Method for obtaining isolated layer on base plate and composite material containing base plate and isolated layer

A technology of isolation layer and substrate, which is applied in the direction of coating, device for coating liquid on the surface, special surface, etc. It can solve the problem that the decomposition reaction cannot occur at high temperature, affect the cost and yield of titanium material, and the interface bonding of steel-titanium It is easy to prepare and use, improve the yield and production efficiency, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-3

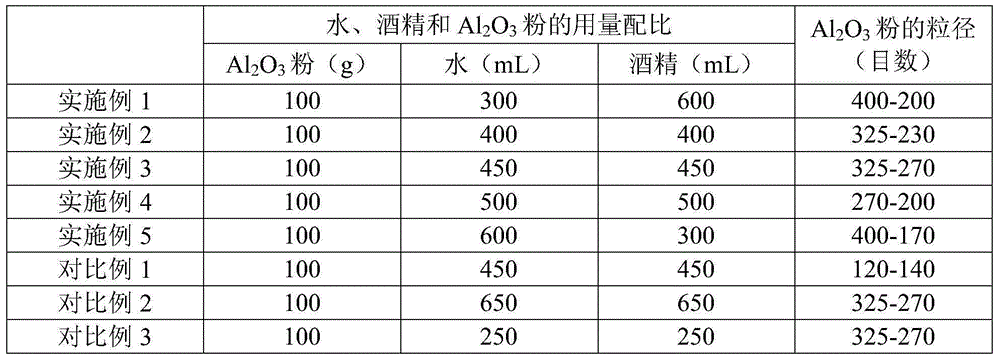

[0029] Add water, alcohol and Al 2 o 3 Powder (particle size as shown in Table 1), after adding, stir evenly to obtain the release agent.

[0030] Table 1

[0031]

Embodiment 6-10 and comparative example 4-8

[0033] According to the mode shown in table 2, embodiment 6-10 and comparative example 4-8 take respectively the release agent that embodiment 1-5 and comparative example 1-3 make, and it is evenly sprayed on the composite titanium plate Then it was dried naturally at room temperature for about 5 minutes to obtain an isolation layer.

[0034] Table 2

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com