Novel foil producing device for electrolytic copper foil and preparation method of cathode roller

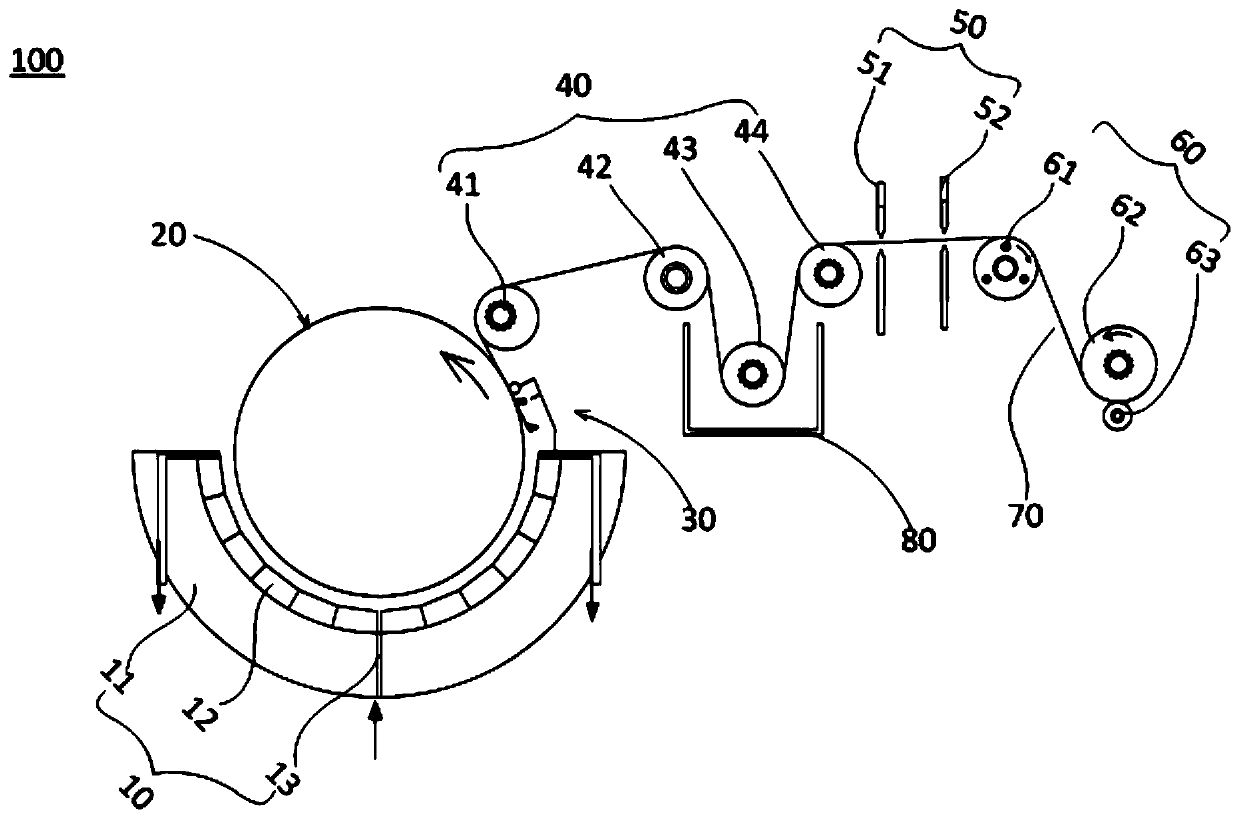

A technology of electrolytic copper foil and cathode roller, which is applied in the direction of electrolysis process, electroforming, metal material coating process, etc., can solve the problems affecting the yield rate of copper foil, etc., and achieve the effect of solving easy breakage and eliminating pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

