Atmospheric analytical recovery tower for high-ammonia-content wastewater

A recovery tower and waste water technology, applied in the field of chemical equipment, can solve problems such as restricting the economic benefits of production enterprises, affecting ammonia nitrogen emission indicators, and short service life of fillers, so as to reduce the cost of repair and maintenance and the loss of production stoppage, and reduce resource consumption , Corrosion reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

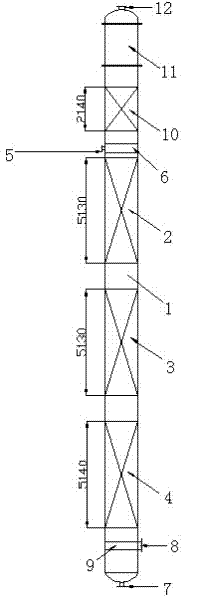

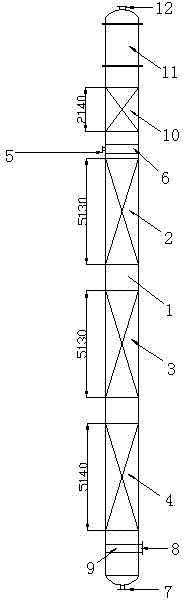

[0017] Embodiment 1: as figure 1 As shown, the main body of this embodiment is the tower body 1, and feed material (ammonia content is about 30mg / L) at the feed port 5 at the tower height of 23.7 meters, and the feed liquid is evenly distributed through the feed distributor 6, from top to bottom Through the upper stainless steel structured packing 2, the middle stainless steel structured packing 3, and the lower stainless steel structured packing 4, the height of each layer is 5.13 meters, and the overall height is 15.4 meters. Stripping is carried out, and the material is discharged through the outlet 7 at the bottom of the tower (waste liquid Ammonia content is 0mg / L).

[0018] At the same time, the 0.6MPa saturated low-pressure steam enters the steam distributor 9 through the steam inlet 8 for uniform distribution, passes through the stripping section of the lower stainless steel structured packing 4, the middle stainless steel structured packing 3, and the upper stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com