Patents

Literature

39results about How to "Avoid scrap rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

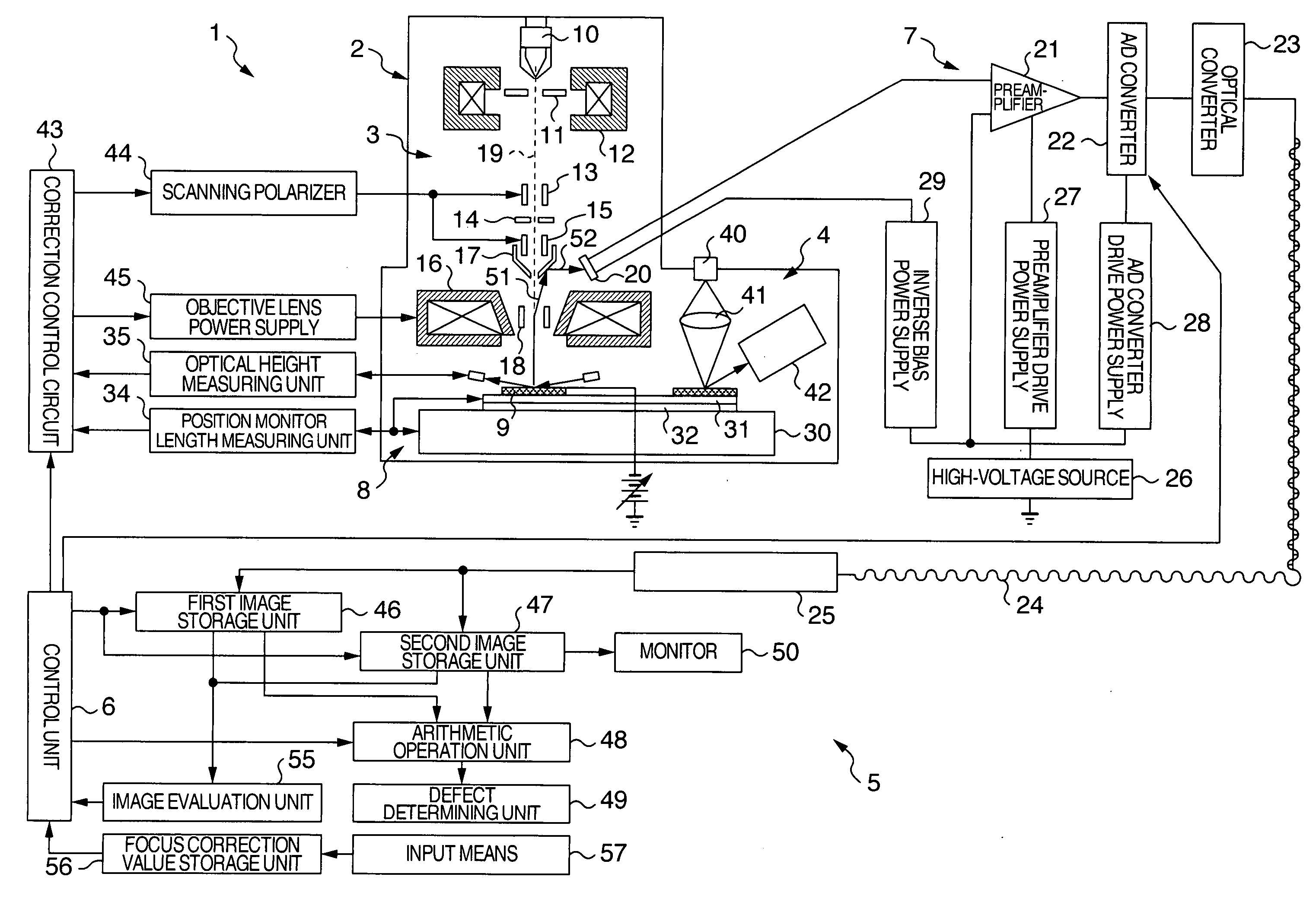

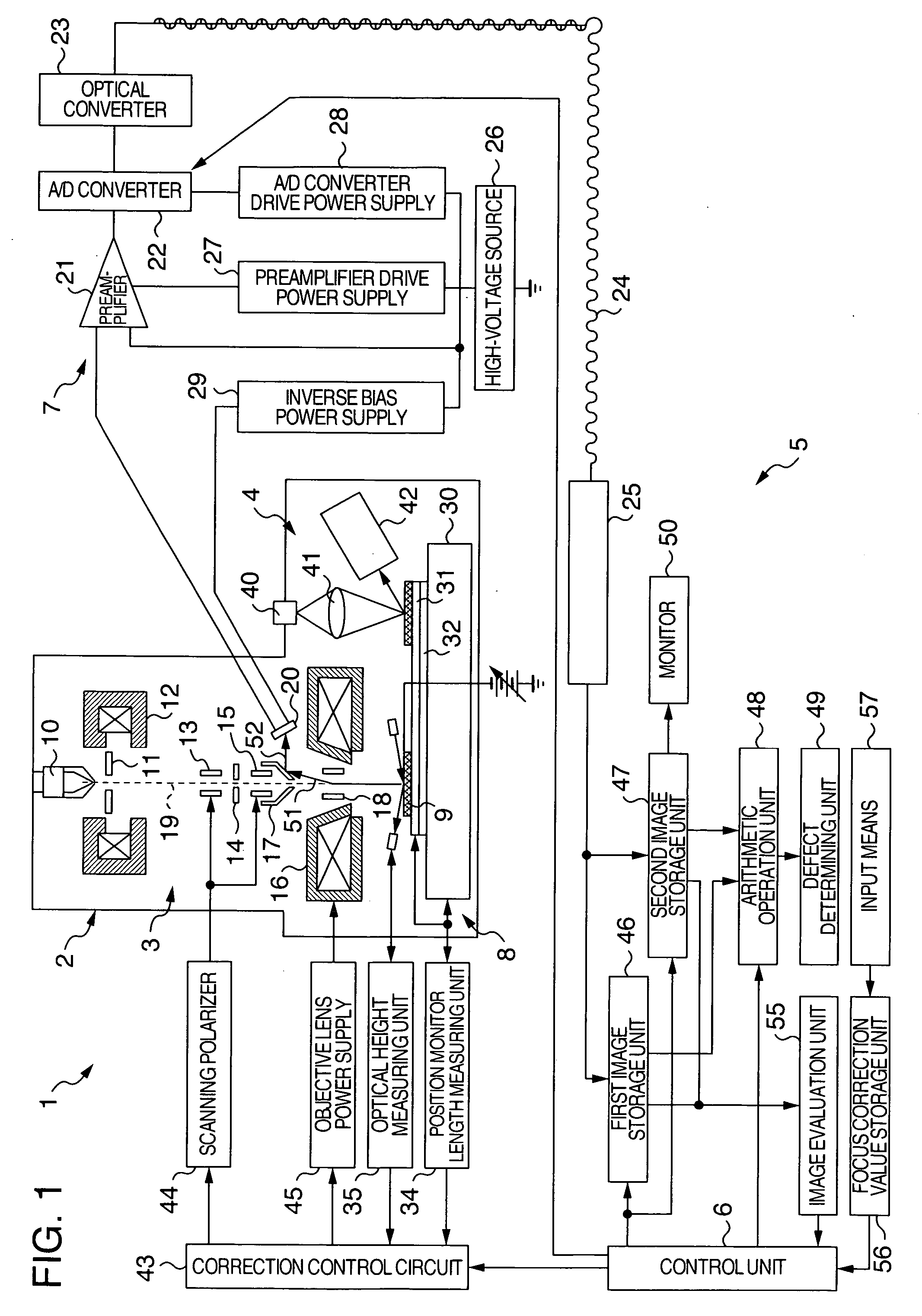

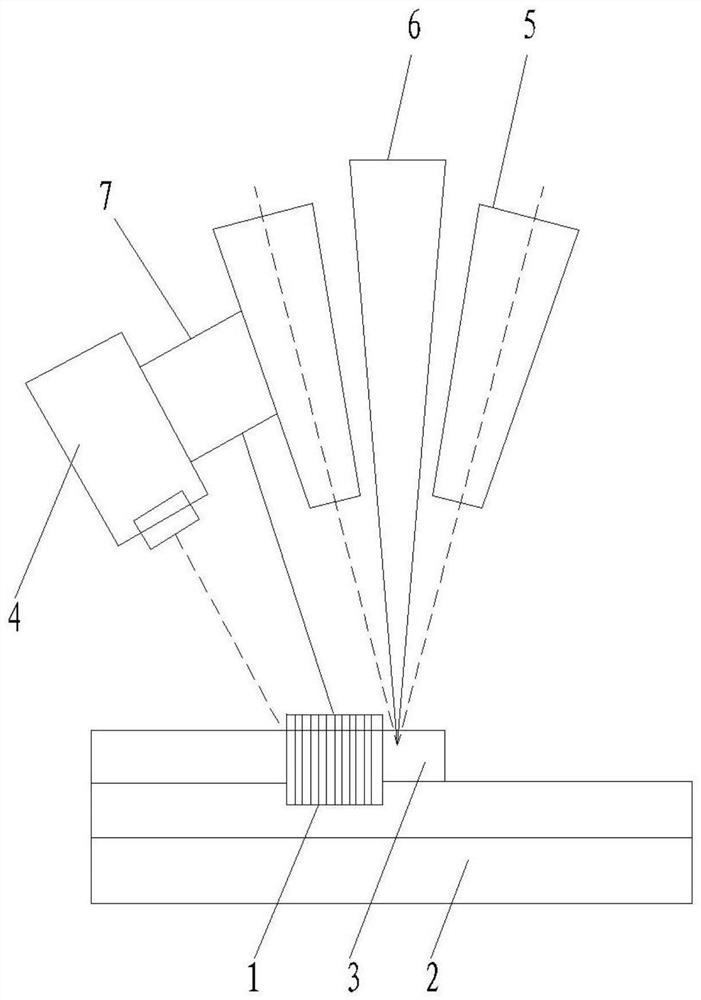

Focus correction method for inspection of circuit patterns

InactiveUS20060284088A1Avoid scrap rateReduce false informationMaterial analysis using wave/particle radiationElectric discharge tubesComputational physicsEngineering

A charged particle application circuit pattern inspection apparatus and method are disclosed, in which the reduction in the rejection rate attributable to an out-of-focus state due to the change in the charge condition on the sample surface is prevented and the false information is reduced to improve the apparatus reliability. The image acquisition position on a sample is stored in an image acquisition position storage unit, a focus correction value is stored in a focus correction value storage unit in accordance with the image acquisition position and the sample charge condition, the inspection conditions and the sample to be inspected are input from an input unit, the sample charge condition is evaluated in accordance with the image position acquisition position, and the focal point is corrected by a focus correction unit.

