Double-edge cutting automatic device and cutting method for special vibration-damping sound-absorbing adhesive tape for high-speed rail carriage

A technology of automatic devices and carriages, applied in transportation and packaging, metal processing, sending objects, etc., can solve the problems of not being able to cut off the anti-sticking paper, not meeting the time and quality requirements of mass production, and dimensional errors, so as to ensure quality and The consistency of weight, meeting the requirements of mass production and ensuring the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

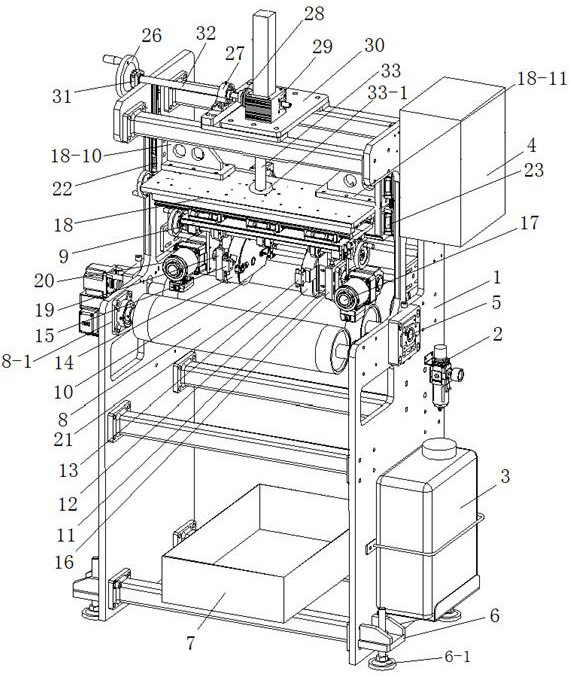

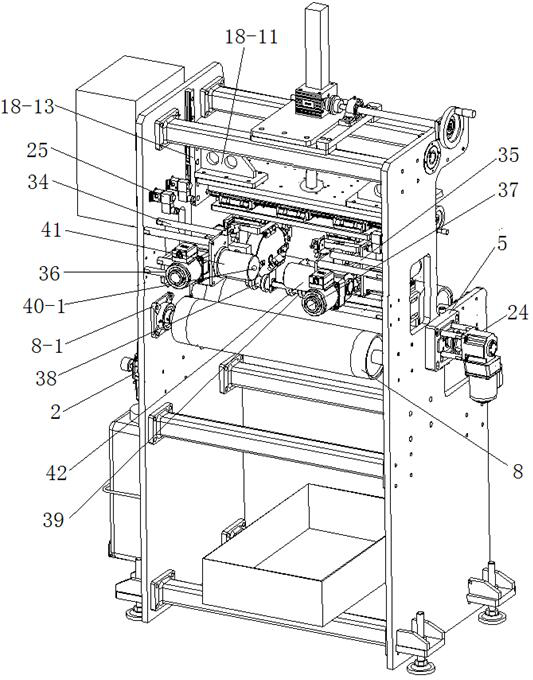

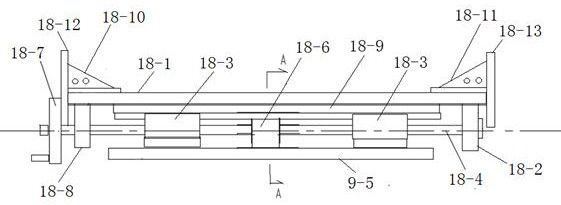

[0057] like Figure 1 to Figure 12 As shown, the double-sided automatic device for cutting vibration-absorbing and sound-absorbing tapes for high-speed rail carriages includes: frame 1, air pressure valve 2, water tank 3, electrical box 4, adjustment seat 5, adjustment rod seat 6, waste water recovery box 7, and auxiliary guide rollers 8. Left and right knife independent traverse assembly 9, left knife 10, right knife 11, right knife protective cover 12, right water spray valve 13, left knife protective cover 14, left water spray valve 15, right knife motor assembly Forming adjustment seat 16, right cutter motor assembly 17, left and right cutter overall traverse lifting assembly 18, left cutter motor assembly adjustment seat 19, left cutter motor assembly 20, active guide roller 21, left slider 22 , right track 23, motor assembly 24, solenoid valve 25, lifting hand wheel 26, bearing seat I 27, coupling 28, elevator 29, flat plate 30, hand wheel bracket 31, hand wheel shaft 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com