Sky blue mirror reflection coated glass and preparation method thereof

A technology of mirror reflection and coated glass, which is applied in the direction of coating, etc., can solve the problems of long production cycle, uneven thickness of silver layer, unstable product quality, etc., to improve product production efficiency, good acid and alkali corrosion resistance, shorten The effect of the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

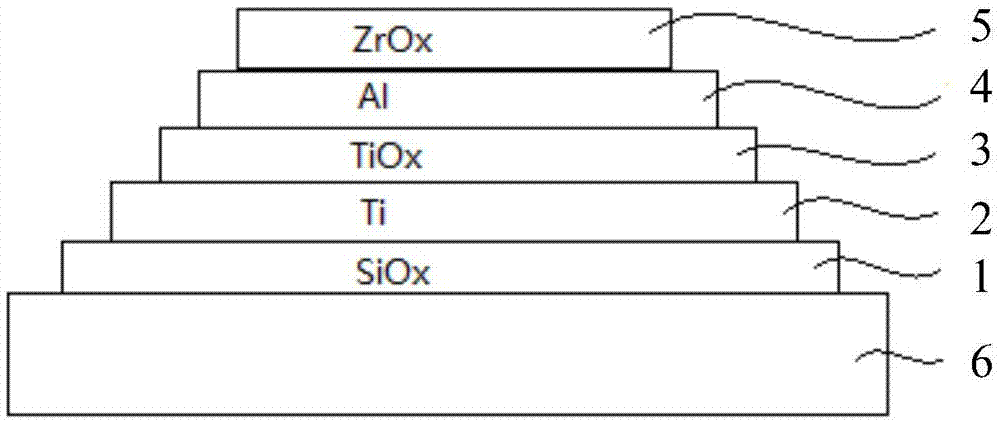

[0023] After the original glass sheet is cleaned and polished, it is plated on it in turn by using the measurement and control sputtering coating equipment:

[0024] The bottom dielectric layer is 1SiOx, and the film thickness is 30nm;

[0025] The first metal absorption layer 2Ti, the film thickness is 10nm;

[0026] The first dielectric layer is 3TiOx, the film thickness is 80nm;

[0027] The second metal absorption layer 4Al, the film thickness is 32nm;

[0028] The thickness of the outer protective layer 5ZrOx film is 15nm.

[0029] After the plating is completed, the colors of the obtained specular reflection glass are shown in Table 1.

[0030] Table 1

[0031]

Embodiment 2

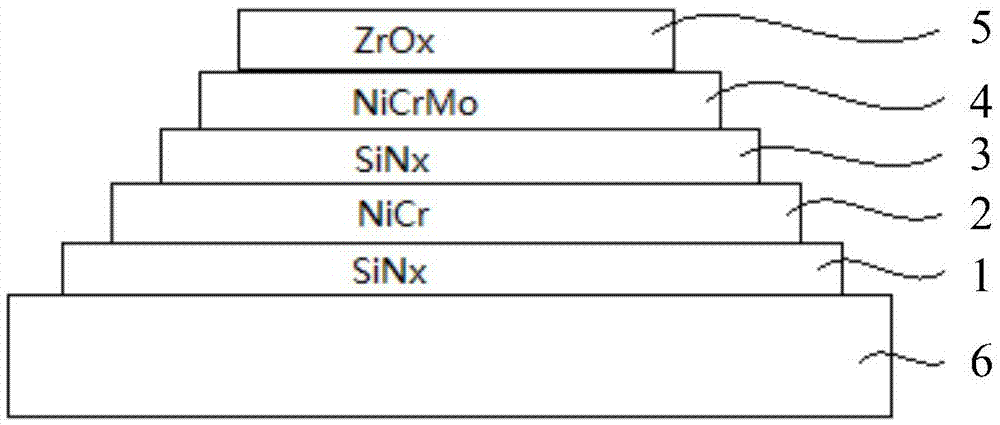

[0033] After the original glass sheet is cleaned and polished, it is plated on it in turn by using the measurement and control sputtering coating equipment:

[0034] The bottom dielectric layer is 1SiNx, and the film thickness is 23nm;

[0035] The first metal absorption layer is 2NiCr, and the film thickness is 14.5nm;

[0036] The first dielectric layer is 3SiNx, with a film thickness of 98nm;

[0037] The second metal absorption layer is 4NiCrMo, the film thickness is 42nm;

[0038] The thickness of the outer protective layer 5ZrOx film is 10nm.

[0039] After the plating is completed, the colors of the obtained specular reflection glass are shown in Table 2.

[0040] Table 2

[0041]

[0042] After tempering the specular reflection glass, its color is shown in Table 3.

[0043] table 3

[0044]

Embodiment 3

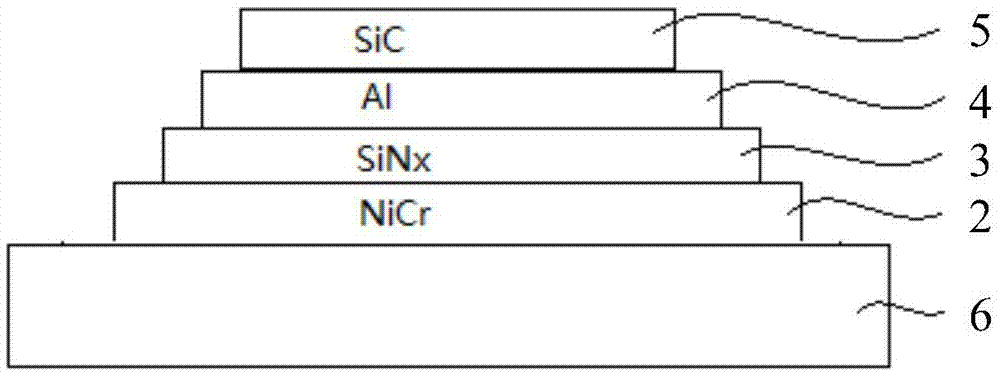

[0046] After the original glass sheet is cleaned and polished, it is plated on it in turn by using the measurement and control sputtering coating equipment:

[0047] The first metal absorption layer is 2NiCr, and the film thickness is 18nm;

[0048] The first dielectric layer is 3SiNx, with a film thickness of 88nm;

[0049] The second metal absorption layer 4Al, the film thickness is 35nm;

[0050] The thickness of the outer protective layer 5 SiC film is 20nm.

[0051] After the plating is completed, the colors of the obtained specular reflection glass are shown in Table 4.

[0052] Table 4

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com