Owner:HITACHI HIGH-TECH CORP

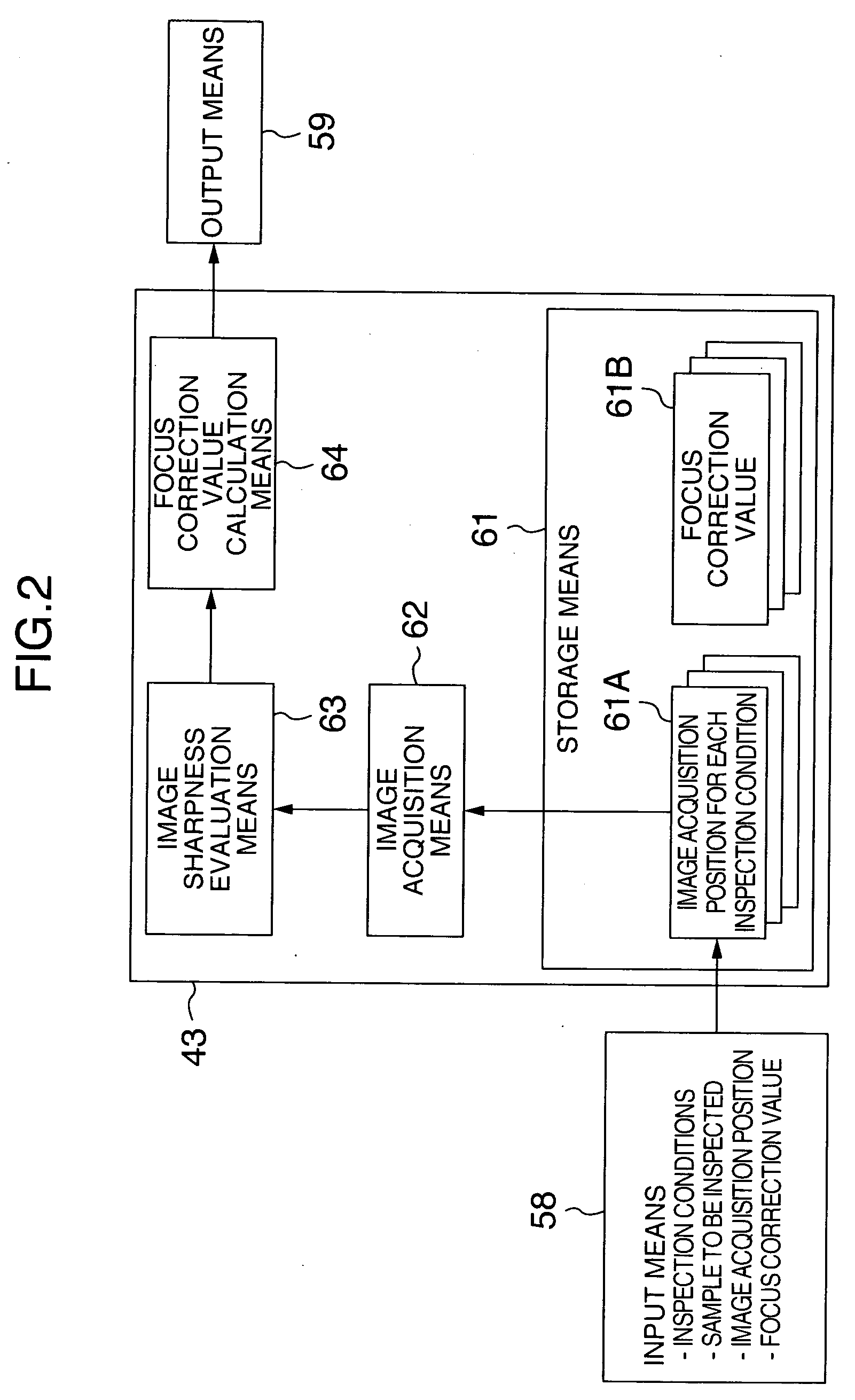

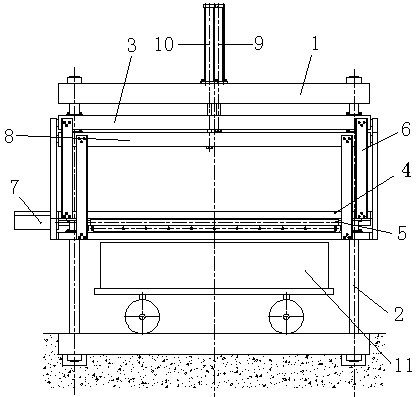

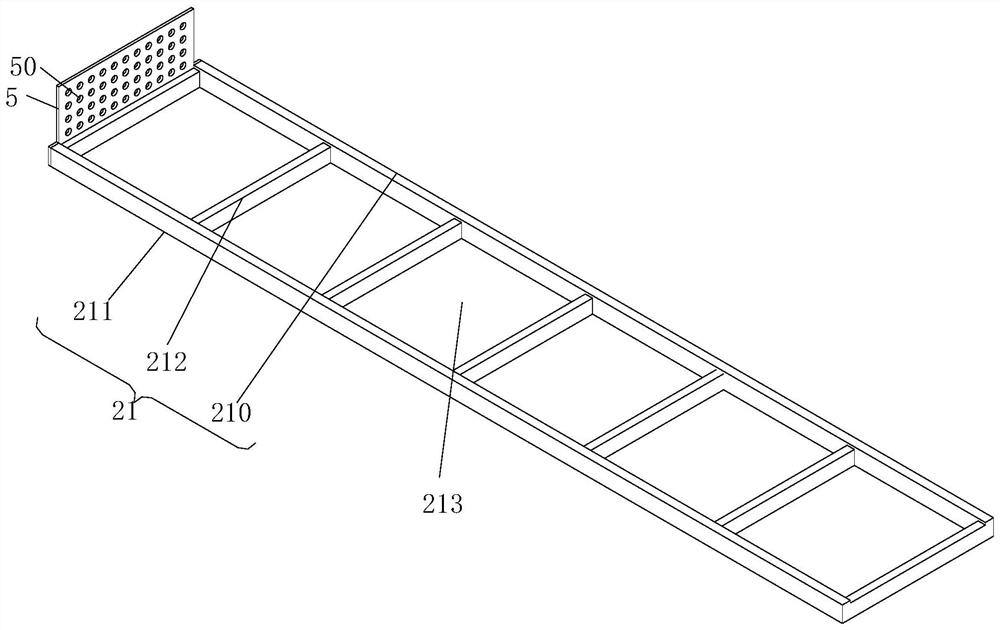

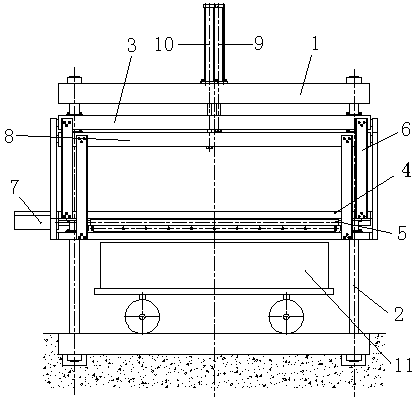

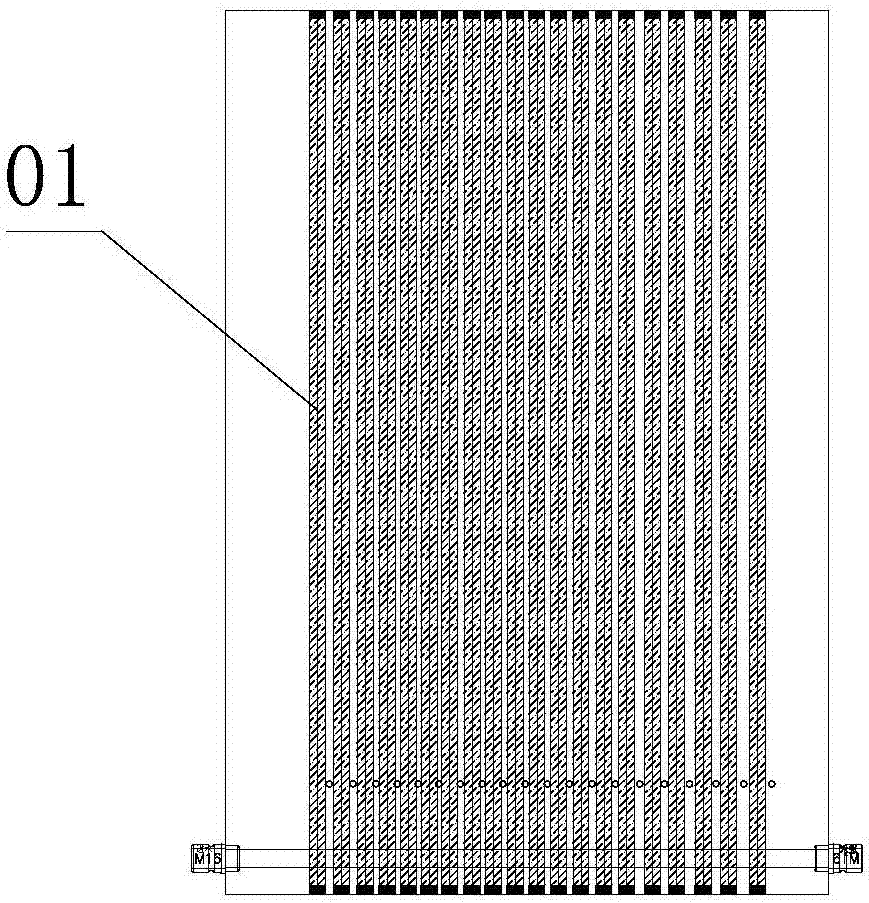

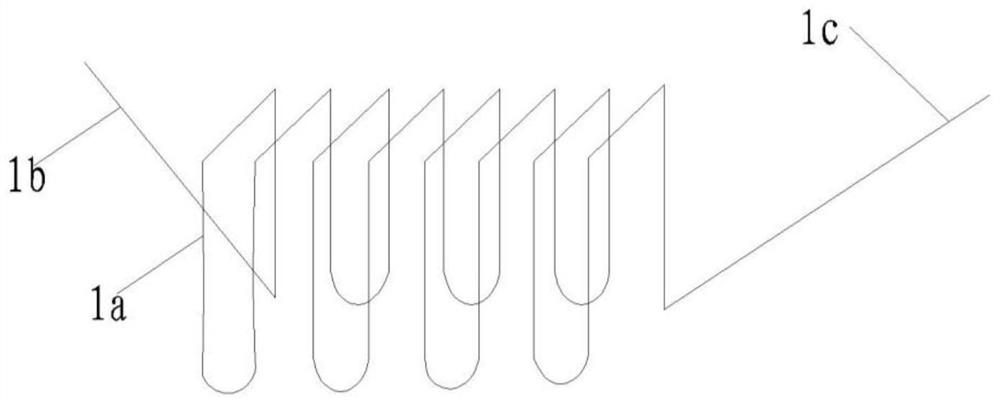

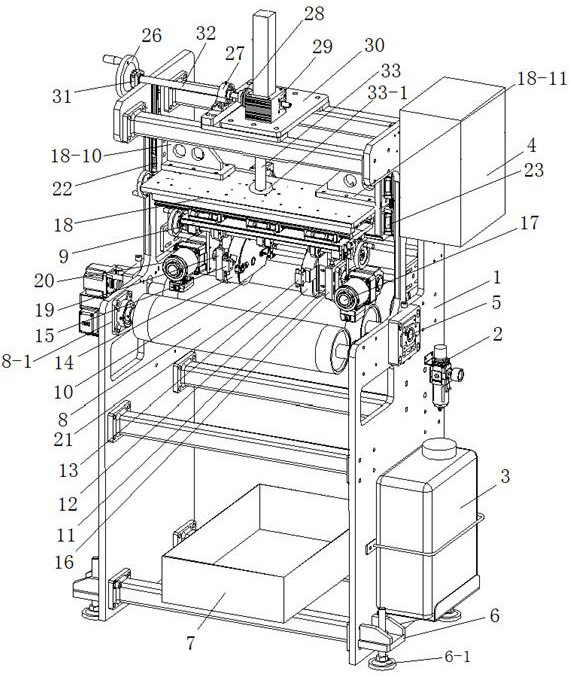

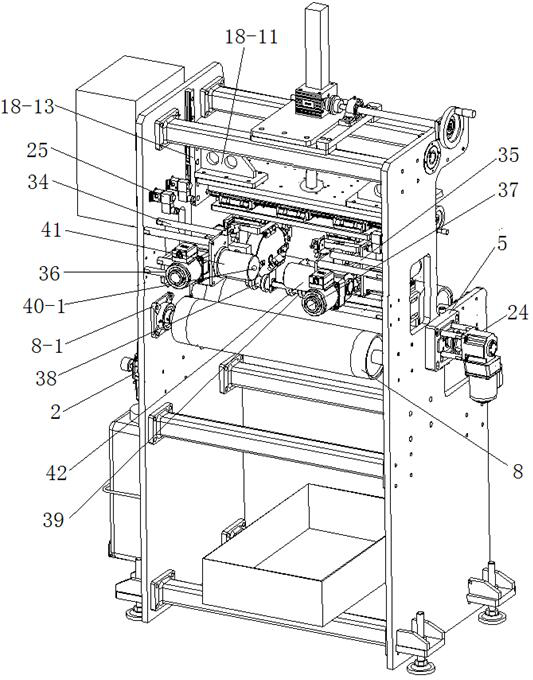

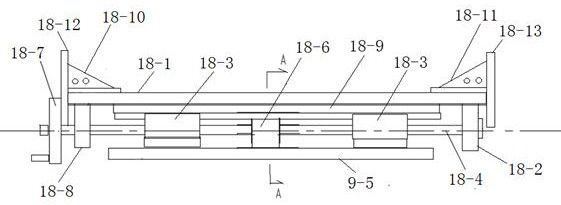

Cutting machine for foamed concrete blocks

InactiveCN102601855AAvoid cross interferenceThe overall structure is simpleCeramic shaping apparatusStructural engineeringMechanical engineering

The invention discloses a cutting machine for foamed concrete blocks, which comprises a rectangular frame and a cutting device. Four guide columns are vertically arranged at four corners of the rectangular frame. The cutting machine is characterized in that the cutting device comprises a transverse cutting mechanism and a vertical cutting mechanism. Compared with the prior art, the cutting machine has the advantages that the transverse cutting mechanism and the vertical cutting mechanism are separately arranged, so that cross interference can be well avoided. Further, since the transverse cutting mechanism and the vertical cutting mechanism are both obtained by basically identical structures, the integral structure is relatively simple, implementation is convenient, and implementation cost is low. Transverse cutting and longitudinal cutting are operated separately, a travelling mechanism drives a cutting wire to reciprocate for extruding cutting during reciprocated friction, and accordingly cutting resistance is greatly reduced while energy loss is reduced. More importantly, smoothness in cutting is improved, concrete blank disintegration is avoided, cutting success rate is greatly increased, and product scrappage is decreased.