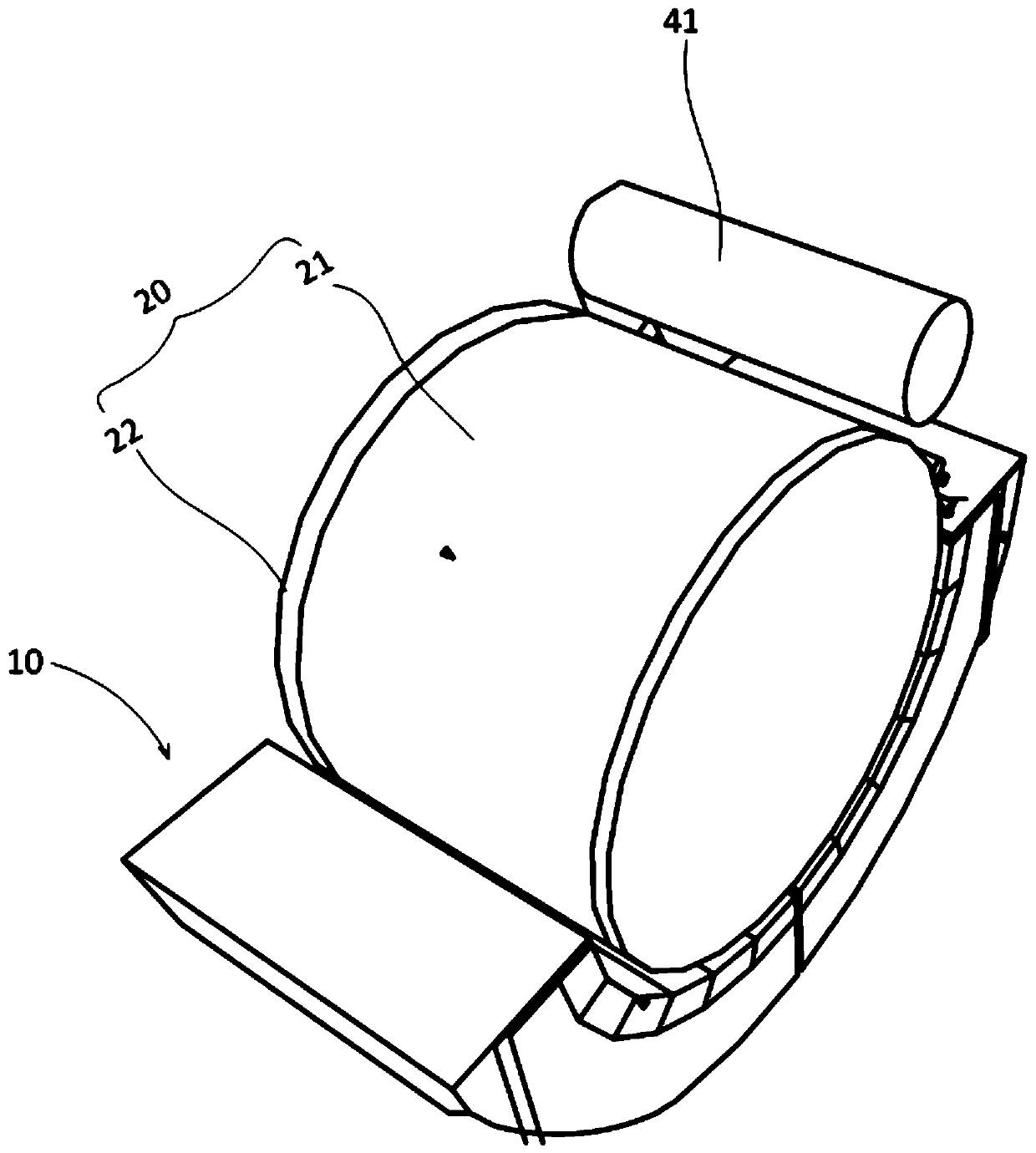

[0051] Please refer to Figure 7 , the present invention also provides a preparation method of electrolytic copper foil, comprising the following steps:

[0052] S4, copper sulfate electrolyte configuration: heat and dissolve high-purity copper wires with a purity of 99.95% and above in sulfuric acid solution to generate copper sulfate electrolyte;

