Patents

Literature

118results about How to "Does not affect environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for obtaining release agent layer on base plate and composite material containing base plate and release agent layer

ActiveCN105238216AAvoid stickingPlay an isolation roleLayered productsEpoxy resin coatingsTitaniumMaterials science

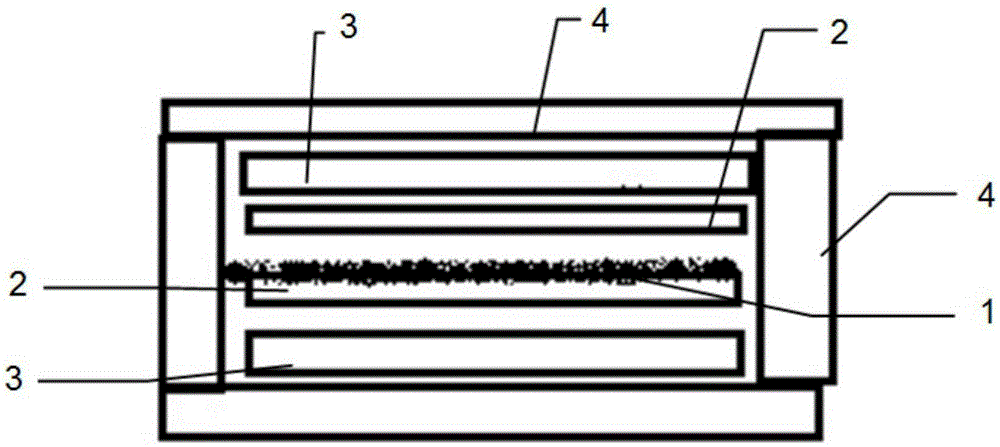

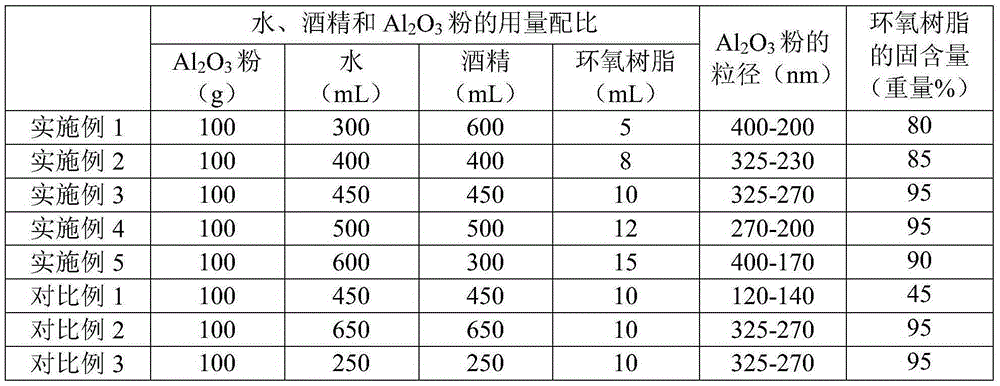

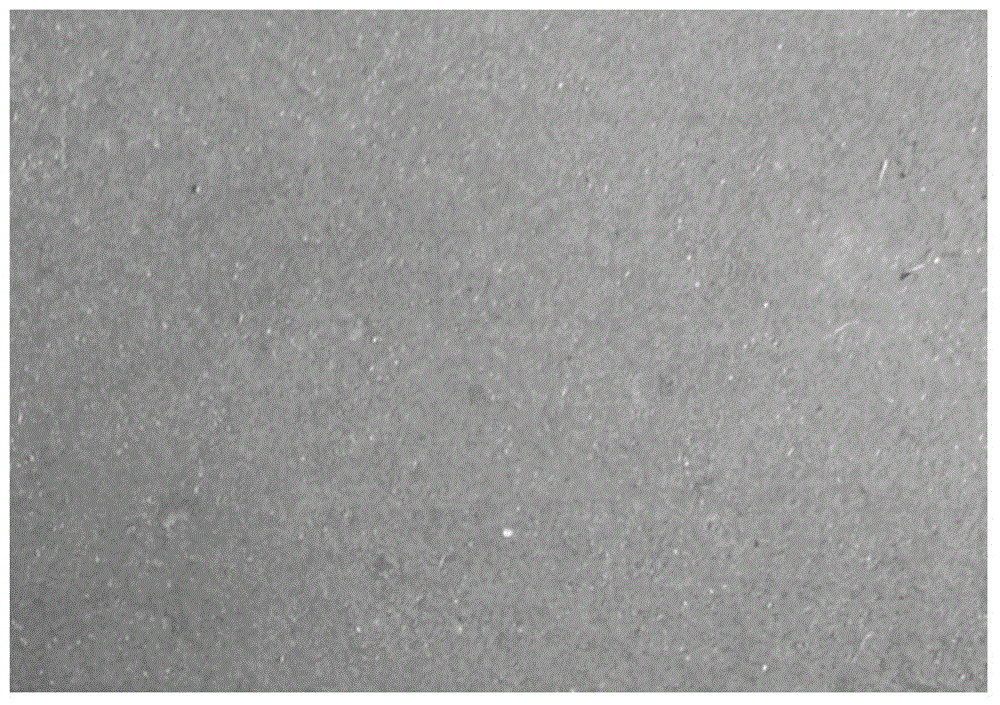

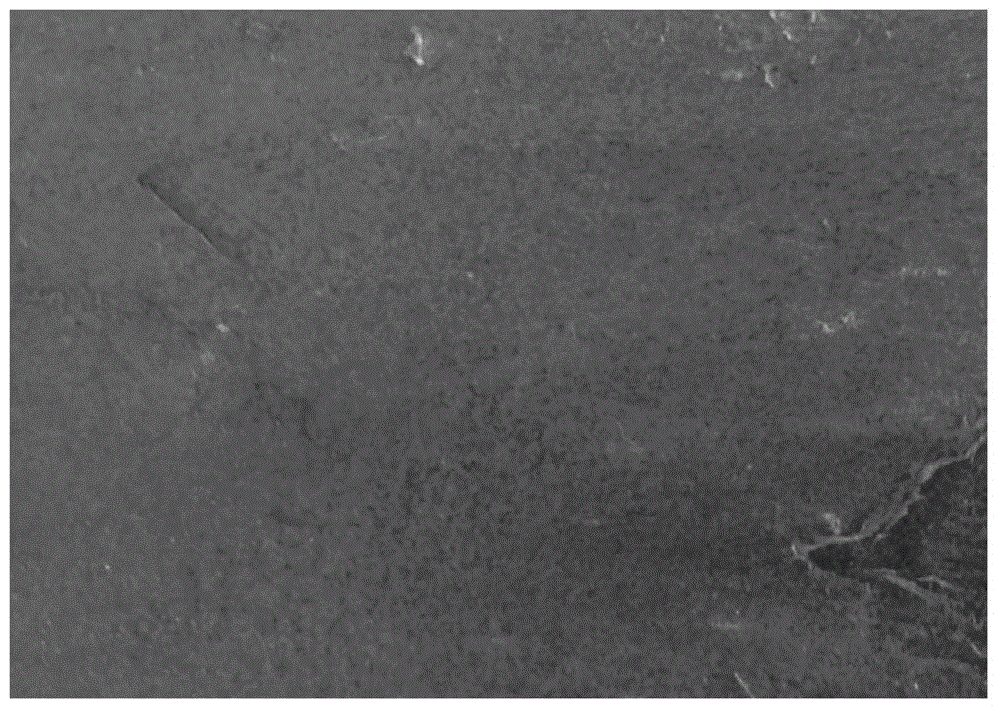

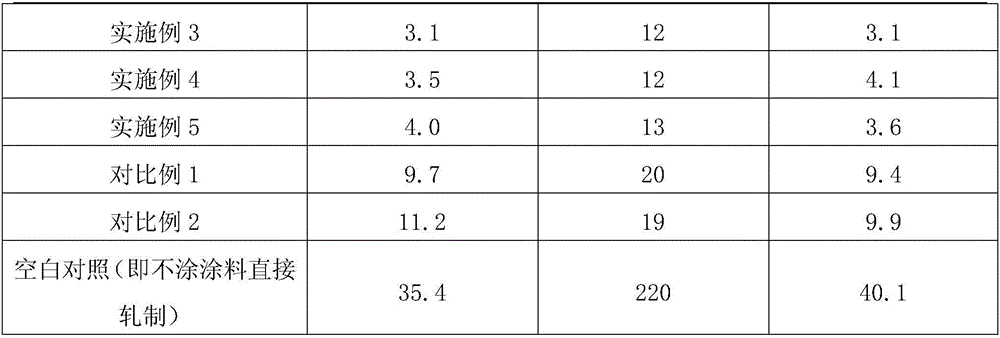

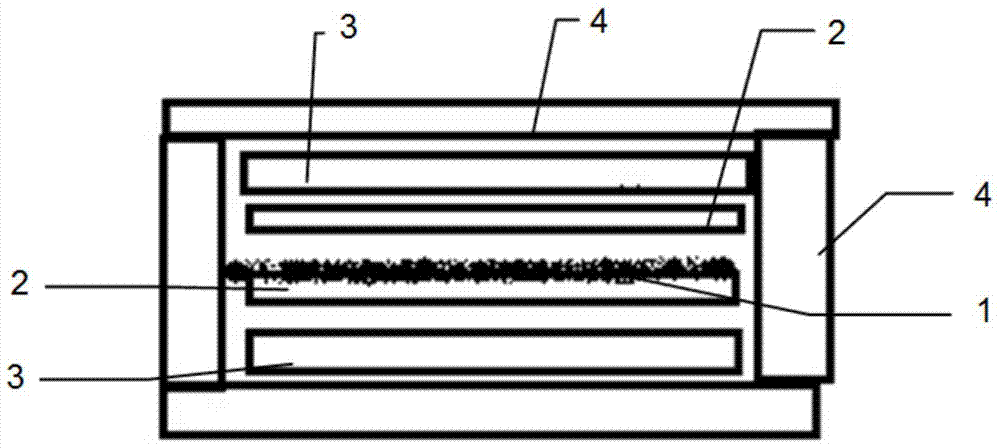

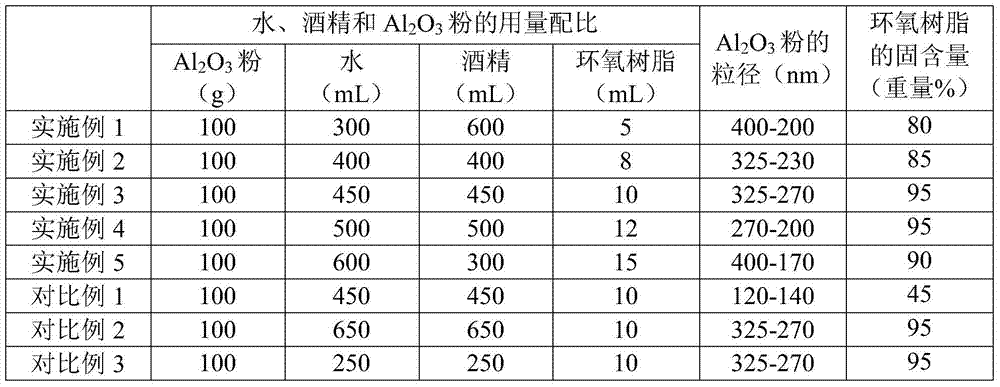

The invention relates to the field of release agents, in particular to a method for obtaining a release agent layer on a base plate and a composite material containing the base plate and the release agent layer. The method for obtaining the parting agent layer on the base plate comprises coating a release agent on the base plate, and drying to form the parting agent layer on the base plate. The method is characterized in that the release agent comprises water, alcohol, epoxy resin and Al2O3 powder, wherein relative to 100g of Al2O3 powder, the dosage of the water is 300-600mL, the dosage of the alcohol is 300-600mL, and the dosage of the epoxy resin is 5-15mL. The release agent can be online directly sprayed on the surface of a composite titanium board, and can be quickly cured to form a self-drying type coating to achieve a parting effect, so that in a 4-6h constant-temperature process at 800-1000 DEG C and a rolling process of a titanium steel composite board, adhesion and surface roughness increase phenomena of a titanium-titanium interface are avoided, and the yield and the production efficiency for titanium steel composite board processing are improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369AEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

