Design method of glass sintering assembly product torsion control tool

A technology for glass sintering and glass control, which is applied in glass production, glass forming, glass reshaping, etc. It can solve the problems of inconsistent welding cup angles of glass sintering components, shorten the production cycle, and facilitate the removal of tooling and easy loading and unloading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

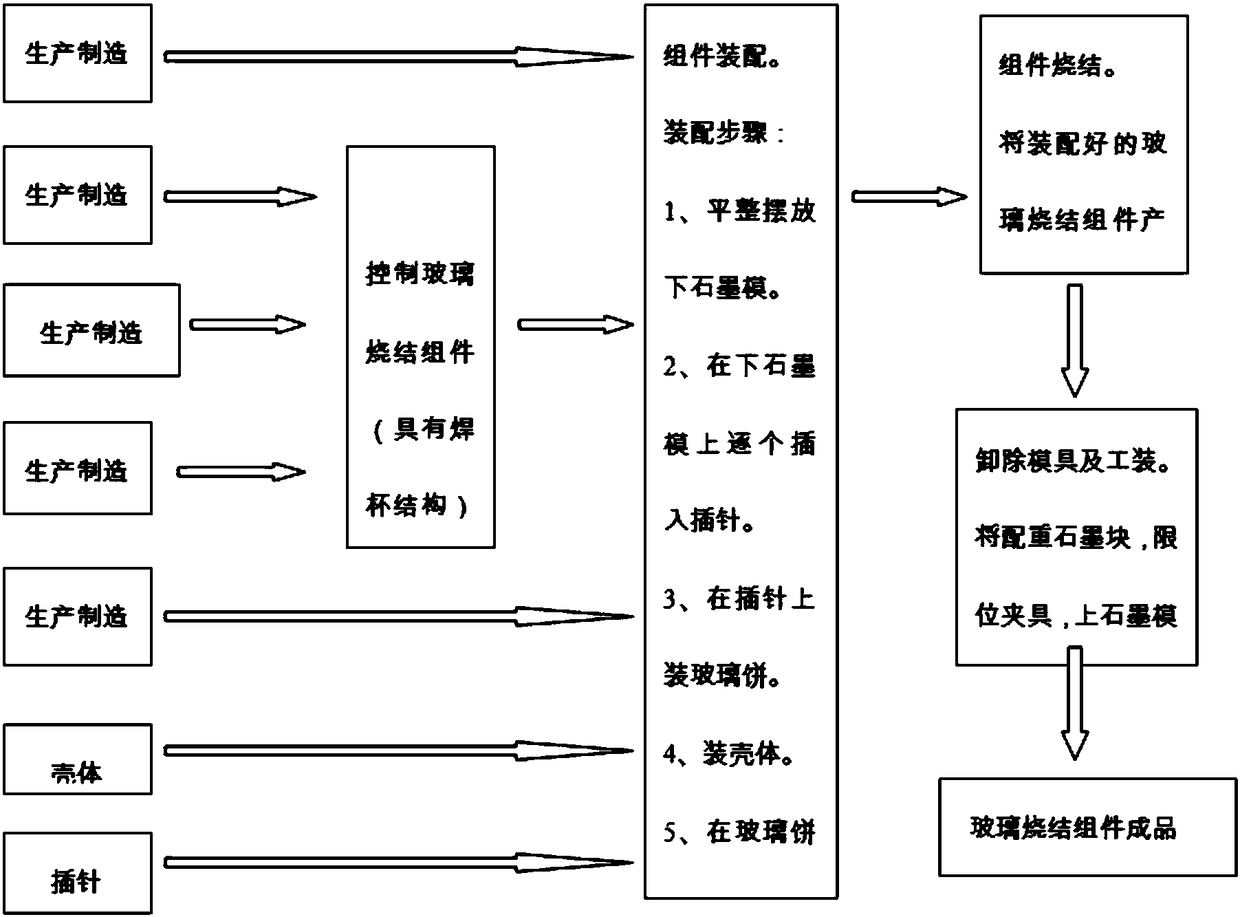

Method used

Image

Examples

Embodiment Construction

[0035] Step 1: According to the product map of glass sintered components, produce the lower graphite mold in the shape of a boss. When the lower graphite mold is inserted into the pin, the gap should not be too large, and the gap should be between 0.05 and 0.2mm. The lower graphite mold plays a role in controlling the vertical position of the pin.

[0036] Step 2: According to the map of the glass sintered component and the direction and size of the milling cut of the pin, make a cylindrical limit fixture. The limit fixture has a semicircular through hole at the same position as the glass sintered map. The through hole should not be too large. If the gap with the pin solder cup is too large, it will easily cause the direction of the pin solder cup to deflect after sintering. The limit fixture can be buckled on the pins to fix the left and right positions of the solder cups of the pins in the plane direction, so as to ensure that the angles of the solder cups of the pins are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com