Tool for litter box forming and application method thereof

A technology for cat litter and tooling, applied in packaging, application, animal houses, etc., can solve the problems of incorrectly pasting the double-layer corner board and the upper board, increasing the loss of working hours, and waste products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

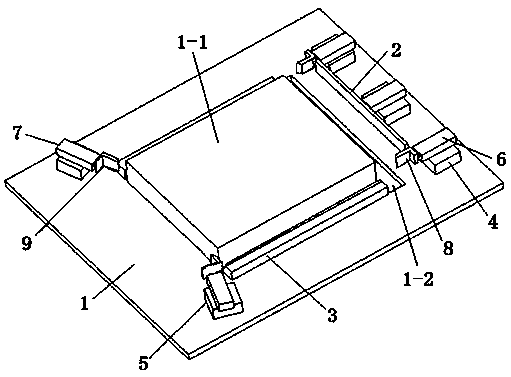

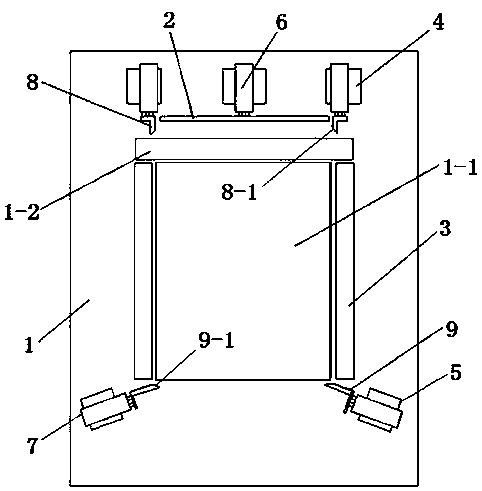

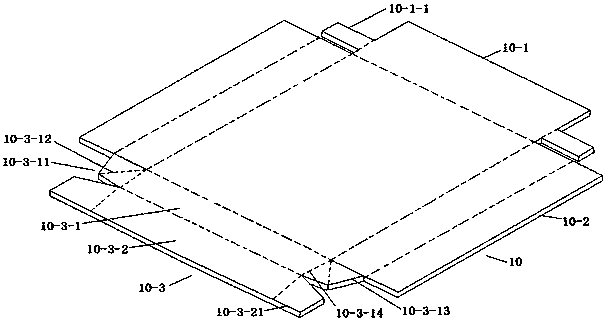

[0029] like figure 1 , figure 2 As shown, a tooling for forming a cat litter box, including a base 1, a strip top piece 2, a fixed plate 3, a rectangular support column I4, a rectangular support column II5, a cylinder I6, a cylinder II7, and an L-shaped guide piece I8 , L-shaped guide Ⅱ 9.

[0030] The L-shaped guide Ⅰ8 and the L-shaped guide Ⅱ9 have the same structure, and are composed of two rectangular pieces that are integrated. The inner surface of the front end of the L-shaped guide Ⅰ8 is an arc surface Ⅰ8-1, and the L-shaped guide Ⅱ9 is one. The inner surface of the front end of the rectangular sheet is arc surface II9-1.

[0031] The base 1 is in the shape of a rectangular plate, and a rectangular boss 1-1 and a strip-shaped hollow sink 1-2 are respectively arranged on the surface of the base 1, and the strip-shaped hollow sink 1-2 is arranged on the rectangular boss. In front of 1-1, a fixed plate 3 is respectively fixed on both sides of the rectangular boss 1-1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com