Owner:重庆市旌弘建材有限公司

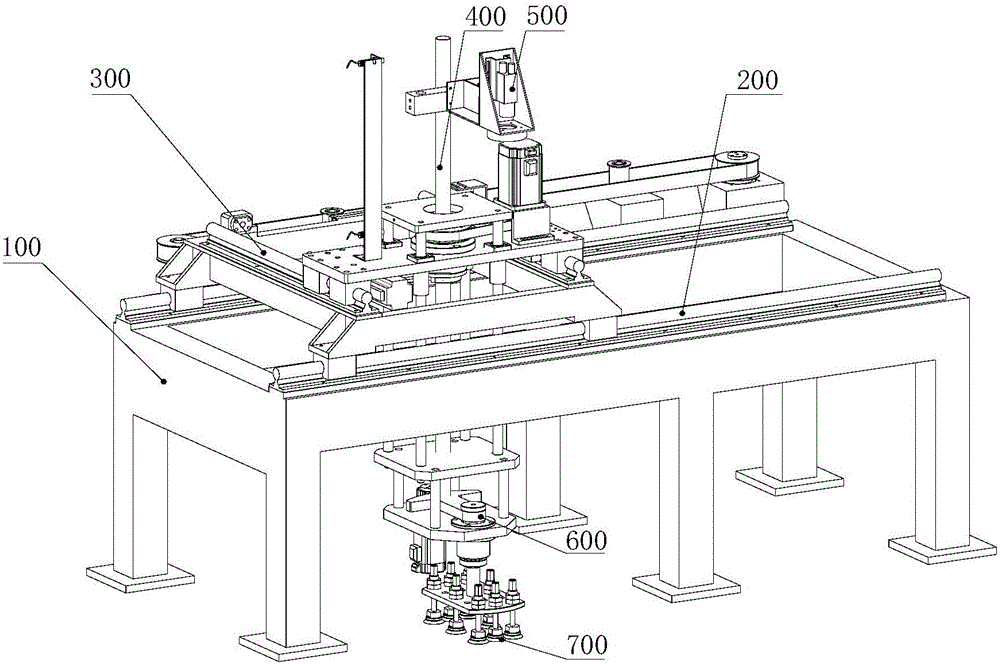

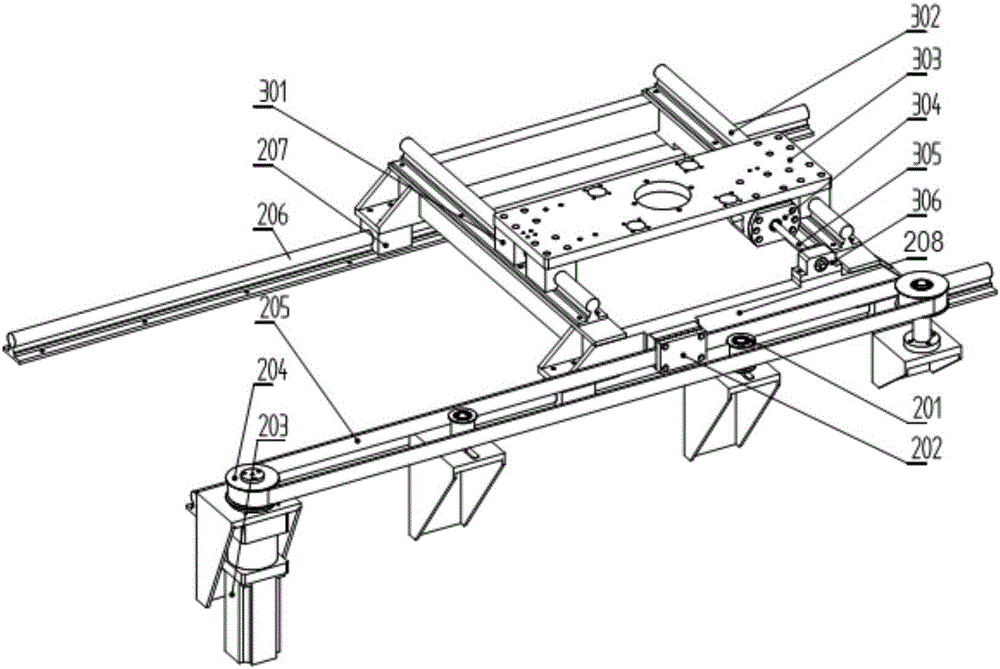

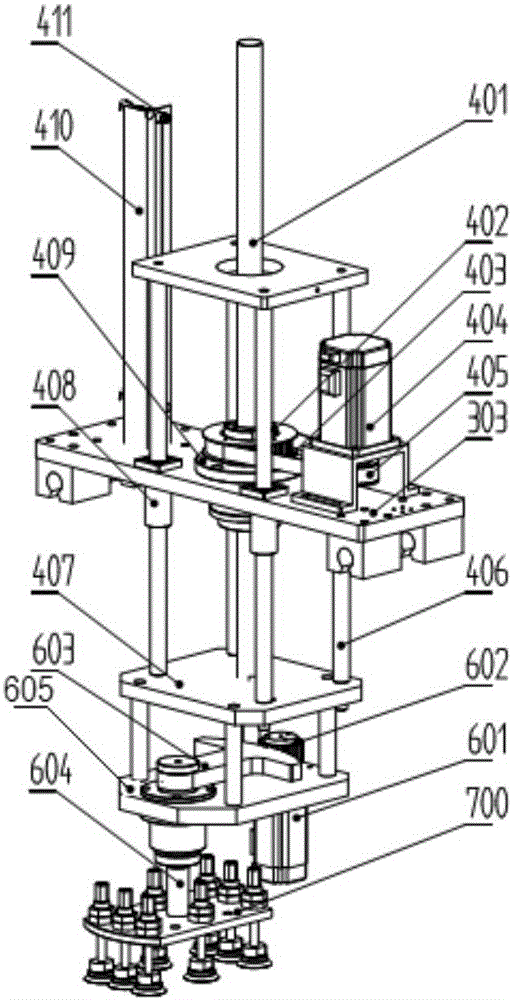

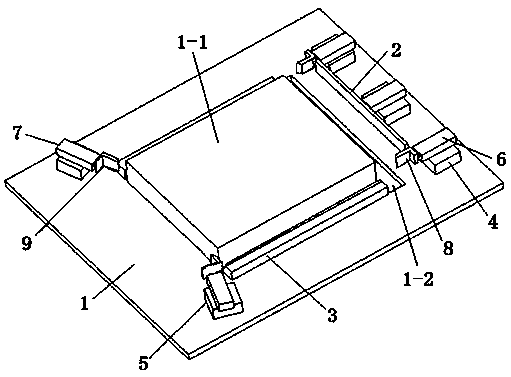

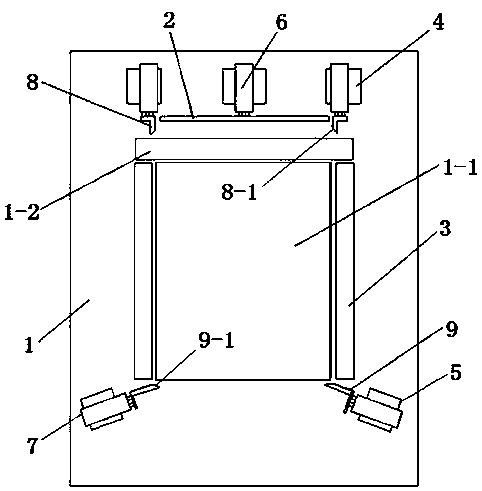

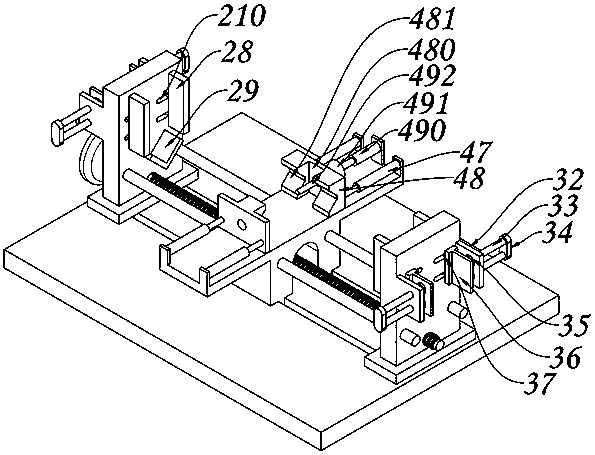

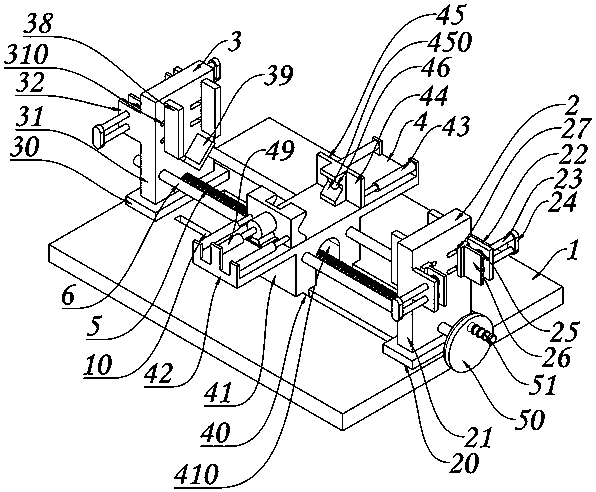

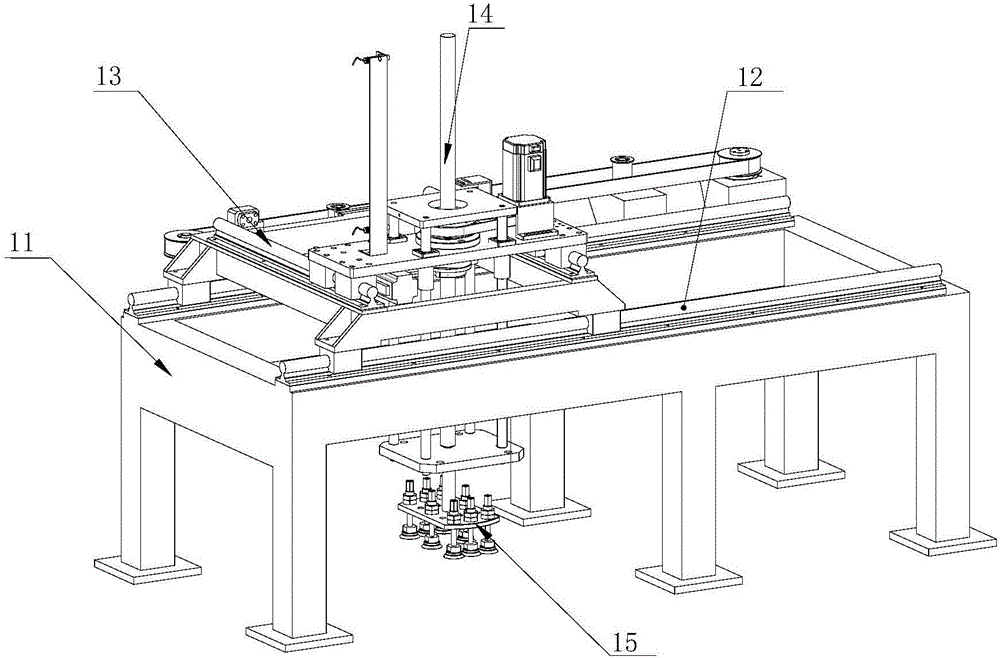

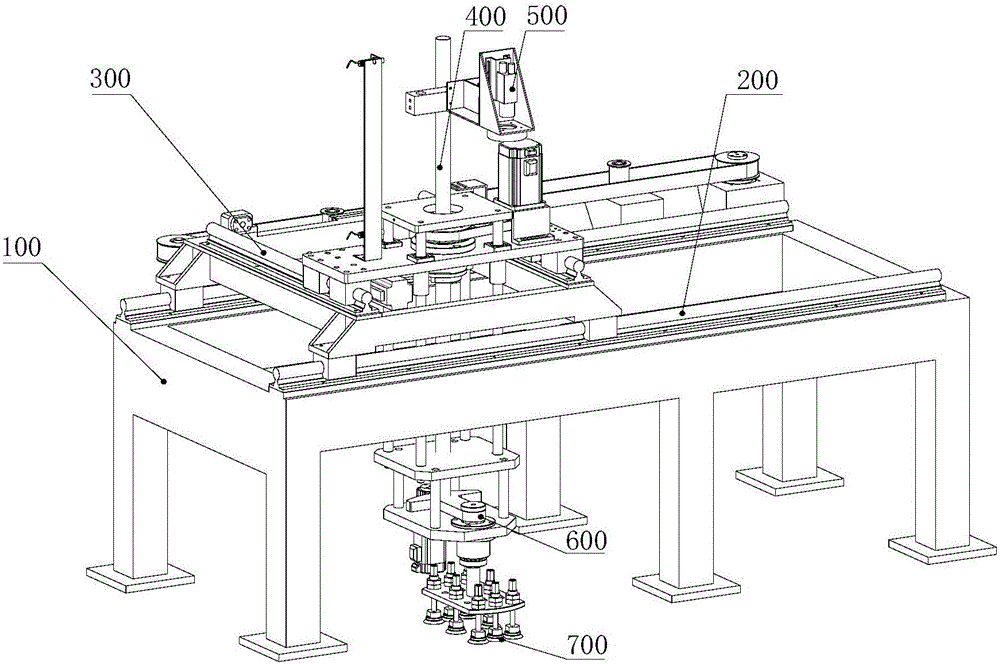

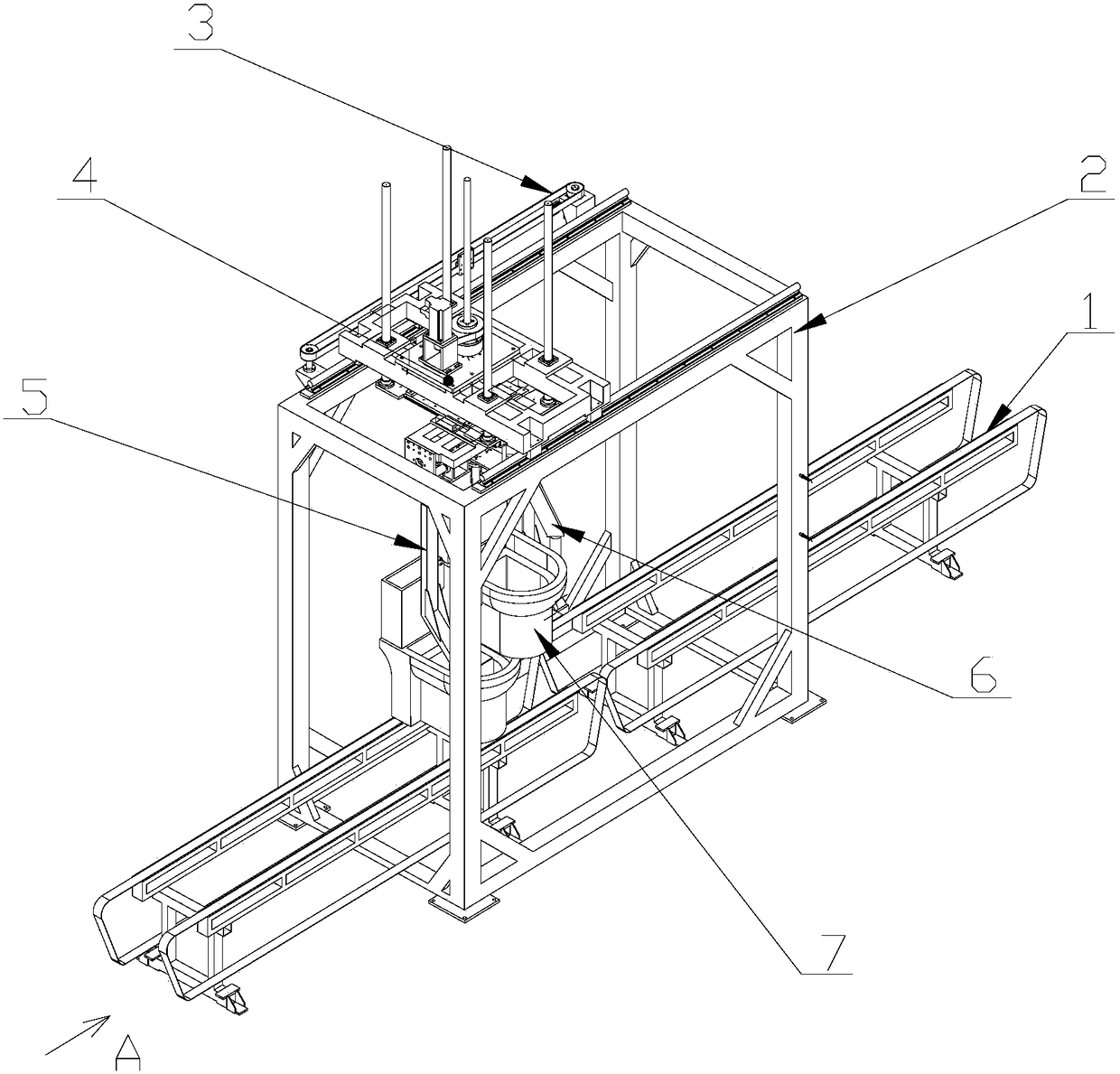

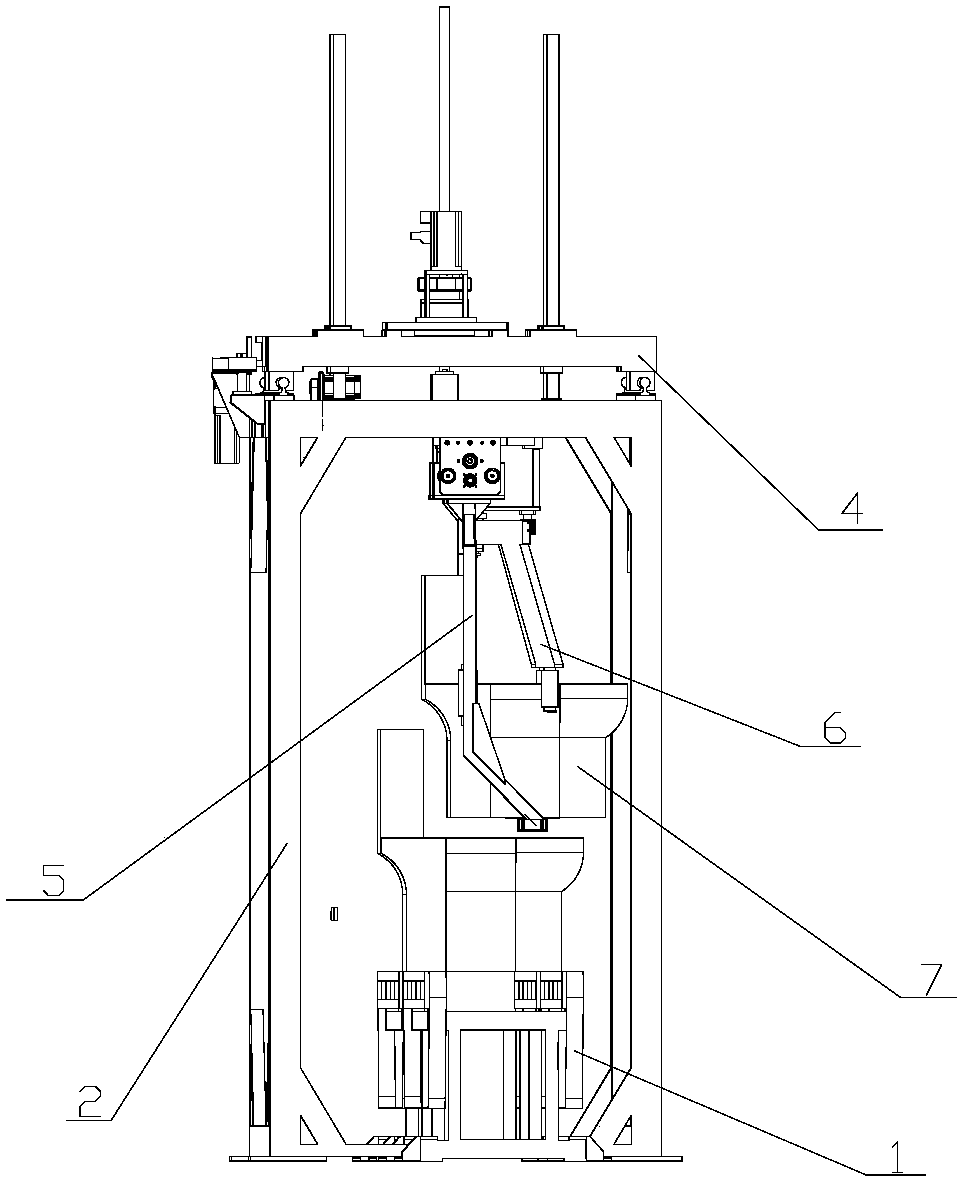

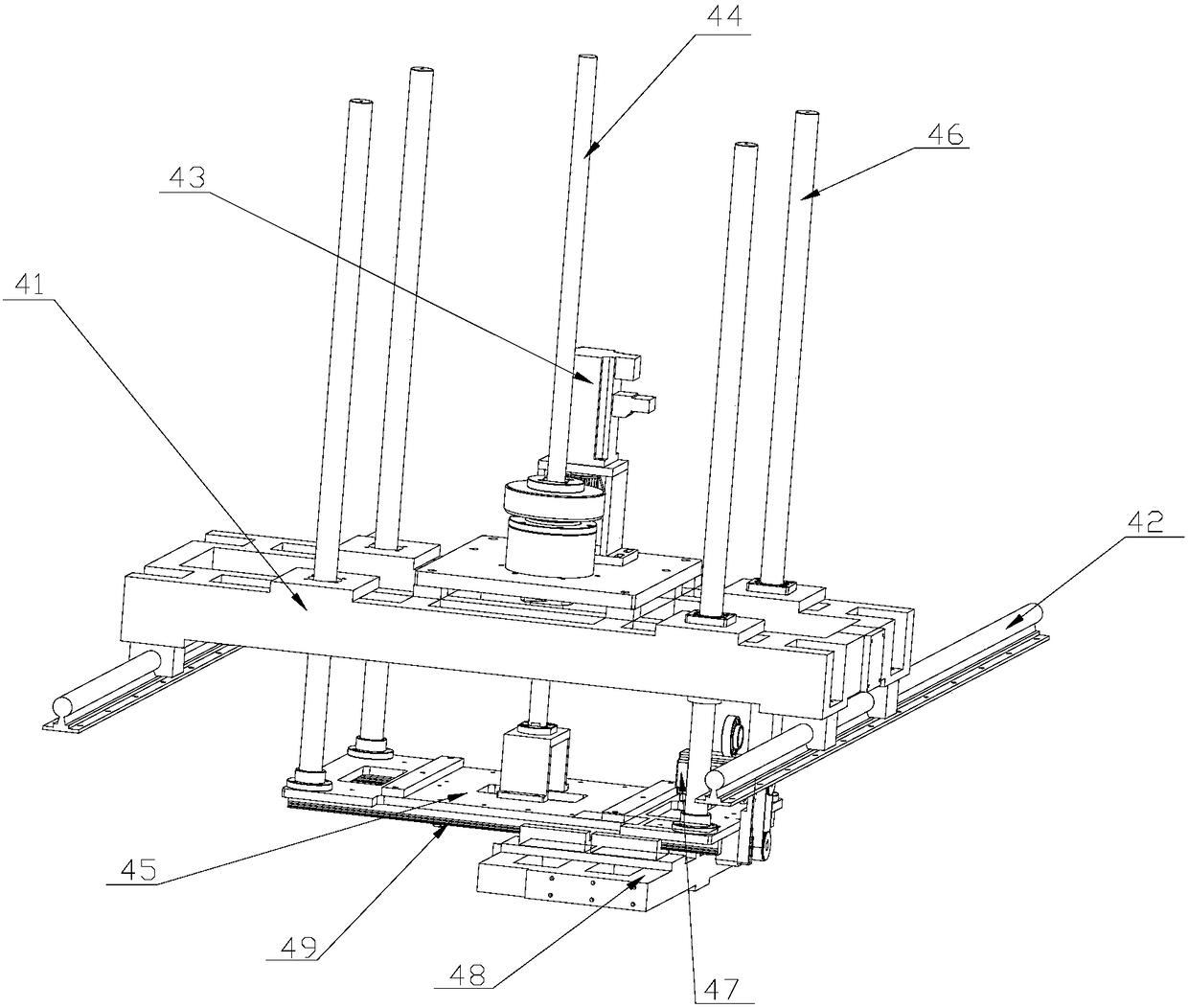

Automatic covering system of ceramic toilet water tank cover

ActiveCN105729081AImprove working environmentReduce work intensityWater closetsMetal working apparatusEngineeringVisual system

The invention discloses an automatic covering system of a ceramic toilet water tank cover. The automatic covering system comprises a rack, a transmission device, a chuck, a camera and a chuck fine regulating device, wherein the transmission device is composed of a transverse transmission device, a longitudinal transmission device and a vertical transmission device, and the chuck fine regulating device comprises a chuck fine regulating servo motor, a fine regulating gear, a swing arm gear, a chuck center shaft and a fine regulating seat. According to the automatic covering system, the transverse transmission device, the longitudinal transmission device and the vertical transmission device are mutually matched, so that the chuck is quickly sent to a specified position. Then, a visual system is matched with the chuck fine regulating device, so that the angle of the chuck is regulated, and the water tank cover corresponds to a ceramic toilet water tank. Finally, the water tank cover is slowly placed on the ceramic toilet water tank by the longitudinal transmission device in a thread transmission mode, so that the automation of a covering process of the ceramic toilet water tank cover is realized.

Owner:GUANGDONG INST OF INTELLIGENT MFG

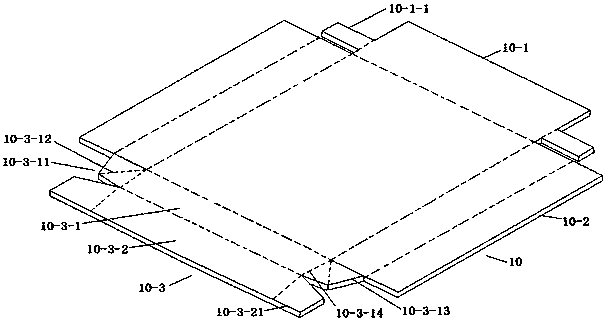

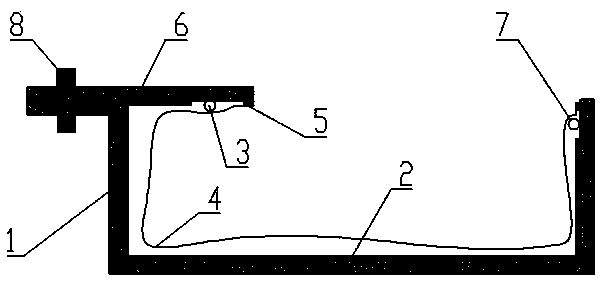

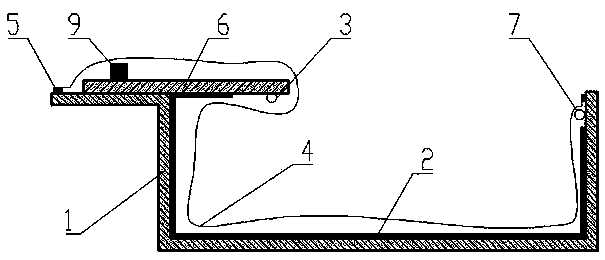

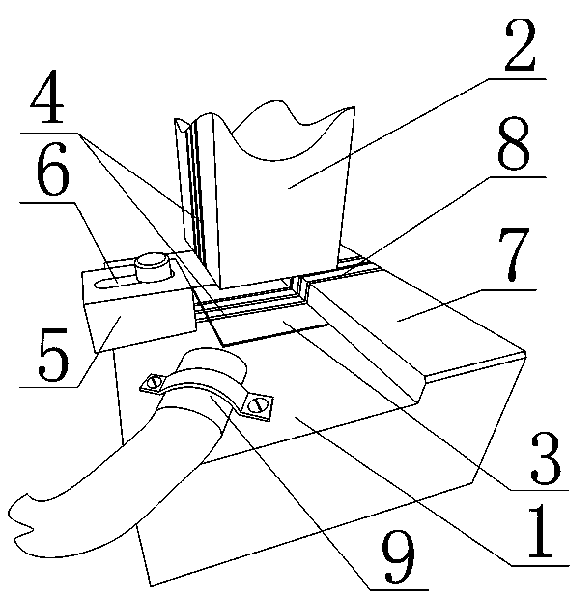

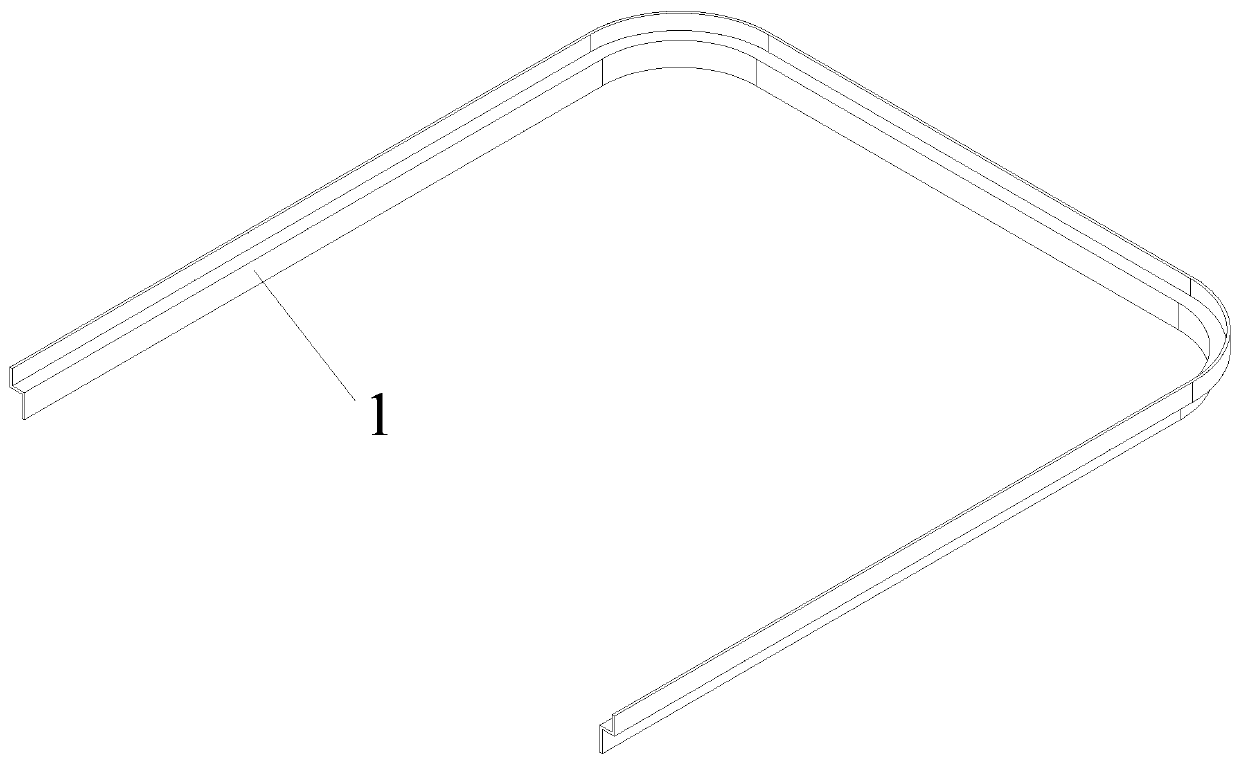

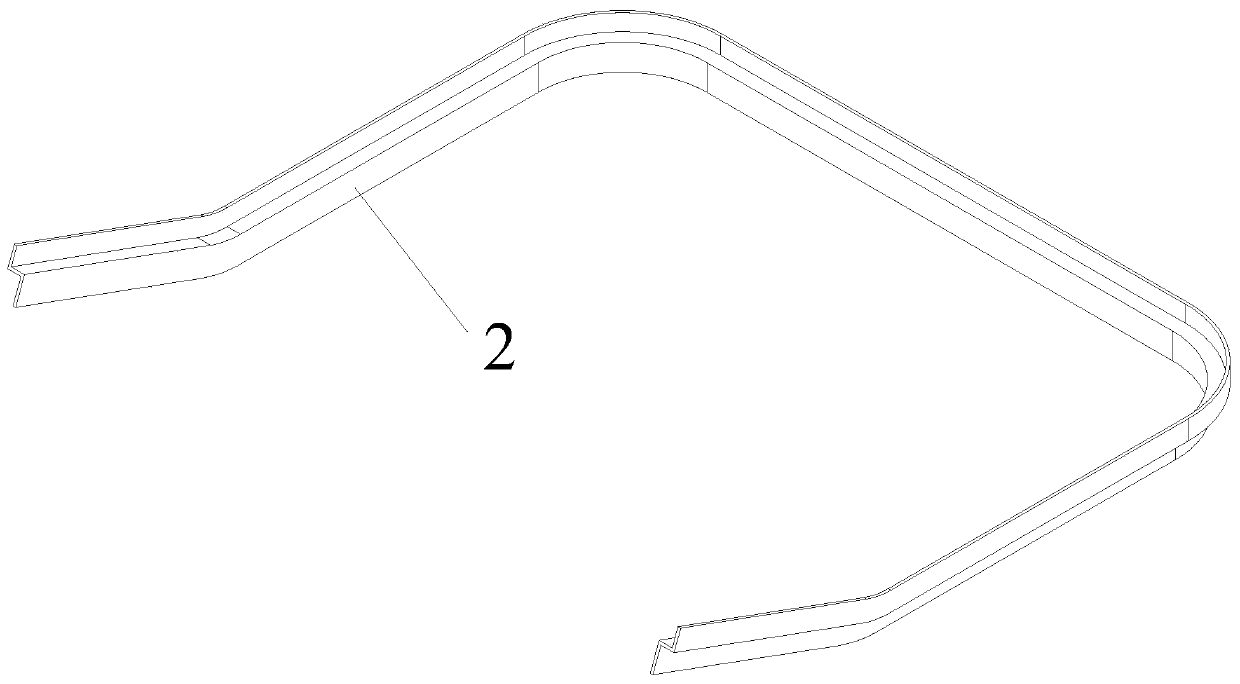

Tool for litter box forming and application method thereof

PendingCN109263140AEnsure consistencyAvoid scrap rateBox making operationsPaper-makingCardboardPolygonal line

The invention relates to a tool for litter box forming and an application method thereof. The method includes: a litter box paper board is fastened to the tool, a litter box flip cover is inserted into the hollow sunken opening of the tool, two litter box lateral plates are respectively inserted between two fixing plates and two lateral sides of a boss, a litter box bottom plate is bent downwardlyto attach to the lateral side of the boss, corner plates on two sides of the bevel oblique fold lines of two upper plates to move downwardly so as to be connected together through butt joint to formdouble-layer corner plates, and the two double-layer corner plates are folded and adhered to the upper plate; a switch is pressed, air cylinders I drives strip-shaped push pieces to push against the litter box flip cover, the front end arc-shaped faces II of the L-shaped guide pieces II of two air cylinders II move horizontally to solidly adhere the two double-layer corner plates to the upper plate; the front end arc-shaped faces I of the L-shaped guide pieces I of the two air cylinders I move vertically to solidly adhere two litter box flip cover bevels to the litter box lateral plates; the litter box bottom plate is upwardly folded to be adhered with the upper plate, bottom plate bevels on two sides of the litter box bottom plate are bent inwardly to be adhered to the two lateral platesof the litter box paper board, and solid adhering of various bevels is completed.

