Oily High Temperature Resistant Titanium-Steel Bonding Coating and Its Application

A high temperature resistant and oily technology, applied in the field of titanium-steel anti-bonding coating, can solve the problems of poor film formation and adhesion, long preparation time, and complicated preparation process, so as to improve product precision, size and surface quality, and improve Yield and production efficiency, the effect of simple production and use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

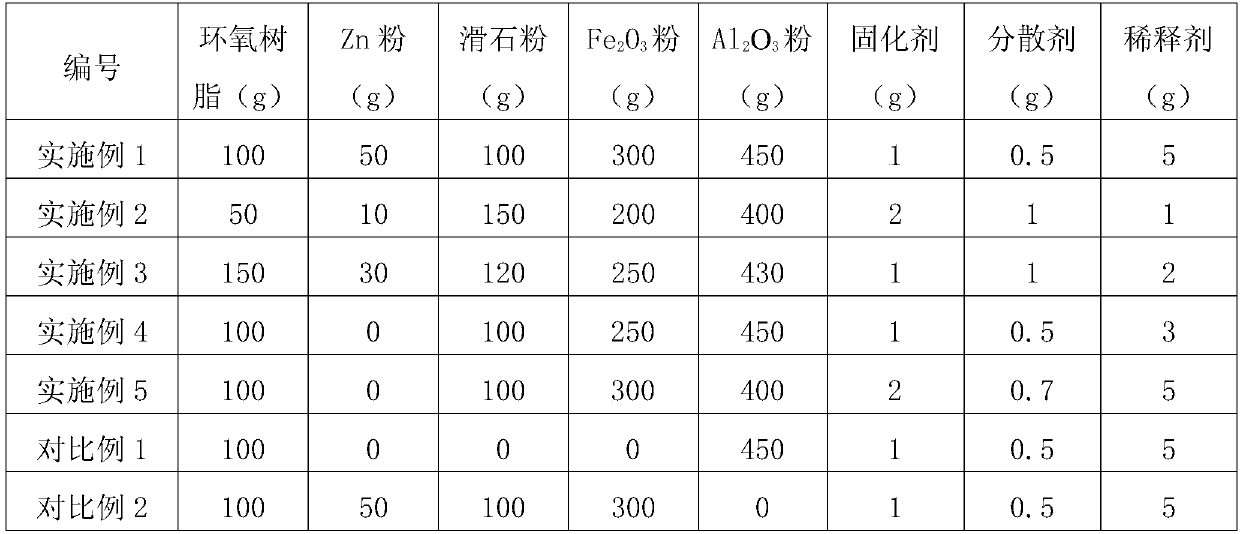

[0039] Under normal temperature and pressure, take epoxy resin (solid part content 50%) and place in container, stand-by; Add diluent, stand-by after stirring evenly; Measure Zn powder, talcum powder, Fe 2 o 3 Powder, Al 2 o 3 powder, slowly add to the container, stirring continuously during the adding process, and stir evenly; then measure the curing agent SiO 2 powder, put it into a container, and stir evenly; then measure and add polyvinyl alcohol 200 as a dispersant, add it to the container, and stir until the solution is in a uniform and stable phase to obtain the oily high temperature resistant anti-titanium-steel bonding coating of the present invention. The consumption of each raw material is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com