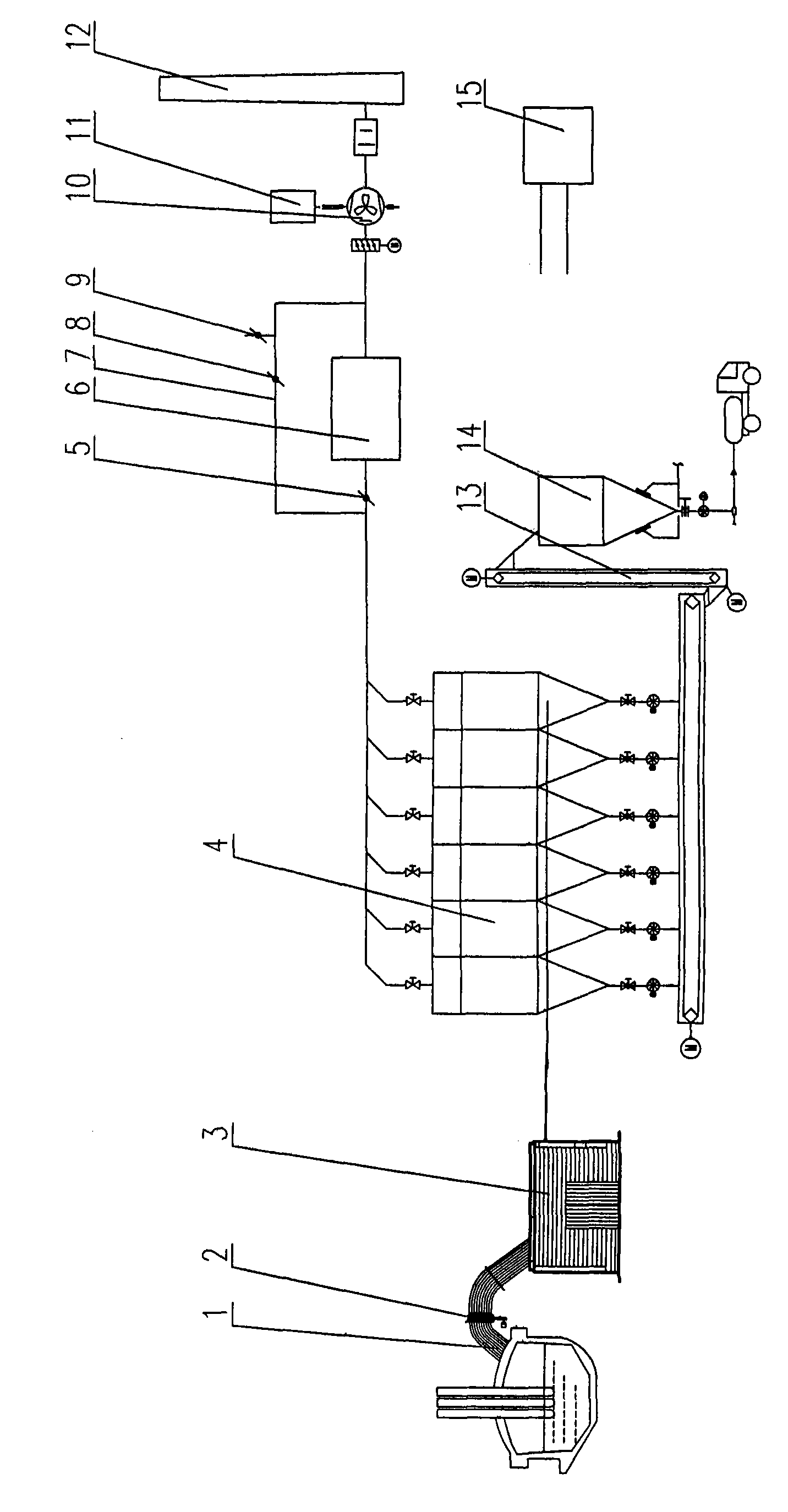

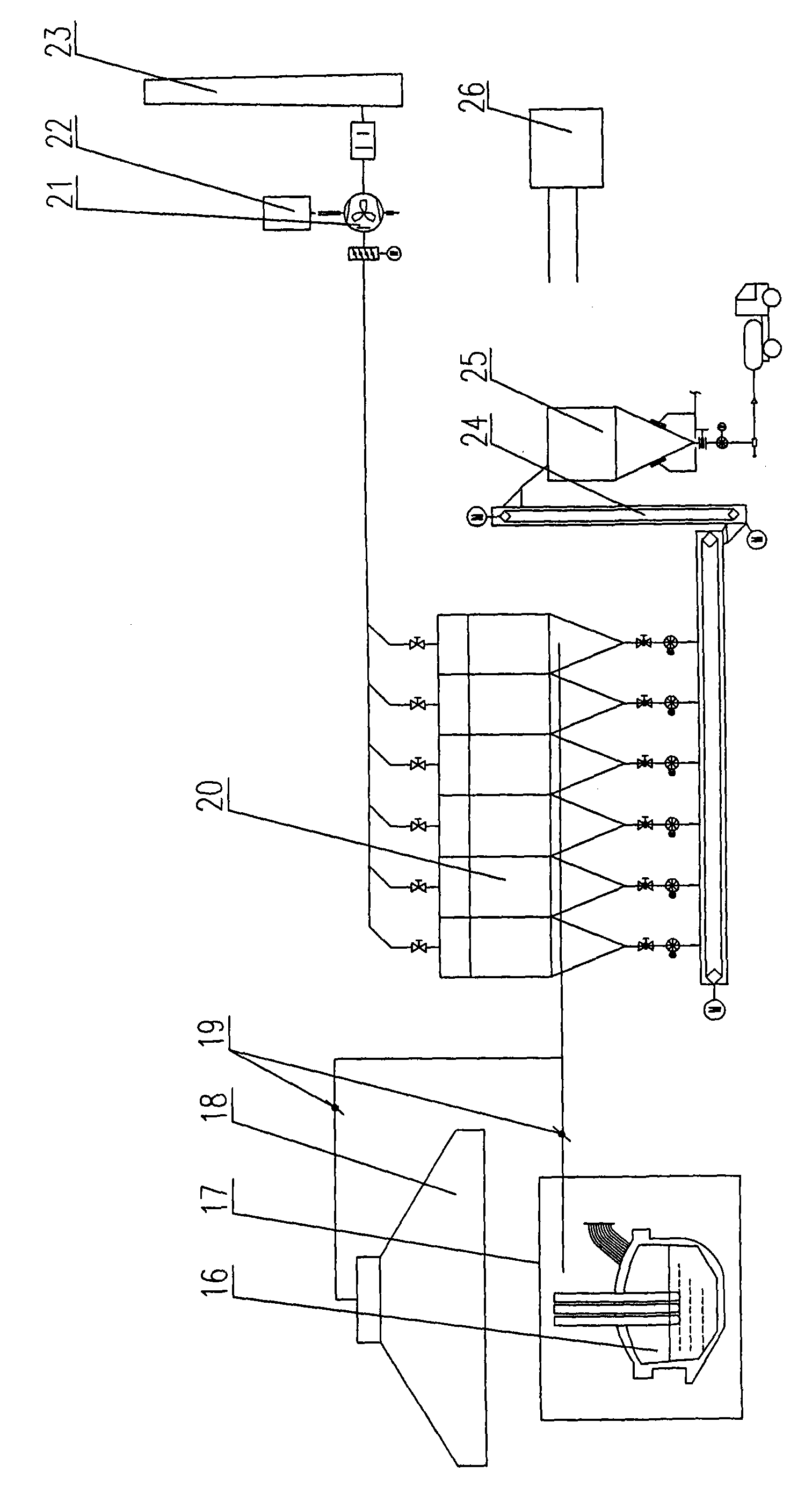

The invention relates to a flue gas waste heat recovery and negative energy consumption dust-removal system for an electric stove, comprising a first flue gas dust-removal and waste heat recovery system for the electric stove which is connected with the smoke hole of the electric stove to absorb high temperature flue gas generated by the electric stove during smelting phase and a secondary flue gas dust-removal system for the electric stove which is in charge of absorbing the flue gas generated by the electric stove during charging and tapping phase. The first flue gas dust-removal and waste heat recovery system for the electric stove comprises a water cooling travelling tube, an evaporation cooling device, a high temperature resistant dust remover, a waste heat boiler, a dust removal fan and a chimney; wherein the evaporation cooling device replaces the original water cooling flue gas path and combustor. The secondary flue gas dust-removal system for the electric stove comprises a collecting cover, a dust remover worked at normal temperature, a dust removal fan and a chimney. The invention is high in dust removal efficiency and high in vapor recovery rate, saves a first cooling device and a secondary cooling device, reduces device investment and maintenance charge and prolongs the service life of the filter pocket of the dust remover.