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

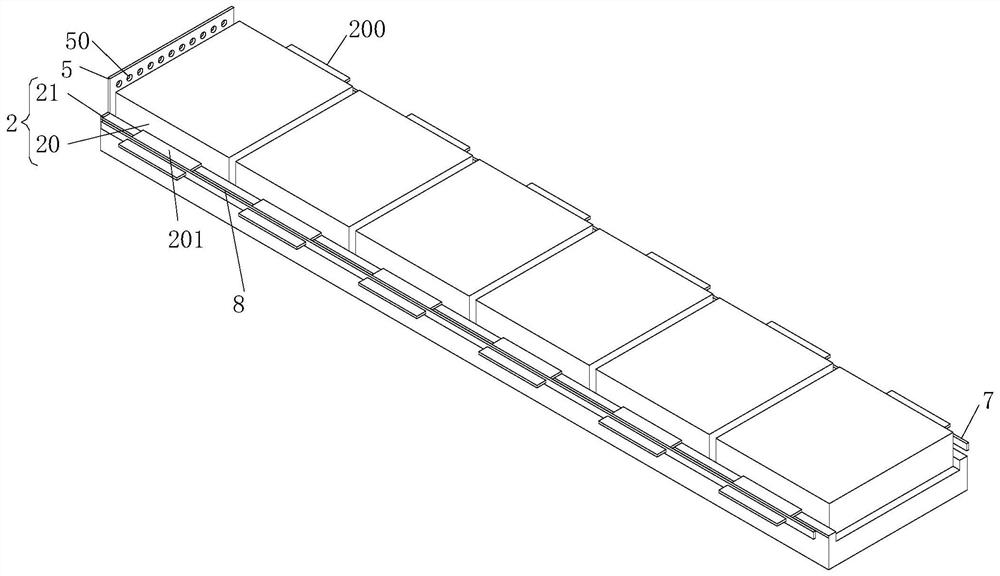

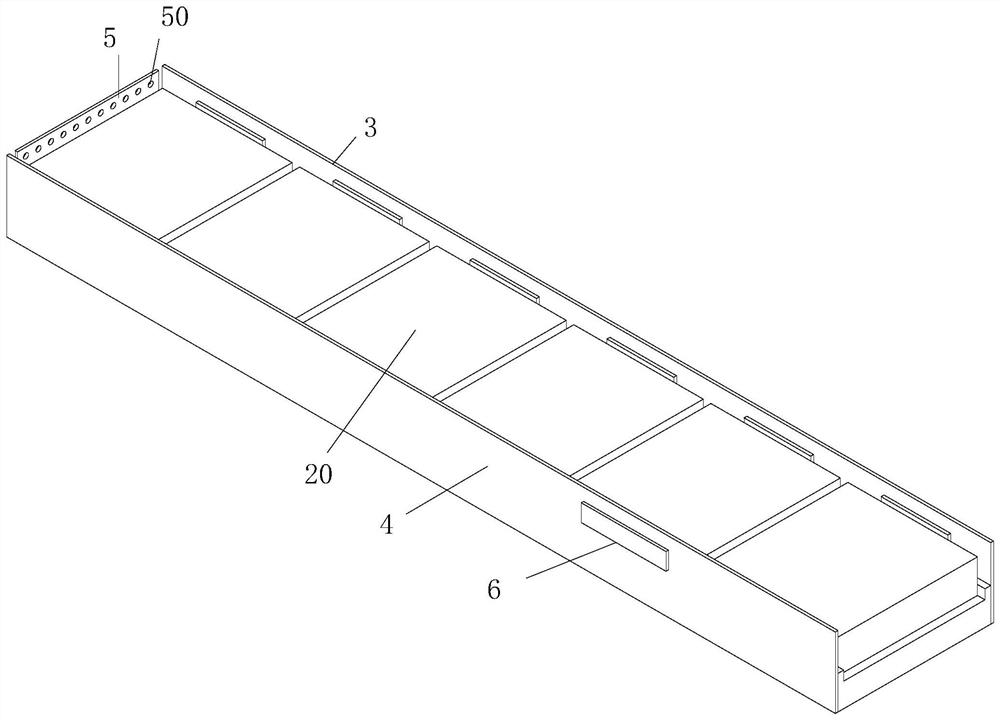

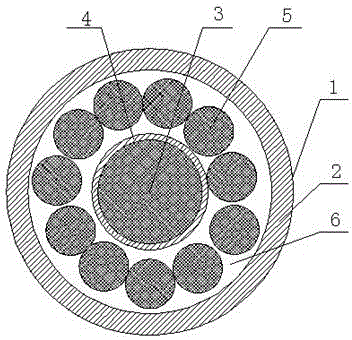

Power lithium ion battery

PendingCN113851698AAvoid wastingImprove qualityFinal product manufactureSecondary cellsStructural engineeringLithium-ion battery

The invention discloses a power lithium ion battery. The power lithium ion battery comprises a shell, a roll core group, a positive electrode cover plate and a negative electrode cover plate, wherein the roll core group comprises a fixed support and a plurality of roll cores, the fixed support is provided with a plurality of placing grooves, the roll cores are placed in the placing grooves, the roll cores are in one-to-one correspondence with the placing grooves, positive electrode tabs of the plurality of roll cores are connected in series, and negative electrode tabs of the plurality of roll cores are connected in series; the positive electrode cover plate and the negative electrode cover plate are respectively fixed on two opposite sides of the roll core group and are used for wrapping the two opposite sides of the roll core group; the shell is arranged on the outer side of the roll core set and used for wrapping the roll core set. According to the battery disclosed by the invention, an A / B roll core pairing process is cancelled, so that waste caused by the problems of wrong roll core pairing, mismatched quantity and the like is avoided, and the product quality is greatly improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

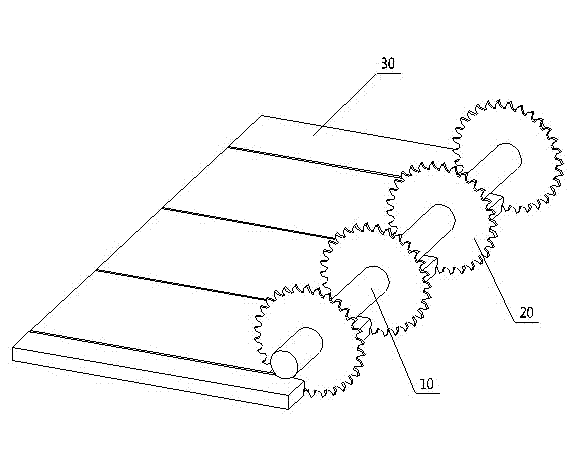

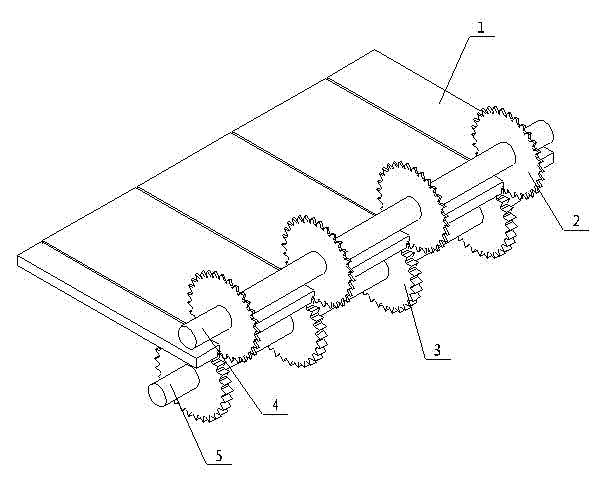

Novel multi-blade saw device

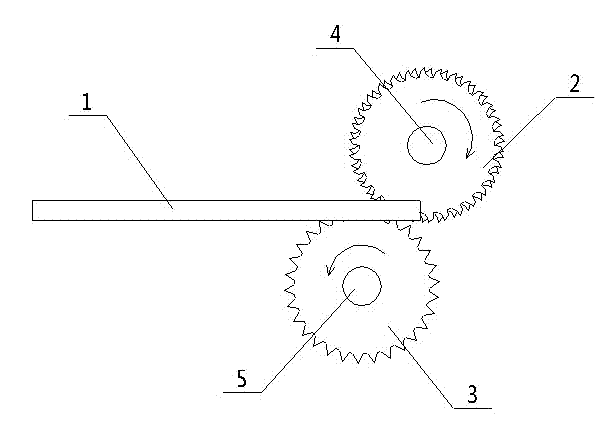

The invention discloses a novel multi-blade saw device, which comprises a spindle and a plurality of saw blades. The saw blades are coaxially mounted on the spindle, a milling cutter is arranged on the lower side of each saw blade, each saw blade and the corresponding milling cutter share the same central radial plane, the saw blades and the milling cutters are respectively positioned on the upper side and the lower side of a to-be-processed plate, and the milling cutters are closer to a to-be-processed plate feed inlet as compared with the saw blades, and are coaxially mounted on an arbor. The novel multi-blade saw device in the scheme is simple in design and easy in manufacture, the problem of working procedures for edge stepped surface processing and cutting processing of the plate is solved, processing procedures of the plate are shortened, production efficiency is improved, simultaneously, scrap of processing of the plate is prevented, materials and cost are saved, and the novel multi-blade saw device brings great economical benefit for manufacturers.

Owner:苏州豪特景精密机械有限公司

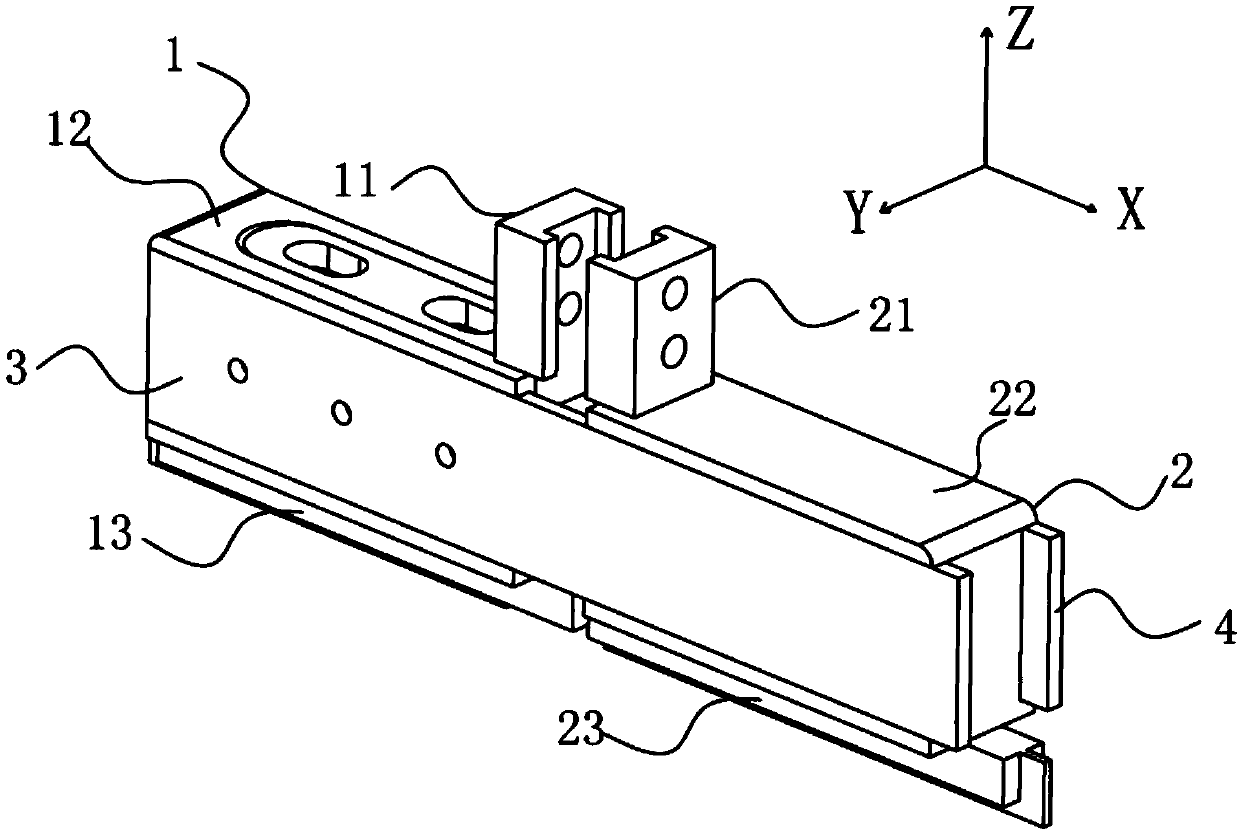

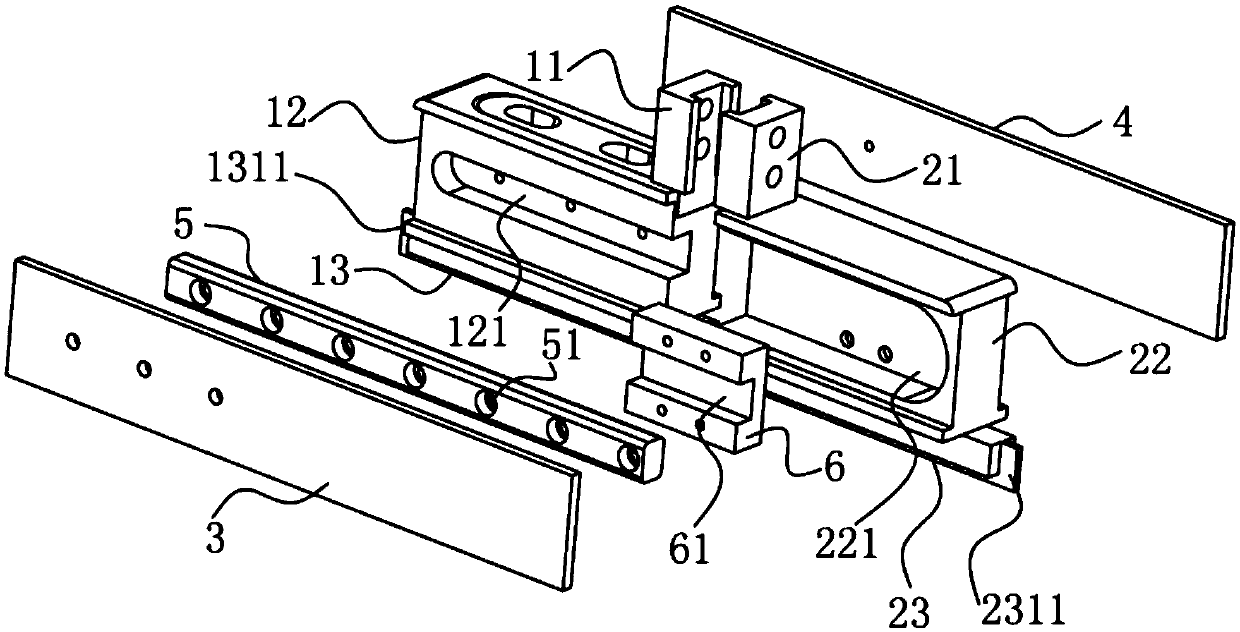

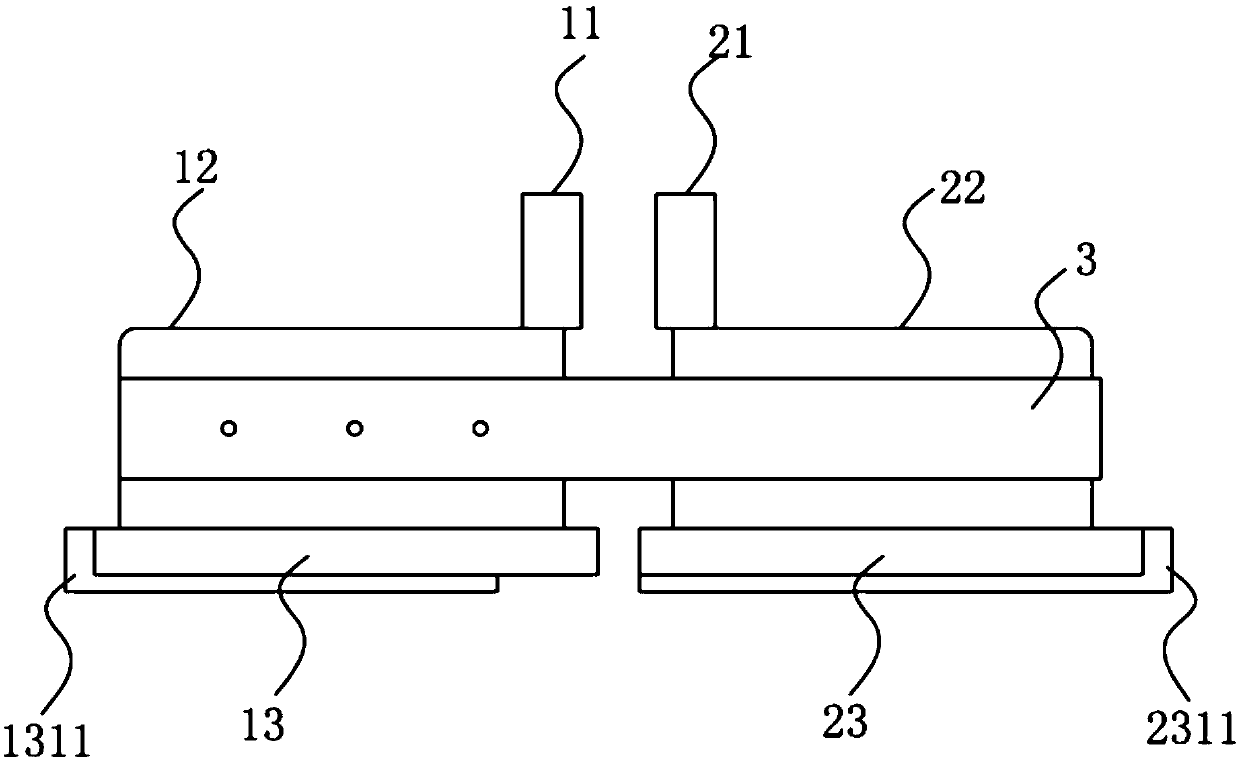

Small-diameter steel pipe perforating device

PendingCN110026580APrecise positioningEasy to operateWork clamping meansPositioning apparatusArchitectural engineeringSteel tube

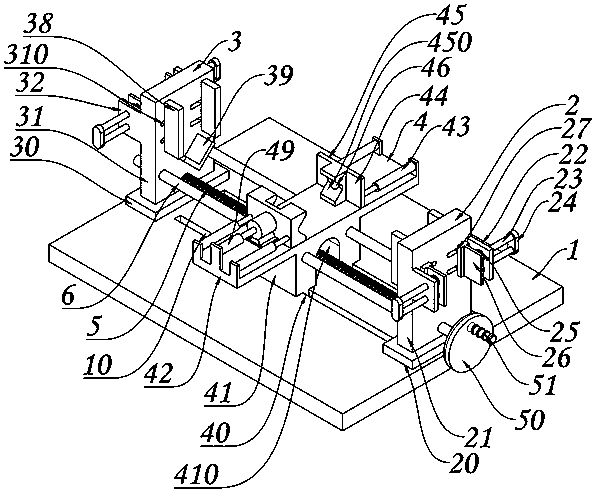

The invention discloses a small-diameter steel pipe perforating device. The small-diameter steel pipe perforating device comprises a bottom plate, a fixed clamping mechanism arranged at one end of thebottom plate, a movable clamping mechanism arranged at the other end of the bottom plate and a perforating mechanism arranged on the bottom plate and positioned between the fixed clamping mechanism and the movable clamping mechanism. According to the small-diameter steel pipe perforating device, the perforating efficiency of a small-diameter steel pipe is improved, the phenomenon of deviation ofthe position of the small-diameter steel pipe in the perforating operation is effectively prevented, the cost investment of enterprises is reduced, the scrap rate of the steel pipe is effectively prevented, and higher practicability is achieved.

