Corrosion-resistant environment-friendly glaze for tiles

A corrosion-resistant and environmentally friendly technology, applied in the field of ceramic glaze processing, can solve problems such as the lack of strong tolerance of alkaline stains, affect the decorative effect of ceramic tiles, and shorten the service life of ceramic tiles, so as to promote heat transfer, improve aesthetics and performance Corrosion resistance, effect of lowering firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

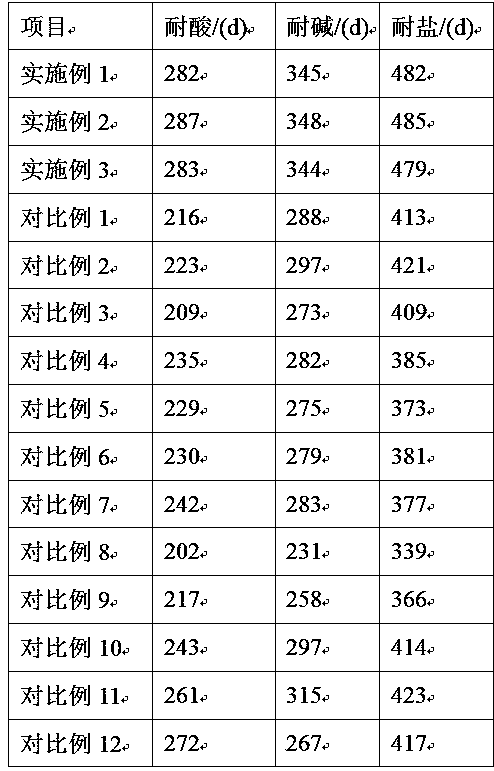

Examples

Embodiment 1

[0019] A corrosion-resistant and environmentally friendly glaze for tiles, made of the following raw materials in parts by weight: silicon dioxide 37, barite 26, feldspar 24, pyrophyllite 17, kaolinite 14, tin oxide 5.2, pentoxide Niobium 4.5, tungsten oxide 4.1, cerium oxide 3.4, cobalt oxide 2.3, graphene 0.3.

[0020] A method for preparing a corrosion-resistant and environmentally friendly glaze for ceramic tiles, comprising the following steps:

[0021] (1) Crush the pyrophyllite to 140 mesh to obtain pyrophyllite powder;

[0022] (2) Add cobalt oxide to pyrophyllite powder, ball mill it to 300 mesh, raise the temperature to 220°C within 30 minutes, keep it warm for 15 minutes, then raise the temperature to 560°C at a rate of 2°C / min, keep it warm for 10 minutes, and cool down naturally to get Modified pyrophyllite;

[0023] (3) Mix silica, barite, feldspar and kaolinite, and crush them to 100 mesh to obtain mixed stone powder;

[0024] (4) Add water to the mixed stone...

Embodiment 2

[0030] A corrosion-resistant and environmentally friendly glaze for ceramic tiles, made of the following raw materials in parts by weight: silicon dioxide 38, barite 27, feldspar 25, pyrophyllite 18, kaolinite 15, tin oxide 5.4, pentoxide Niobium 4.7, tungsten oxide 4.3, cerium oxide 3.6, cobalt oxide 2.5, graphene 0.4.

[0031] A method for preparing a corrosion-resistant and environmentally friendly glaze for ceramic tiles, comprising the following steps:

[0032] (1) Crush the pyrophyllite to 170 mesh to obtain pyrophyllite powder;

[0033] (2) Add cobalt oxide to pyrophyllite powder, ball mill it to 350 mesh, raise the temperature to 240°C within 35 minutes, keep it for 20 minutes, then raise the temperature to 590°C at a rate of 2.5°C / min, keep it for 15 minutes, and cool down naturally to get Modified pyrophyllite;

[0034] (3) Mix silica, barite, feldspar and kaolinite, and crush them to 130 mesh to obtain mixed stone powder;

[0035] (4) Add water to the mixed stone...

Embodiment 3

[0041] A corrosion-resistant and environmentally friendly glaze for ceramic tiles, made of the following raw materials in parts by weight: silicon dioxide 39, barite 28, feldspar 26, pyrophyllite 19, kaolinite 16, tin oxide 5.6, pentoxide Niobium 4.9, tungsten oxide 4.5, cerium oxide 3.8, cobalt oxide 2.7, graphene 0.5.

[0042] A method for preparing a corrosion-resistant and environmentally friendly glaze for ceramic tiles, comprising the following steps:

[0043] (1) Crush the pyrophyllite to 200 mesh to obtain pyrophyllite powder;

[0044] (2) Add cobalt oxide to pyrophyllite powder, ball mill it to 400 mesh, raise the temperature to 260°C within 40 minutes, keep it warm for 25 minutes, then raise the temperature to 620°C at a rate of 3°C / min, keep it warm for 20 minutes, and cool down naturally to get Modified pyrophyllite;

[0045] (3) Mix silica, barite, feldspar and kaolinite, and crush them to 160 mesh to obtain mixed stone powder;

[0046] (4) Add water to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com