Integrated molding and pouring process for semi-enclosed glass fiber reinforced plastic products with infolded flanges

A glass fiber reinforced plastic, semi-closed technology, applied in the field of infusion technology, can solve the problems of high production cost, reduce mold sealing, affect product quality, etc., achieve the effect of reducing production cost, ensuring product quality, and accelerating production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

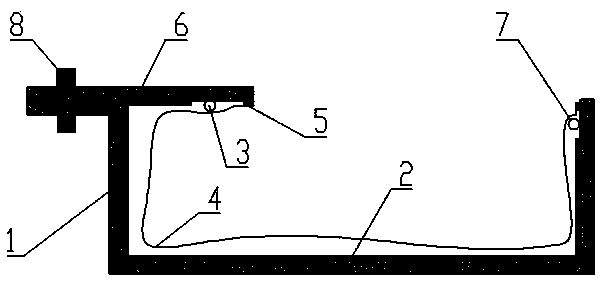

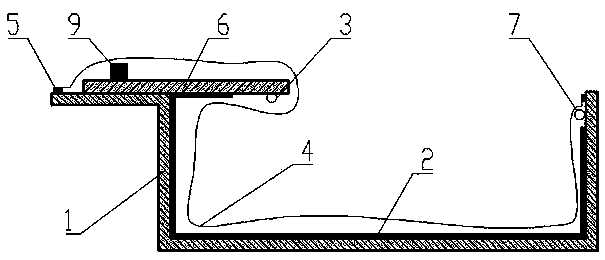

[0021] see figure 1 , image 3 and Figure 4 : the present invention comprises the following sequential steps:

[0022] ①. Manufacture the mold, which is suitable for the semi-closed FRP product to be poured. The mold includes a main part 1 and a flange part 6. The main part 1 extends out to be connected with the flange part 6. On this side A bolt 9 is pre-embedded, and the bottom end of the bolt 9 is an integral structure with the main body part 1, and the top end of the bolt 9 protrudes. The flange part 6 is drilled with a bolt hole corresponding to the position of the bolt 9, and the flange part 6 is fixed on the main part 1 by the bolt 9, and a sealing tape is left on the peripheral surface of the side of the fixed flange part 6 of the main part 1. Ample space for 5.

[0023] ②. Carry out a series of conventional treatments of cleaning the main body part 1 and the flange part 6 of the mould, removing mold wax or wiping off mold water. After the treatment is finished,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com