Owner:BAOSTEEL ENG & TECH GRP

Fabric post-finishing agent based on modified silk fibroin solution and preparation method of fabric post-finishing agent

ActiveCN105544210ASkin-friendlyHigh affinityBiochemical fibre treatmentGrip property fibresDissolutionSolvent

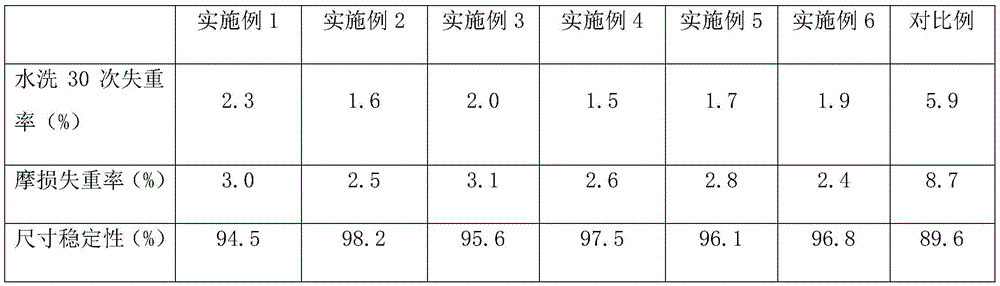

The invention provides a fabric post-finishing agent based on a modified silk fibroin solution and a preparation method of the fabric post-finishing agent. The preparation method comprises the following specific operational steps: (1) removing impurities from waste silk, putting the impurity-free waste silk in a sodium bicarbonate solution for boiling and degumming, taking out and wringing out the degummed waste silk, washing with clean water till the greasy feel is eliminated, putting the primarily treated waste silk in the sodium bicarbonate solution again for boiling and degumming, taking out and wringing out the degummed waste silk again, washing again with clean water till the greasy feel is eliminated, putting the secondarily treated waste silk in an oven for drying, so as to obtain degummed silk; (2) putting the degummed silk in a lithium bromide solution for standing and dissolution, taking out the treated silk, and performing cooling, dialysis and concentration to obtain a silk fibroin solution; and (3) adding glycerin and gelatin into the silk fibroin solution, uniformly stirring to form a membrane solution, adjusting the pH value of the membrane solution and then adding glutaraldehyde and chitosan, uniformly stirring, and finally mixing the treated membrane solution with a solvent containing additives, so as to obtain the fabric post-finishing agent. The fabric post-finishing agent obtained according to the preparation method covers the fabric surface in the form of a composite membrane; and the preparation method is beneficial to improvements in the membrane forming property, the ductility and the like of a silk fibroin finishing agent.

Owner:SUZHOU INSILK CO LTD

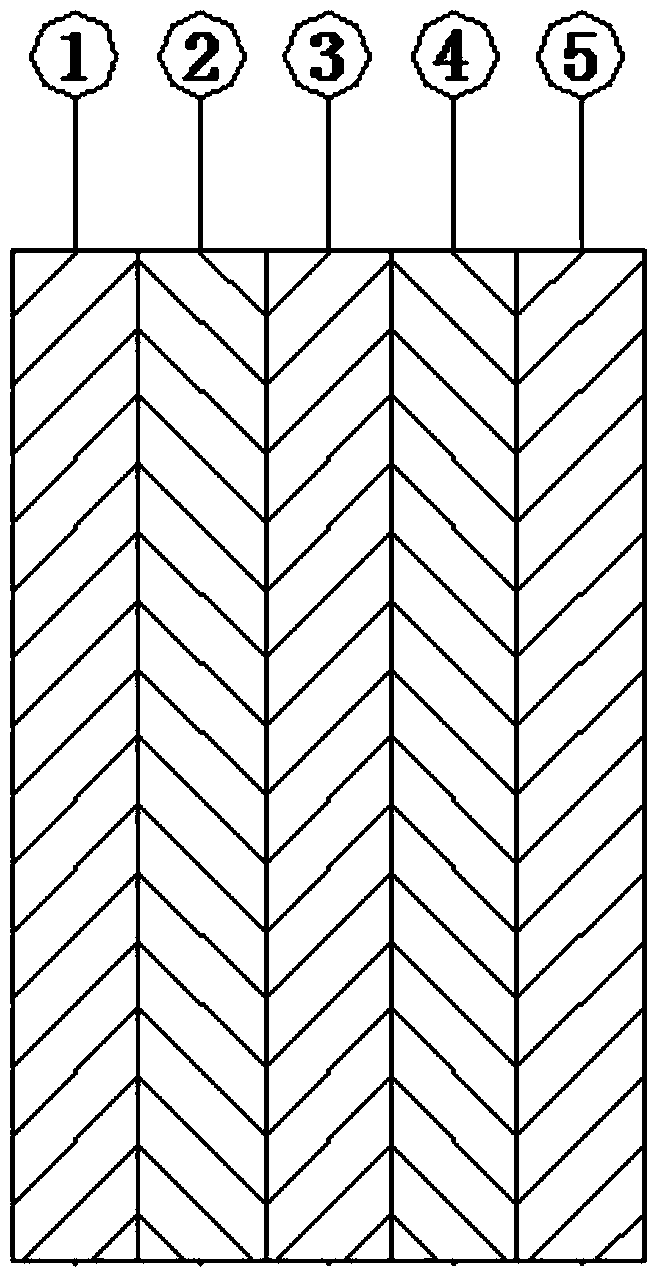

Method for obtaining isolated layer on base plate and composite material containing base plate and isolated layer

InactiveCN105195403AAvoid stickingHeat stableCoatingsSpecial surfacesIsolation effectAqueous alcohol

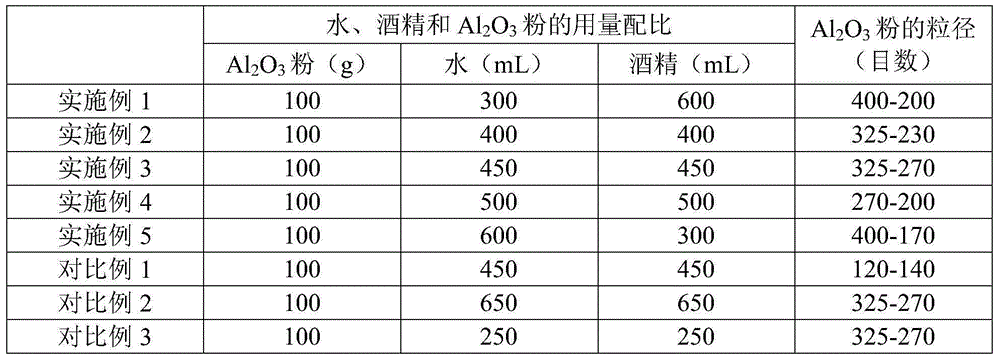

The invention relates to the field of an isolating agent, and particularly relates to a method for obtaining an isolated layer on a base plate and a composite material containing the base plate and the isolated layer. The method for obtaining the isolated layer comprises the steps of spraying the isolating agent onto the base plate, drying and forming the isolated layer on the base plate, and is characterized in the isolating agent contains water, ethyl alcohol and Al 203 powder, wherein the use amount of the water is 300 to 600mL, the use amount of the ethyl alcohol is 300 to 600mL relative to 100g of the Al 203 powder, and the particle size of the Al 203 powder is 20 to 90mum. The isolating agent provided by the invention is capable of being directly spayed on the surface of a composite titanium plate, curing rapidly, and forming an air-drying coating, and the isolation effect is achieved, so that phenomena that adhesion and surface roughness of a titanium-titanium interface do not occur during a process of heating at 800 to 1000 DEG C of constant temperature for 4 to 6 hours and a rolling process of a titanium-steel clad plate, and the yield and production efficiency of the titanium-steel clad plate are improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

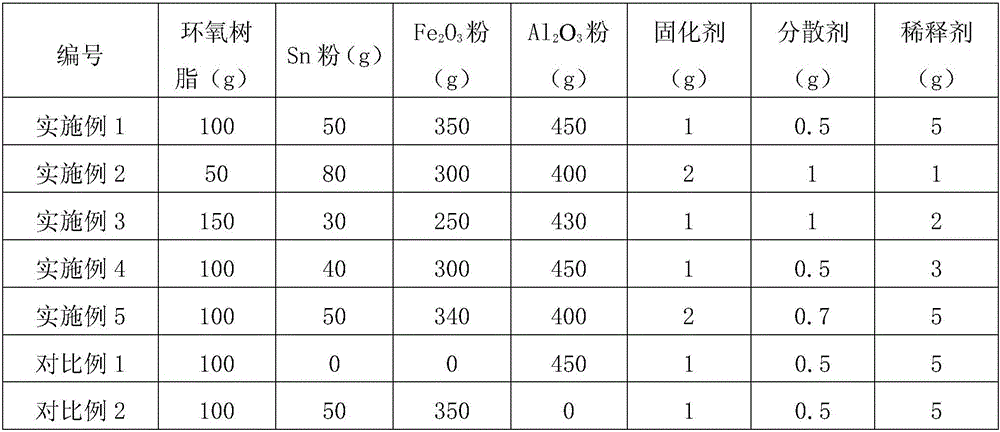

Oily high-temperature-resisting bonding prevention titanium coating and application thereof