Owner:SICHUAN WUHUAN PETROCHEM EQUIP CO LTD

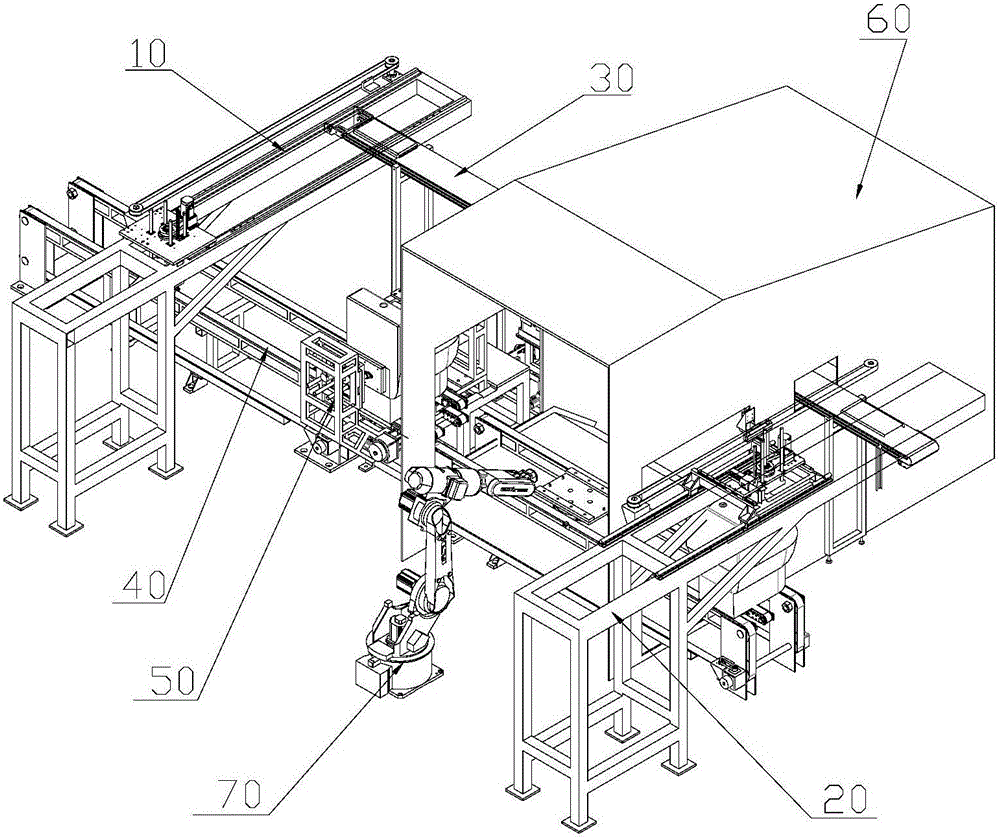

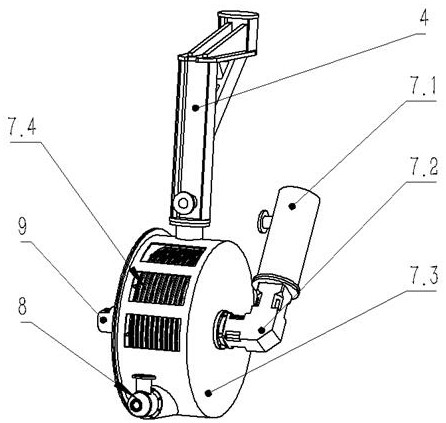

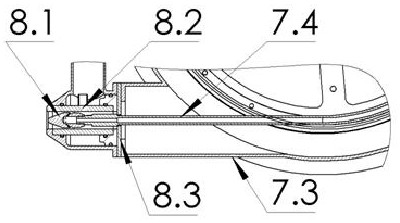

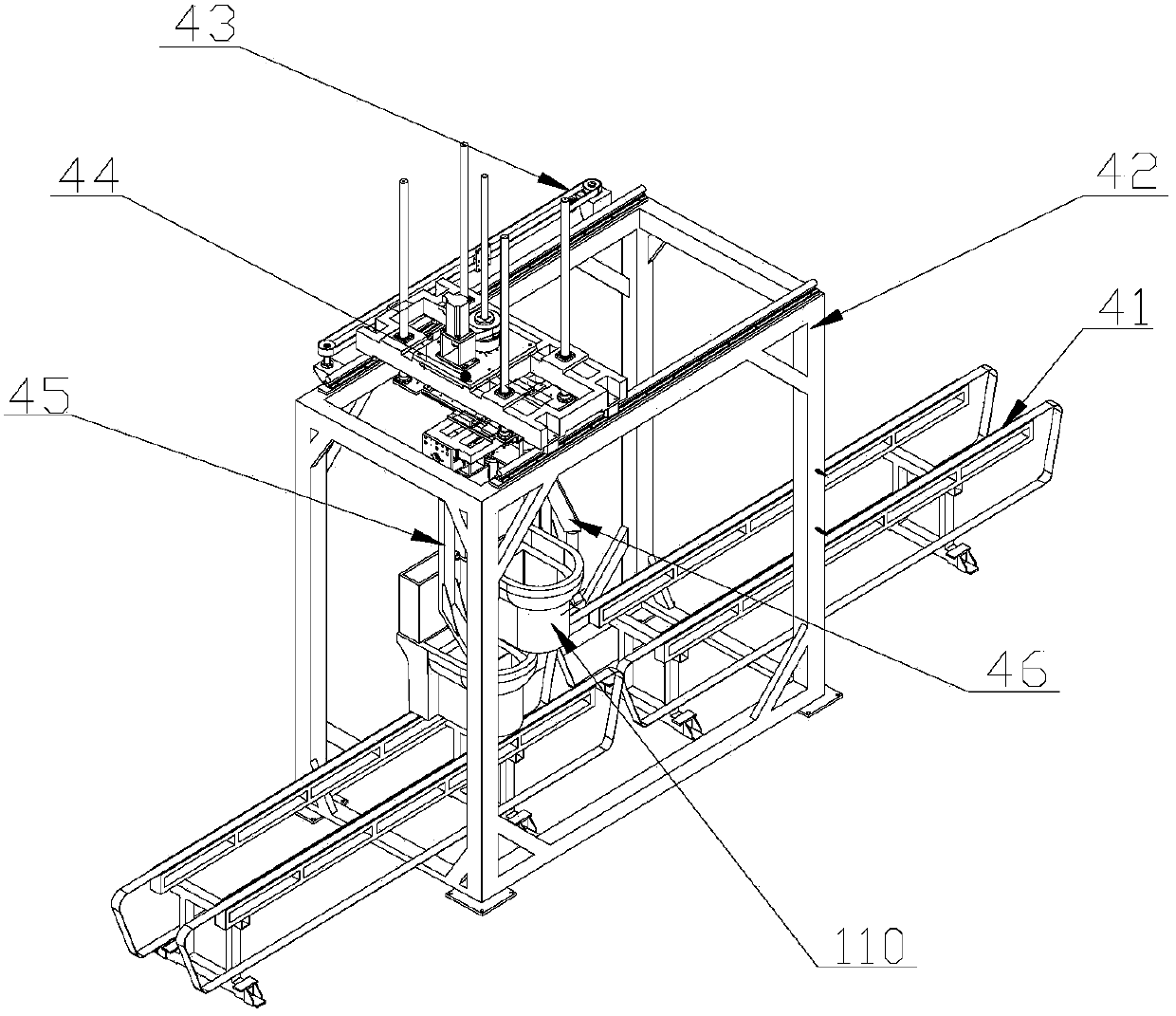

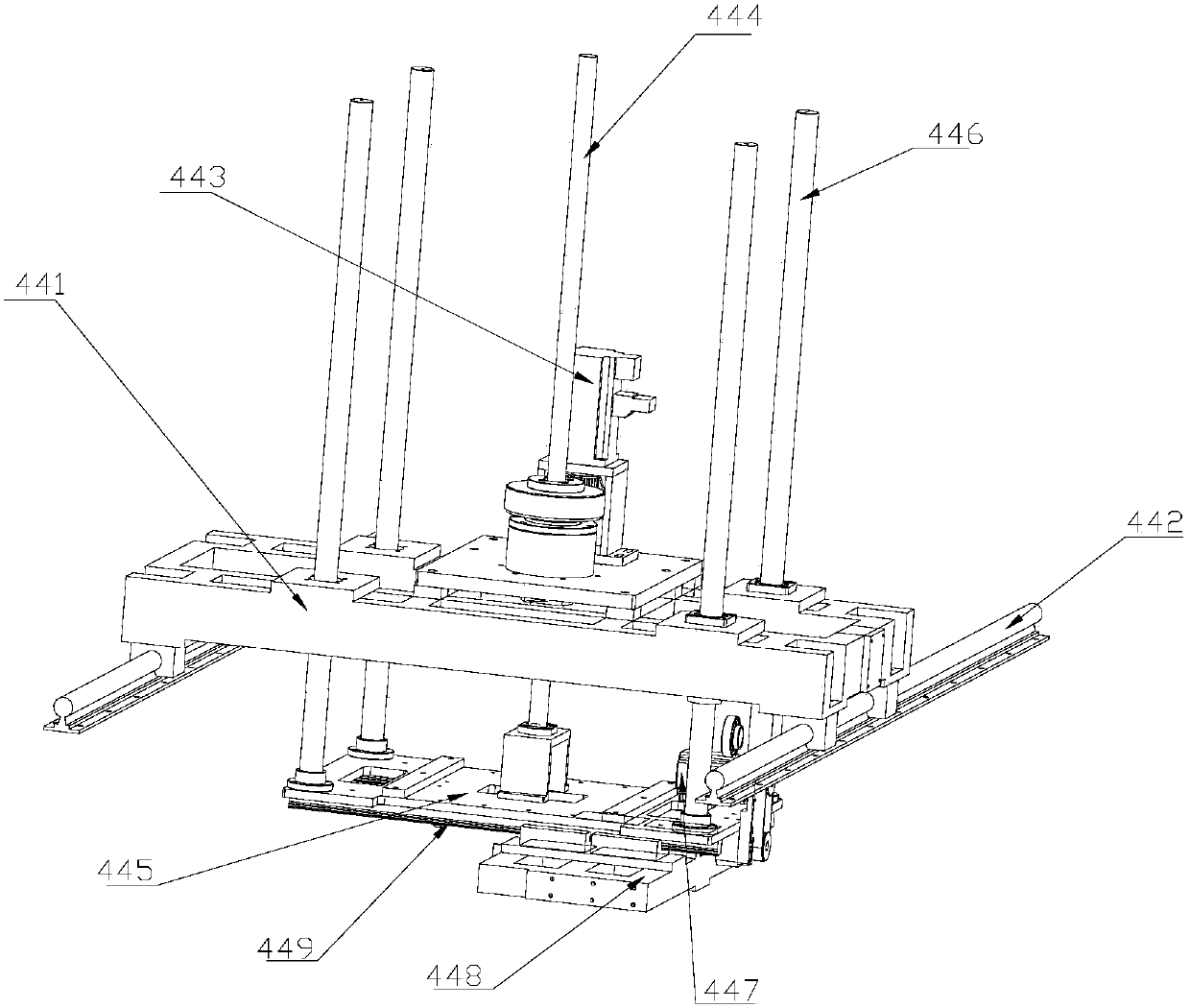

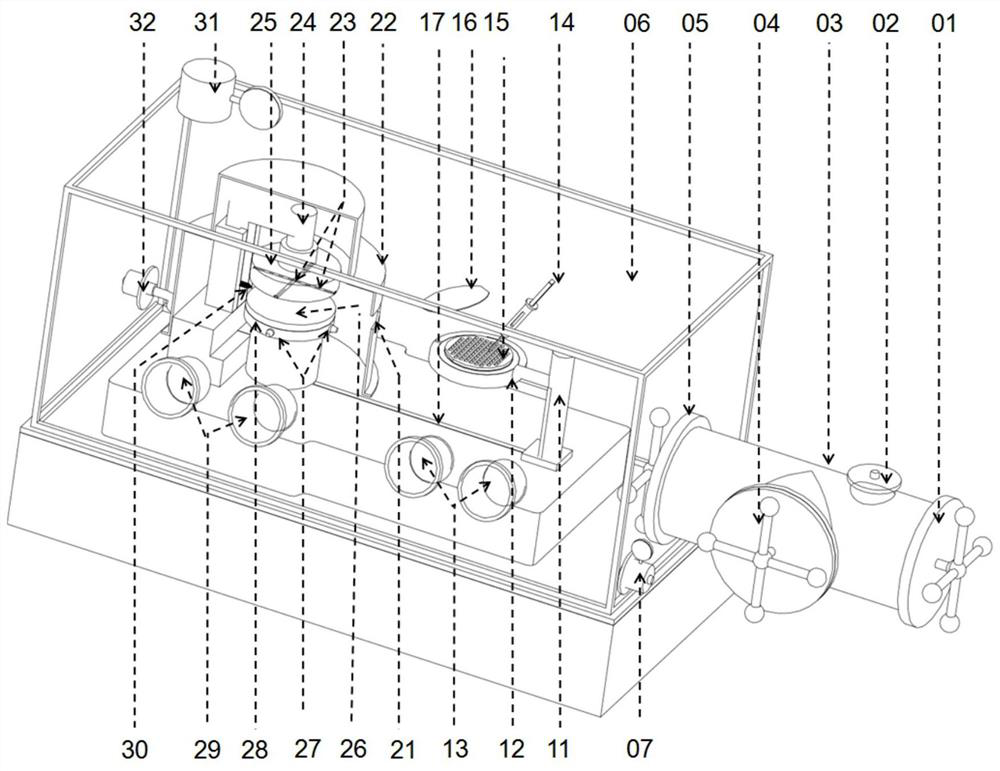

Automatic disassembly and assembly system of ceramic toilet water tank cover

ActiveCN105729082AImprove working environmentReduce work intensityWater closetsMetal working apparatusEngineeringAssembly structure

The invention discloses an automatic disassembly and assembly system of a ceramic toilet water tank cover. The automatic disassembly and assembly system comprises an automatic disassembly mechanism, an automatic assembly mechanism and a water tank cover conveying line, wherein the automatic disassembly mechanism is used for disassembling the water tank cover; the automatic assembly mechanism is used for assembling the water tank cover on a water tank; the water tank cover conveying line is used for conveying the water tank cover disassembled by the automatic disassembly mechanism to the automatic assembly mechanism; both the automatic disassembly mechanism and the automatic assembly mechanism comprise racks, transmission devices and chucks; the automatic assembly mechanism further comprises a camera and a chuck fine regulating device, and the chuck fine regulating device comprises a chuck fine regulating servo motor, a fine regulating gear, a swing arm gear, a chuck center shaft and a fine regulating seat. According to the automatic disassembly and assembly system, the water tank cover is automatically disassembled by the automatic disassembly mechanism, the water tank cover is conveyed to the automatic assembly mechanism through the water tank cover conveying line, and the transmission device, the camera, the chuck and the chuck fine regulating device of the automatic assembly mechanism are matched, so that the water tank cover is automatically assembled on the water tank.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Integrated molding and pouring process for semi-enclosed glass fiber reinforced plastic products with infolded flanges

The invention relates to an integrated molding and pouring process for semi-enclosed glass fiber reinforced plastic products with infolded flanges. The process comprises the steps of: first, producing a mould, wherein the mould consists of a main body part and a flange part, a positioning and locking part is embedded at the side of the main body part in advance; the flange part is provided with a locking structure corresponding to the position of the positioning and locking part, and is fixed on the main body part by the positioning and locking part; second, paving a product framework on the inner wall of the mould; third, paving one sealing film layer on the surface of the framework, wherein the edge of the sealing film extends out of the cavity of the main body part of the mould, rounds the flange part, and is adhered on the peripheral face of the edge of the main body part of the mould with sealing adhesive tape, on the part fixedly provided the flange part, then, a hermetical space is formed between the main body part of the mould and the sealing film, the product framework and the flange part of the mould are encapsulated in the hermetical space, and the clearance between the mating faces of the main body part and the flange part is not communicated with the atmosphere; fourth, processing a suction port and a pouring port, which are respectively connected with a vacuum pump and a pouring device, on the sealing film; fifth, vaccumizing and pouring resin; and sixth, demoulding.

Owner:四川东树新材料有限公司

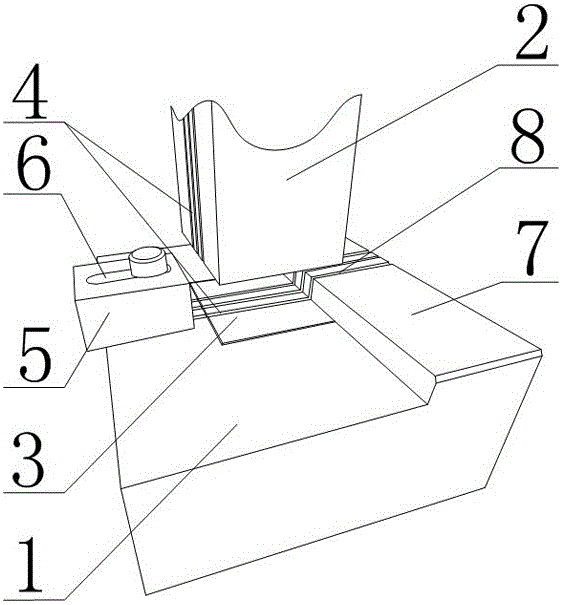

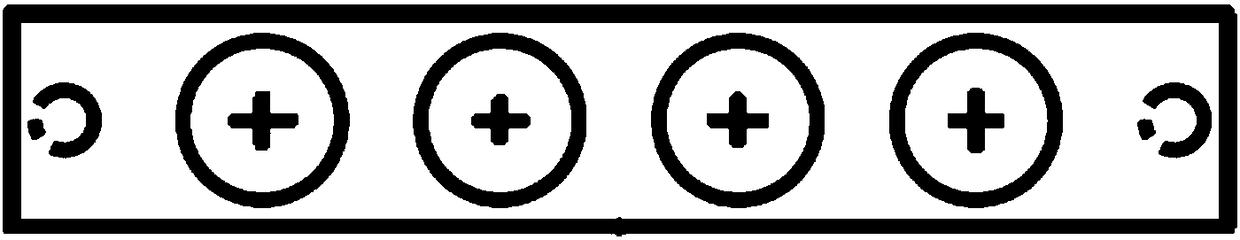

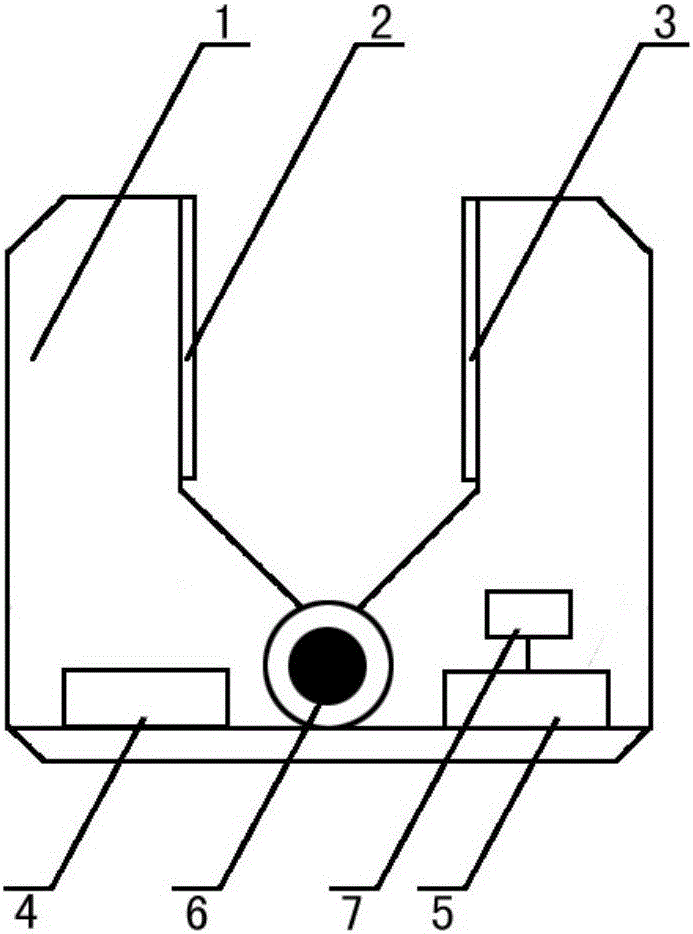

Pneumatic sensor welding pin punching mold capable of realizing convenient material placing

The invention discloses a pneumatic sensor welding pin punching mold capable of realizing convenient material placing. The pneumatic sensor welding pin punching mold is characterized by comprising a male mold positioned at the upper side and a female mold positioned right under the male mold, wherein a concave pit matched with the male mold is arranged on the female mold, a bottom mold matched with the male mold is arranged in the concave pit and is arranged on the female mold through a spring, after the spring is compressed, the bottom mold is recessed in the female mold, a position limiting block and a material placing table which are positioned at the two sides of the bottom mold are arranged on the female mold, continuous grooves are respectively formed in the female mold, the bottom mold and the inner wall, near the position limiting block, of the concave pit, the grooves extend on the material placing table for forming material clamping grooves, a groove is formed in the bottom surface of the male mold, the groove formed in the bottom surface of the male mold extends along the side surface, opposite to the position limiting block, of the male mold, and a spray nozzle connected with a high-pressure air source is arranged on the female mold. The pneumatic sensor welding pin punching mold has the advantages that the rejection rate of workpieces is avoided, the product qualification rate is improved, the production time is greatly saved, and in addition, the production cost is greatly reduced.

