Rapid continuous feeding stamping method of welding pin

A fast and soldering pin technology, applied in the field of molds, can solve the problems of shortened processing time, high cost, long soldering pin processing time, etc., and achieve the effects of saving production time, convenient operation, shortening time and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

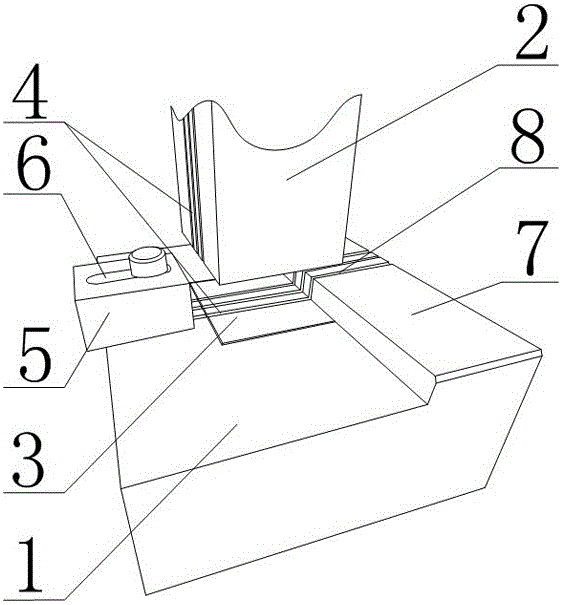

[0018] Such as figure 1 As shown, a rapid continuous feed stamping method for welding pins of the present invention includes a male mold 1 and a female mold 2. The female mold 2 is a platform as a whole, and a pit is arranged on its surface, and a Bottom mold 3, bottom mold 3 is fixed in the pit by spring or other elastic components, the highest position of bottom mold 3 is the plane of female mold 2, the lowest position of bottom mold 3 is the pit bottom, and a limiter is installed on female mold 2. The position block 5 is provided with a position adjustment groove 6 on the limit block 5, and the position of the limit block 5 is adjusted by bolts and fixed on the female mold 2; The side walls of the pit are provided with three parallel continuous grooves 4; a discharge platform 7 is also provided on the female mold 2, and the discharge platform 7 and the limit block 5 are respectively located on both sides of the pit. There is a clamping groove 8, and the clamping groove 8 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com