Power lithium ion battery

A lithium-ion battery and power technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem of difficulty in controlling voltage and capacity consistency, hindering production efficiency and pass rate, and confusing A/B winding core matching and other problems, to achieve the same production process and parameters, avoid the barrel effect, and achieve good flatness consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

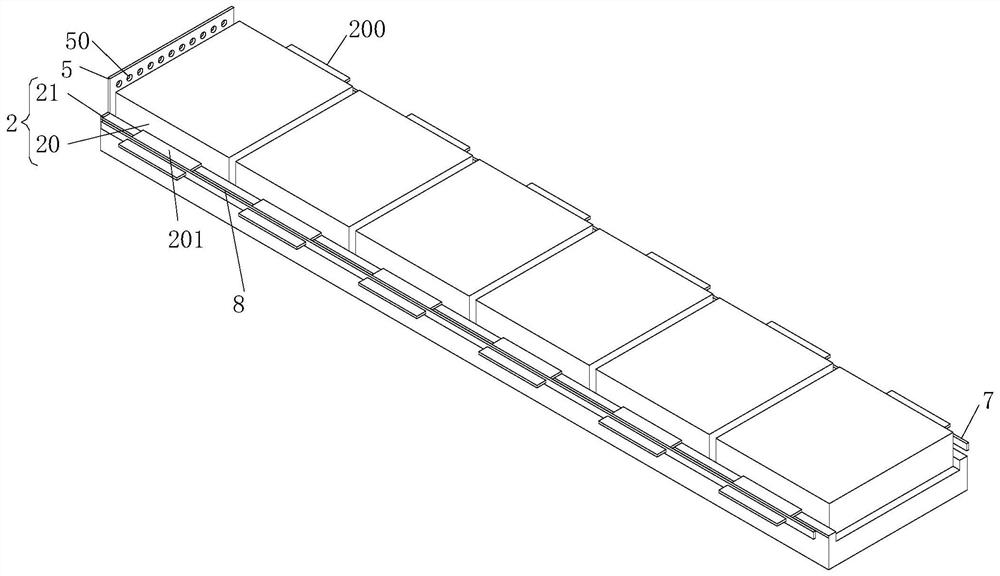

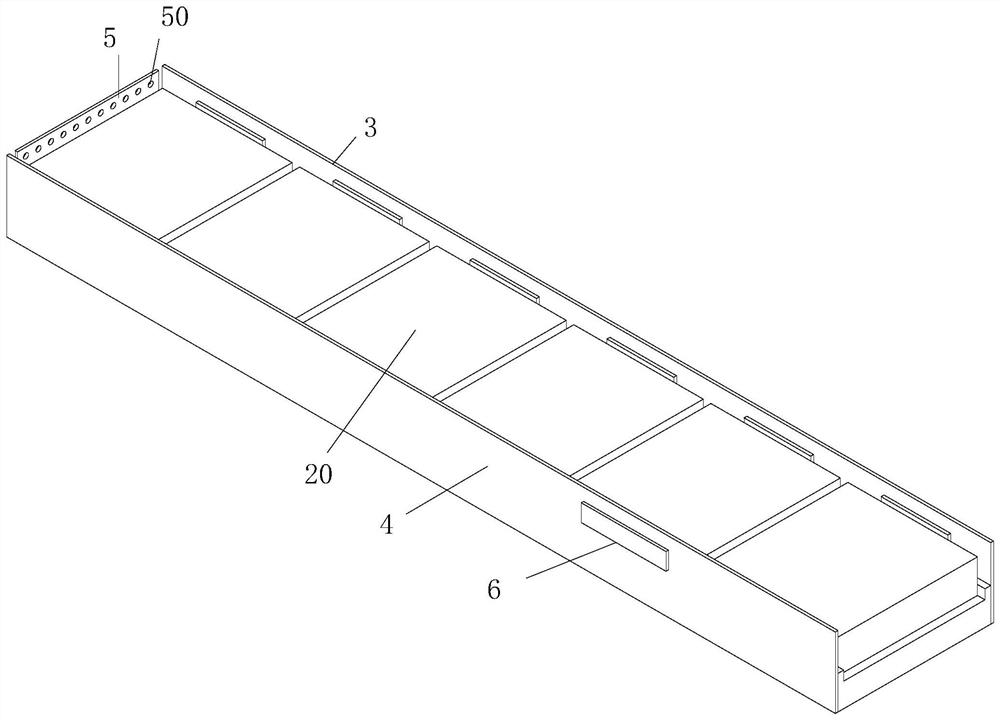

[0051] Such as Figure 1-5 A power lithium-ion battery shown includes a casing 1, a winding core set 2, a positive electrode connecting piece 7, a negative electrode connecting piece 8, a positive electrode cover plate 3 and a negative electrode cover plate 4, wherein:

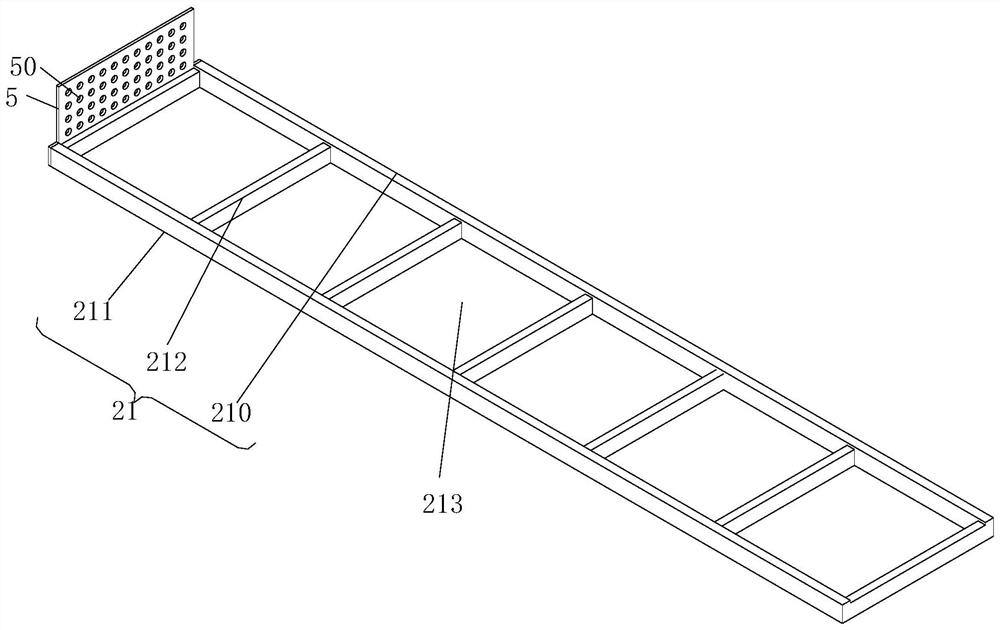

[0052] The winding core group 2 includes a winding core 20 and a fixed bracket 21;

[0053] There are multiple winding cores 20 in the winding core group 2. In this embodiment, there are six winding cores 20, and the six winding cores 20 are placed in the fixed bracket 21 in turn. When the winding cores 20 are placed, all the winding cores 20 The positive tabs 200 face the same side, and all the winding cores 20 negative tabs 201 face the same side;

[0054] Specifically, the fixed bracket 21 includes a positive support rod 210, a negative support rod 211 and a plurality of separation rods 212, the positive support rod 210, the negative support rod 211 and a plurality of separation rods 212 are made of insula...

Embodiment 2

[0073] Such as Figure 6-9 As shown, the difference between this embodiment and the above-mentioned embodiments is that the side plate of the closed winding core 20 is composed of the side plate of the positive electrode cover plate 3, the negative electrode cover plate 4 and the fixing bracket 21, that is, the side plate of the closed winding core 20 The plate is formed by welding the positive cover plate 3 and the positive support rod 210 and the negative cover plate 4 and the negative support rod 211, that is, the casing 1 forms a closed cavity with the positive cover plate 3, the negative cover plate 4 and the fixing bracket 21, and the closed cavity For closing the core 20;

[0074] The advantage of this embodiment over the previous embodiment is that it facilitates the installation of the positive cover plate 3 and the negative cover plate 4. Before installing the positive connecting piece 7 and the negative connecting piece 8, the positive cover plate 3 and negative cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com