Owner:SICHUAN KAIMING INVESTMENT

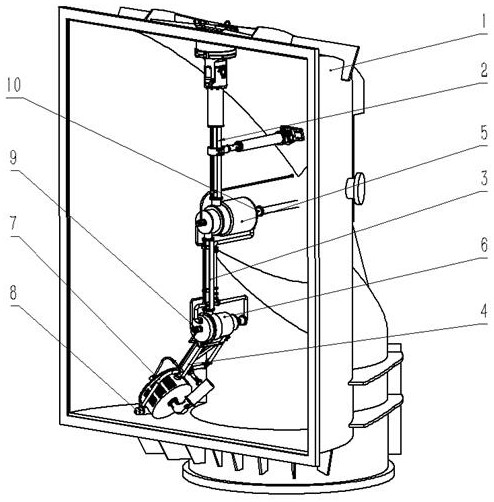

Integrated cleaning device of condenser integrated robot

InactiveCN112344786AShorten the wear pathExtend your lifeFlush cleaningControl engineeringMechanical engineering

The invention discloses an integrated cleaning device of a condenser integrated robot. The integrated cleaning device comprises a mechanical arm fixedly installed on a condenser water chamber and a cleaning mechanism fixedly arranged at the tail end of the mechanical arm. The mechanical arm is of a two-stage joint mechanical arm structure and comprises a base, a first joint arm, a second joint arm, a first-stage transmission mechanism and a second-stage transmission mechanism. The base is fixedly connected to a shell of the condenser water chamber. The first-stage transmission mechanism is fixedly connected with the base. The first joint arm is fixedly connected to the free end of the first-stage transmission mechanism. The second-stage transmission mechanism is fixedly connected to the first joint arm. The second joint arm is fixedly connected to the free end of the second-stage transmission mechanism. The cleaning mechanism comprises a coil pipe device and a spray head clamp device.The coil pipe device is fixedly arranged on the second joint arm. The spray head clamp device is fixedly arranged on the coil pipe device. According to the integrated cleaning device, the abrasion distance of a water pipe is remarkably shortened, the service life of a high-pressure cleaning hose is prolonged, the phenomenon that the cleaning hose is wound around the mechanical arm is avoided, andthe pipe winding fault rate is reduced.

Owner:南京拓耘达智慧科技有限公司

Cutting machine for foamed concrete blocks

InactiveCN102601855BPrevent collapseImprove cutting accuracyCeramic shaping apparatusFoam concreteEngineering

The invention discloses a cutting machine for foamed concrete blocks, which comprises a rectangular frame and a cutting device. Four guide columns are vertically arranged at four corners of the rectangular frame. The cutting machine is characterized in that the cutting device comprises a transverse cutting mechanism and a vertical cutting mechanism. Compared with the prior art, the cutting machine has the advantages that the transverse cutting mechanism and the vertical cutting mechanism are separately arranged, so that cross interference can be well avoided. Further, since the transverse cutting mechanism and the vertical cutting mechanism are both obtained by basically identical structures, the integral structure is relatively simple, implementation is convenient, and implementation cost is low. Transverse cutting and longitudinal cutting are operated separately, a travelling mechanism drives a cutting wire to reciprocate for extruding cutting during reciprocated friction, and accordingly cutting resistance is greatly reduced while energy loss is reduced. More importantly, smoothness in cutting is improved, concrete blank disintegration is avoided, cutting success rate is greatly increased, and product scrappage is decreased.

Owner:重庆市旌弘建材有限公司

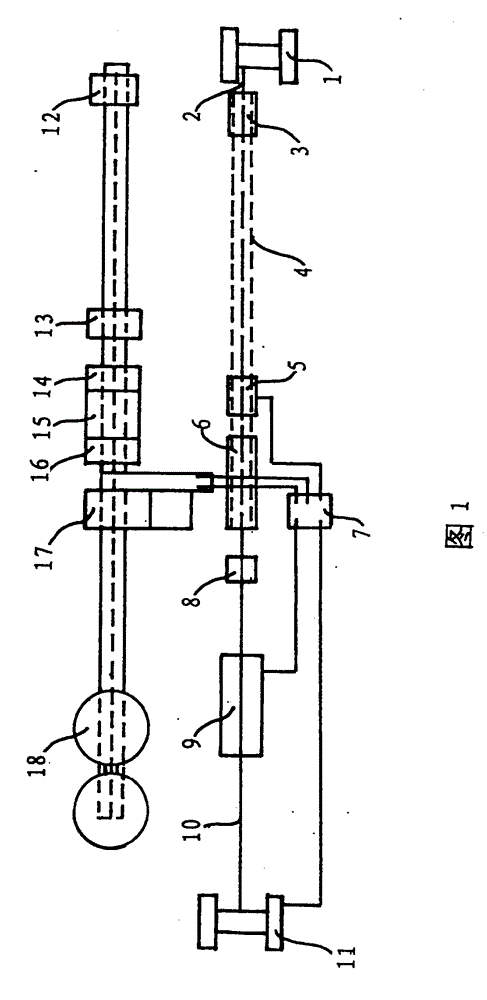

Production process of aluminum sheath cable

ActiveCN101685690BEliminate pinholesAvoid scrap rateCable/conductor manufactureHigh energyEngineering

The invention discloses a production process of an aluminum sheath cable, relating to the field of communication and signal cable production. The traditional high-frequency welding process is difficult to avoid the problems of pin holes and tack weld, and the standard length of each weldment is only 6 m; in order to weld an aluminum sheath cable, the length of which can reach thousand meters, the invention provides the production process for welding the aluminum sheath cable by the following steps: firstly shaping by a sheath and then welding at high frequency, wherein the thickness of an aluminum tape is 0.5-2.5 mm, the diameter of the aluminum sheath is 10-70 mm, the welding depth is 0.3-2.0 mm, the welding meeting angle is 4-12 degrees, the frequency of induced current is 350-500kHz, the welding power is 100-200kW and the welding speed can approach 100m / min; heating the aluminum sheath cable to be in a molten state at the edge of the meeting angle; then combining contact surface molecules by the extrusion of both side extruding devices to form crystal so as to achieve the goals of no pin holes, no tack weld and even welding; and finally reducing and shaping. The invention has the advantages of simple process, reliable quality, low cost, high production efficiency and little energy consumption.

Owner:TIANSHUI RAILWAY CABLE

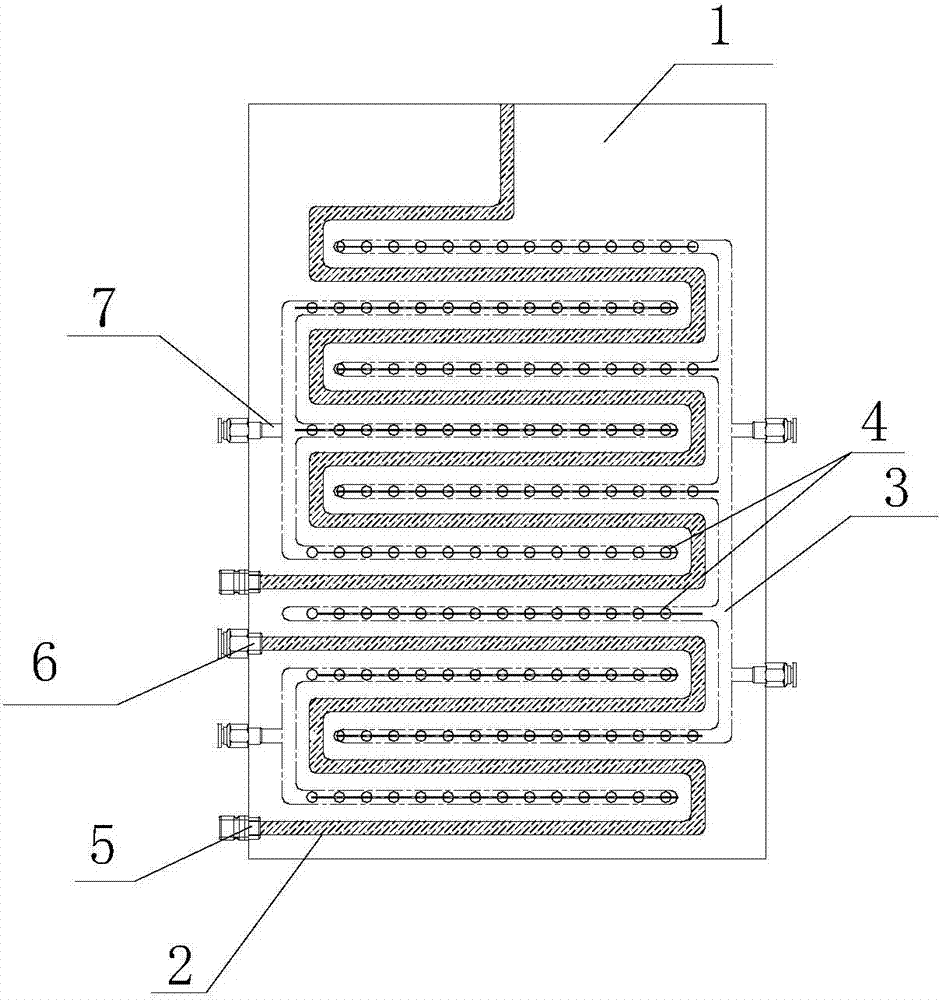

Board sheet forming mould

The invention discloses a board sheet forming mould. The board sheet forming mould comprises a mould body. Curvy water ways are formed in the mould body, curvy air ducts are formed between the curvy water ways in a staggered mode, and air holes arranged densely are distributed in the curvy air ducts. The joints of the curvy water ways and the surface of the mould body are provided with water inlets and water outlets, sealing is conducted by adopting plugs, and disassembly can also be conducted. The joints of the air ducts and the surface of the mould body are provided with air inlets and air outlets, sealing is also conducted by adopting plugs, and disassembly can also be conducted. The curvy water ways are machined through a milling machine, the size and the depth are not limited, machining is convenient, and the curvy water ways are improved a lot compared with previous linear type water ways. According to the board sheet forming mould, a novel water way machining mode is adopted, the forming effect is quick, machining is easy, the efficiency is improved, and the rejection rate is completely eradicated.

Owner:湖北天瑞塑料模具有限公司

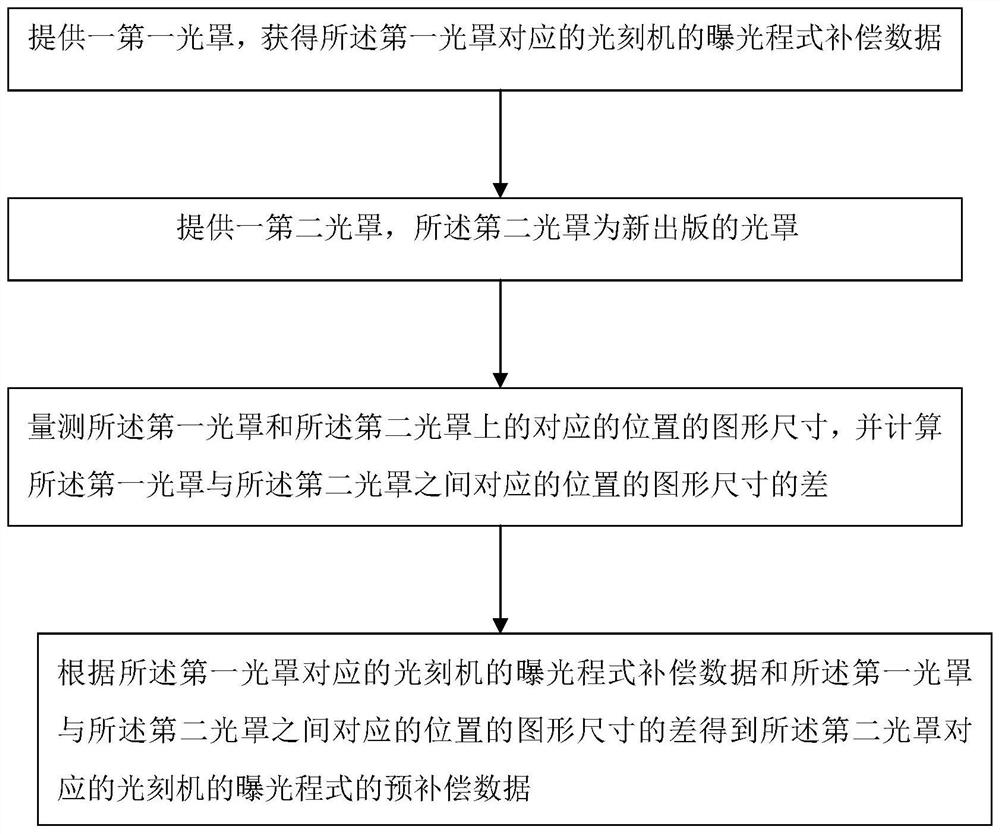

A method for improving in-plane uniformity of a critical dimension of a device

ActiveCN112180690AAvoid scrap rateImprove yieldSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusLithography processManufacturing technology

The invention relates to a method for improving in-plane uniformity of a critical dimension of a device, and relates to a manufacturing technology of a semiconductor integrated circuit. The method includes obtaining pre-compensation data of the exposure program of the photoetching machine corresponding to the second photomask in advance according to the difference between the exposure program compensation data of the photoetching machine corresponding to the used first photomask and the pattern size of the corresponding position between the first photomask and the second photomask; performingcorresponding exposure program compensation when the second photomask starts to be applied to a photoetching process, therefore, the condition that the compensation is carried out after the technological processes such as trial run, measurement of final critical dimensions after dry etching and the like are performed after the photomask enters a factory can be avoided, so that the exposure programcompensation neutral period is avoided, and the probability that the wafer is scrapped in the neutral period is avoided, and the product yield is improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Additive manufacturing metal cooling method

PendingCN112809183ASpeed up coolingReduce depthLaser beam welding apparatusHeat-affected zoneSupersaturated solid solution

The invention discloses an additive manufacturing metal cooling method. A cooling device is included, and the cooling device achieves cooling in the additive manufacturing process through the following steps of S1, additive manufacturing, wherein laser cladding equipment or electric arc additive equipment is adopted for conducting additive manufacturing on a substrate; and S2, online cooling, wherein the cooling device is arranged behind a heat source and follows the rear portion of the heat source to cool a sintered cladding layer and a heat affected zone below the cladding layer in real time. The cooling device closely follows the rear portion of the heat source, the cooling speed of the cladding layer can be increased, and the depth of the heat affected zone can be reduced; and the cooling speed near a solid solution line is increased in an online cooling manner, supersaturated solid solution of a material is achieved, the strength of the material can be greatly improved only through aging treatment later, and for materials which cannot be subjected to heat treatment strengthening, grains can be refined and the performance can be optimized through the method.

Owner:AIR FORCE UNIV PLA

Rapid continuous feeding stamping method of welding pin

The invention discloses a rapid continuous feeding stamping method of a welding pin. The rapid continuous feeding stamping method is characterized in that a male die positioned above a female die and the female die under the male die are provided; a concave pit matched with the male die is formed in the female die; a bottom die matched with the male die is mounted in the concave pit, and is mounted on the female die by a spring; the bottom die sinks in the female die after the spring is compressed; a limiting block and a material placement platform that are positioned on the two sides of the bottom die respectively are mounted on the female die; continuous grooves are formed in the female die, the bottom die, and the inner wall, close to the limiting block, of the concave pit; the grooves extend to form material clamping grooves in the material placement platform; the grooves are formed in the bottom surface of the male die; and the grooves in the bottom surface of the male die extend along the side surface, opposite to the limiting block, of the male die. Compared with the traditional copper product electroplating mode, the rapid continuous feeding stamping method of the welding pin saves the production time greatly and reduces the production cost greatly; the structure is simple; the operation is convenient; and in a cutting process, a steel wire material is positioned in the same state all the time, so that the efficiency and the product yield are improved and increased.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

