Water-based polyurethane anticorrosive coating for containers and preparation method for coating

An anti-corrosion coating, water-based polyurethane technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor water resistance, affecting the health of construction workers, and low hardness of acrylic paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

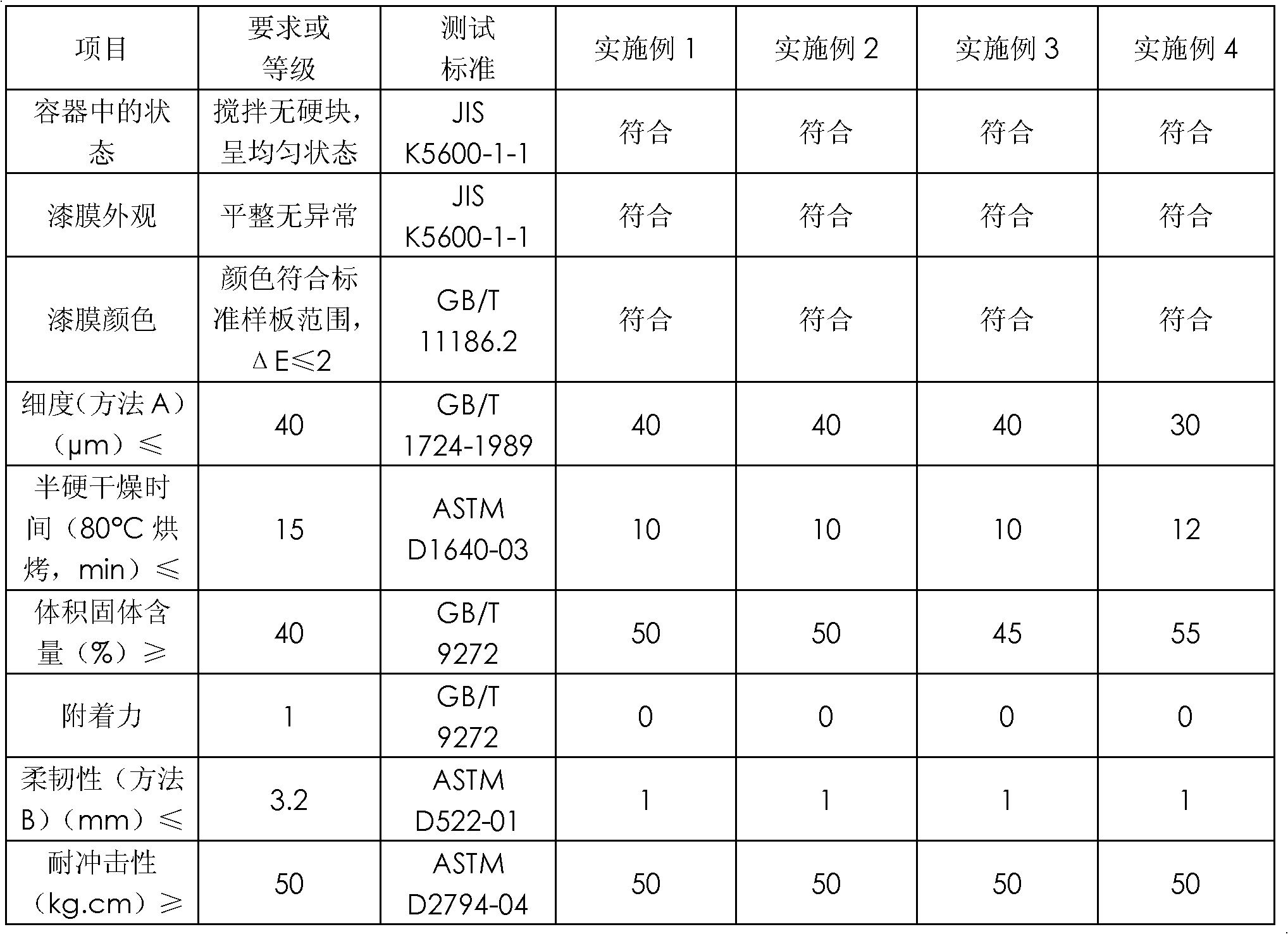

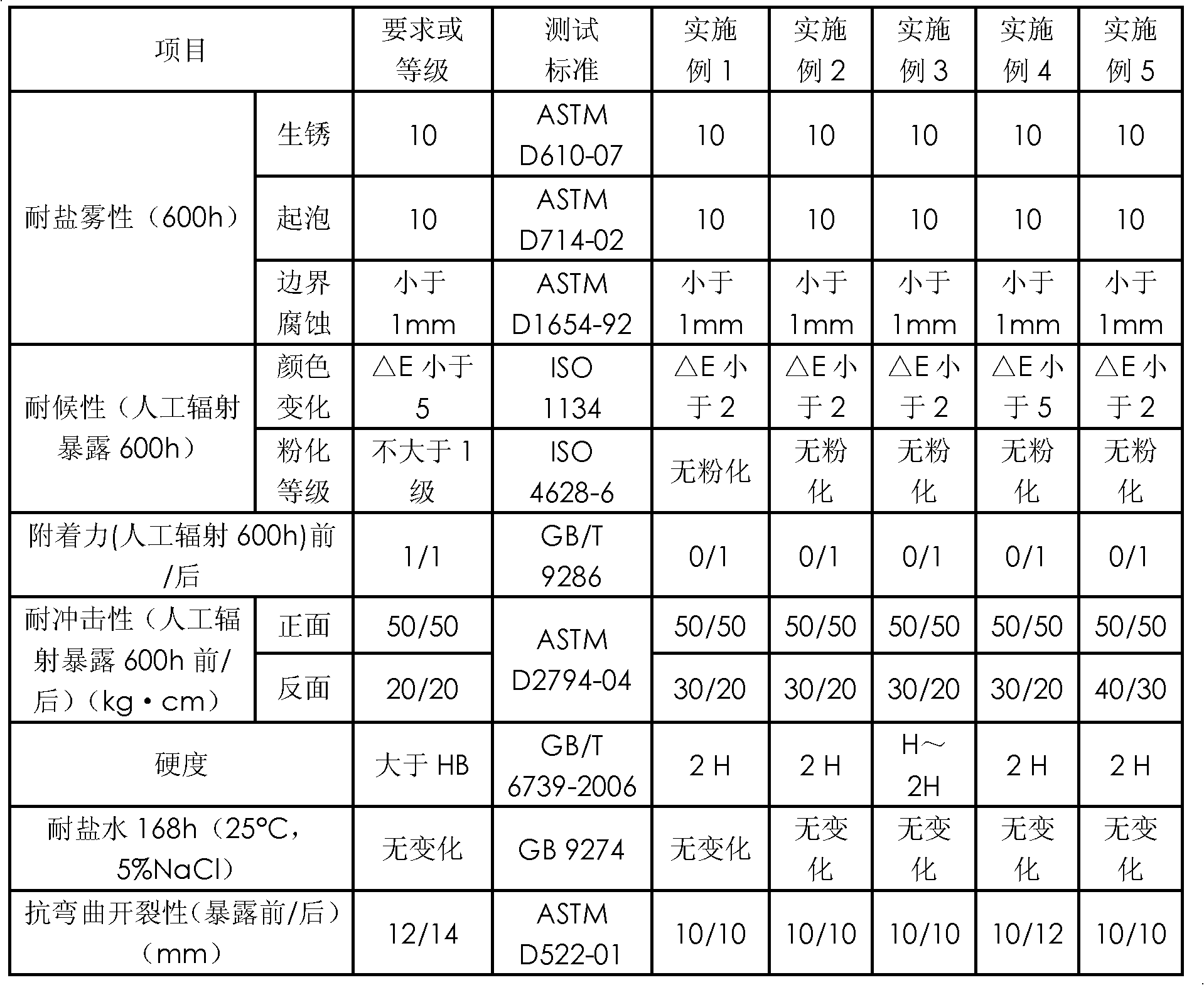

Examples

Embodiment 1

[0047] Under the rotating speed of 600r / min, add 1.5 parts of film-forming aids (DPM, Dow Chemical) in the formula successively, 1.5 parts of film-forming aids (alcohol ester-12, Eastman chemical industry), antifreeze agent (propylene glycol, Dow Chemical) 1 part, salt spray resistant hydrophobic agent (TEGO Phobe 1401, Tego Chemicals) 0.5 part, stirred for 10 minutes to prepare a premixed solution for later use.

[0048] Add 8 parts of tap water, 0.1 part of anti-corrosion and anti-mold agent (SR1138, Sol Chemical, UK), 1 part of anti-sedimentation agent (HL-200, CNPC Shuangji Chemical), wetting and dispersing agent (X-405, Rohm Ha Adams company) 0.4 parts, pH regulator (AMP-95, ANGUS, USA) 0.2 parts, defoamer (FoamStar A36, Corning) 0.2 parts, after stirring for 10 minutes, adjust the speed to 1200r / min, and then add Then add 10 parts of inorganic coloring pigments (titanium dioxide / iron oxide red / iron oxide black / iron oxide yellow, Lockwood Pigment Co., Ltd.), antirust pigm...

Embodiment 2

[0052] Under the rotating speed of 600r / min, add 1.5 parts of film-forming aids (DPM, Dow Chemical) in the formula successively, 1.5 parts of film-forming aids (alcohol ester-12, Eastman chemical industry), antifreeze agent (propylene glycol, Dow Chemical) 0.5 part, salt spray resistant hydrophobic agent (TEGO Phobe 1401, Tego Chemicals) 1 part, stirred for 10 min to prepare a premixed solution for later use.

