Manufacturing method of window beam for urban railway car

A manufacturing method and technology for urban railway cars, which are applied in the directions of manufacturing tools, railway car body parts, beams, etc., can solve the problems of low work efficiency, high production labor intensity, large correction and forming of window beams, etc., and achieve convenient operation and promotion. popular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

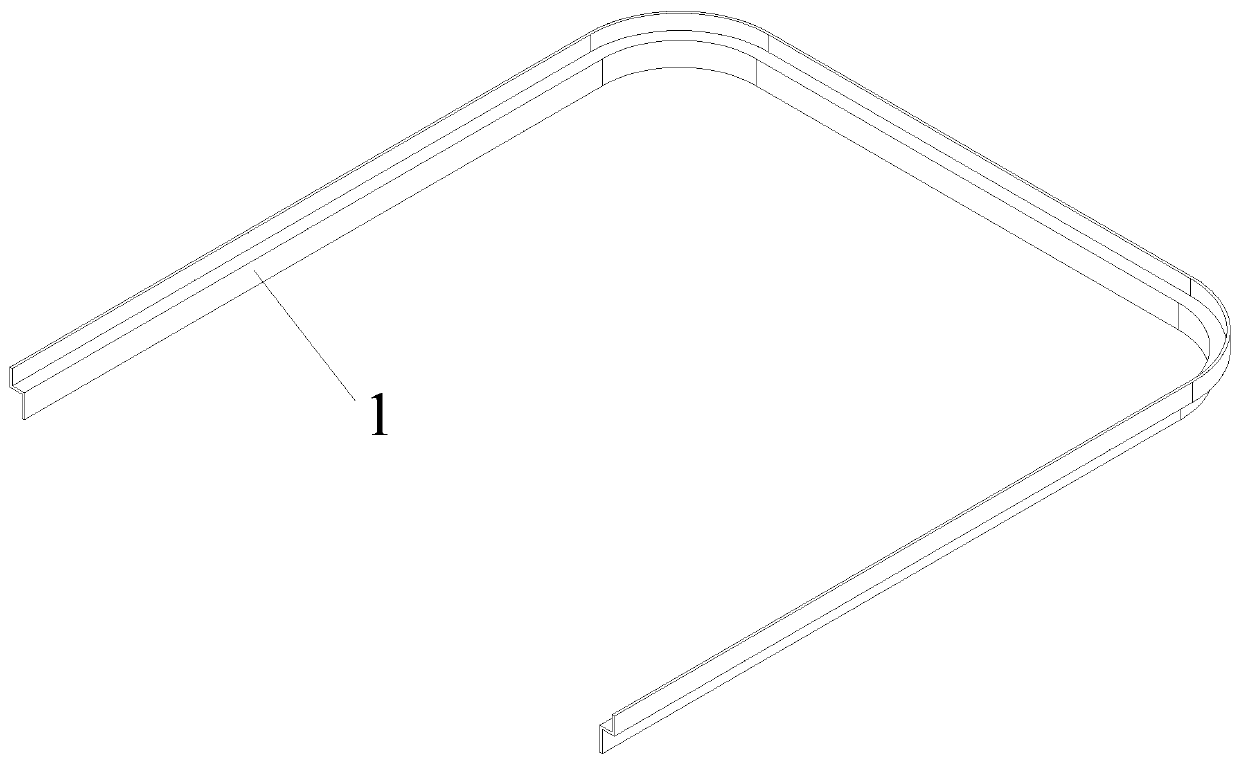

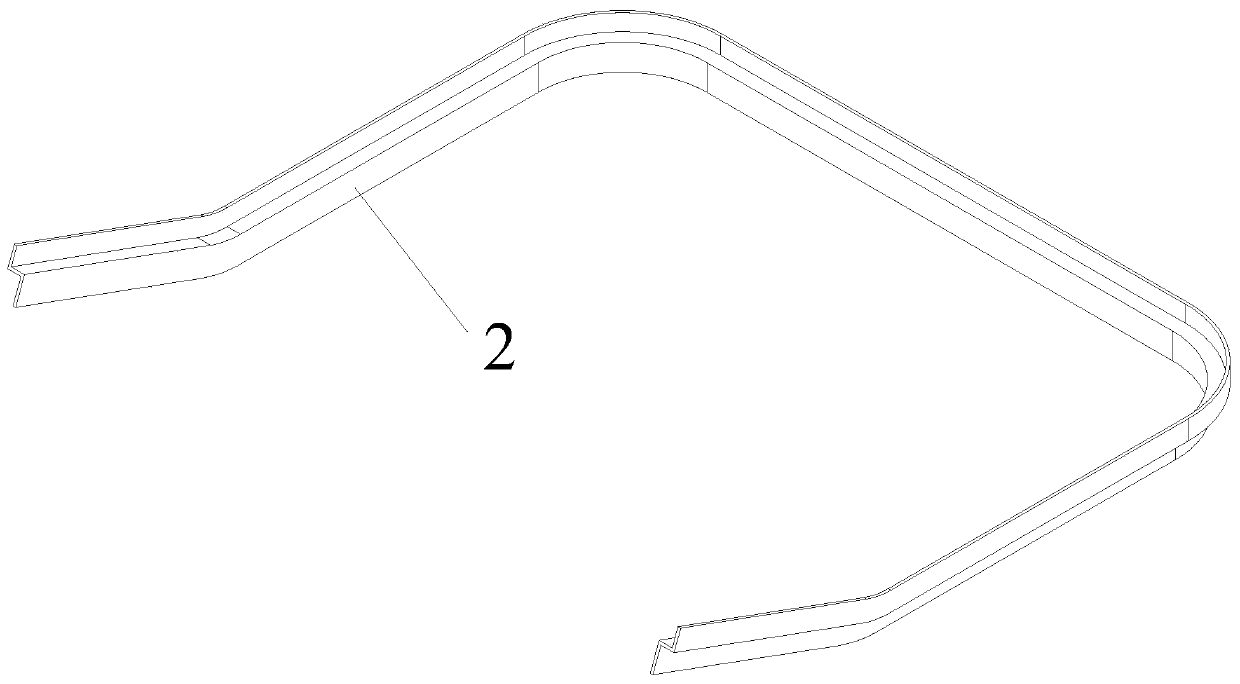

[0030] Such as figure 1 and figure 2 As shown, when specifically applying the manufacturing method of the urban railway car window beam of the present invention, the following steps are performed:

[0031] Step 1: Execute the preparation work before processing, which specifically includes the following sub-steps:

[0032] Step 1.1: Check whether the material, size and appearance quality of the blank 1 of the window beam meet the technical requirements of the drawings, and repair or replace the blank 1 of the window beam that does not meet the inspection requirements;

[0033] Step 1.2: Check whether the working pressure of the hammer forming equipment, the FWA802 / 4X compression mold, and the SW4T calendering mold are in good condition, and adjust them to normal working conditions;

[0034] Step 1.3: Check whether the working pressure of the vibrating hamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com