface layer of the oxygen-inhibited polymer paint film, has clean taste, clear, no yellowing, and has excellent physical and chemical properties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

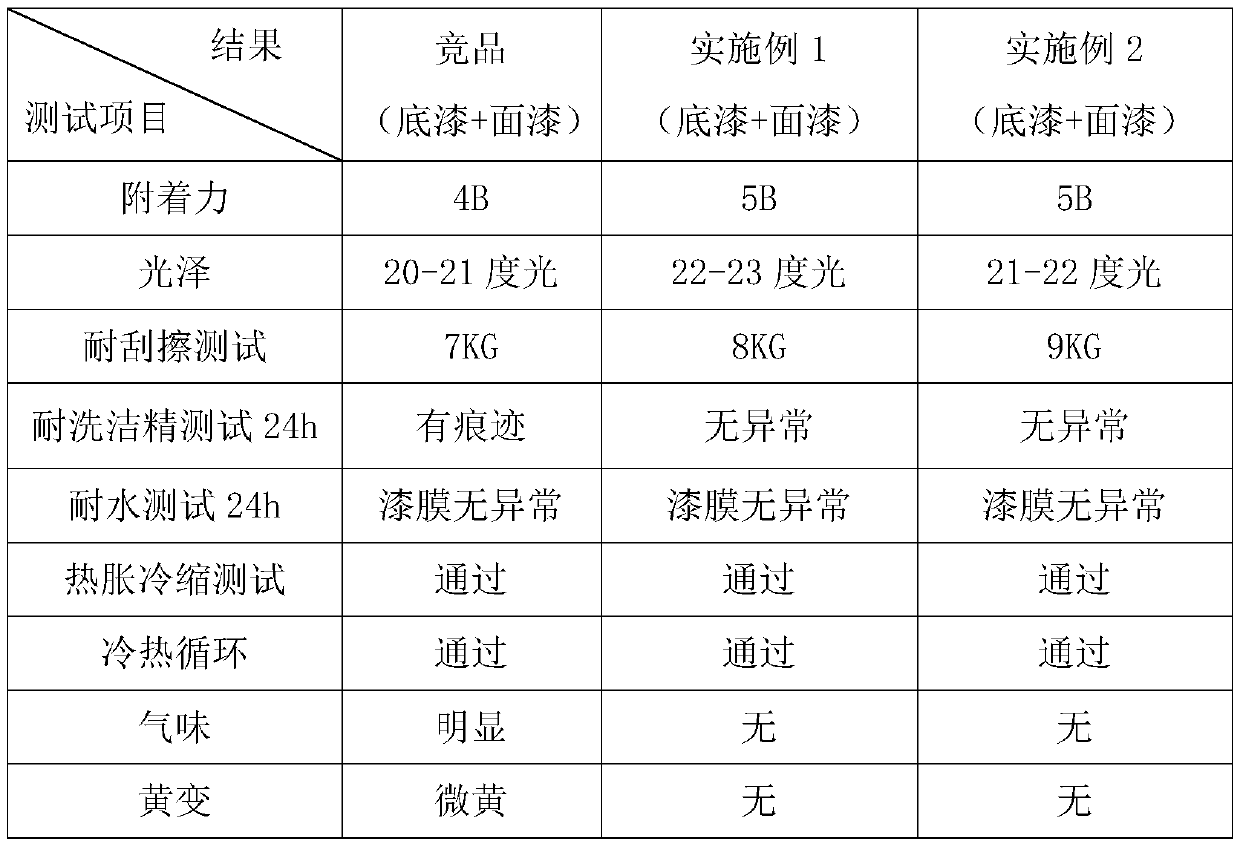

Comparison scheme

Effect test

Embodiment 1

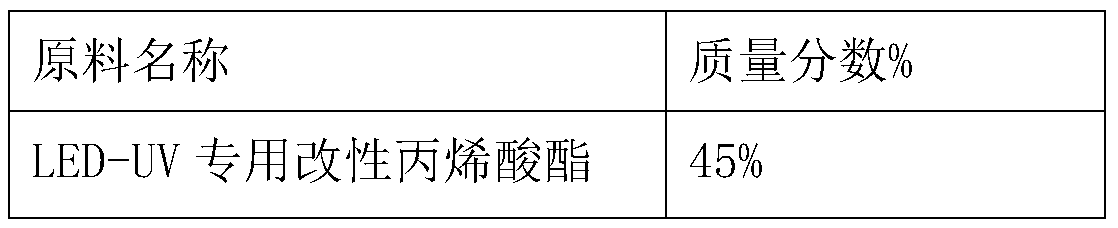

[0033] Example 1: Primer:

