Cable erecting and fixing device

A fixing device and cable technology, applied in the field of electric power, can solve the problems of easy damage to cables by sharp tools, high winding work intensity, low process quality, etc., and achieve the effects of reducing carrying, shortening work time, and strong winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

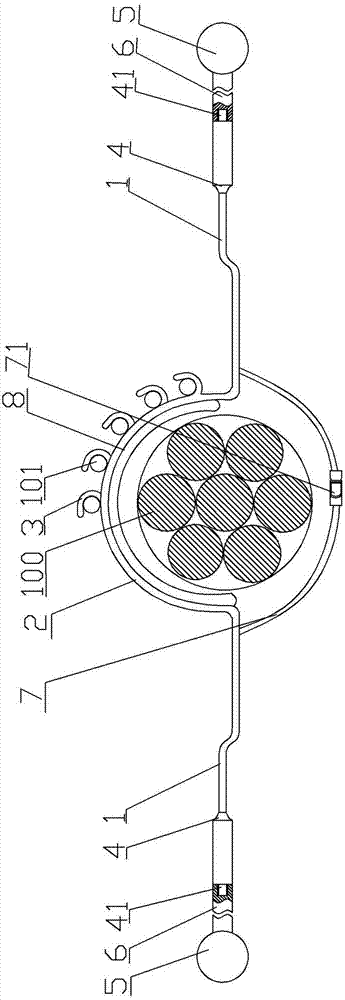

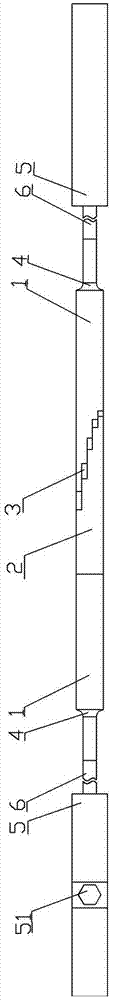

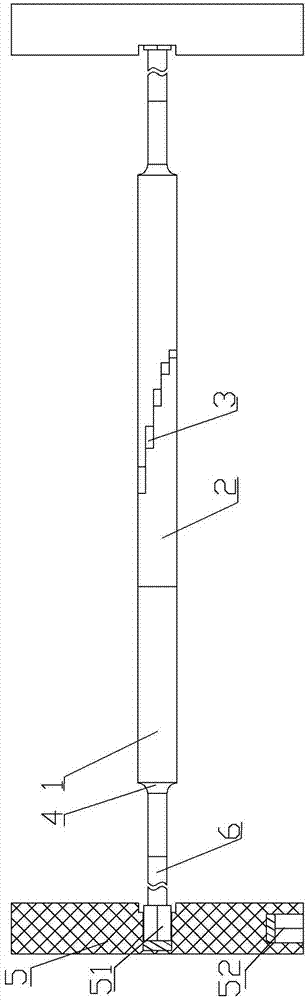

[0023] The following will be combined with Figure 1-5 The present invention will be described in further detail.

[0024] as attached figure 1 and 4 As shown, a cable erection and fixing device includes a main body 1, a twisting hook 3 and a handle 5, an arc-shaped portion 2 is arranged in the middle of the main body 1, and connectors 4 are symmetrically arranged at both ends of the main body 1, The handle 5 is connected with a connecting rod 6 , the connecting head 4 is provided with a threaded rod 41 , and the connecting rod 6 is provided with a threaded hole matching the threaded rod 41 . Five skein hooks 3 are arranged on the outer edge of the arc-shaped portion 2, the inner edge of the arc-shaped portion is provided with an anti-friction layer 8, and the two ends of the arc-shaped portion 2 are provided with an anti-off band 7, and the anti-off band 7 The free end is provided with a buckle 71 . In this embodiment, the anti-friction layer 8 is a non-metallic material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com