A kind of detection method of tire label position in tire vulcanization production process

A production process and tire vulcanization technology, applied in the field of visual inspection, can solve problems such as increasing difficulty, unqualified product quality, and affecting the accuracy of tire labels, so as to improve work efficiency and avoid scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Based on the visual calibration method, the present invention designs a set of methods for solving the problem of inaccurate placement of labels due to the position change of the vulcanizer membrane cavity during the vulcanization process.

[0027] Attached below figure 1 and figure 2 The concrete implementation steps of this method are described:

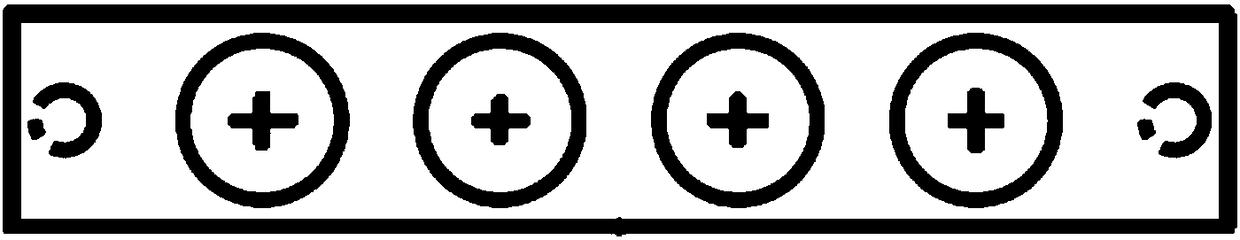

[0028] Step 1) Design the target, see figure 1 . The target is used to accurately measure the position of the target and the benchmark for whether it is placed in place. There are N(N>2) rings of the same size printed on the target. (One or more groups of targets can be selected. The more rings there are, the more accurate the position change calculation will be.) The targets are engraved on the stainless steel material, the surface is sprayed with white matte paint, and the rings and the center cross are sprayed with black.

[0029] Step 2) Design a label placement range template, see figure 2 . Due to the particul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com