[0034] raw material name

Mass fraction%

Modified acrylate for LED-UV

45%

active monomer

35.5%

Photoinitiator for LED-UV

6%

Dispersant

1%

0.3%

filler

12%

leveling agent

0.2%

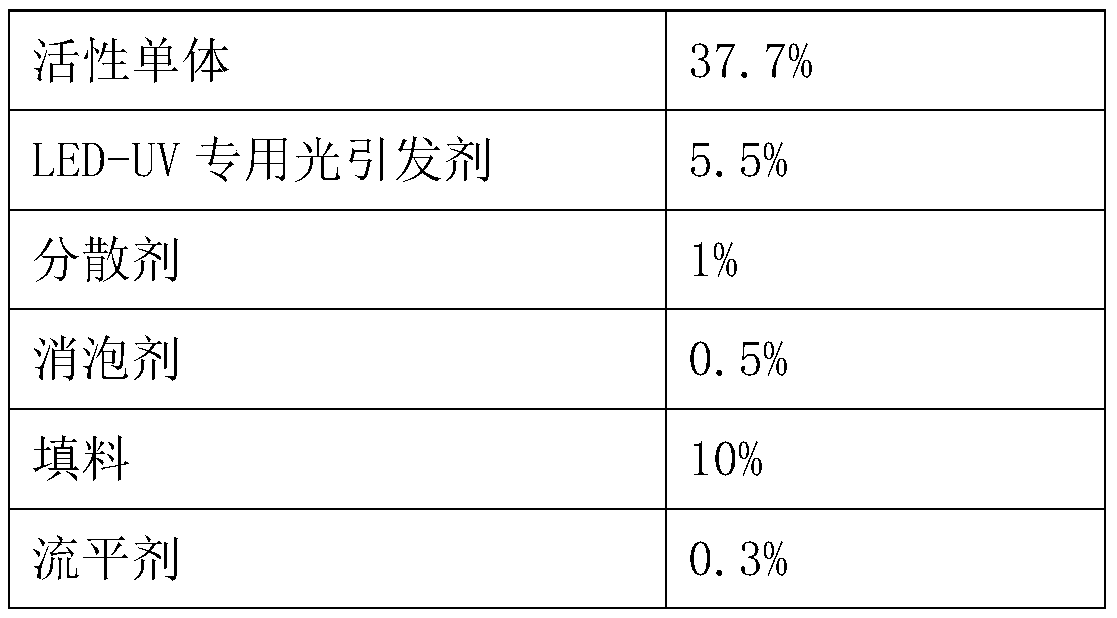

[0035] Topcoat:

[0036] raw material name

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a LED-UV light curing solventless varnish. The varnish comprises a primer and a topcoat which are cooperatively used; wherein the primer is prepared by the following componentsin mass percent: 40-50% of modified acrylate special for LED-UV, 30-40% of an active monomer, 5-6%of a photo initiator special for LED-UV, 0-1% of a dispersant, 0-1% of an anti-foaming agent, 10-15%of a filler, and 0-1% of a leveling agent; and the topcoat is prepared by the following components in mass percent: 40-55% of modified acrylate special for LED-UV, 35-45% of an active monomer, 4-6% ofa photo initiator special for LED-UV, 0-1% of a dispersant, 0-1% of an anti-foaming agent, 5-10% of delustering powder, and 0-1% of a leveling agent. The prepared varnish products can break through the problem of oxygen inhibitory polymerization, pinholes in the coating can be eliminated, the corrosion resistance is improved, and the paint film surface layer curing, taste cleaning, clearing and no yellowing are achieved, so that the varnish has excellent physical and chemical properties.

Description

technical field [0001] The invention relates to IPC classification C09D coating composition product technology, in particular to an LED-UV photocurable solvent-free varnish. Background technique [0002] UV paint is ultraviolet photocurable paint, also known as photoinitiated paint and photocured paint. It is automatically rolled and showered onto the surface of the furniture board by machinery and equipment. Under the irradiation of ultraviolet light, the initiator is decomposed, free radicals are generated, the resin is reacted, and the resin is instantly cured to form a film. It is currently the most environmentally friendly paint. UV paint has been widely promoted in the furniture industry due to its high efficiency, environmental protection and good mechanical properties. [0003] At present, the light source used by most UV paints is mercury lamps. Mercury lamps are bulky, slow to start, and have a wide excitation spectrum band. The curing effect is mainly on a wavele...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D4/02C09D4/06C09D5/08

Inventor 刘伟范新强邓文根

Owner 上海君子兰新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com