A Modular Robotic Precise Glazing System

A robotic and modular technology, applied in the field of flexible processing, can solve the problems of difficulty in further improving the quality of glaze spraying, long equipment development cycle, and low precision of the conveying system, so as to solve the problem of high-precision conveying, reduce the design and development cycle, and improve the control The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

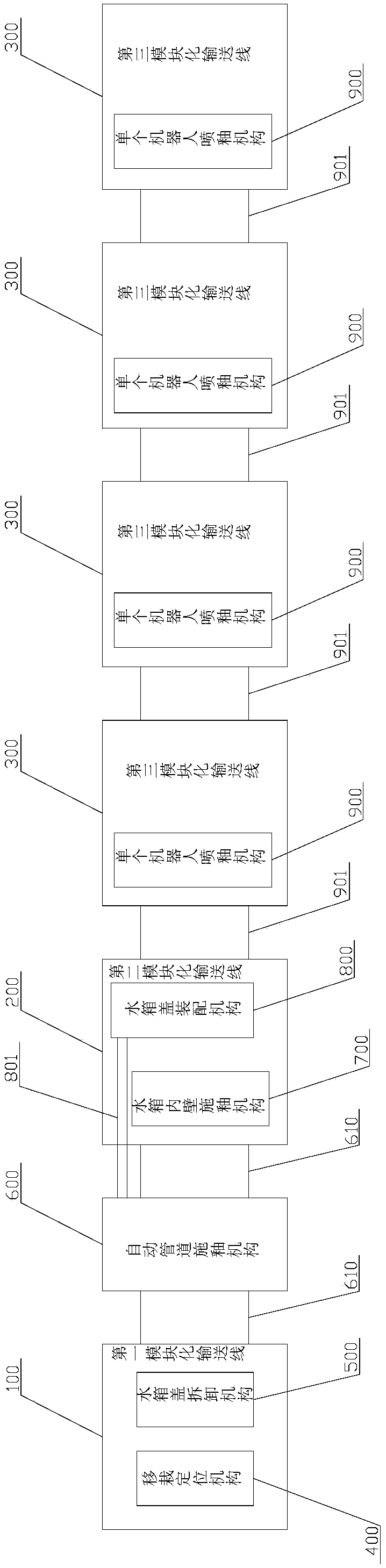

[0056] Such as figure 1 As shown, the modular robot precise spraying glaze system includes: it is mainly composed of three modular conveying lines, namely the first modular conveying line 100, which is mainly used for transplanting and positioning the ceramic toilet body 110 and removing the water tank cover The second modular conveying line 200 is mainly used for glaze spraying on the inner wall of the ceramic toilet body 110 water tank cover and the assembly of the water tank cover, and the third modular conveying line 300 is mainly used for spraying glaze on the outer wall of the ceramic toilet body 110 and Embryo drying; In addition, an automatic pipeline glazing mechanism 600 is provided between the first modularized conveying line 100 and the second modularized conveying line 200 .