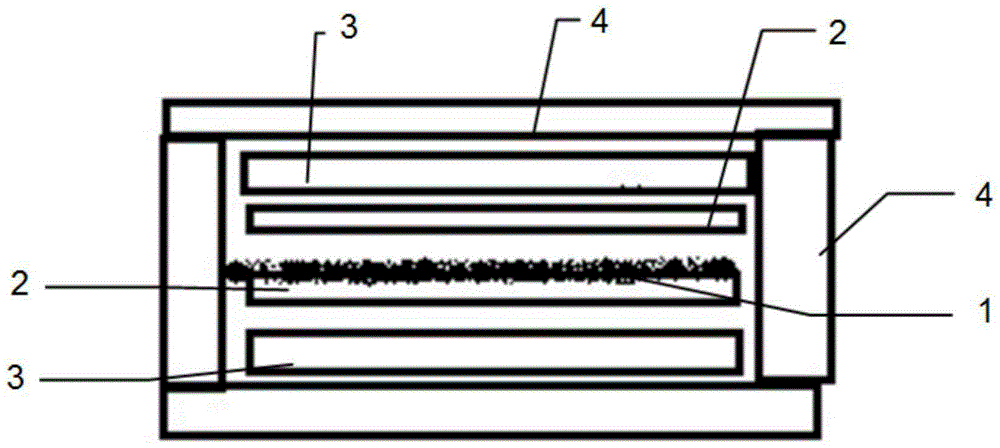

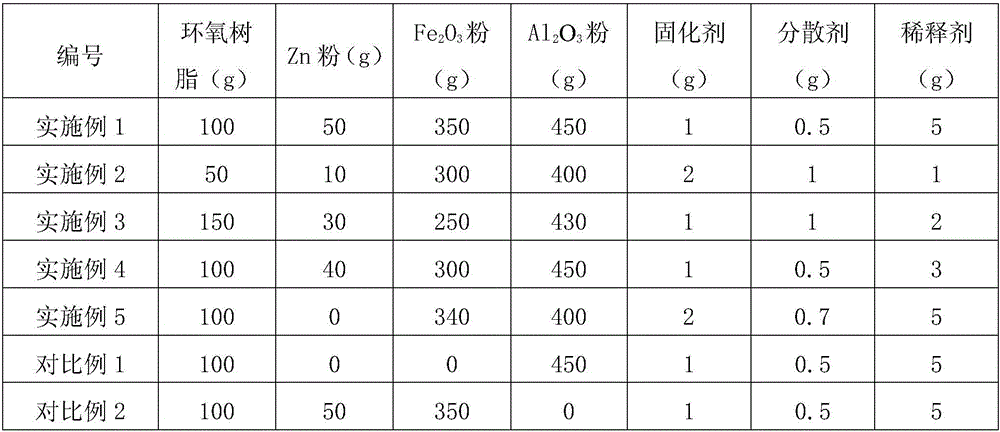

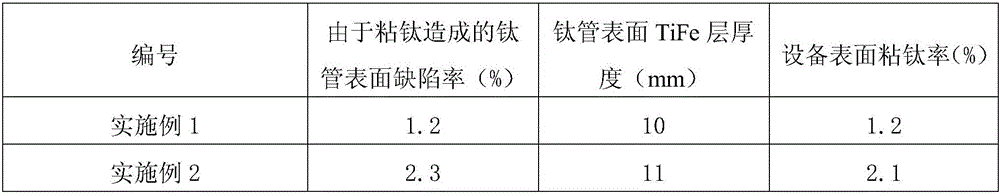

ActiveCN105969084AHigh yieldIncrease productivityFireproof paintsPolyurea/polyurethane coatingsTitanium coatingIsolation layer

The invention relates to an oily high-temperature-resisting bonding prevention titanium coating and application thereof, belongs to the technical field of titanium-steel bonding prevention coatings and aims at providing an oily high-temperature-resisting bonding prevention titanium coating used in titanium tube rolling. The coating is prepared from, by weight, 50-150 parts of an oily film-forming agent, 0-50 parts of zinc powder, 250-350 parts of ferric oxide and 400-450 parts of aluminum oxide powder. The oily high-temperature-resisting bonding prevention titanium coating is applied to a steel and iron device, a roller or a winch to form a very good isolation layer and can ensure that titanium ingots do not produce bonding reaction with the steel and iron device, the roller or the winch in the 900 DEG C rolling or perforation process, improve the size precision and surface quality of products, improve the machining yield and production efficiency of titanium materials and reduce the production costs.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Aqueous high temperature resistant protection paint and application thereof and titanium ingot production method

The invention discloses an aqueous high temperature resistant protection paint prepared by evenly mixing a raw material mixture, the raw material mixture contains an oxidation protective agent, a water soluble film-forming agent and water; the oxidation protective agent contains Al powder, Fe powder and Cu powder, the weight ratio of Al powder to Fe powder to Cu powder is 1:0.01-0.1:0.01-0.1. The invention also discloses the application of the aqueous high temperature resistant protection paint in titanium ingot production and a titanium ingot production method. The aqueous high temperature resistant protection paint can guarantee that titanium ingot surface cannot be oxidized to crack at a constant high temperature of 1000 DEG C for 8h, can greatly reduce the formation of a dissolved oxygen layer, has the environmental protection function, and is simple in the preparation process, and a variety of coating methods can be used. The titanium ingot production method has good economic benefit and social benefit, and has broad popularization and application prospects in titanium plate and titanium tube production industry.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-temperature oxygen suction resistant coating material, application thereof and titanium ingot production method

The invention discloses a high-temperature oxygen suction resistant coating material. The high-temperature oxygen suction resistant coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent, a water-soluble film forming agent and water; the oxidation protecting agent contains Al powder, Zn powder and Fe powder which are in the weight ratio of 1: (0.005-0.06): (0.003-0.04). The invention further discloses application of the high-temperature oxygen suction resistant coating material in titanium ingot production and a titanium ingot production method. The high-temperature oxygen suction resistant coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot is subjected to constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, and the formation of an oxygen dissolved layer can be greatly reduced; the high-temperature oxygen suction resistant coating material has an environmental-friendly effect; the preparation process is simple; a variety of coating manners can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

High-temperature protective oil paint, application thereof and production method of titanium ingots

The invention discloses a high-temperature protective oil paint. The high-temperature protective oil paint is obtained after mixing a raw material mixture uniformly, wherein the raw material mixture contains an oxidation protective agent and oil film-forming agents; the oxidation protective agent contains Al powder and Zn powder in a weight ratio of 1 to (0.01-0.1). The invention also discloses an application of the high-temperature protective oil paint to titanium ingot production and a production method of titanium ingots. The high-temperature protective oil paint can ensure that the surfaces of the titanium ingots are not oxidized to crack at a constant high temperature of 1000 DEG C for 8 hours, can greatly reduce formation of dissolved oxygen layers and improve the yield and production efficiency of titanium plates, has the environmental effects, is simple in preparation process and can adopt various coating modes, such as pneumatic spraying, vacuum spraying, brush coating and the like. The production method of titanium ingots has good economic and social benefits and has wider popularization and application prospects in the titanium plate and titanium pipe production industry.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Aqueous titanium ingot high-temperature-resistant oxygen-absorbing coating material, applications thereof and production method of titanium ingot

The invention discloses an aqueous titanium ingot high-temperature-resistant oxygen-absorbing coating material. The coating material is prepared by uniformly mixing a raw material mixture. The raw material mixture comprises an oxidation protective agent, an aqueous film-forming agent and water. The oxidation protective agent comprises Al powder, Zn powder, Fe powder and Cu powder, with the weight ration of the Al powder, the Zn powder, the Fe powder and the Cu powder being 1: 0.01-0.1: 0.01-0.1: 0.01-0.1. The invention also discloses applications of the coating material in titanium ingot production and a production method of a titanium ingot. The coating material can guarantee that the surface of the titanium ingot is not oxidized or cracked after the titanium ingot is put at a constant temperature of 1000 DEG C for 8 h. The coating material can largely reduce the formation of oxygen dissolved layers, and has an effect of environment protection. The coating material is simple in preparation process, and can adopt a plurality of coating manners. The production method has a wide popularization and application prospect in the production industry of titanium plates and titanium tubes.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Oily high-temperature resistant coating material, application thereof and titanium ingot production method

ActiveCN104151909AReduce formationHigh yieldPolyurea/polyurethane coatingsPaints with free metalsAl powderSocial benefits

The invention discloses an oily high-temperature resistant coating material. The oily high-temperature resistant coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Cu powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses application of the oily high-temperature resistant coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment and the like are not affected, so that the oily high-temperature resistant coating material has an environment-friendly effect; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

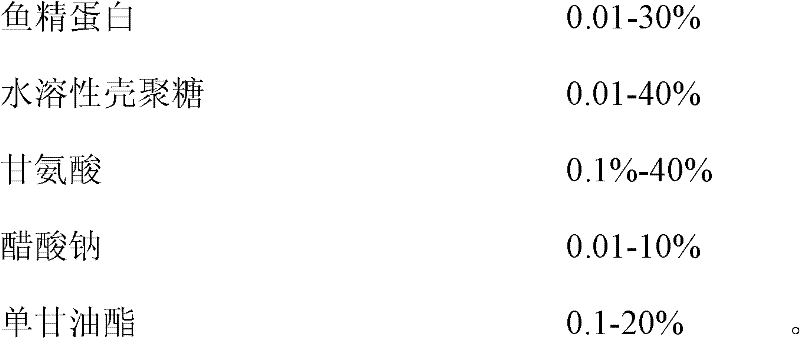

Protamine compounded preparation, preparation method and application thereof

ActiveCN102405935ADoes not affect environmental protectionUnique effectAntibacterial agentsBiocideSodium acetateMonoglyceride

The invention discloses protamine compounded preparation, a preparation method and application thereof. The protamine compounded preparation of the invention can be singly prepared with the protamine and chitosan, or prepared by compounding one or mixture of over two of glycine, sodium acetate, undecynol monoglyceride, acetic acid, absolute alcohol, lysostaphin, lysozyme, anti-bacterial peptide and sterilized distilled water. The method for preparing the protamine compounded preparation comprises the following steps: accurately weighting each component according to rate in aseptic or clean workshops; putting in clean glass or stainless steel, and uniformly stirring; and sealing in sterile containers. The product not only effectively kills the gram-positive cocci, such as staphyloccocus aureus rosenbach, monilia albican, neisseria gonorrhoeae, streptococcus, anaerobic bacteria, pseudomonas aeruginosa, escherichia coli, pneumococcus, D enterococcus, staphylococcus tetragenus, listeria monocytogenes, stenotrophomonas maltophilia and stomach helicobacter pylori, but also kills the gram-negative bacteria.

Owner:广东康乃欣生物医疗科技有限公司

High-temperature resistant protective coating used for titanium, applications thereof and titanium ingot producing method

High-temperature resistant protective coating used for titanium is disclosed. The coating is prepared by uniformly mixing a raw material mixture. The raw material mixture comprises an oxidation protective agent and an oily film forming agent. The oxidation protective agent comprises Al powder, Zn powder, Fe powder, Sn powder and Cu powder. The weight ratio of the Al powder, the Zn powder, the Fe powder, the Sn powder and the Cu powder is 1:0.01-0.1:0.01-0.1:0.01-0.1:0.01-0.1. Applications of the coating in titanium ingot production and a titanium ingot producing method are also disclosed. The coating can ensure that surfaces of titanium ingots are not oxidized or cracked after the titanium ingots are disposed at a constant high temperature of 1000 DEG C for 8 h, and largely reduce formation of oxygen dissolving layers. The coating is environmental friendly and simple in preparation process, and can adopt a plurality of coating manners. The titanium ingot producing method has a wide popularization and application prospect in production of titanium plates and titanium tubes.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