[0053] Add 8 parts of tap water, 0.1 part of anti-corrosion and anti-fungal agent (SR1138, Thor Chemical, UK), 1 part of anti-settling agent (BentoneEW, Hemings, USA), and 0.9 part of wetting and dispersing agent (SN-5027, Shenzhen Haichuan Chemical) , 0.4 part of pH regulator (ammonia water, Dow Chemical), 0.4 part of defoamer (Foamex 815, Digao Chemical), after stirring for 10 min, the rotating speed was adjusted to 1200r / min, and then the premixed solution prepared above was added, Then add 12 parts of inorganic colored pigments (titanium dioxide / iron oxide red / iron ...

Embodiment 3

[0057] Under the speed of 600r / min, add 1 part of film-forming aid (DPM, Dow Chemical) in the formula successively, 2 parts of film-forming aid (alcohol ester-12, Eastman chemical industry), antifreeze agent (propylene glycol, Dow Chemicals) 1.5 parts, salt spray resistant hydrophobic agent (TEGO Phobe 1500N, Tego Chemicals) 0.5 parts, stirred for 10 minutes, prepared a premixed solution for later use.

[0058] Add 11 parts of tap water, 0.2 parts of antiseptic and antifungal agent (YN-187, Beijing Aohan Chemical), 0.5 part of anti-sedimentation agent (A200, Degussa), wetting and dispersing agent (Orotan 731A, Rohm and Haas, USA) ) 1 part, pH regulator (AMP-95, ANGUS, USA) 0.3 part, defoamer (Defomer 155, Haichuan Chemical) 0.3 part, after stirring for 10 minutes, adjust the rotating speed to 1200r / min, then add the previously prepared Mixed solution, then add 6 parts of inorganic colored pigments (titanium dioxide / iron oxide red / iron oxide black / iron oxide yellow, Lockwood Pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com