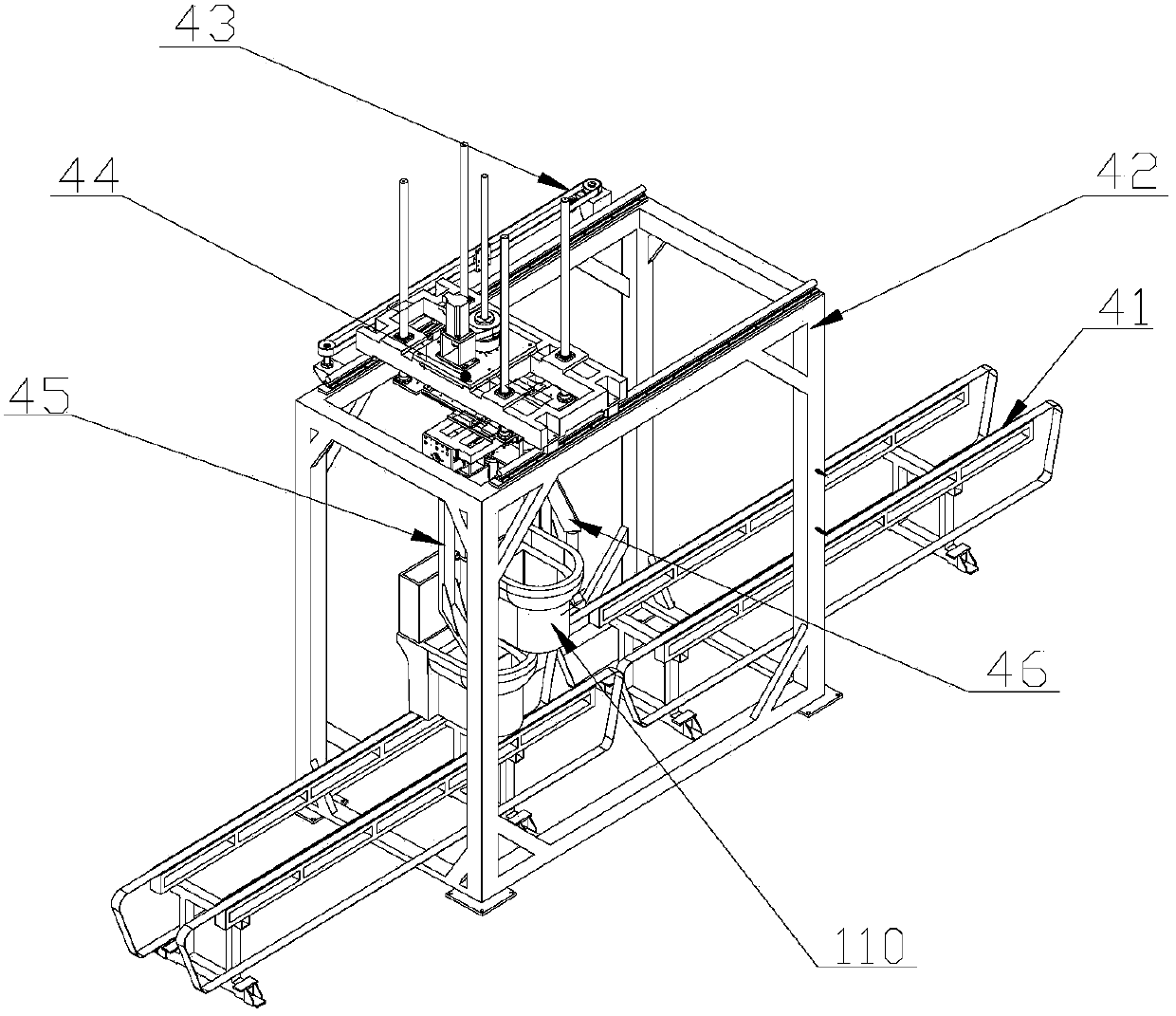

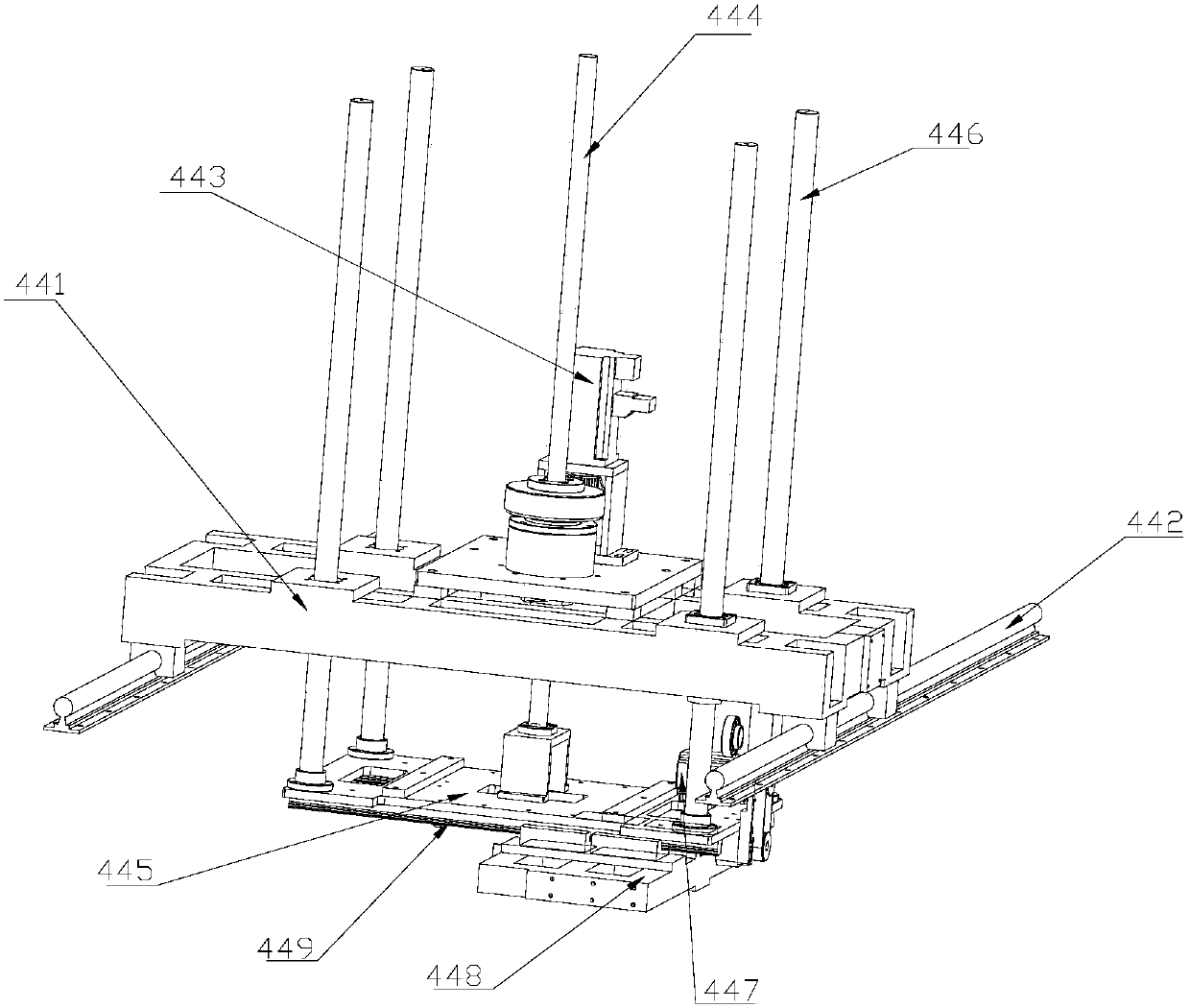

[0057] The first modular conveying line 100 includes a first conveying line body and a transplanting positioning mechanism 400 and a water tank cover dismantling mechanism 500 which are sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com