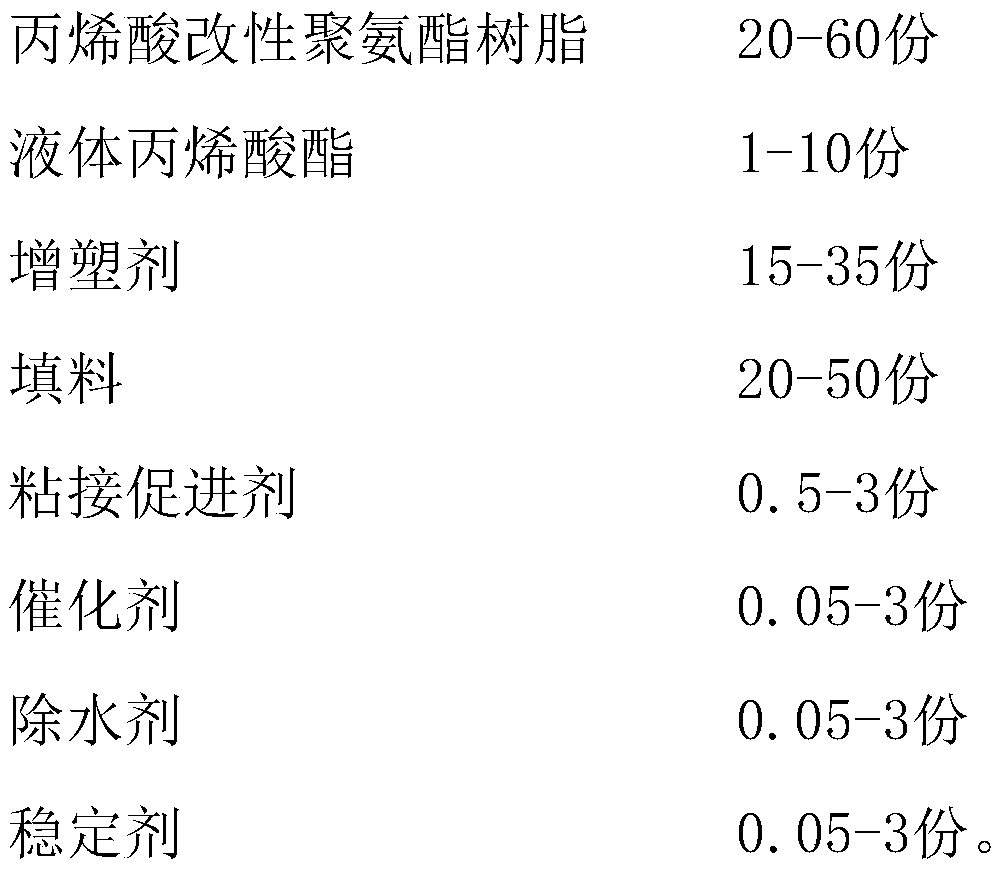

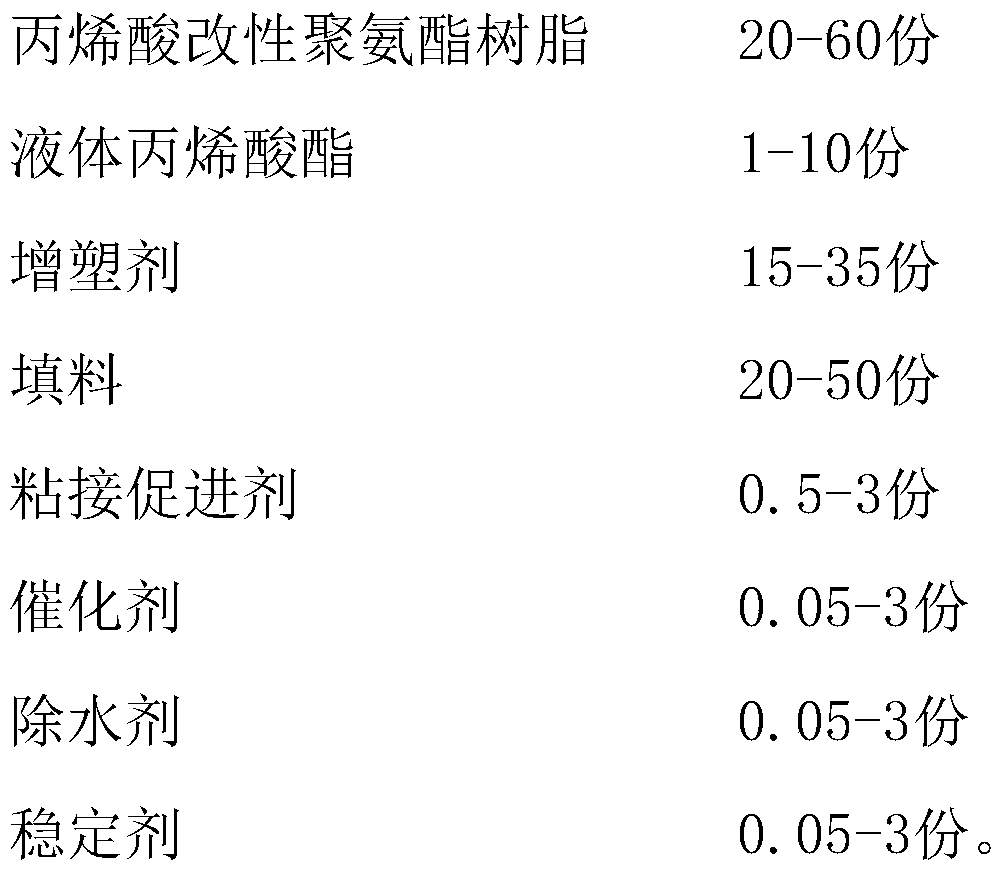

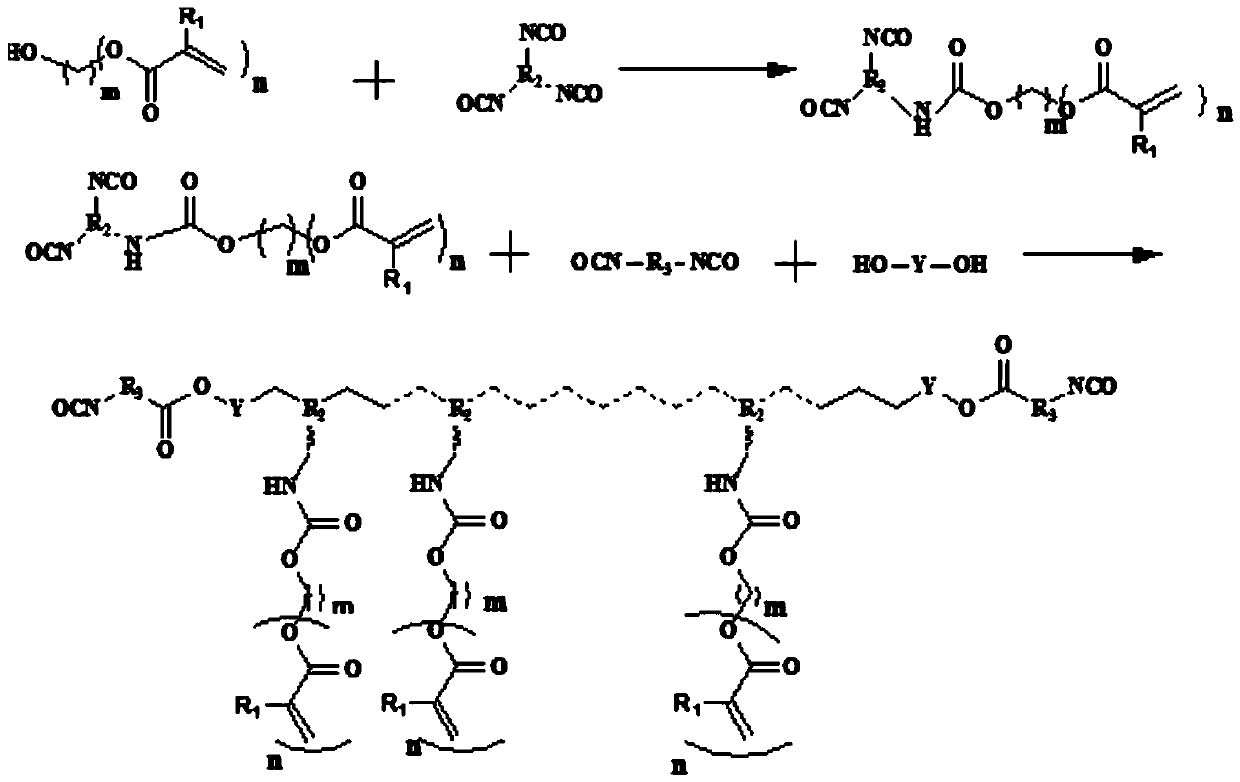

Acrylate modified polyurethane sealant and preparation method thereof

ActiveCN110791251AExtended service lifeGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

The invention relates to the technical field of sealants, more specifically relates to a sealant, in particular to an acrylate modified polyurethane sealant and a preparation method thereof. The acrylate modified polyurethane sealant is prepared from the following raw materials in parts by weight: 20 to 60 parts of acrylic acid modified polyurethane resin, 1 to 10 parts of liquid acrylate, 15 to 35 parts of a plasticizer, 20 to 50 parts of filler, 0.5 to 3 parts of an adhesion promoter, 0.05 to 3 parts of a catalyst, 0.05 to 3 parts of a water removal agent and 0.05 to 3 parts of a stabilizer.According to the invention, the acrylate modified polyurethane resin is adopted; the addition type liquid acrylate resin is matched; the prepared sealant is used in a later natural environment; the energy of ultraviolet irradiation can be transferred to acrylate bonds, so that the acrylate bonds are slowly crosslinked, carbamate bonds in a sealant system are protected, meanwhile, due to crosslinking of acrylate, the weather resistance of the sealant is further improved, the cohesiveness is wide, and the outdoor service life of the polyurethane sealant is prolonged.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

Protective paint, application thereof and titanium ingot production method

The invention discloses a protective paint. The protective paint is obtained after a raw material mixture is uniformly mixed; the raw material mixture contains an oxidation protectant, a water-soluble film-forming agent and water; the oxidation protectant contains Al powder and Sn powder which are in the weight ratio of 1: (0.01-0.1). The invention also discloses an application of the protective paint in titanium ingot production and a titanium ingot production method. The protective paint disclosed by the invention has the environment-friendly effects of greatly reducing formed dissolved oxygen layers, increasing the yield and production efficiency of titanium materials, generating no influences to the construction environment, ensuring that the surface of a titanium ingot is not oxidized and cracked at the constant high temperature of 1000 DEG C within 8h and the like; the protective paint is simple in preparation process; and various coating ways such as air pressure spraying, vacuum spraying, brush coating and the like can be adopted. The titanium ingot production method disclosed by the invention has favorable economic and social benefits and has relatively wide popularization and application prospects in titanium plate and titanium pipe production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Aqueous protective coating material, application thereof and titanium ingot production method

The invention discloses an aqueous protective coating material. The aqueous protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent, a water-soluble film forming agent and water; the oxidation protecting agent contains Al powder, Sn powder and Cu powder which are in the weight ratio of 1: (0.01-0.1): (0.01-0.1). The invention further discloses application of the aqueous protective coating material in titanium ingot production and a titanium ingot production method. The aqueous protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot is subjected to constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, and the formation of an oxygen dissolved layer can be greatly reduced; the aqueous protective coating material has an environmental-friendly effect; the preparation process is simple; a variety of coating manners can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Oily high-temperature resistant coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant coating material. The oily high-temperature resistant coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder, Fe powder and Sn powder which are in the weight ratio of 1: (0.01-0.1): (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, and the forming possibility of an oxygen dissolved layer can be greatly reduced; the oily high-temperature resistant coating material has an environment-friendly effect; the preparation process is simple; a variety of coating manners can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