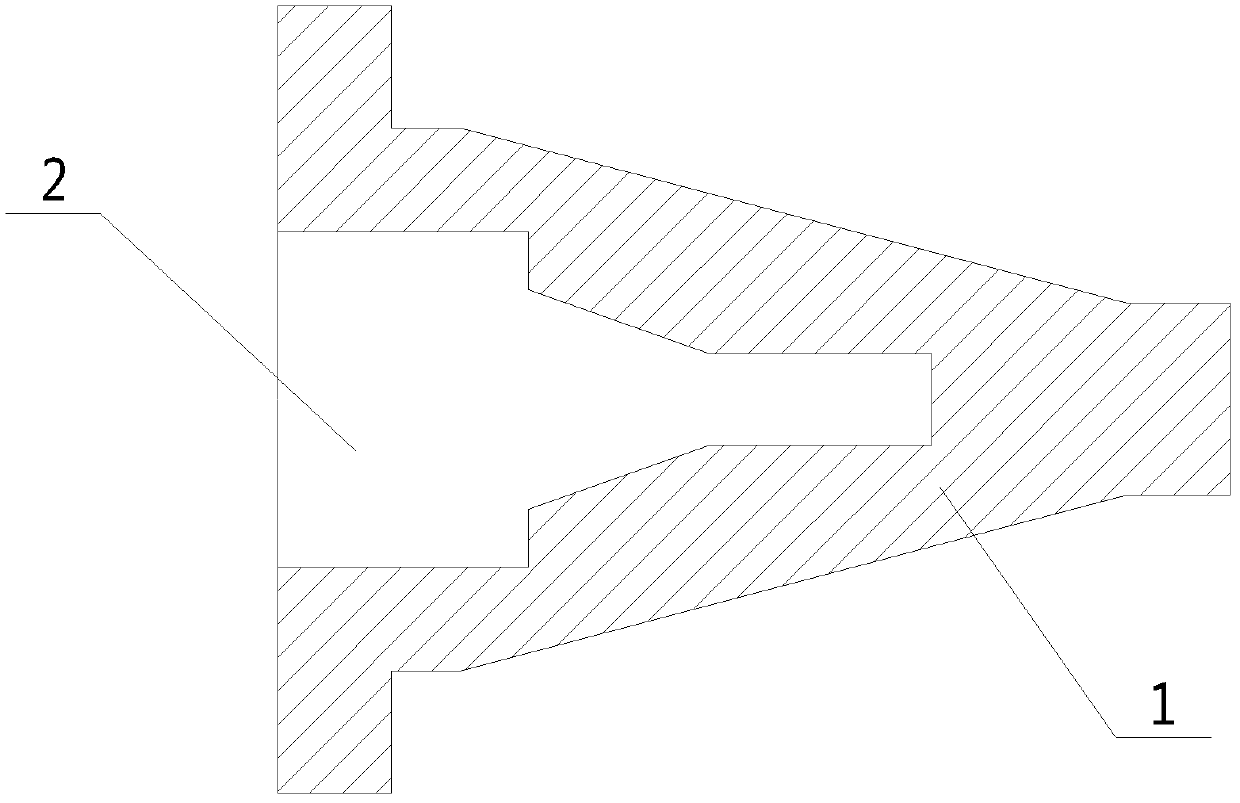

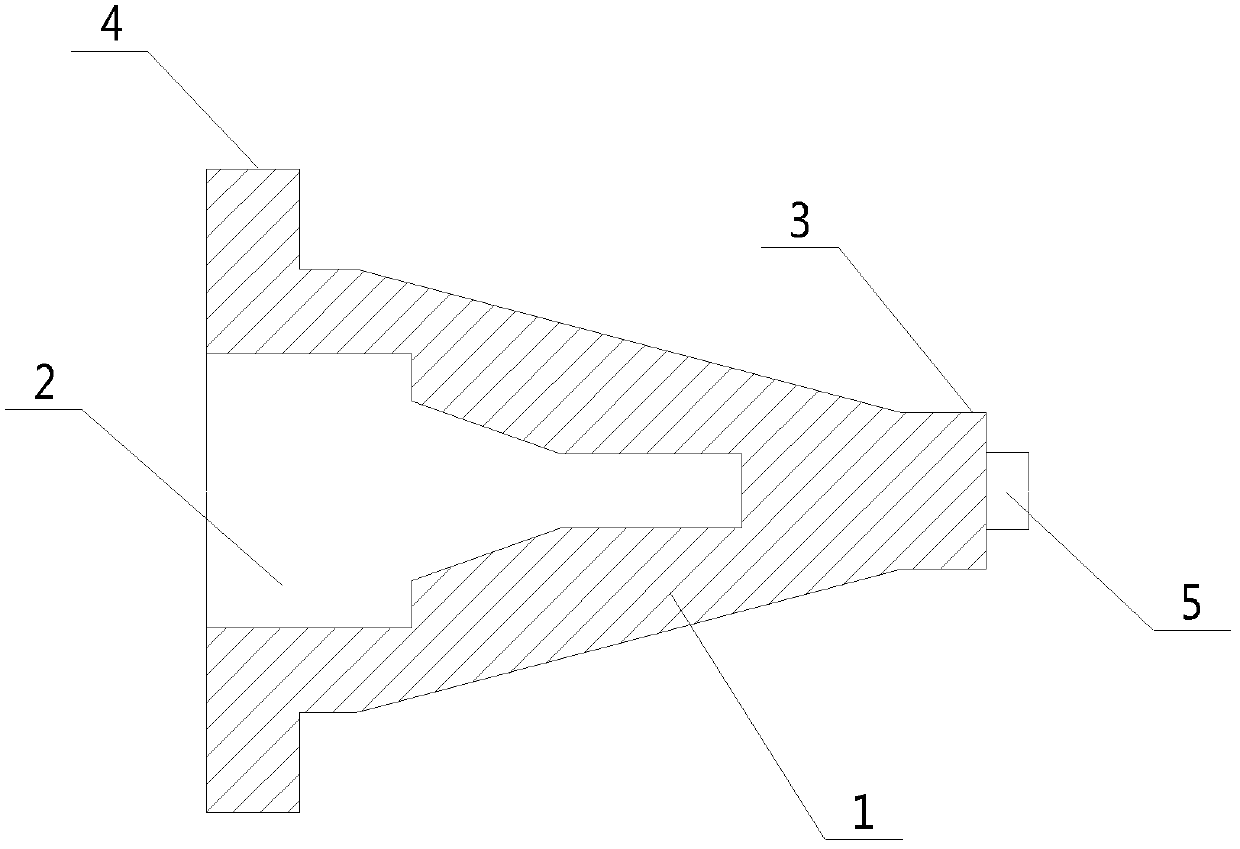

Process for machining molding core

The invention discloses a process for machining a molding core. The method comprises the following steps: clamping a molding core blank, machining a first reference plane of the molding core at one end of the molding core, and machining a cylindrical process terminal on the end face of the first reference plane; clamping the molding core with the first reference plane as reference, machining an inner cavity of the molding core, and machining a second reference plane at the other end of the molding core; clamping the molding core with the second first reference plane as reference, supporting the tail end of the process terminal with a core clamper, machining an outer profile of the molding core, and finally cutting the process terminal to complete the machining of the molding core. The process machines the molding core by use of the two reference planes on the molding core, so as to prevent the radial run out of the molding core during the machining of the outer profile, ensure the coaxiality of the inner cavity and the outer profile of the molding core, improve the machining precision of the molding core and avoid rejection of the molding core during machining.

Owner:SUZHOU YAER PLASTIC TECH

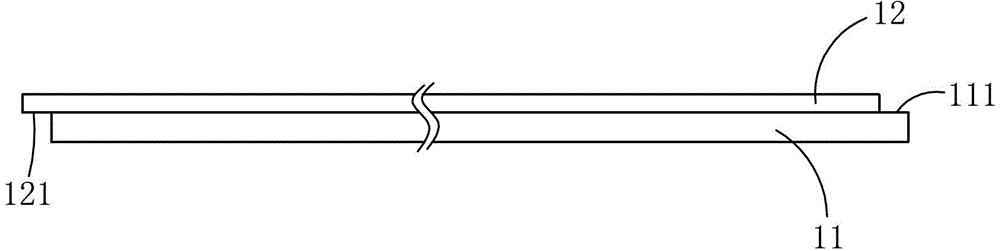

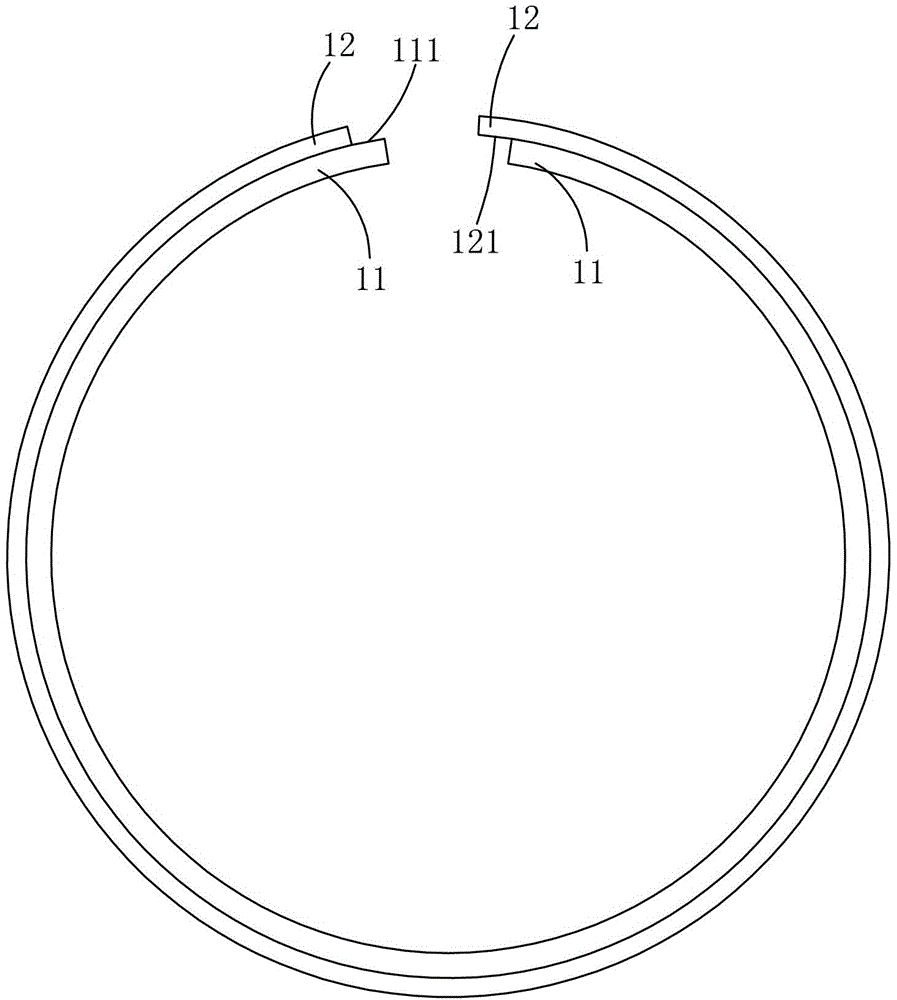

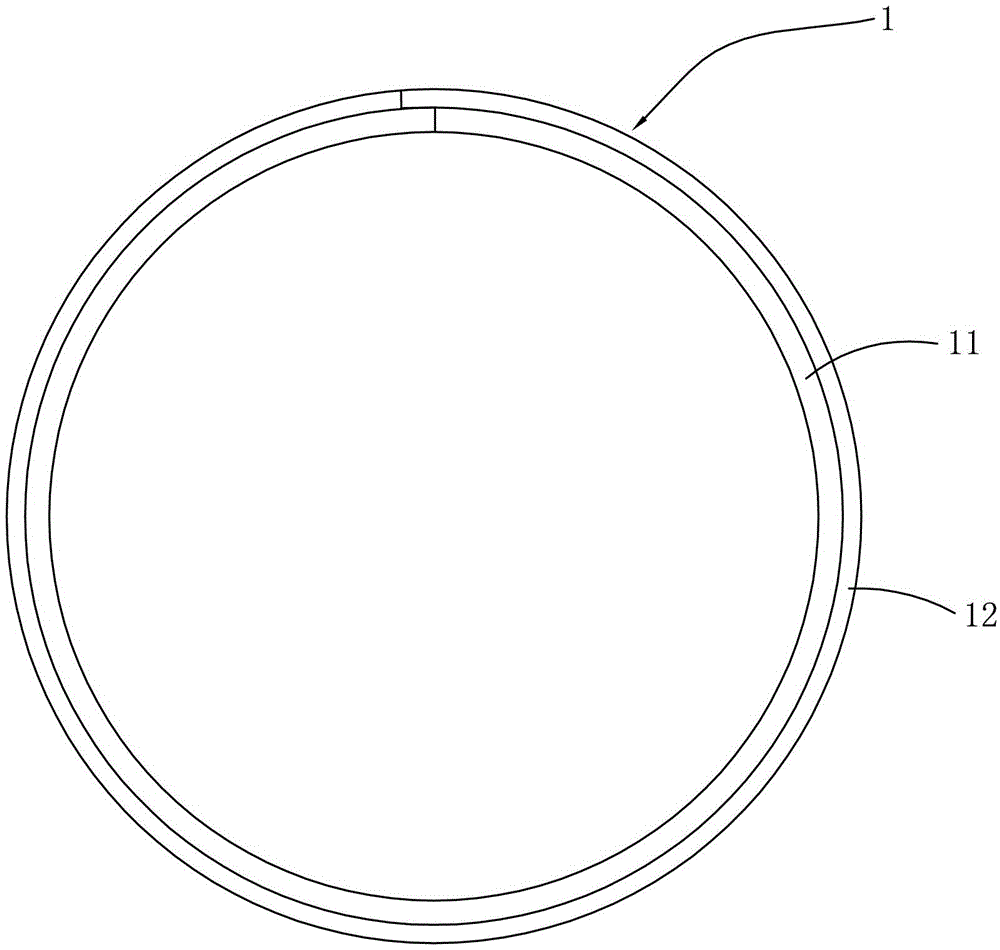

Seamless welding hose and production method thereof

ActiveCN102963601BReduce manufacturing costReduce difficultyLayered productsRigid pipesTube formationEngineering

A seamless welded tube and a manufacturing method therefor. The tube comprises a tube body (1). The tube body (1) comprises an inner film (11) and an outer film (12) that are stacked together. The inner film (11) and the outer film (12) are alternately compounded together and respectively form right-angle stepped ports at two ends in the circumferential direction of the tube body (1). The outer surface (111) of the inner film (11) at one of the ports is exposed outside of the outer film (12), while the inner surface (121) of the outer film (12) at the other port is exposed outside of the inner film (11). The inner surface (121) of the outer film (12) that is exposed is lap-welded onto the outer surface (111) of the inner film (11) that is exposed. Also, the two ends in the circumferential direction of the outer film (12) are welded together, while the two ends in the circumferential direction of the inner film (11) are welded together. The manufacturing method comprises: the steps of thin-film manufacturing, thin-film compounding, winding for tube formation, and welding. The inner film (11) and the outer film (12) are alternately compounded together during thin-film compounding. The manufacturing method for the multilayered seamless tube allows for reduced difficulty in a printing process. The tube is smooth and seamless at where same is welded. The tube is provided with an aesthetic overall appearance. In addition, the need for cropping to acquire the right-angle stepped ports is obviated, the manufacturing process flow is simple, and the manufacturing costs for the tube are reduced.

Owner:SHENZHEN BEAUTY STAR

A kind of detection method of tire label position in tire vulcanization production process

ActiveCN106739050BSolve the problem of inaccurate placementAvoid scrap rateTyresVulcanizationEngineering

The invention belongs to the technical field of vision detection, and particularly relates to a method for detecting a tire label position in a tire vulcanization producing process. The method comprises the steps that 1, a target is designed; 2, a label placement range template is designed; 3, the target is fixedly installed on the outer edge of a vulcanizing machine film cavity; 4, the position of the target and the position of the label placement range template are demarcated; and 5, the tire label position is detected in practical production. By means of the method, the problem that the label position is inaccurate due to the fact that the position of the vulcanizing machine film cavity is changed in a vulcanizing process is solved, the rejection rate is avoided, and working efficiency is improved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

A positioning device for transplanting ceramic toilet

ActiveCN105777201BImprove working environmentReduce work intensityEngineeringPerpendicular direction

The invention discloses a ceramic-toilet-bowl transplanting positioning device.The ceramic-toilet-bowl transplanting positioning device comprises a machine frame, a conveying line, a moving mechanism, a bottom supporting arm and a centering arm.The conveying line penetrates through the machine frame and is used for conveying ceramic toilet bowls; the moving mechanism is used for achieving three-dimensional movement in the transverse direction, the perpendicular direction and the longitudinal direction; the bottom supporting arm is installed on the moving mechanism and used for supporting the backs of the ceramic toilet bowls and placing the ceramic toilet bowls to appointed positions through the moving mechanisms; the centering arm is installed on the moving mechanism and used for clamping the front portions of the ceramic toilet bowls and finely adjusting the angles of the front portions of the ceramic toilet bowls; the bottom supporting arm comprises a bottom supporting arm body, a bottom supporting rotating lead screw and a bottom supporting servo motor fixedly installed on the moving mechanism and used for driving the bottom supporting rotating lead screw to rotate; the centering arm comprises centering arm bodies, centering connecting pieces, gears, a centering air cylinder, a centering base and centering stand columns.According to the ceramic-toilet-bowl transplanting positioning device, the ceramic toilet bowls are accurately positioned under the cooperation of the bottom supporting arm, the centering arm and the moving mechanism.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

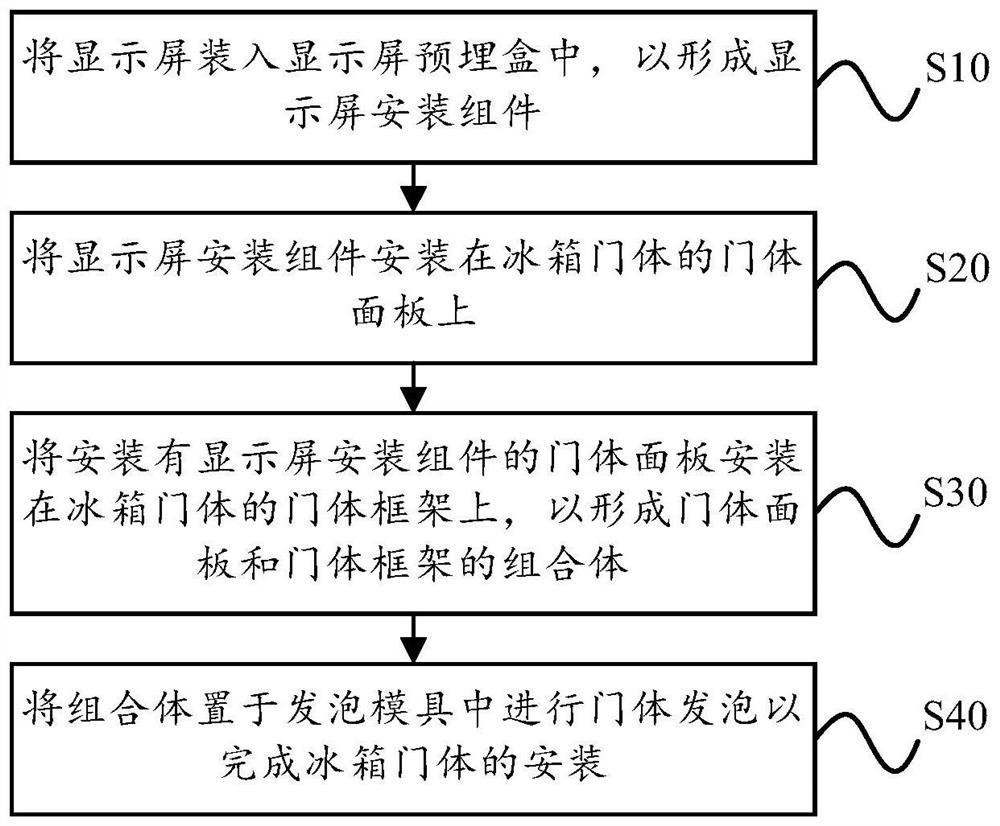

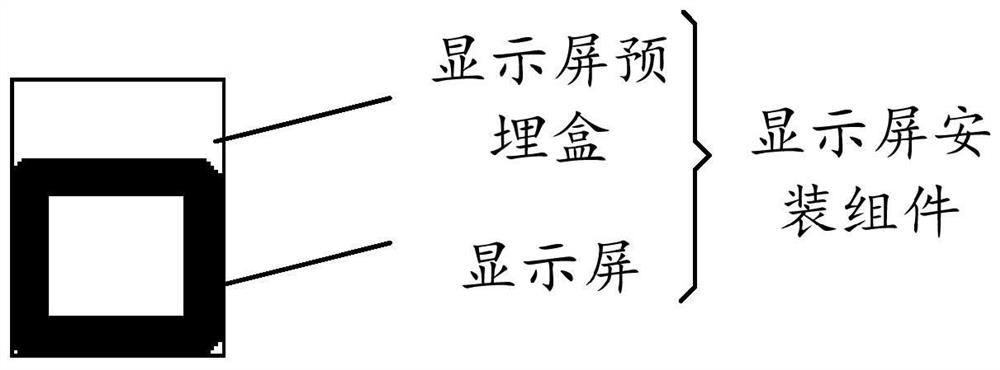

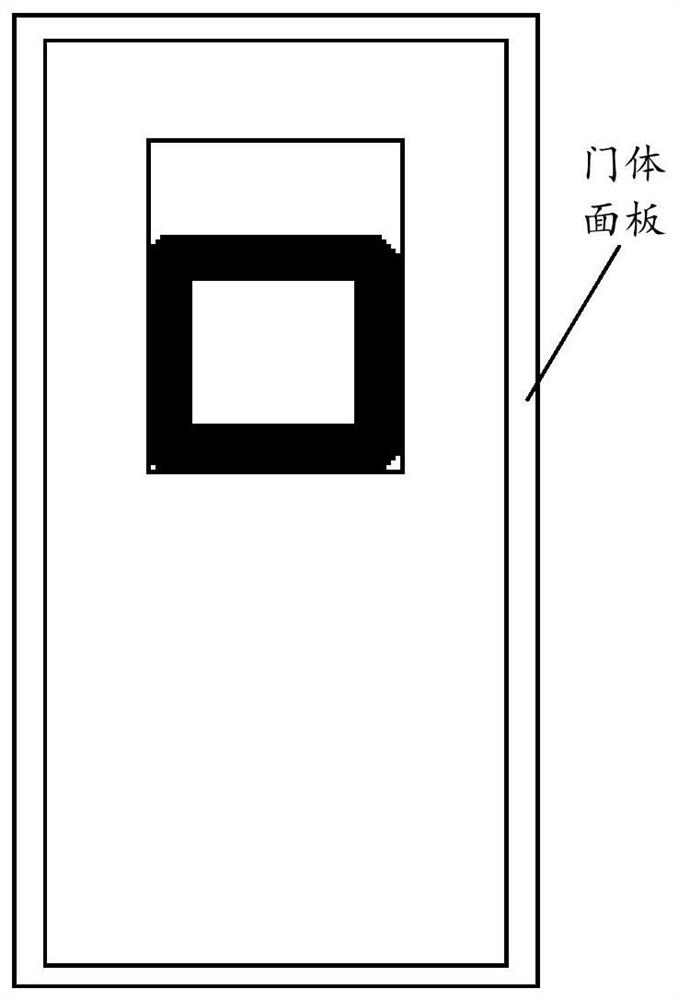

Installation method of refrigerator door body, refrigerator door body and refrigerator