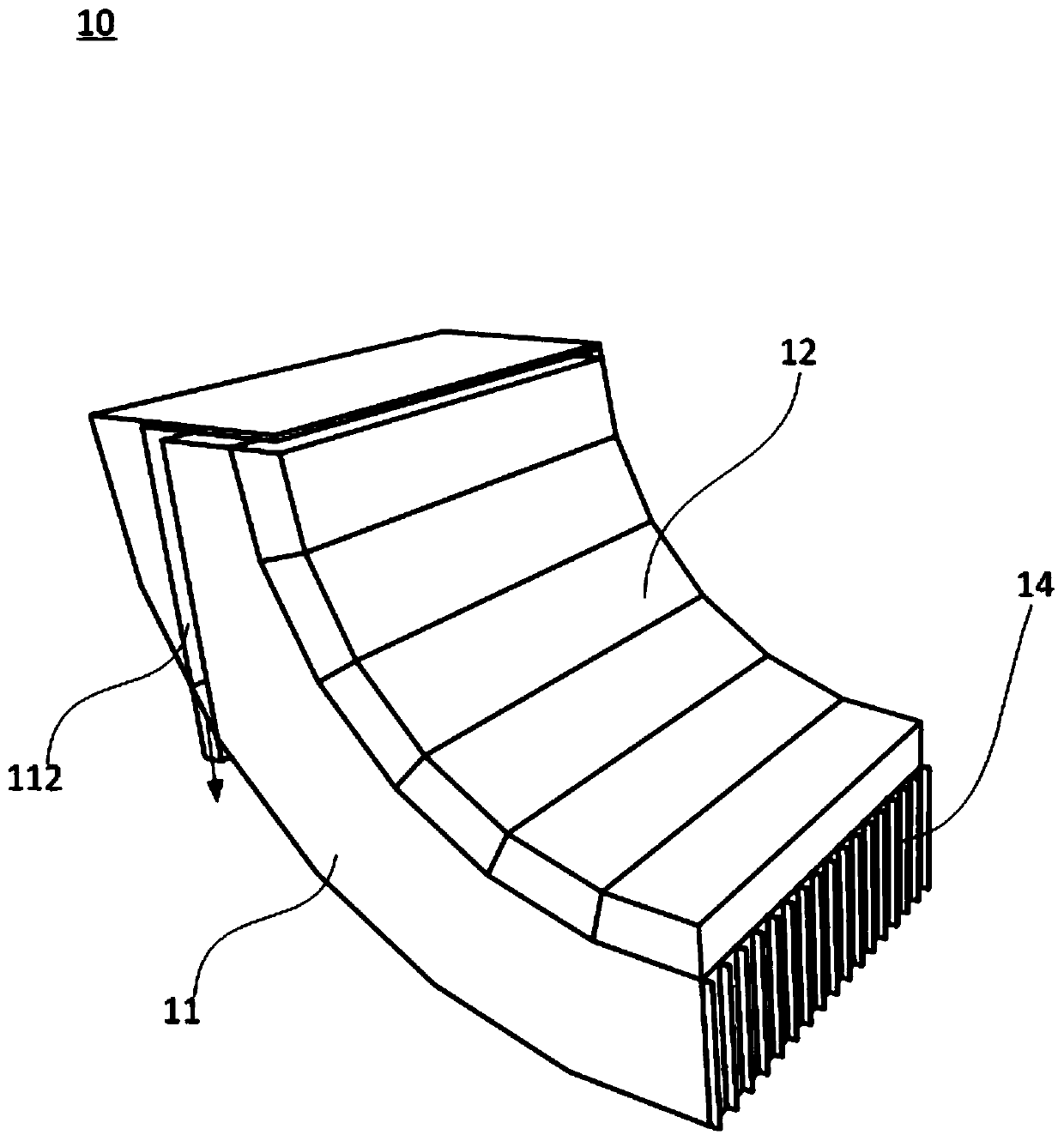

[0053] S5, raw foil manufacturing; add additives to the copper sulfate electrolyte, and transport it to the electrolytic cell of the foil machine for electrolytic raw foil, wherein; the process parameters of electrolytic raw foil are: the temperature of the electrolytic solution is controlled at 50-60 °C, the current density of the anode plate 12 during the foil production process is 38-45A / dm 2 , Cu 2+ Concentration is 90~95g / L, H 2 SO 4 Concentration is 100-110g / L, gelatin concentration is 100-300ppm, ceric sulfate concentration is 0.5-10ppm, MESS concentration is 1-20ppm, SPS concentration is 10-50ppm, Cl - The concentrati...

Embodiment

[0066] Example: heating and dissolving a high-purity copper wire with a purity of 99.95% in a sulfuric acid solution to form a copper sulfate electrolyte; adding additives to the copper sulfate electrolyte, and transporting it to the electrolytic cell of a foil production machine for electrolytic foil production. Among them; the process parameters of electrolytic raw foil are: the temperature of the electrolyte is controlled at 58 ° C, Cu 2+ Concentration is 94g / L, H 2 SO 4 Concentration is 106g / L, gelatin concentration is 150ppm, ceric sulfate concentration is 4ppm, MESS concentration is 12ppm, SPS concentration is 25ppm, Cl - The concentration is 28ppm; copper foils of 4 microns, 4.5 microns, 5 microns and 6 microns are respectively obtained by controlling the current density of the anode plate during the foil production process. The test data of various copper foils are as follows:

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com