Assistive device for covering residual liquid during automobile coating

A coating and residual liquid technology, applied in the direction of spraying devices, etc., can solve the problems of kinetic energy consumption and working time, poor anti-corrosion performance of anti-rust primer, increase of labor workload of employees and cost of spraying cars, etc., so that the production process is not complicated , low cost, and the effect of improving the coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

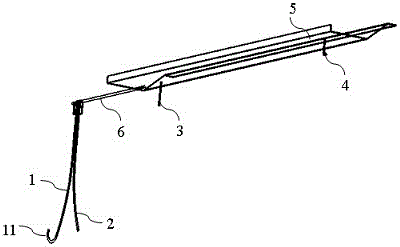

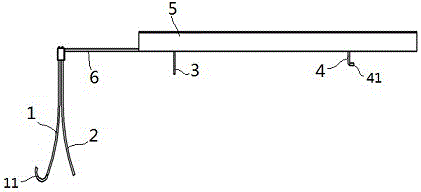

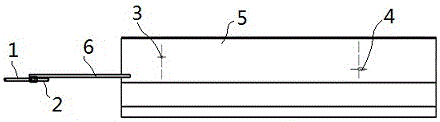

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] Figure 1 to Figure 4 It shows an auxiliary tool for covering residual liquid in automobile painting, including a fixed rod 1 , an auxiliary fixed rod 2 , a long positioning post 3 , a short positioning post 4 , a cover plate 5 and a connecting rod 6 . The long positioning column 3 and the short positioning column 4 are arranged on the lower surface of the cover plate 5 , and the fixed rod 1 and the secondary fixed rod 2 are connected to one end of the cover plate 5 through a connecting rod 6 . The cover plate 5 cooperates with the original process hole of the front fender of the vehicle body through the fixed rod 1, the long positioning column 3, and the short positioning column 4, and then the cover plate 5 is effectively fixed on the top of the front fender of the vehicle body.

[0032] The cover plate 5 plays the role of covering the residual liquid. Cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com