A positioning device for transplanting ceramic toilet

A technology of positioning device and toilet, which is applied in the technical process of ceramic toilet glazing, which can solve the problems of manpower consumption, uncontrollable manual alignment accuracy, and affecting the quality of spraying glaze, so as to achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

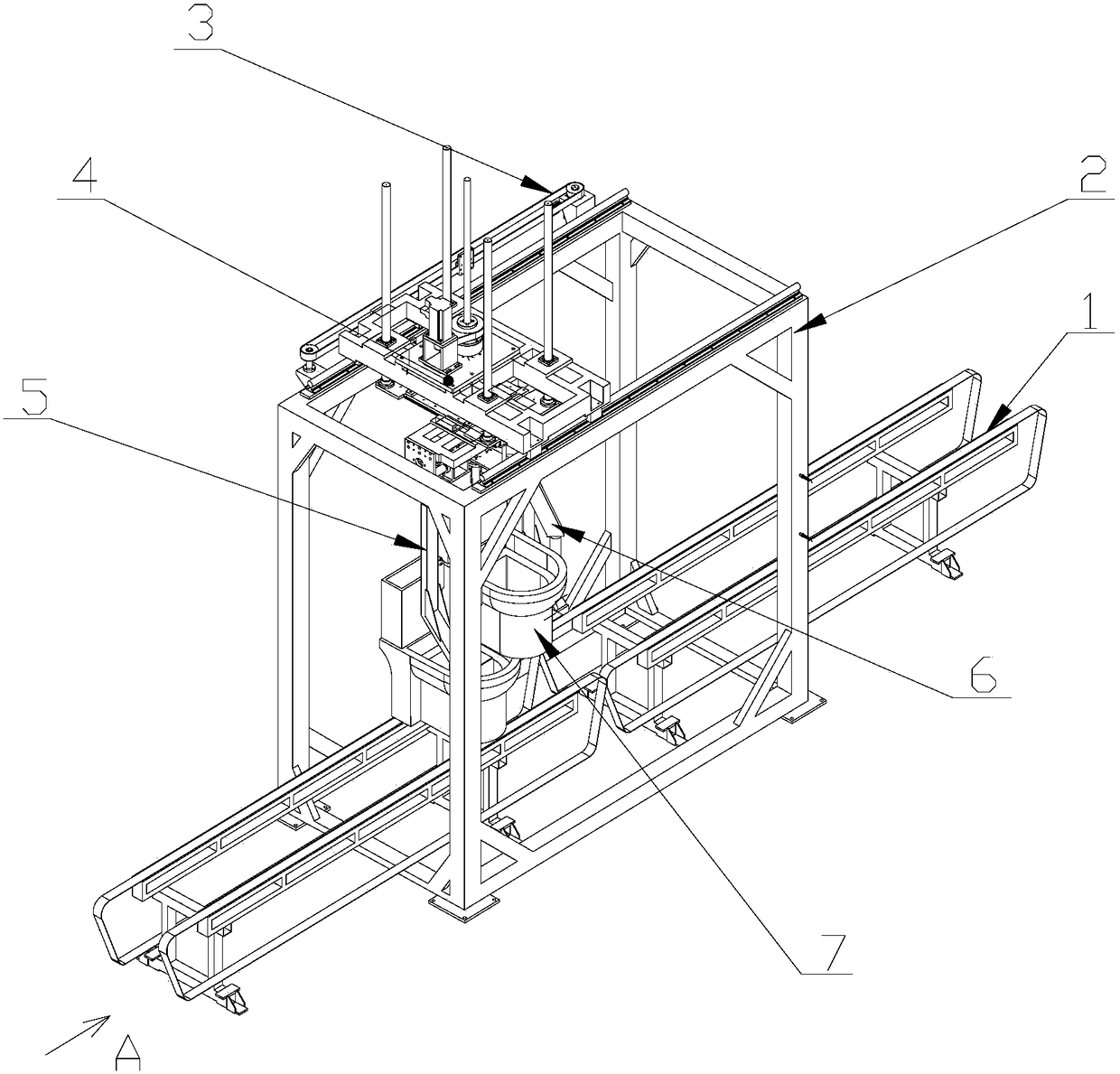

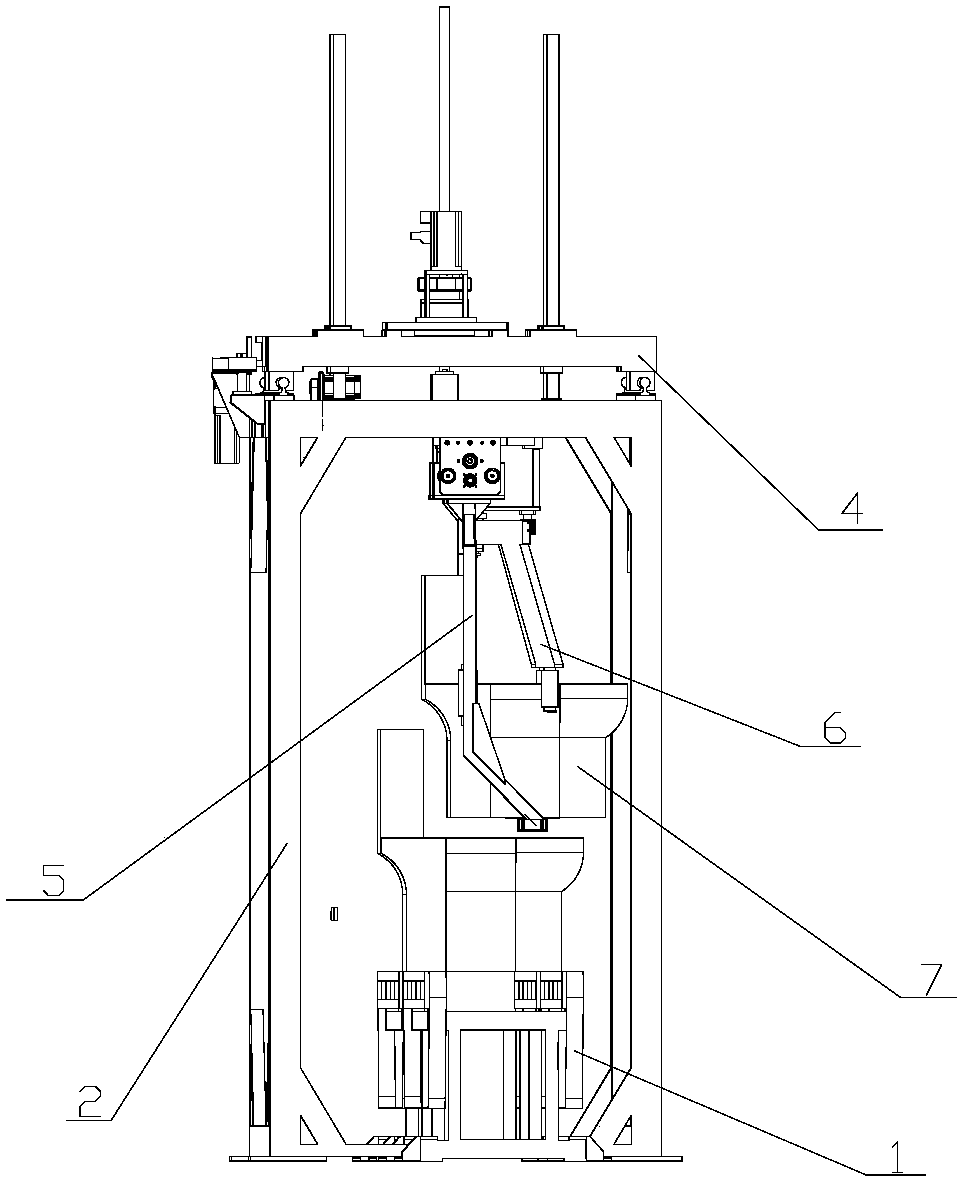

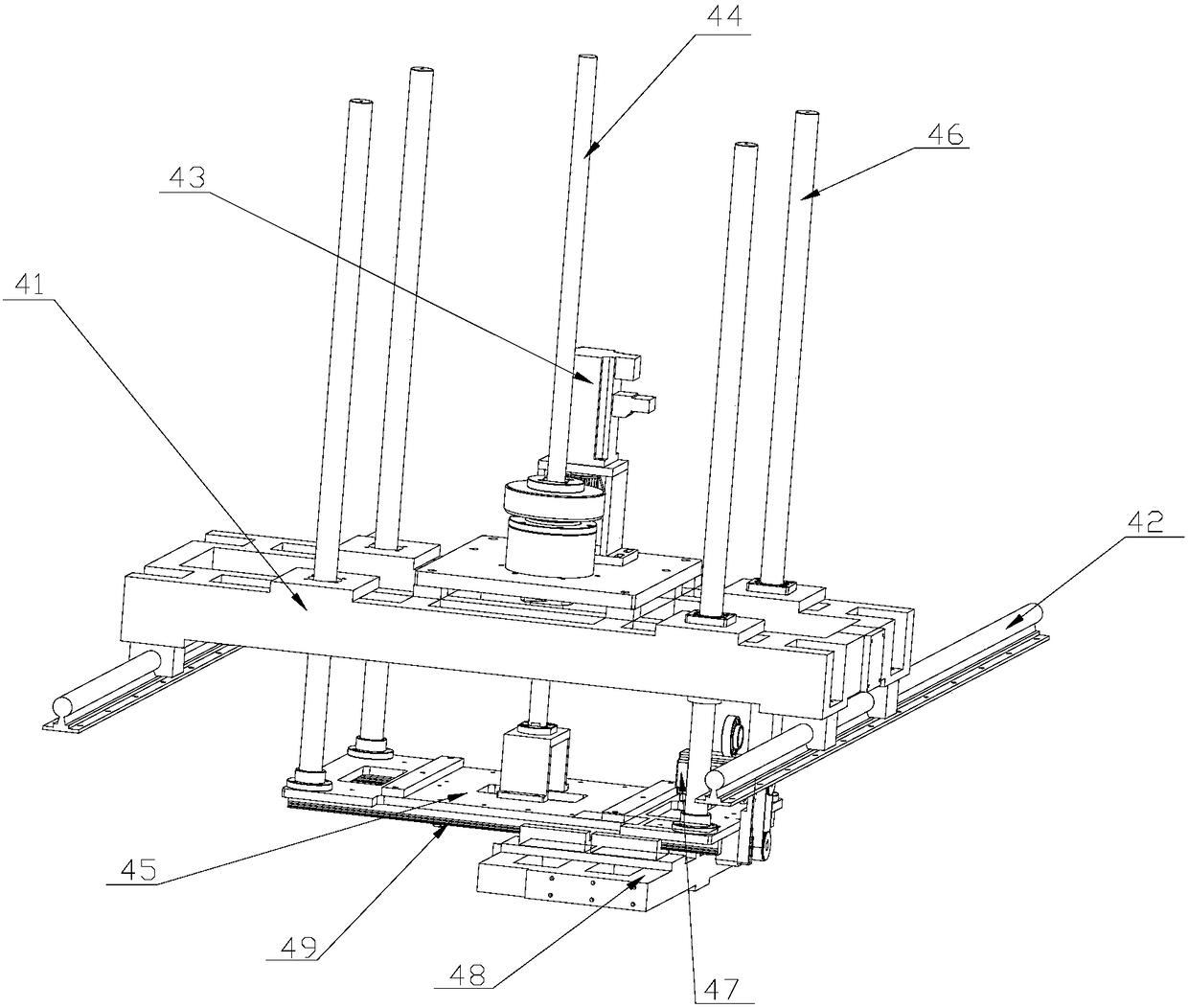

[0039] Please refer to figure 1 and figure 2As shown, a ceramic toilet transplanting positioning device generally includes a frame 2, a conveying line 1, a moving mechanism 4, a supporting hand 5 and a righting hand 6. Among them, the conveying line 1 is an automatic glaze spraying and glazing conveying line, which passes through the frame 2 and is used to transport the ceramic toilet 7 to the spraying and glazing position; the moving mechanism 4 is used to drive the supporting hand 5 and the righting hand 6 on the machine Horizontal, vertical and longitudinal three-dimensional movement is realized on the frame 2; the handling and placement of the ceramic toilet 7 is realized. The supporting hand 5 is installed on the moving mechanism 4, and is used to support the rear portion of the ceramic toilet 7 and places the ceramic toilet 7 at a designated position by means of the moving mechanism; the righting hand 6 is also installed on the moving mechanism, and is used for clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com