Acrylate modified polyurethane sealant and preparation method thereof

A technology of polyurethane sealant and acrylate, which is applied in the field of sealants, can solve the problems of reducing weather resistance, poor weather resistance, and easy pulverization, and achieve the effects of improving service life, wide adhesion, and prolonging weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

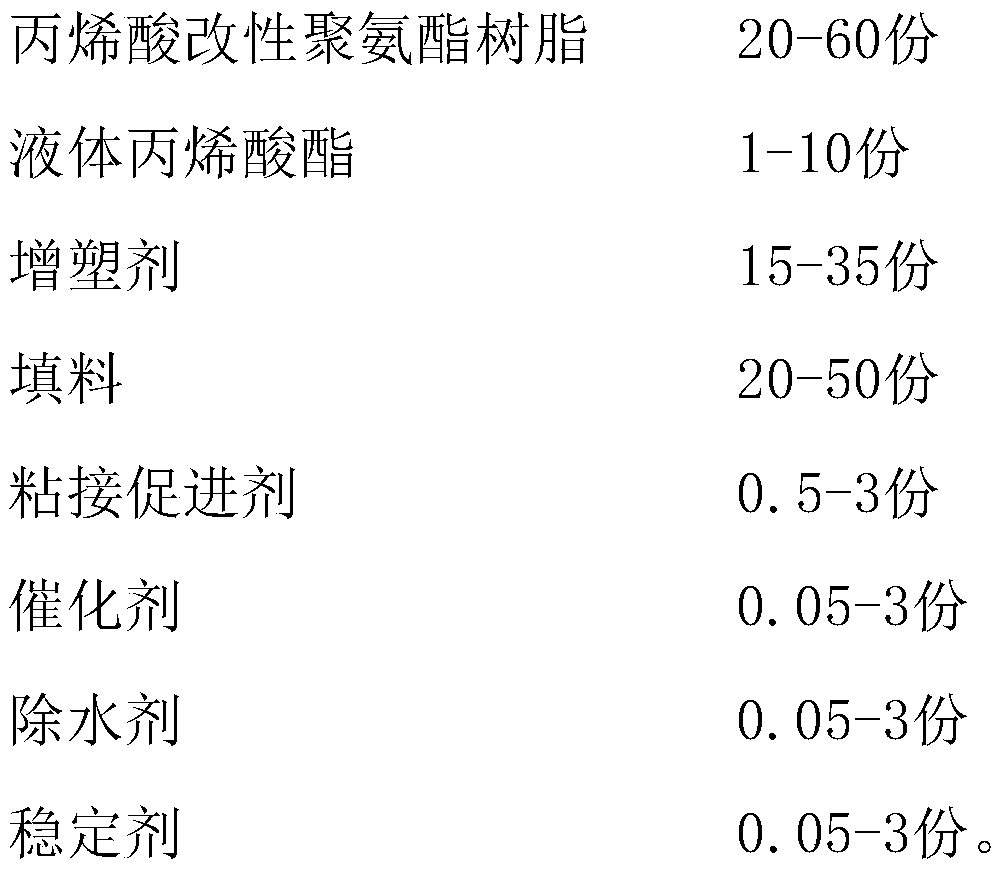

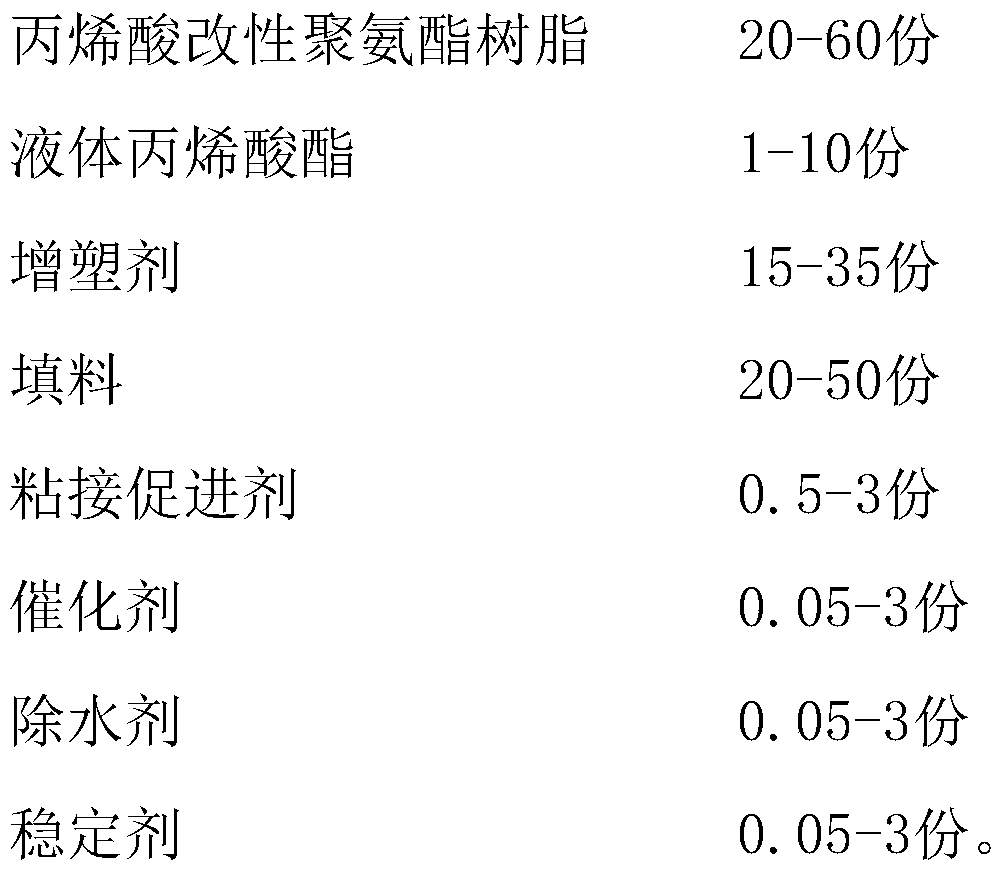

Method used

Image

Examples

Embodiment 1

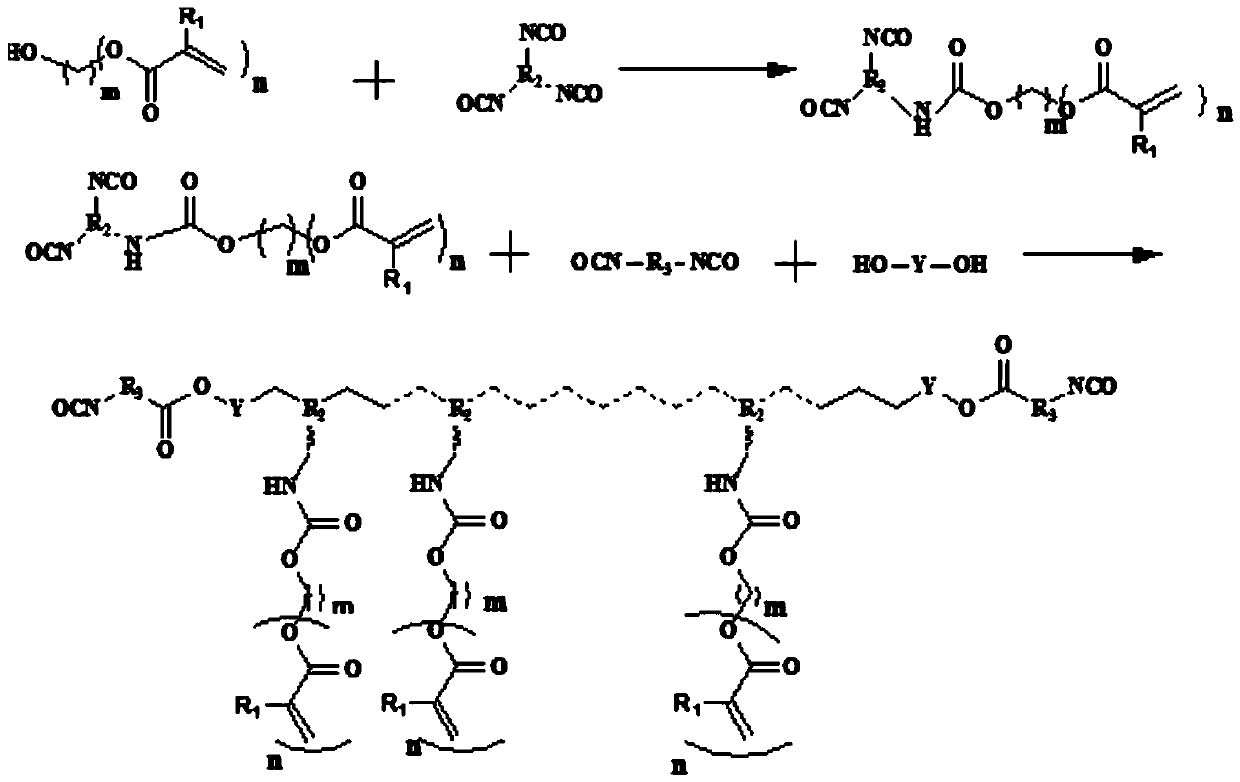

[0053] Step 1. Synthesis of acrylate-modified isocyanate group I:

[0054] Under the protection of nitrogen, add 55.25g (0.12mol) of 1,6-hexamethylene diisocyanate trimer in the three-necked flask, add 30g of dry ethyl acetate, 0.05g of hydroquinone, after dissolving, pass Slowly add 4.64g (0.04mol) of 2-hydroxyethyl acrylate dropwise into the constant pressure dropping funnel, react at 50°C for 4h, and titrate the NCO value.

[0055] Step 2, the synthesis of acrylate-modified polyurethane resin A:

[0056] Under nitrogen protection, add 800g (0.1mol) of polyether diol (Mr=8000), 120g (0.02mol) of polyether triol (Mr=6000), 27.86g (0.16mol) ) of toluene diisocyanate, 59.4g (0.1mol) of acrylate-modified isocyanate group I, 150g of didecyl phthalate, and 0.02% of the total mass of the above mixture of tin octoate, react at 80°C for 2-5h , react until the free NCO reaches the theoretical value.

[0057] Wherein, the polyether diol is polyoxyalkylene diol, and the polyether tri...

Embodiment 2

[0060] Step 1, the synthesis of acrylate-modified polyurethane resin B:

[0061] Under nitrogen protection, add 800g (0.1mol) of polyether diol (Mr=8000), 120g (0.02mol) of polyether triol (Mr=6000), 4.8g (0.03mol) ) of 2,3-dihydroxypropyl methacrylate, 55.72g (0.32mol) of toluene diisocyanate, 0.15g of hydroquinone, 150g of didecyl phthalate, and accounting for the total mass of the above mixture 0.02% tin octoate is reacted at 80°C for 2-5 hours until the free NCO reaches the theoretical value.

[0062] Wherein, the polyether diol is polyoxyethylene diol, and the polyether triol is polyoxyalkylene triol.

[0063]Step 2. Preparation of polyurethane sealant: Add acrylate modified polyurethane resin B, plasticizer, liquid acrylate M-6200 into the planetary stirring tank, stir for 15 minutes, then add dry modified calcium carbonate, PVC paste resin and charcoal Black and mix under vacuum for 10 minutes, increase the mixing speed and mix for 15 minutes after the filler is wette...

Embodiment 3

[0065] Step 1, polyurethane resin synthesis:

[0066] Under nitrogen protection, 1200g (0.1mol) of dry polyether diol (Mr=8000), 120g (0.02mol) of polyether triol (Mr=6000), 45.28g (0.26 mol) of dimethyl diphenylmethane diisocyanate, 150g of didecyl phthalate, and 0.01% tin octoate accounting for the total mass of the above mixture, react for 2-5h at a temperature of 65°C, and react Stop the reaction until the free NCO reaches the theoretical value.

[0067] Wherein, the polyether diol is polyoxypropylene diol, and the polyether triol is polyoxypropylene triol.

[0068] Step 2. Preparation of polyurethane sealant: Add unmodified polyurethane resin, plasticizer, diethylene glycol acrylate (DEGDA), liquid acrylate to the planetary stirring tank M-7300K, min, then add dry modified calcium carbonate, PVC paste resin and carbon black, and mix under vacuum for 10 minutes, increase the mixing speed and mix for 15 minutes after the filler is wetted, add adhesion promoter, catalyst,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com