ActiveCN107677036BSimplify the installation processImprove installation efficiencyLighting and heating apparatusCooling fluid circulationIceboxStructural engineering

The invention provides an installation method for a refrigerator door body, and further provides the refrigerator door body assembled adopting the installation method and a refrigerator with the refrigerator door body accordingly. The installation method comprises the steps that a display screen is loaded into a display-screen embedded box to form a display-screen installation component; the display-screen installation component is installed on a door body panel of the refrigerator door body; the door body panel provided with the display-screen installation component is installed on a door body frame of the refrigerator door body to form a combination body of the door body panel and the door body frame; and the combination body is placed into a foaming mould to be subjected to door body foaming to complete the installation of the refrigerator door body. According to the installation method for the refrigerator door body, the refrigerator door body assembled adopting the installation method and the refrigerator with the refrigerator door body, by means of the manner that the display screen is placed into the display-screen embedded box before the door body foaming procedure is performed, thus the procedure of installation and disassembly of foaming tooling in related technologies is omitted, the installation procedure of the refrigerator door body is simplified, and dirty hard to clean generated on the display screen is further effectively avoided and the possibility of scratching the door body panel is eliminated.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

Optical fiber patch cord

InactiveCN106199869AAvoid scrap rateSimple structureFibre mechanical structuresFiberEnvironmental resistance

The invention discloses an optical fiber patch cord. The optical fiber patch cord includes an optical fiber patch cord main body. The utmost external end of the optical fiber patch cord main body is provided with a housing sheath. The utmost middle part of the optical fiber patch cord main body is provided with a larger macrofiber cable core. An external end of the macrofiber cable core wraps a protective reinforcing sleeve. The housing sheath and the protective reinforcing sleeve are provided therebetween with a plurality of smaller fine fiber cable cores which surrounds the macrofiber cable core. The external end of the fine fiber cable core is provided with a filling layer of a flexible material. According to the invention, the optical fiber patch cord has simple and reasonable structure, is safe and easy to use, and has strong protection. The optical fiber patch cord can be used even when an optical fiber is folded, so that the optical fiber patch cord avoids the probability of entire discarding of the optical fiber, reduces the frequency of optical fiber changing, reduces labor cost and production cost, and meets the requirements of economic and environmental protection.

Owner:HEFEI AGEDE INFORMATION TECH

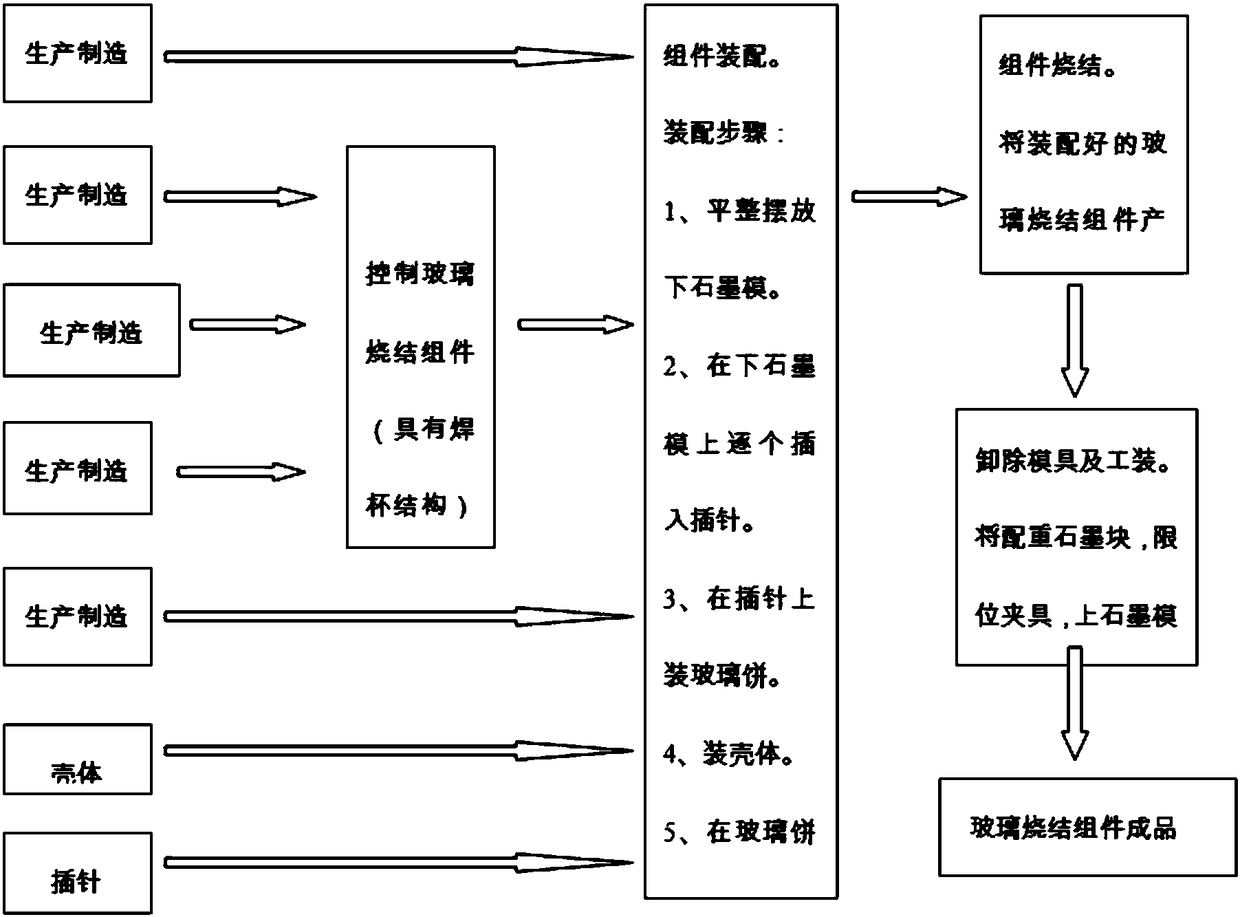

Design method of glass sintering assembly product torsion control tool

InactiveCN108178498ACommon materialSimple and fast operationGlass reforming apparatusGlass productionGraphiteRejection rate

The invention belongs to the technical field of design methods of tool fixtures and particularly relates to a design method of a glass sintering assembly product torsion control tool. A lower graphitemold is produced according to a glass sintering assembly map; a limit fixture is produced according to the glass sintering assembly map as well as the direction and the size of pin welding cup milling openings. An upper graphite mold piece is produced according to the glass sintering assembly map, and regular and clear reverse concave characters are required to be engraved on the upper graphite mold piece. A cylindrical counter weight is produced. Assembly assembling is performed. An assembled glass sintering assembly is put in a sintering furnace to be sintered. The tool has the advantages that the raw material price is low, the production method is simple, the tool is convenient to operate and the like. The tool has the characteristics that the production cost of the fixture is low, andthe fixture is convenient to operate and easy to load and unload by operators in the production and use process, the welding cup directions of the glass sintering assembly product produced with the tool are consistent, and the rejection rate caused by non-consistent welding cup directions is prevented. The production efficiency is greatly improved and the production cycle is shortened.

Owner:GUIZHOU HUAFENG ELECTRICAL APPLIANCES

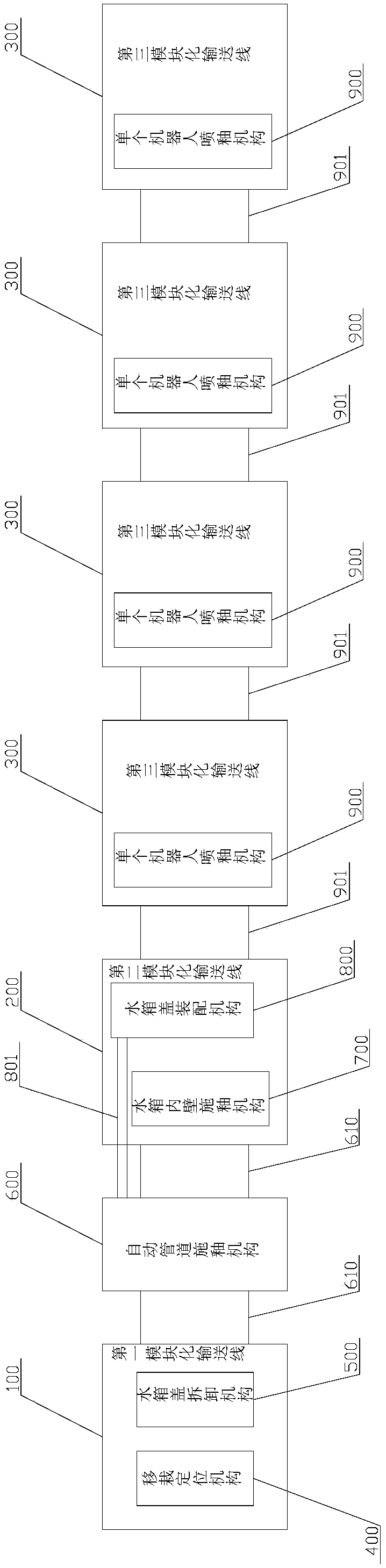

A Modular Robotic Precise Glazing System

ActiveCN105622170BSolve the problem of high-precision conveyingGlaze realizationTransition lineButt joint

The invention discloses a modularized robot accurate glaze spraying system. The glaze spraying system comprises a first modularized conveying line, an automatic pipeline glazing mechanism, a second modularized conveying line and at least one third modularized conveying line which are sequentially arranged in the operation direction of a ceramic pedestal pan blank, wherein the first modularized conveying line comprises a first conveying line body, a transplant positioning mechanism and a water tank cover disassembling mechanism; the second modularized conveying line comprises a second conveying line body, a water tank inner wall glazing mechanism and a water tank cover assembling mechanism, and a water tank cover, disassembled by the water tank cover disassembling mechanism, of the ceramic pedestal pan blank is conveyed to the water tank cover assembling mechanism through a water tank cover conveying line; the automatic pipeline glazing mechanism comprises a conveying butt-joint line and two first powerless transition lines; each third modularized conveying line comprises a third conveying line body, a single robot glaze spraying mechanism and at least one non-glaze-spraying station. Glaze spraying operation on the ceramic pedestal pan blank can be realized in a flexible module matching combination mode.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Clamp clamping and releasing device for shaft part

InactiveCN105773235AAvoid displacementCause displacementMeasurement/indication equipmentsPositioning apparatusShape changeComputer module

The invention provides a clamp clamping and releasing device for a shaft part. A contact induction module (2), a friction induction module (3) and a transmission module (4) are arranged at the two operating ends of a chuck (1). The contact induction module (2) induces the contact space between the two sides of the chuck (1) and the shaft part. The friction induction module (3) induces the intensity of friction generated between the two sides of the chuck (1) and the shaft part. A central control device (5) is arranged. During use, the transmission module (4) transmits induced information to the central control device (5), and a computer of the central control device analyzes the tightening situation in real time and judges whether locking needs to be conducted through a locking ring or not; a shape induction module (6) is arranged, the shape changes of the shaft part are detected at the same time, and whether deformation is caused or not is judged; and displacement, caused when a clamp is not fastened, of the shaft part can be prevented, and the part rejection rate is more effectively prevented.

Owner:ANQING FENGBANG IND PROD DESIGN

An inclusive plugin approach

ActiveCN106879187BStable clampingAvoid Horizontal Angle OffsetPrinted circuit assemblingRejection rateManipulator

Owner:SHENZHEN KUNQI XINHUA

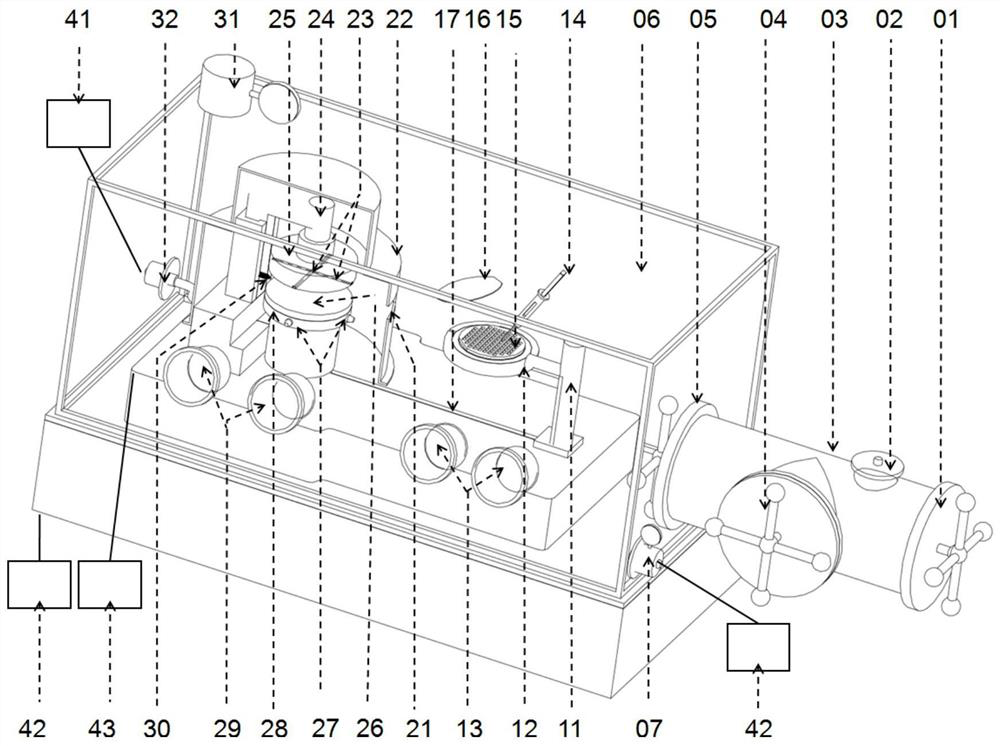

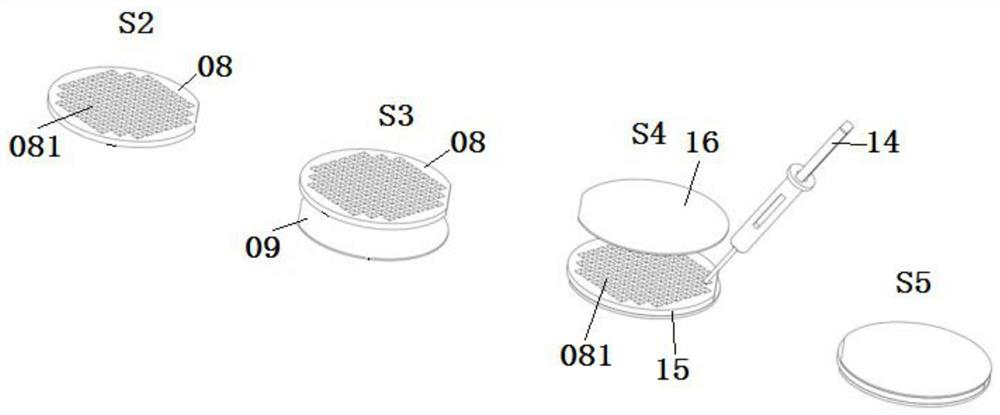

Integrated bonding device and method for manufacturing atomic gas chamber for alkali metal direct filling

PendingCN112723306AImprove automationGood production efficiency and yieldPrecision positioning equipmentSoldering apparatusSilicon chipAnodic bonding

The invention discloses an atomic gas chamber manufacturing integrated bonding device and method for alkali metal direct filling. The device comprises a vacuum conveying mechanism; a protection mechanism used for realizing an alkali metal direct charging atmosphere; an object moving mechanism used for realizing conveying and alkali metal direct filling operation; and an anodic bonding mechanism used for realizing anodic bonding of the silicon wafer and the high borosilicate glass. The protection mechanism comprises a base and a sealing cover; the sealing cover covers the base in a sealing manner to form a closed space; the object moving mechanism and the anodic bonding mechanism are accommodated in the closed space; the vacuum conveying mechanism is communicated with the closed space; and the object moving mechanism is used for conveying the silicon wafer and the high borosilicate glass to the anodic bonding mechanism. According to the invention, the manufacturing atmosphere of alkali metal direct filling for manufacturing the atomic air chamber is realized, and meanwhile, a clean and dry conveying atmosphere is also provided by the vacuum conveying mechanism; the integrated production of anodic bonding, packaging and alkali metal filling of the atomic gas chamber is realized, the automation degree is high, and the production efficiency and the yield are good.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

Double-edge cutting automatic device and cutting method for special vibration-damping sound-absorbing adhesive tape for high-speed rail carriage

PendingCN111633711AGuaranteed service lifeGuarantee the quality of useMetal working apparatusArticle deliveryAdhesive beltElectric machinery

The invention relates to a double-edge cutting automatic device and a cutting method for a special vibration-damping sound-absorbing adhesive tape for a high-speed rail carriage. The method comprisesthe following steps of: rotating a transverse moving right hand wheel clockwise or anticlockwise to finally position the distance between a left cutter and a right cutter; rotating a lifting hand wheel clockwise or anticlockwise to finally position the distance between the left cutter and a driving guide roller and the distance between the right cutter and the driving guide roller; correspondinglymounting a left paper tube and a right paper tube on two slip shafts; starting an electromagnetic valve and a pneumatic valve, wherein one path of the pneumatic valve provides an air source for the slip shafts through an air filling gun, and the other path of the pneumatic valve provides an air source for a right water spraying valve and a left water spraying valve through the electromagnetic valve; and starting a left cutter motor assembly and a right cutter motor assembly to cut double edges of the sound-absorbing adhesive tape, and winding waste edges on the left paper tube or the right paper tube, wherein the width of anti-sticking paper of the cut sound-absorbing adhesive tape is not changed, and an aluminum foil and glue are cut according to set sizes. According to the device, the qualified special vibration-damping sound-absorbing adhesive tape for the high-speed rail carriage is produced, the production efficiency is improved by more than ten times, and the requirement on large-batch production is met.

Owner:三友(天津)高分子技术有限公司

Manufacturing method of window beam for urban railway car

ActiveCN107891102BOptimize production process conditionsSimple methodLoad-supporting pillarsWindow arrangementsManufacturing technologyMachining

The invention relates to a manufacturing method of an urban subway window beam, and belongs to the field of mechanical processing and manufacturing methods. According to actual production, the methodcomprises a plurality of steps of processing and adjusting a window beam workpiece, and the conditions, methods and processing sequence of a production process of the window beam workpiece are improved again, so that the window beam workpiece which conforms to the drawing standard is manufactured. According to the manufacturing method, standard process parameters and normalized operating processesare given, so that standard mass production of the window beam workpiece can be realized, and a plurality of inherent defects such as defects of the forming quality of the window beam, the rejectionrate of the window beam workpiece and high productive labor intensity and low working efficiency caused by unreasonable processes of an existing manufacturing process of the window beam are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com