Field emission display structure by utilizing thick film medium as separant

A display structure and field emission technology, which is applied in the manufacture of image/graphic display tubes, discharge tubes/lamps, cathode ray tubes/electron beam tubes, etc., can solve the problem of increasing device performance stability and inaccurate spacer alignment , complex installation process and other issues, to achieve the effect of avoiding complex installation process, solving inaccurate alignment, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

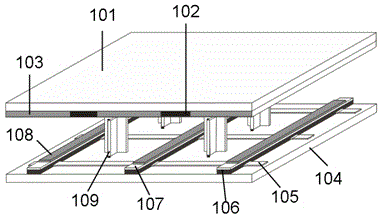

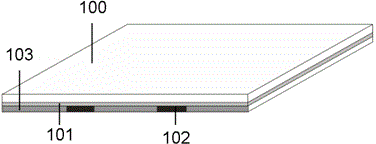

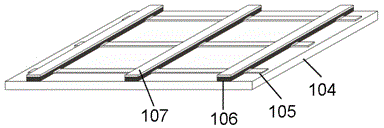

[0027] figure 1 It is a schematic diagram of a field emission display structure using a thick film dielectric as a spacer according to the first preferred embodiment of the present invention. Figure 2 to Figure 10 A structural diagram of the realization of a field emission display structure using a thick film dielectric as a spacer is shown. Combine the following Figure 2 to Figure 10 The first embodiment of the present invention provides a detailed description of a field emission display structure using a thick film dielectric as a spacer and a manufacturing method thereof.

[0028] A field emission display structure using a thick film medium as a spacer and a manufacturing method thereof, characterized in that the field emission display structure is composed of a cathode substrate and an anode substrate, and a thick layer is arranged between the cathode substrate and the anode substrate. The membrane dielectric spacer is arranged on the glass base of the cathode substrat...

Embodiment 2

[0046] Figure 11 It is a schematic structural diagram of a field emission display using a thick film medium as a spacer according to the second embodiment of the present invention. The field emission display structure is composed of a cathode substrate and an anode substrate. A thick-film dielectric spacer is arranged between the cathode substrate and the anode substrate. The spacer is arranged on the glass base of the cathode substrate and is firmly bonded to the glass base. into a whole. The field emission display structure includes a dipole structure, a tripole structure and a multipole structure. The tripole structure or the multilevel structure includes a front gate type structure, a back gate type structure and a flat gate type structure. The preferred second embodiment of the present invention provides the structure. A method for fabricating a back gate type field emission display structure using a thick film dielectric as a spacer, comprising the following steps:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com