Integrated cleaning device of condenser integrated robot

A technology for cleaning devices and condensers, which is used in cleaning heat transfer devices, flushing, lighting and heating equipment, etc. It can solve the problems of high-pressure water pipes moving at high speed, long distances, and large cleaning angles, and achieve a consistent speed. Improve the performance, avoid high scrap rate, and ensure the effect of sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

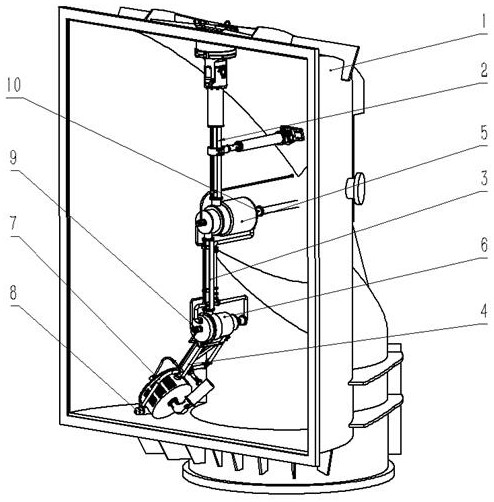

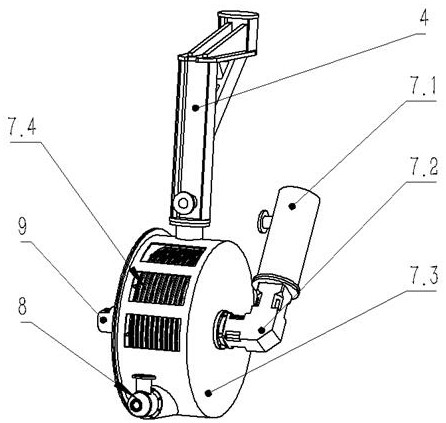

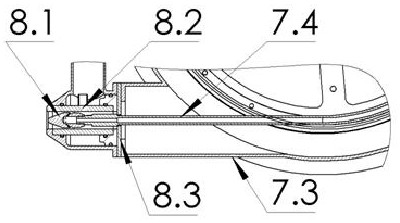

[0028] Such as Figure 1 to Figure 3 , a condenser integrated robot integrated cleaning device according to the present invention, comprising a condenser water chamber 1, a base 2, an articulated arm 3, an articulated arm 2 4, a primary transmission mechanism 5, a secondary transmission mechanism 6, and a coil Device 7 , nozzle fixture device 8 , water pipe rotary joint 9 , and rotating line pipe 10 .

[0029] The base 2 is installed in the condenser water chamber 1, and the joint arm 1 is connected to the joint arm 3 through the primary transmission mechanism 5. The joint arm 1 3 and the joint arm 2 4 are the secondary transmission mechanism 6, and the end of the joint arm 2 4 is equipped with a disc The tube device 7, the side of the coil body shell 7.3 in the coil device 7 is equipped with a servo motor 7.1 and a high-precision non-hollow reducer 7.2 to provide the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com