Automatic disassembly and assembly system of ceramic toilet water tank cover

A technology of automatic disassembly and assembly of the water tank cover, which is applied in water supply devices, flushing toilets, transportation and packaging, etc., can solve problems such as collision damage of embryonic parts, high work intensity of workers, dense air and dust, etc., and achieve product quality improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

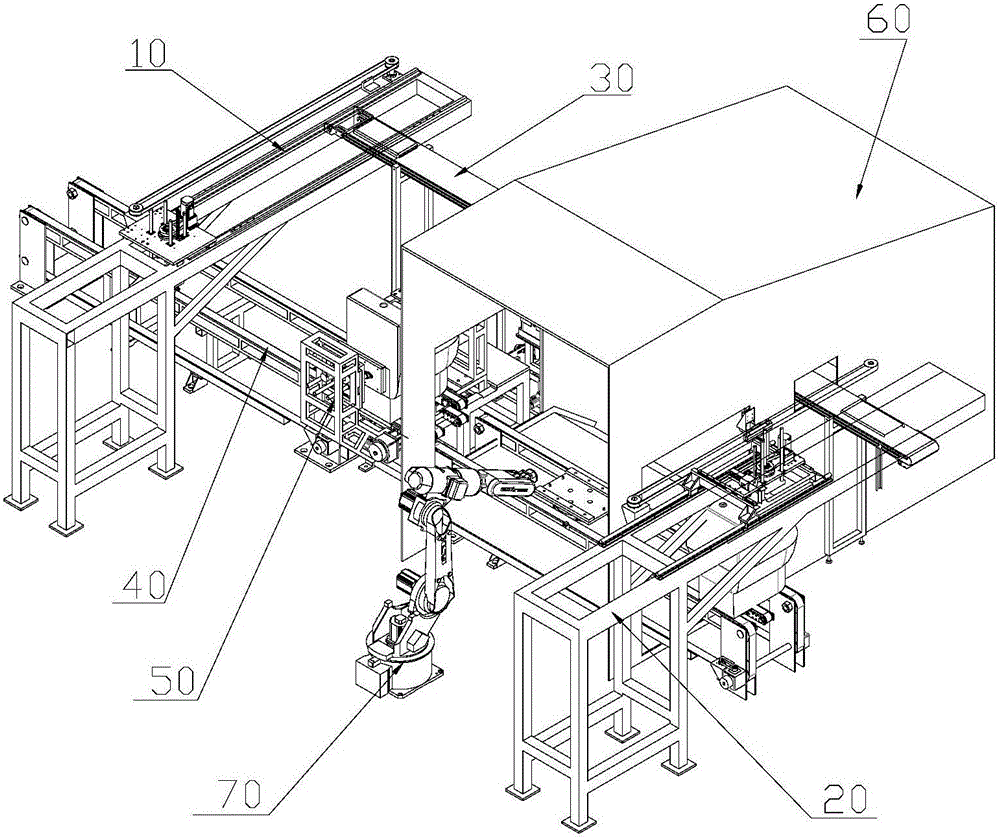

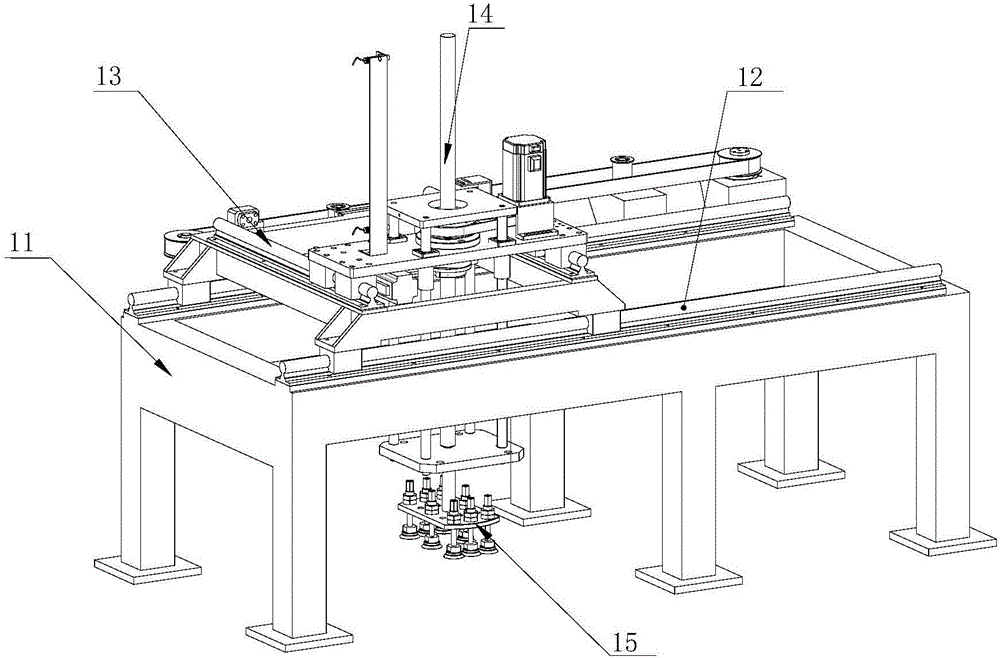

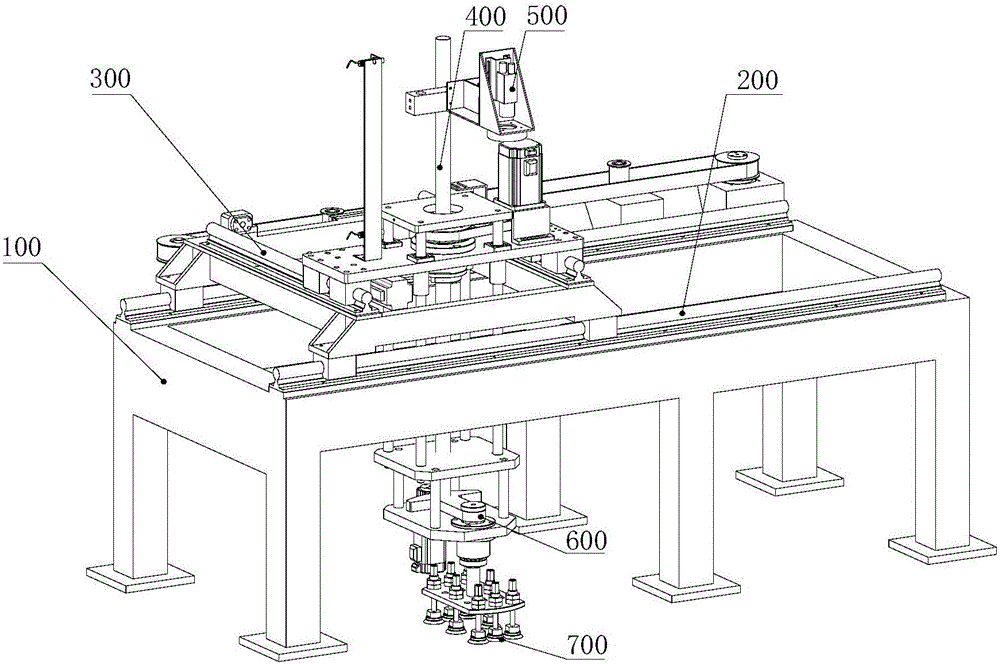

[0037] Please refer to figure 1 As shown, an automatic disassembly and assembly system for a water tank cover of a ceramic toilet is mainly composed of an automatic disassembly mechanism 10 , an automatic assembly mechanism 20 and a water tank cover conveying line 30 . Among them, please refer to figure 2 As shown, the automatic dismounting mechanism 10 comprises a frame 11, a transverse transmission device 12, a longitudinal transmission device 13, a vertical transmission device 14 and a suction cup 15; please refer to image 3 As shown, the automatic assembly mechanism 20 mainly includes a frame 100 , a transverse transmission device 200 , a longitudinal transmission device 300 , a vertical transmission device 400 , a camera 500 , a suction cup fine-tuning device 600 , and a suction cup 700 .

[0038] The two ends of the water tank cover conveying line 30 are positioned at the lower side of the frame 11 and the frame 100, and the pipeline glazing mechanism 50 and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com