Additive manufacturing metal cooling method

A technology of additive manufacturing and metal cooling, applied in the field of additive manufacturing, which can solve problems such as deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

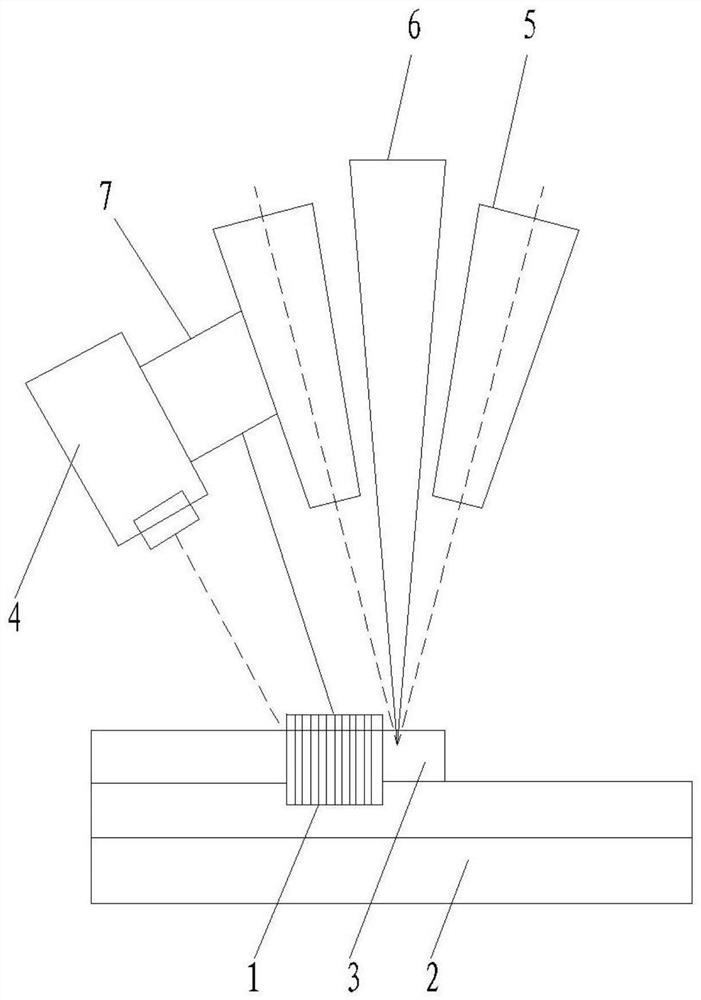

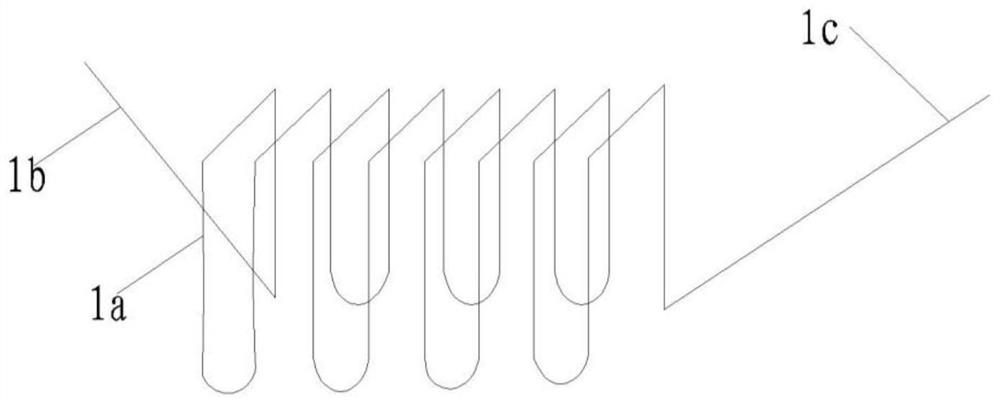

[0021] As shown in the figure, the metal cooling method for additive manufacturing in this embodiment includes a cooling device 1, and the cooling device realizes cooling during the additive manufacturing process through the following steps:

[0022] S1: Additive manufacturing: using laser cladding equipment or arc additive equipment to perform additive manufacturing on the substrate 2;

[0023] S2: On-line cooling: the cooling device is set behind the heat source and follows the heat source to cool the cladding layer 3 and the heat-affected zone below the cladding layer in real time. The heat source is the position of the sintering raw material of the additive manufacturing equipment and the position of the molten pool; after the additive equipment prints two layers, adjust the cooling device to a suitable height, and turn on the cooling cycle immediately behind the heat source to realize the Rapid cooling of the cladding layer and the heat-affected zone below;

[0024] S3: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com