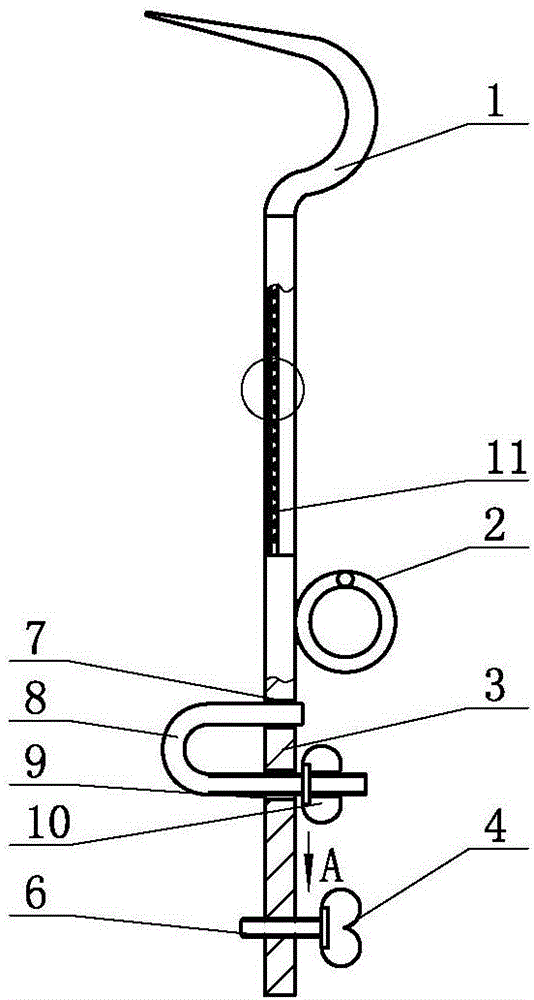

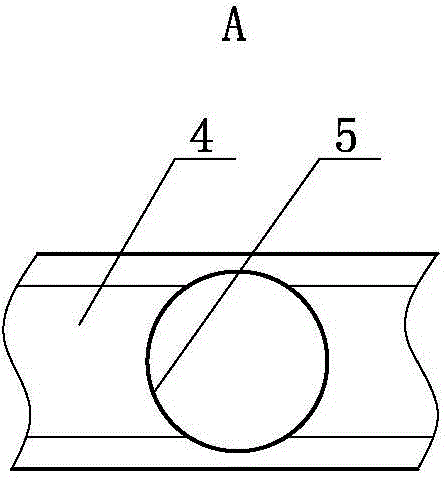

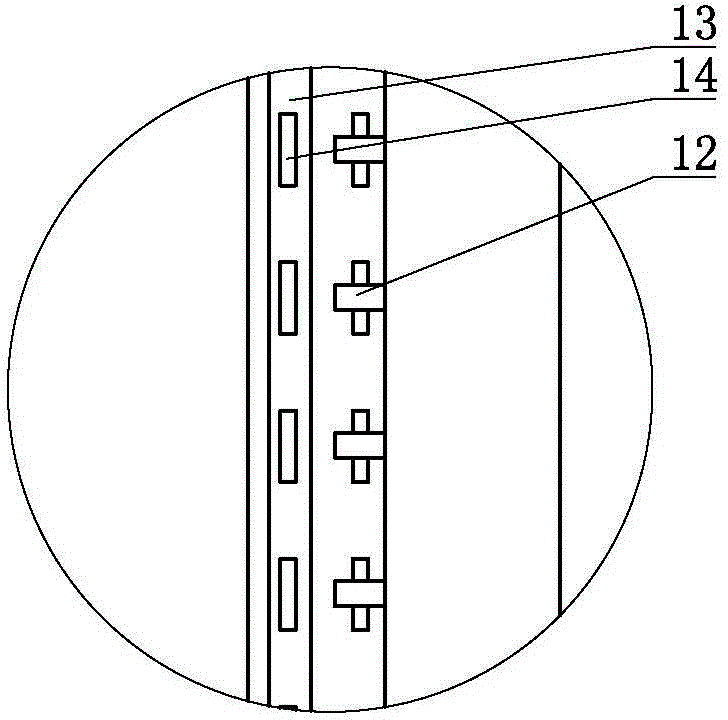

Anti-falling convenient pin remover

A pin remover and anti-fall technology, which is applied to electrical components, overhead lines/cable equipment, insulators, etc., can solve the problems of low success rate of insulator pins, easy to fall from high altitude, and no anti-fall device for pin removers. , to achieve the effect of facilitating industrial production, reducing temperature and optimizing production process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also includes a preparation method of an insulating sleeve, comprising the following steps:

[0019] (1) Mix 30-40 parts by weight of chlorosulfonated polyethylene rubber, 35-45 parts of polyurethane rubber and 20-30 parts of EPDM rubber into the internal mixer for 2-4 minutes , the banburying temperature is 90-100°C;

[0020] (2) Continue to add 2-4 parts by weight of antioxidant 4020, 2-10 parts of reinforcing agent, 5-8 parts of magnesium oxide, 10-15 parts zinc oxide, 3-7 parts of ethylene thiourea and 2-5 parts of calcium oxide, and continue banburying for 5-8 minutes; the reinforcing agent is white carbon black and aluminum hydroxide according to the weight of 2-4:1 ratio preparation;

[0021] (3) Adjust the temperature of the mill to 40-45°C, and mill the raw materials after step (2) for 4-8 minutes, then cool the material, and then put it into the mill, adding 10-15 parts by weight. Parts of tris (2-chloroethyl) phosphate, thin pass 2-4 ...

Embodiment 1

[0027]An insulating sleeve, in parts by weight, consists of the following components: 30 parts of chlorosulfonated polyethylene rubber, 35 parts of polyurethane rubber, 20 parts of EPDM rubber, 2 parts of anti-aging agent 4020, 2 parts of reinforcing agent, three 10 parts of (2-chloroethyl) phosphate, 5 parts of magnesium oxide, 10 parts of zinc oxide, 3 parts of ethylene thiourea and 2 parts of calcium oxide; the reinforcing agent is white carbon black and aluminum hydroxide at a ratio of 2:1 The weight ratio of the preparation.

Embodiment 2

[0029] An insulating sleeve, in parts by weight, consists of the following components: 40 parts of chlorosulfonated polyethylene rubber, 45 parts of polyurethane rubber, 30 parts of EPDM rubber, 4 parts of anti-aging agent 4020, 10 parts of reinforcing agent, three 15 parts of (2-chloroethyl) phosphate, 8 parts of magnesium oxide, 15 parts of zinc oxide, 7 parts of ethylene thiourea and 5 parts of calcium oxide; the reinforcing agent is white carbon black and aluminum hydroxide according to the ratio of 4:1 The weight ratio of the preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com