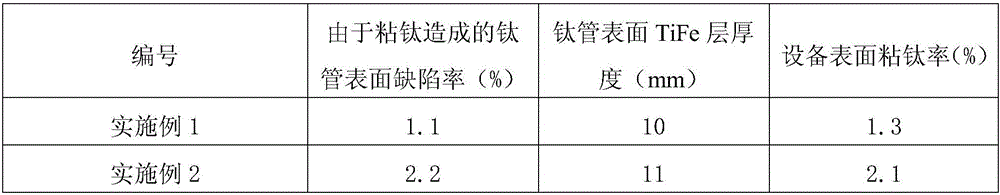

Oil-based high-temperature-resistant anti-bonding titanium coating and application thereof

ActiveCN105969090AImprove product precision size and surface qualityImprove production efficiency and yieldEpoxy resin coatingsTitaniumSesquioxide

The invention relates to an oil-based high-temperature-resistant anti-bonding titanium coating and application thereof and belongs to the technical field of titanium-steel anti-bonding coatings. The oil-based high-temperature-resistant anti-bonding titanium coating is used in titanium tube rolling. The coating is prepared from, by weight, 50-150 parts of oil-based film-forming agent, 30-80 parts of tin powder, 250-350 parts of iron sesquioxide powder and 400-450 parts of aluminum oxide powder. Steel equipment, roller beds and winches are coated with the oil-based high-temperature-resistant anti-bonding titanium coating, a very good isolation layer is formed, it can be guaranteed that a titanium ingot and steel equipment rollers or the winches are not subjected to a bonding reaction in the rolling or piercing process at the temperature of 900 DEG C, the precision size and surface quality of the product are improved, the yield of titanium material machining is increased, the production efficiency of titanium material machining is improved, and the production cost is reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Colorful transferred lined paper

InactiveCN103924482AMature technologyColorful and novel appearanceFlexible coversWrappersPolyesterPolyethylene terephthalate glycol

The invention discloses colorful transferred lined paper. The lined paper sequentially comprises a lined paper layer, a transfer adhesive layer, a colored metal layer, a release layer and a high-temperature resistant polyester PET (polyethylene terephthalate) film from inside to outside. Compared with the process of common transferred lined paper, the process is more mature, and adopts an advanced vacuum plating technology to plate the surface of the PET film with one colored metal layer to achieve more noble metallic texture and more colorful and novel appearance; a pin hole and a crack are hardly caused, and no flexing and cracking phenomenon is caused; as aluminum foil is not used, energy and materials are saved and the cost is reduced; the colorful transferred lined paper can be recycled and degraded without causing influence on environment protection after being used, meets the current social development requirement, and has strong market competitiveness.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

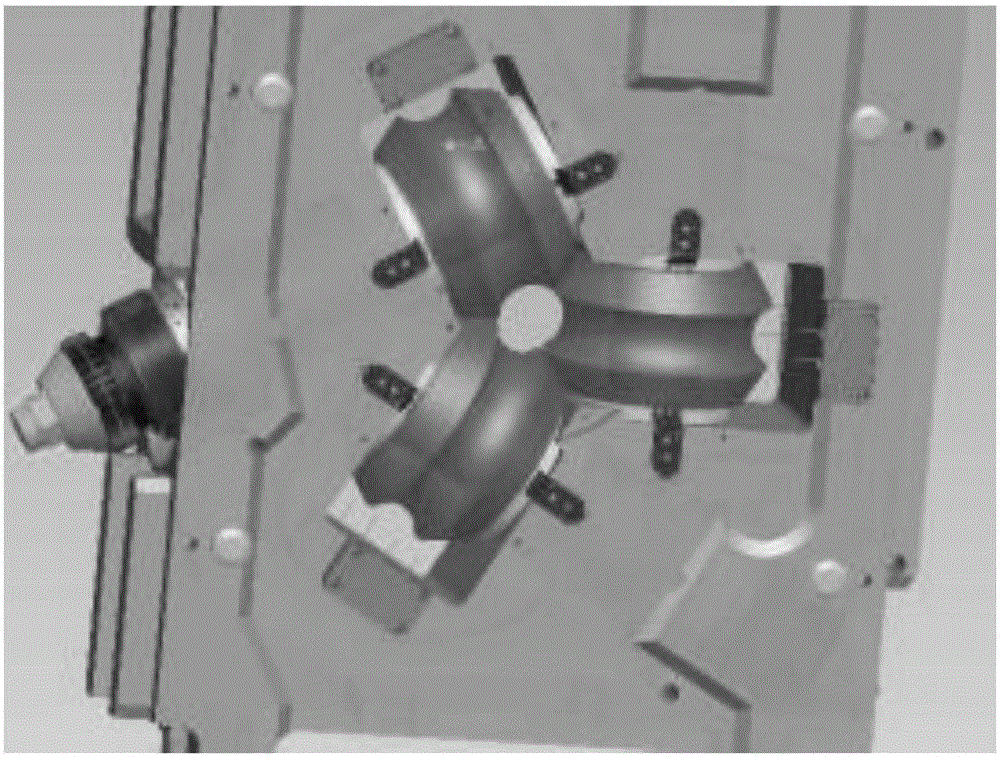

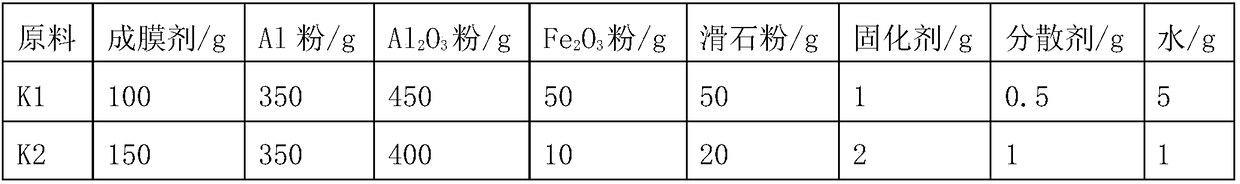

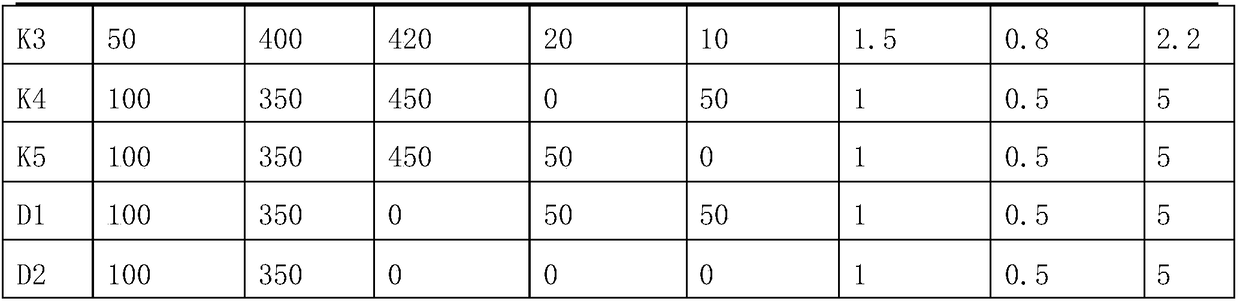

Oil protective coating composition as well as application thereof, and production method of titanium tubes

ActiveCN106010123AHigh yieldIncrease productivityPolyurea/polyurethane coatingsEpoxy resin coatingsAl powderProduction line

The invention relates to the field of coatings, and discloses an oil protective coating composition as well as application thereof, and a production method of titanium tubes. By utilizing the total weight of the oil protective coating composition as 100 parts by weight, the oil protective coating composition comprises 5-15 parts by weight of oil film former, 40-45 parts by weight of Al powder, 0-1 part by weight of Fe powder and 40-50 parts by weight of Al2O3 powder. The oil protective coating composition does not contain harmful elements restrained in RoHS quality; besides, when the oil protective coating composition is applied to production of the titanium tubes, the production process is simple and is easy to operate, and the oil protective coating composition can be on-line used on a production line equipped with pneumatic spraying, vacuum spraying or brush coating equipment.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Aqueous high temperature oxidation resistant protective paint, application thereof and production method of titanium ingot

ActiveCN104004400AGuaranteed not to be oxidized and crackedReduce formationCoatingsTitaniumOxidation resistant

The invention discloses aqueous high temperature oxidation resistant protective paint which is prepared by uniformly mixing a raw material mixture, wherein the raw material mixture contains an oxidation protecting agent, a water-soluble filming agent and water; the oxidation protecting agent contains Al powder, Sn powder, Cu powder and Fe powder at a weight ratio of 1:(0.01-0.1):(0.01-0.1):(0.01-0.1). The invention further discloses application of the aqueous high temperature oxidation resistant protective paint in titanium ingot production, and a production method of a titanium ingot. The aqueous high temperature oxidation resistant protective paint disclosed by the invention ensures that the surface of the titanium ingot is not oxidized or cracked at a constant high temperature of 1000 DEG C for 8 hours, can be used for greatly reducing formation of an oxygen dissolving layer, and has the effect of environmental friendliness; the preparation process is simple; a plurality of coating modes can be adopted. The production method of the titanium ingot is very wide in popularization and application prospect in titanium plates and titanium tube production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Atmospheric analytical recovery tower for high-ammonia-content wastewater

InactiveCN102557167AReduce corrosionEmission reductionWater/sewage treatment by heatingAmmonia preparation/separationChemical industryTitanium

The invention relates to an atmospheric analytical recovery tower for high-ammonia-content wastewater, belonging to the equipment for chemical industry. The atmospheric analytical recovery tower for the high-ammonia-content wastewater consists of a tower body, a feed distributor, a steam distributor, stripping-section stainless steel structured packing materials, a rectifying-section stainless steel structured packing material and a titanium condenser, wherein the upper section of the tower body is a rectifying section, the lower section of the tower body is a stripping section, a feeding port and the feed distributor are arranged at the boundary of the rectifying section and the stripping section, the upper end and the lower end of the tower body are respectively provided with a gas phase outlet and a discharging port, the titanium condenser and the rectifying-section stainless steel structured packing material are sequentially arranged below the gas phase outlet, the stripping-section stainless steel structured packing materials and a steam inlet are sequentially arranged below the feed distributor, and the steam distributor is arranged at the feed distributor. The atmospheric analytical recovery tower for the high-ammonia-content wastewater has the advantages of good effect in recovery, implementation of atmospheric recovery, good equipment stability, cost-saving performance, and energy-saving performance and environment-friendliness.

