Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

A waste heat recovery system and flue gas waste heat technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of reducing the heat transfer efficiency and service life of the heating surface of the heat pipe, increasing the maintenance workload and operating resistance, and wasting energy. Achieve the effect of saving operation and maintenance costs, saving equipment investment, and ensuring normal and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

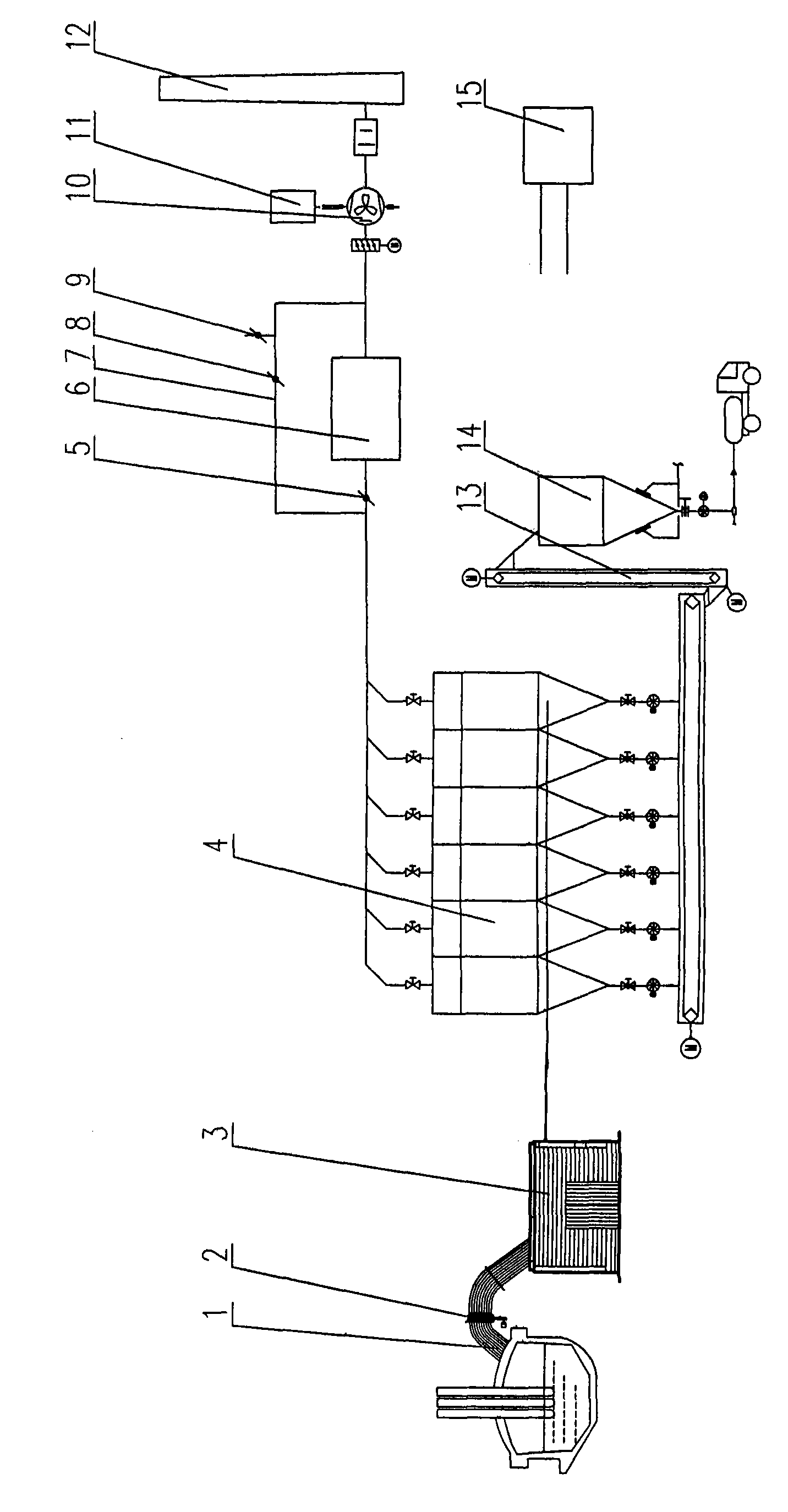

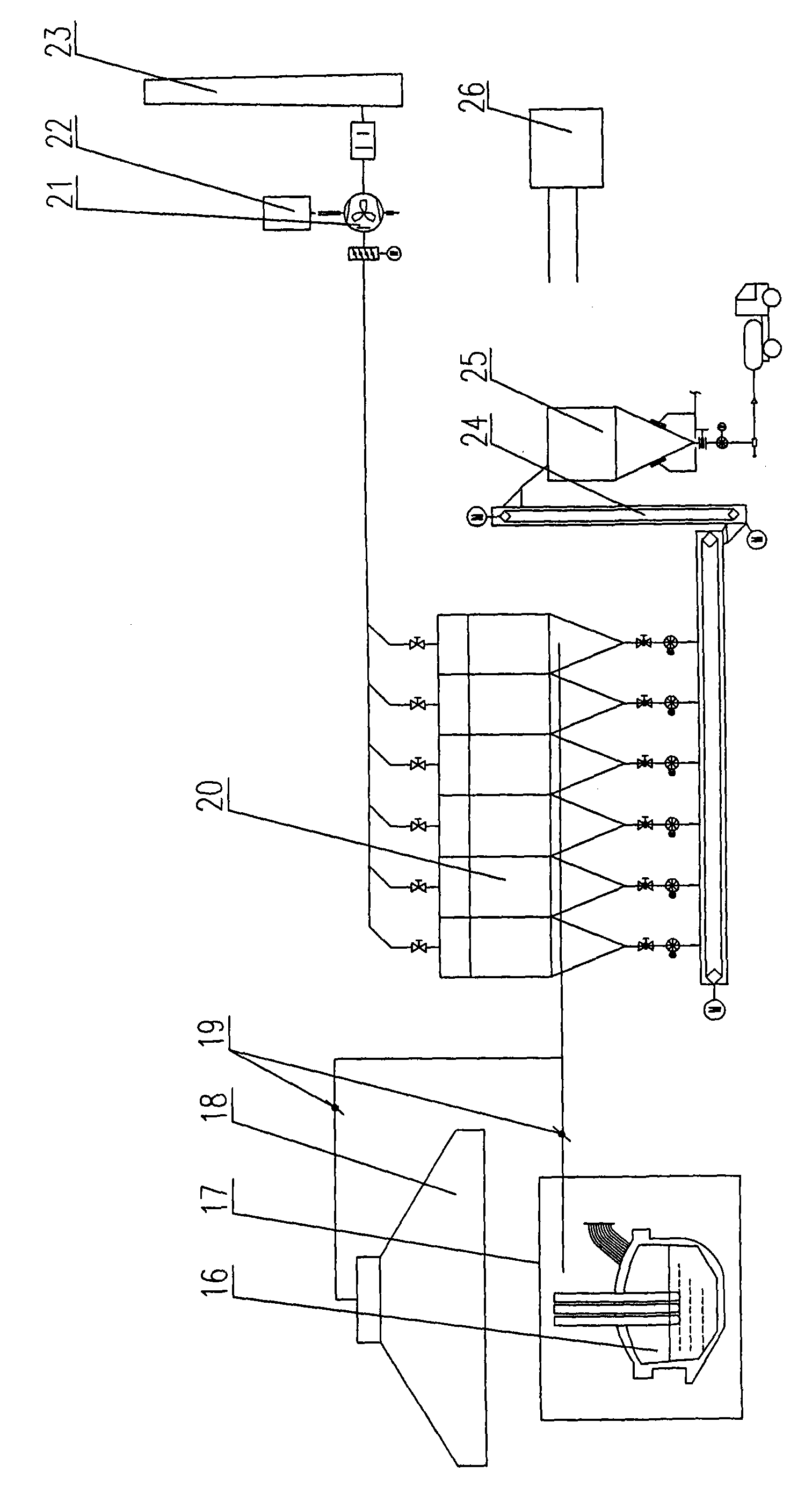

[0028] Attached below Figure 1~2 A preferred embodiment of the present invention will be described in detail.

[0029] The invention divides the electric furnace flue gas waste heat recovery and negative energy consumption dust removal system into two parts, one part is the electric furnace flue gas primary dust removal and waste heat recovery system used to absorb the high temperature flue gas produced by the electric furnace in the smelting stage; the other part is used to absorb The electric furnace flue gas secondary dust removal system for the flue gas generated by the electric furnace during the feeding and tapping stages (including part of the flue gas escaping from the electric furnace cover during the smelting stage).

[0030] see figure 1 , the electric furnace flue gas primary dust removal and waste heat recovery system in the present invention is connected to the electric furnace smoke exhaust hole 1, and the electric furnace flue gas primary dust removal and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com