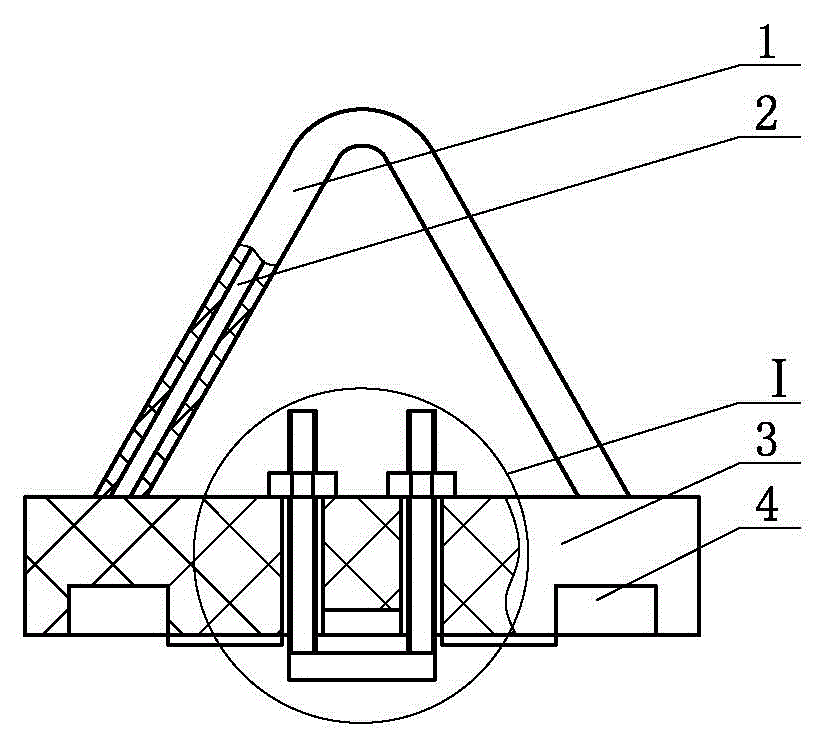

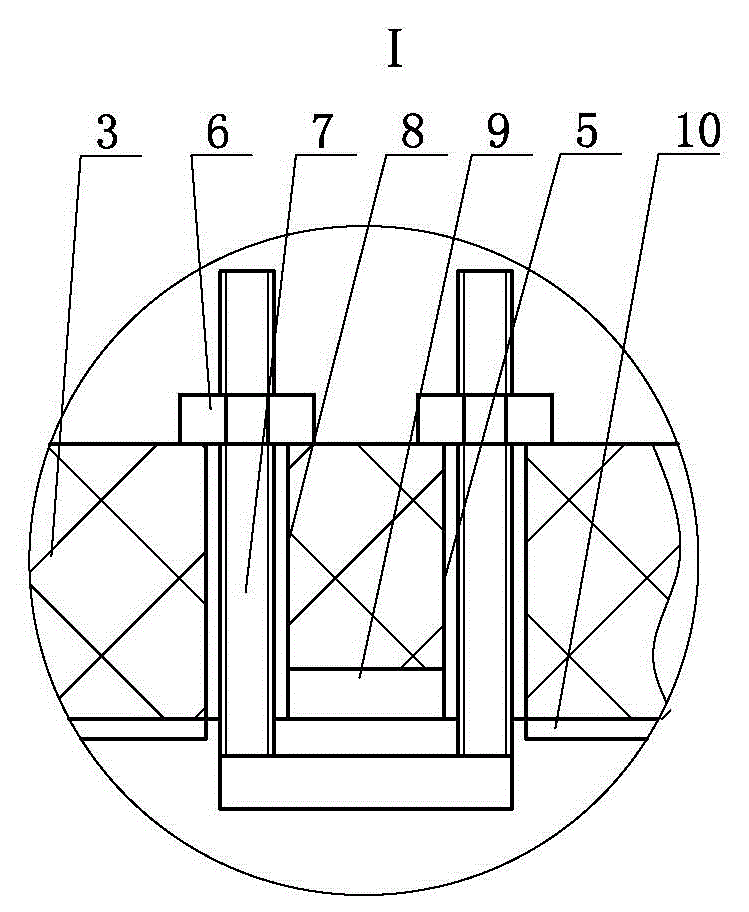

v-shaped heater

A heating chip, U-shaped technology, applied in the direction of heating element materials, reagents, educts, etc., can solve the problems of low-voltage electric shock, limited installation range, etc., and achieve the effects of high tensile strength, increased layout range, and convenient magnet adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also includes a preparation method of a high insulating sleeve, comprising the following steps:

[0019] ① Mix 30-40 parts by weight of chlorosulfonated polyethylene rubber, 35-45 parts of polyurethane rubber and 20-30 parts of EPDM rubber into the internal mixer for 2-4 minutes, and close The refining temperature is 90-100°C;

[0020] ②Continue to add the antioxidant 4020 of 2-4 parts, the reinforcing agent of 2-10 parts, the magnesium oxide of 5-8 parts, the zinc oxide of 10-15 parts in the internal mixer described in step ①, 3-7 parts of ethylene thiourea and 2-5 parts of calcium oxide, and continue banburying for 5-8 minutes; the reinforcing agent is white carbon black and aluminum hydroxide prepared according to the weight ratio of 2-4:1;

[0021] ③Adjust the temperature of the mill to 40-45°C, mill the raw materials after step ② banburying for 4-8 minutes, cool the material, put it into the mill, and add 10-15 parts by weight of three ( 2-C...

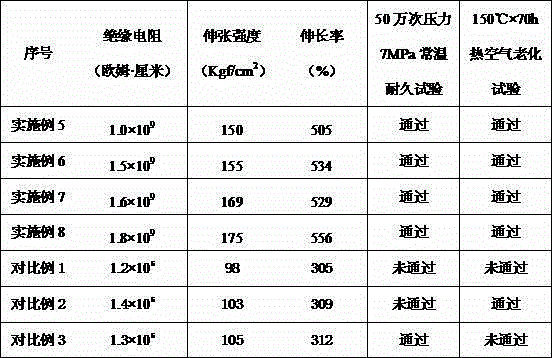

Embodiment 1

[0024] A high insulating sleeve, in parts by weight, consists of the following components: 30 parts of chlorosulfonated polyethylene rubber, 35 parts of polyurethane rubber, 20 parts of EPDM rubber, 40202 parts of anti-aging agent, 2 parts of reinforcing agent, three 10 parts of (2-chloroethyl) phosphate, 5 parts of magnesium oxide, 10 parts of zinc oxide, 3 parts of ethylene thiourea and 2 parts of calcium oxide; the reinforcing agent is white carbon black and aluminum hydroxide at a ratio of 2:1 The weight ratio of the preparation.

Embodiment 2

[0026]A high insulating sleeve, in parts by weight, consists of the following components: 40 parts of chlorosulfonated polyethylene rubber, 45 parts of polyurethane rubber, 30 parts of EPDM rubber, 40204 parts of anti-aging agent, 10 parts of reinforcing agent, three 15 parts of (2-chloroethyl) phosphate, 8 parts of magnesium oxide, 15 parts of zinc oxide, 7 parts of ethylene thiourea and 5 parts of calcium oxide; the reinforcing agent is white carbon black and aluminum hydroxide according to the ratio of 4:1 The weight ratio of the preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com