Automatic covering system of ceramic toilet water tank cover

An automatic on-line and water tank cover technology, applied in the field of automation systems, can solve the problems of increasing production costs, heavy quality of gypsum blanks, and difficulty in guaranteeing product uniformity, and achieves the effect of quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

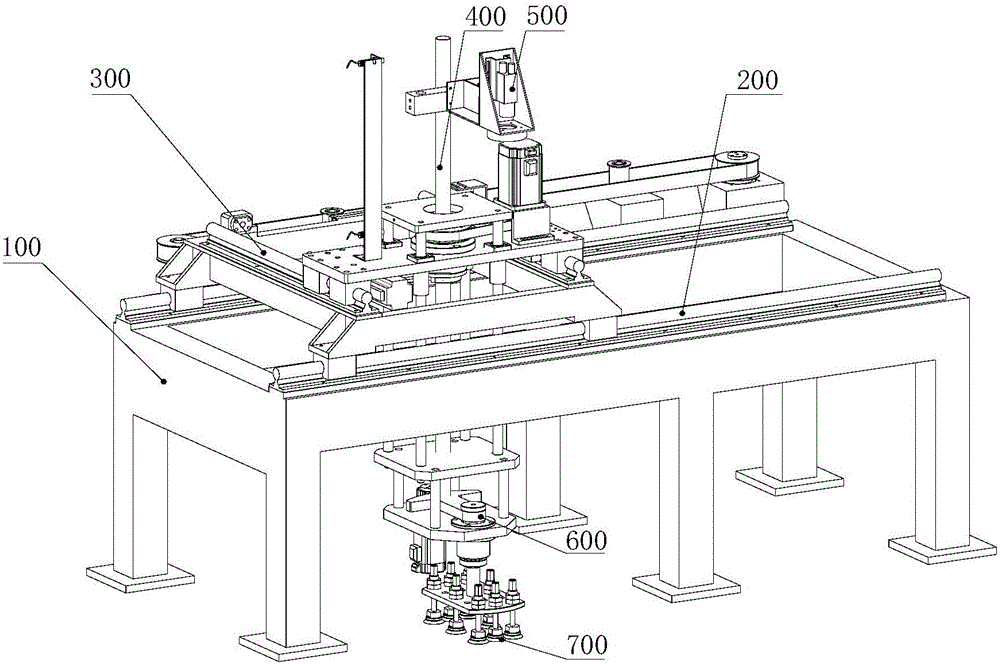

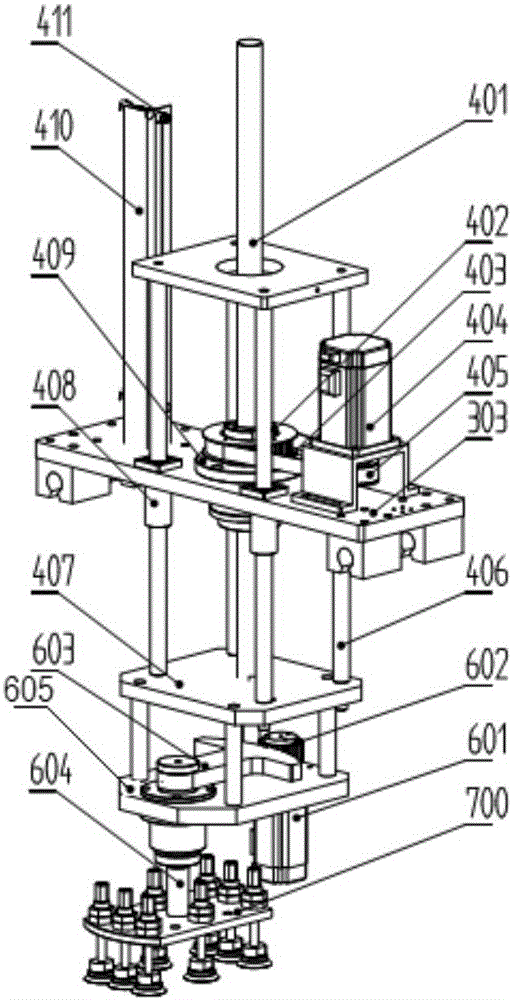

[0033] An automatic on-line system for ceramic toilet water tank cover, such as figure 1 shown. It mainly includes a frame 100 , a transverse transmission device 200 , a longitudinal transmission device 300 , a vertical transmission device 400 , a camera 500 , a suction cup fine-tuning device 600 , and a suction cup 700 .

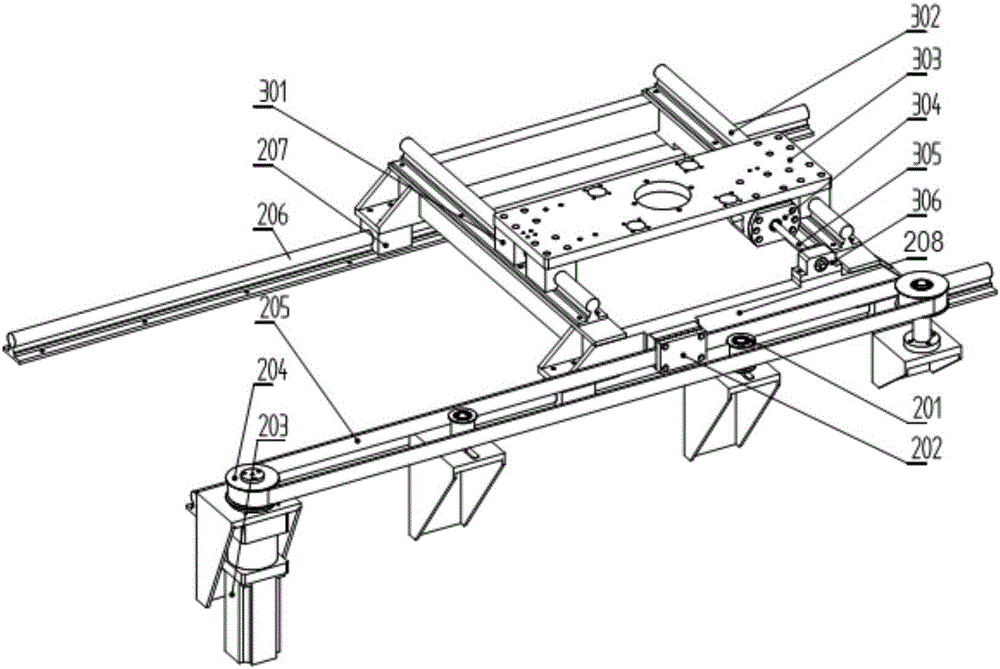

[0034] Such as figure 2As shown, the transverse transmission device 200 is mainly composed of a transverse servo motor 203, a first synchronous pulley 204, a first synchronous belt 205, a synchronous belt toothed connection block 202, a tensioning wheel 201, a transverse linear guide rail 206, and a transverse slider 207 and a mobile bracket 208; the longitudinal transmission device 300 is mainly composed of a longitudinal servo motor 304, a longitudinal ball screw 305, a longitudinal nut 306, a longitudinal linear guide 302, a longitudinal slider 301, and a vertical device connecting seat 303.

[0035] In the transverse transmission device 200 , the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com