Owner:上海金炼化工科技有限公司 +1

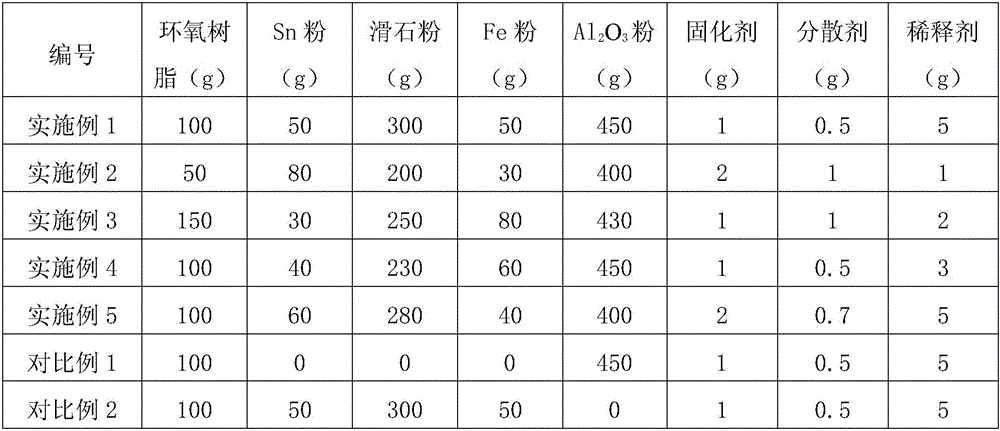

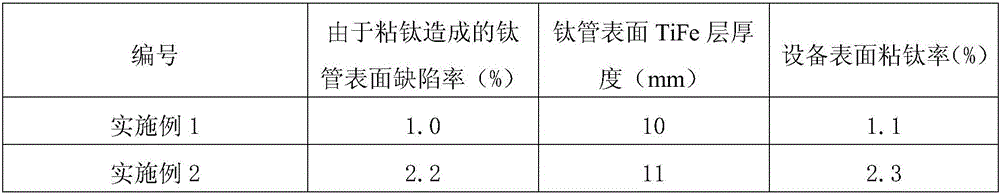

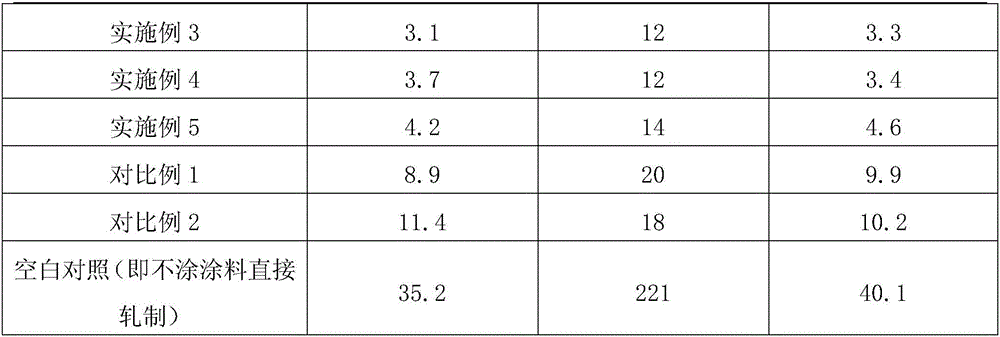

Oily high-temperature steel-titanium isolating paint and application thereof

ActiveCN106147530AHigh yieldIncrease productivityFireproof paintsPretreated surfacesPunchingIron powder

The invention relates to oily high-temperature steel-titanium isolating paint and application thereof, and belongs to the technical field of steel-titanium anti-adhesion coatings. The oily high-temperature steel-titanium isolating paint is applied to rolling of titanium pipes. The paint comprises, by weight, 50-150 parts of oily film forming agents, 30-80 parts of tin powder, 200-300 parts of talcum powder, 30-80 parts o iron powder and 400-450 parts of aluminum oxide powder. Good isolating layers are formed after roller beds or winches of steel equipment are coated with the oily high-temperature steel-titanium isolating paint, so that titanium ingots can be prevented from being adhered to rollers or the winches of the steel equipment during rolling or punching at the temperature of 900 DEG C, product dimension accuracy and surface quality can be improved, yield and production efficiency of titanium material processing can be increased, and production cost can be reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Water-based titanium ingot high temperature resistant oxygen-absorbing coating and its application and production method of titanium ingot

ActiveCN104017424BGuaranteed not to be oxidized and crackedReduce formationCoatingsEnvironmental resistanceFilm-forming agent

The invention discloses an aqueous titanium ingot high-temperature-resistant oxygen-absorbing coating material. The coating material is prepared by uniformly mixing a raw material mixture. The raw material mixture comprises an oxidation protective agent, an aqueous film-forming agent and water. The oxidation protective agent comprises Al powder, Zn powder, Fe powder and Cu powder, with the weight ration of the Al powder, the Zn powder, the Fe powder and the Cu powder being 1: 0.01-0.1: 0.01-0.1: 0.01-0.1. The invention also discloses applications of the coating material in titanium ingot production and a production method of a titanium ingot. The coating material can guarantee that the surface of the titanium ingot is not oxidized or cracked after the titanium ingot is put at a constant temperature of 1000 DEG C for 8 h. The coating material can largely reduce the formation of oxygen dissolved layers, and has an effect of environment protection. The coating material is simple in preparation process, and can adopt a plurality of coating manners. The production method has a wide popularization and application prospect in the production industry of titanium plates and titanium tubes.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

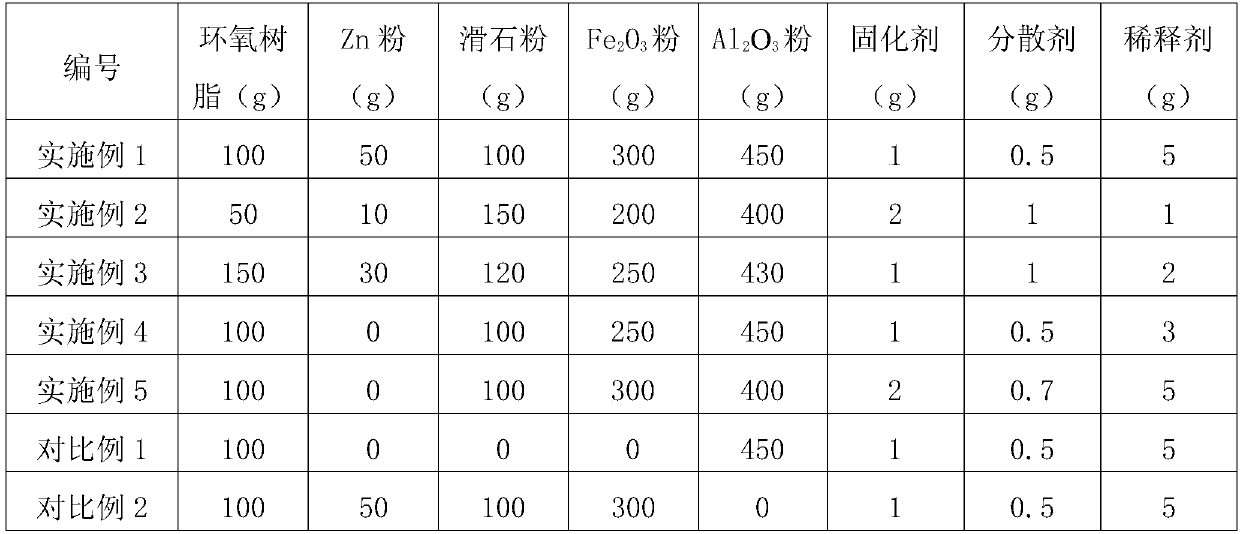

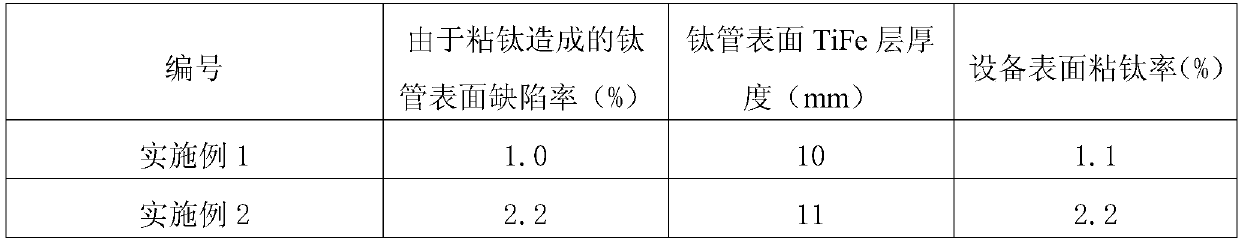

Oily High Temperature Resistant Titanium-Steel Bonding Coating and Its Application

The invention relates to an oily high-temperature-resisting titanium-steel bonding prevention coating and application thereof, belongs to the technical field of titanium-steel bonding prevention coatings and aims at providing an oily high-temperature-resisting titanium-steel bonding prevention coating used in titanium tube rolling. The coating is prepared from, by weight, 50-150 parts of an oily film-forming agent, 0-50 parts of zinc powder, 100-150 parts of talcum powder, 200-300 parts of ferric oxide powder and 400-450 parts of aluminum oxide powder. The oily high-temperature-resisting titanium-steel bonding prevention coating is applied to a steel and iron device, a roller or a winch to form a very good isolation layer and can ensure that titanium ingots do not produce bonding reaction with the steel and iron device, the roller or the winch in the 900 DEG C rolling or perforation process, improve the size precision and surface quality of products, improve the machining yield and production efficiency of titanium materials and reduce the production costs.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Water retention device suitable for planting plants in arid regions

PendingCN111972171AImprove survival rateAvoid waterloggingGrowth substratesCulture mediaNutrientSoil science

The invention provides a water retention device suitable for planting plants in arid regions. The water retention device comprises a water retention bag, wherein the water retention bag is a plantingbag with an open top end and a semi-elliptical cross section; the side edge of the water retention bag is provided with air holes, nutrient soil is placed in the bag body of the water retention bag, and the open top end of the water retention bag is covered with a gravel layer above the nutrient soil. The water retention bag has water-retaining and water-saving functions in the using process, canincrease the survival rate of plants in the initial growth stage, is made of cellulose-based super absorbent materials or wheat straw super absorbent resin, can be degraded in the middle and later growth stages of the plants, and does not affect development of the plants and avoids waterlogging. Nutrient soil in the water retention bags provides nutrient substances for plant growth, meanwhile, thesandy soil layer on the surface layer of the nutrient soil can increase the weight of the nutrient soil to avoid loss of the nutrient soil and block capillary water, the planting survival rate of plants in loess plateau arid areas can be increased, and the ecological restoration effect can be improved conveniently.

