Oil protective coating composition as well as application thereof, and production method of titanium tubes

A technology for protective coatings and production methods, applied in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as easy occurrence of titanium-steel bonding, improve yield, save production costs, The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

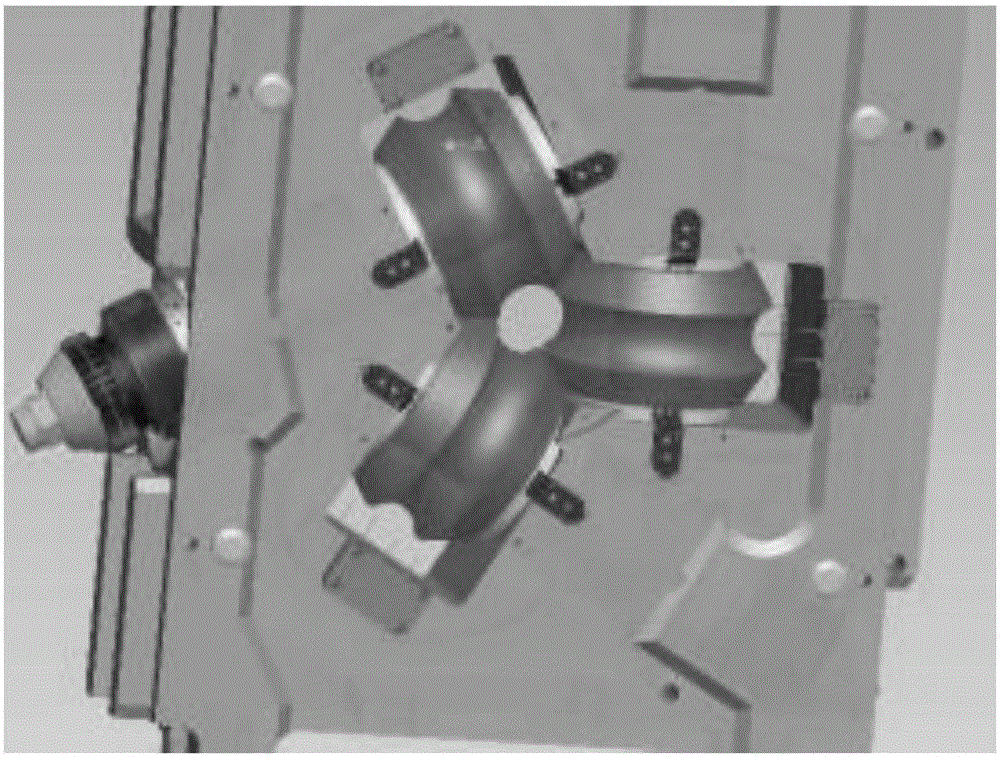

Image

Examples

Embodiment approach

[0019] According to a preferred embodiment of the present invention, the solid content of the oil-based protective coating composition is 83-95% by weight, and the pH is 6.5-9.5. Preferably, the oil-based protective coating composition is weakly alkaline, which is more conducive to forming a uniform high-temperature anti-sticking protective film layer on the surface of the rolling equipment, and at the same time the film layer will be rapidly cured at room temperature; The solid content of the composition is preferably 87-95% by weight, which can prevent the surface film layer from flowing, so that the coating has good adhesion, and the coating adhesion can meet the requirements of the titanium ingot roller table vibrator whether it is wet film or dry film. The need for friction, there will be no coating peeling or powder. Further preferably, the solid content of the oil-based protective coating composition is 90-95 wt %, and the pH is 7.7-9.2; more preferably, the solid conte...

Embodiment 1

[0037] This embodiment is used to illustrate the production method of the oil-based protective coating composition and titanium tube of the present invention.

[0038] (1) At normal temperature and pressure (25°C, 0.1MPa), weigh 100g of oily epoxy resin (purchased from Nantong Xingchen Synthetic Materials Co., Ltd., with a solid content of 50%, the same below) and place it in a container;

[0039] (2) Add 5g of acetone and stir evenly;

[0040] (3) Weigh 410g Al powder and 2g Fe powder, 440g Al 2 O 3 Powder, under stirring, slowly add to the container, stir evenly;

[0041] (4) Weigh 1g of curing agent SiO 2 powder, add to the container, stir well;

[0042] (5) Weigh 0.5 g of dispersant polyvinyl alcohol into a container, and stir to make the solution in a uniform and stable phase to obtain oily protective coating composition A1.

[0043] The solid content of the oily protective coating composition A1 was determined to be 95%, and the pH value was 8.3.

[0044] The oily ...

Embodiment 2

[0046] This embodiment is used to illustrate the production method of the oil-based protective coating composition and titanium tube of the present invention.

[0047] (1) At normal temperature and pressure (25°C, 0.1MPa), weigh 120g of oily epoxy resin (50% solid content) and place it in a container;

[0048] (2) Add 1g of acetone and stir evenly;

[0049] (3) Weigh 440g Al powder and 4g Fe powder, 420g Al 2 O 3 Powder, under stirring, slowly add to the container, stir evenly;

[0050] (4) Weigh 2g curing agent SiO 2 powder, add to the container, stir well;

[0051] (5) Weigh 1 g of the dispersant polyvinyl alcohol into a container, and stir to make the solution in a uniform and stable phase to obtain the oily protective coating composition A2.

[0052] The solid content of the oil-based protective coating composition A2 was determined to be 93%, and the pH value was 8.4.

[0053] The oily protective coating composition A2 is sprayed on the capstan surface with an autom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com