Owner:LANZHOU JIAOTONG UNIV

Waterborne anti-titanium-steel bond coating and its application

ActiveCN106085129BHigh yieldIncrease productivityFireproof paintsPretreated surfacesAl powderWater based

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

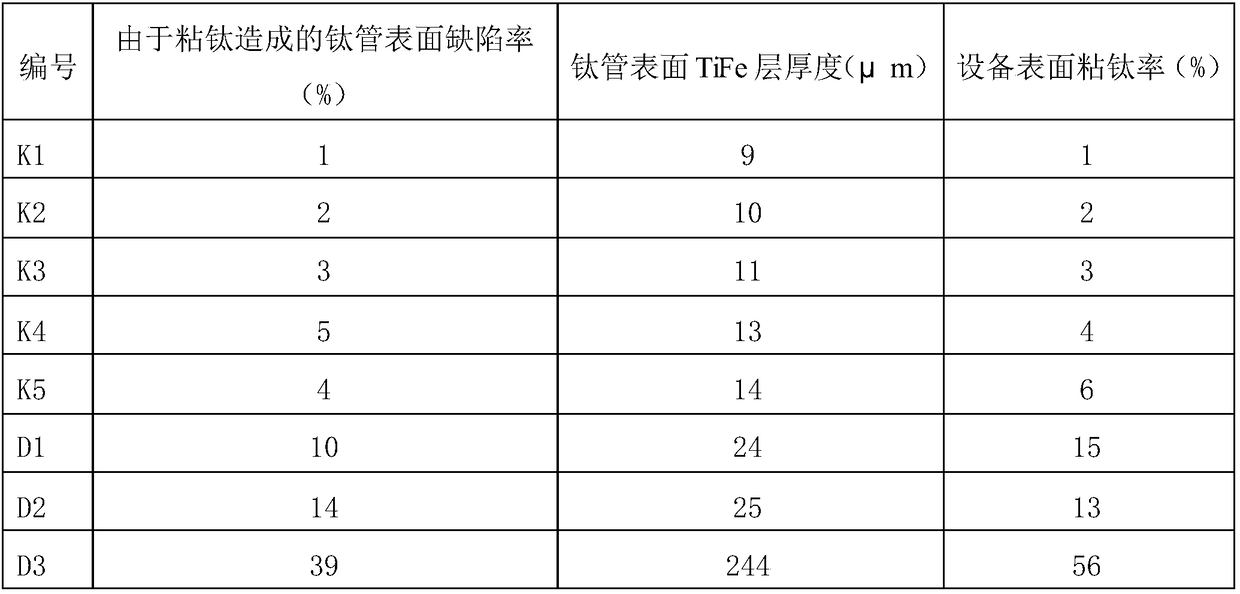

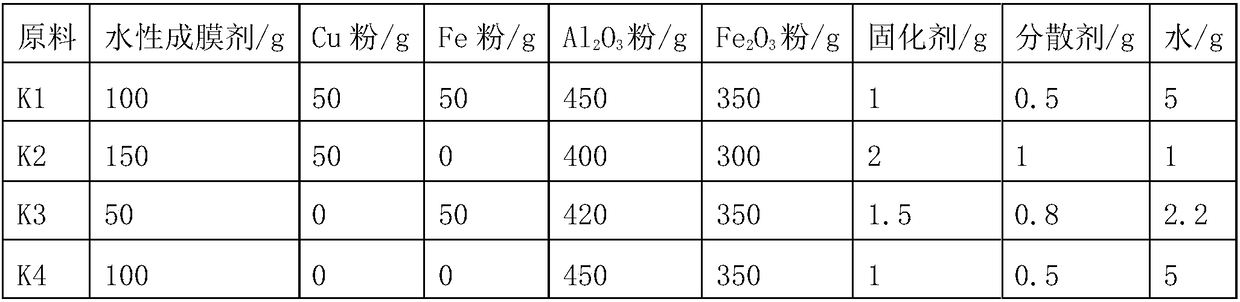

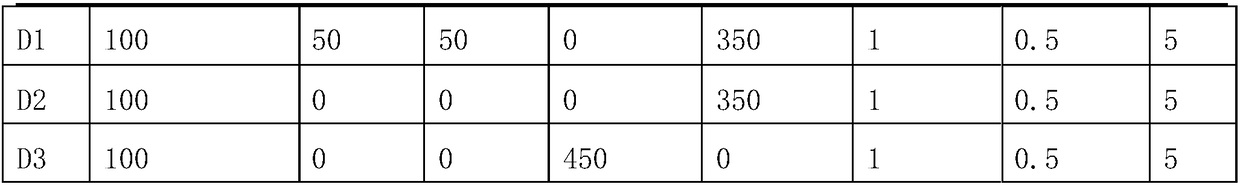

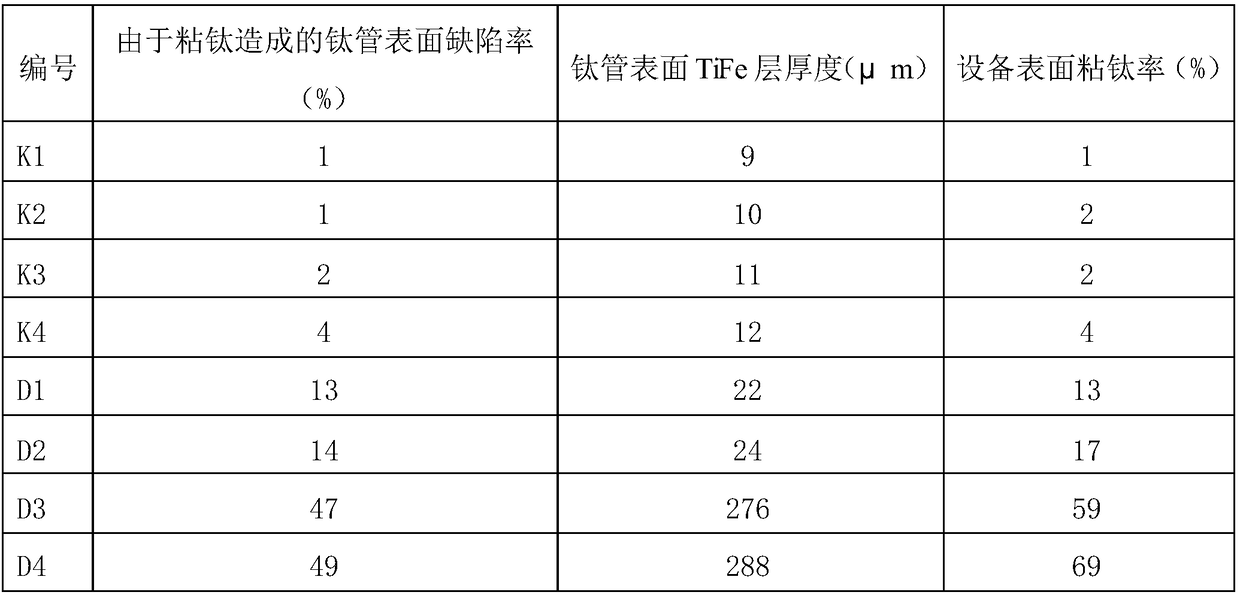

Water-Based Isolation Steel-Titanium Coating and Its Application

ActiveCN106221496BHigh yieldIncrease productivityFireproof paintsPolyurea/polyurethane coatingsTitanium coatingFilm-forming agent

The invention relates to paint for preventing bonding among metals, in particular to waterborne steel-titanium isolating paint and application thereof in the titanium ingot preparation process. The waterborne steel-titanium isolating paint is prepared from, by weight, 50-150 parts of a waterborne film forming agent, 0-50 parts of Cu powder, 0-50 parts of Fe powder, 400-450 parts of Al2O3 powder and 300-350 parts of Fe2O3 powder. Through a coating prepared from the paint, it can be guaranteed that a titanium pipe does not generate a bonding reaction with a rolling roller or a winch of steel equipment in the 900-DEG C rolling or perforating process, the finished product rate of titanium material machining is increased, and the production efficiency of titanium material machining is improved; the technology is simple, operation is easy, and the paint is environmentally friendly, free of pollution and simple in preparation method.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

High temperature protective coating and its application and production method of titanium ingot

ActiveCN104004399BReduce the formation of dissolved oxygen layerReduce manufacturing costCoatingsWater solubleTitanium

The invention discloses a high-temperature protective paint. The high-temperature protective paint is obtained after a raw material mixture is uniformly mixed; the raw material mixture contains an oxidation protectant, a water-soluble film-forming agent and water; the oxidation protectant contains Al powder and Zn powder which are in the weight ratio of 1: (0.01-0.1). The invention also discloses an application of the high-temperature protective paint in titanium ingot production and a titanium ingot production method. The high-temperature protective paint disclosed by the invention has the environment-friendly effects of greatly reducing formed dissolved oxygen layers, increasing the yield and production efficiency of titanium materials, generating no influences to the construction environment, ensuring that the surface of a titanium ingot is not oxidized and cracked at the constant high temperature of 1000 DEG C within 8h and the like; the high-temperature protective paint is simple in preparation process; and various coating ways such as air pressure spraying, vacuum spraying, brush coating and the like can be adopted. The titanium ingot production method disclosed by the invention has favorable economic and social benefits and has relatively wide popularization and application prospects in titanium plate and titanium pipe production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

A method of obtaining a release agent layer on a substrate and a composite material comprising a substrate and a release agent layer

ActiveCN105238216BAvoid stickingPlay an isolation roleLayered productsEpoxy resin coatingsEpoxyAlcohol

The invention relates to the field of release agents, in particular to a method for obtaining a release agent layer on a substrate and a composite material containing a substrate and a release agent layer prepared by the method. The method for obtaining a release agent layer on a substrate includes coating a release agent on the substrate and drying to form a release agent layer on the substrate, wherein the release agent contains water, alcohol, epoxy resin and Al2O3 powder , wherein relative to 100g of Al2O3 powder, the consumption of the water is 300-600mL, the consumption of the alcohol is 300-600mL, and the consumption of the epoxy resin is 5-15mL. The release agent of the present invention can be directly sprayed online on the surface of the composite titanium plate, can be quickly solidified, and forms a self-drying coating to play the role of isolation, so that the titanium steel composite plate can be neutralized at a constant temperature of 800 ° C to 1000 ° C for 4 to 6 hours. During the rolling process, the phenomenon of adhesion and surface roughness increase will not occur at the titanium-titanium interface, which improves the yield and production efficiency of titanium-steel clad plate processing.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com