Process method capable of improving mechanical property of aluminum alloy

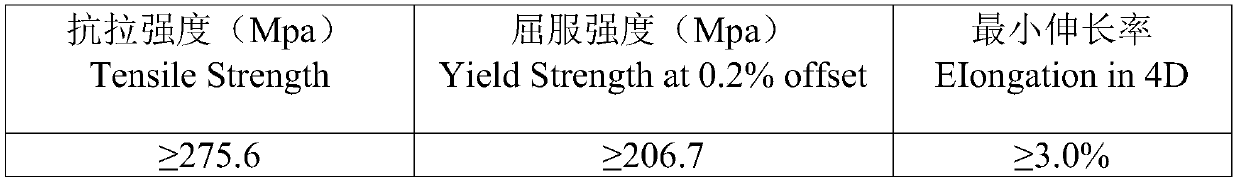

A process method and technology of aluminum alloy, applied in the aviation field, can solve the problems of mechanical properties not meeting the requirements of product specifications, and achieve the effect of eliminating pinholes and shrinkage defects and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

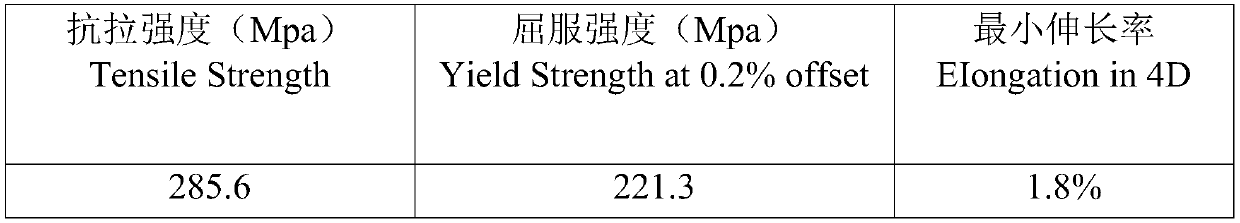

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

[0028] A process method for improving the mechanical properties of aluminum alloy, characterized in that it comprises the following steps:

[0029] (1) Melting: After heating the A356 aluminum alloy ingot to 730-750°C to melt, add a modifier to treat the alloy melt;

[0030] (2) Casting: degassing and refining the A356 aluminum alloy melt obtained in step (1), leaving it still, removing slag, and then casting to obtain the product;

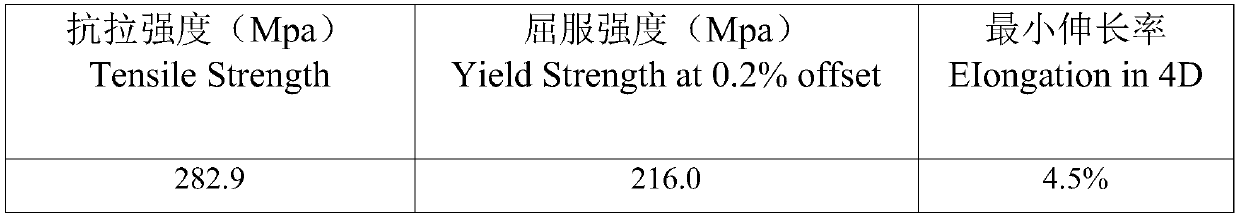

[0031] (3) Hot isostatic pressing: The product obtained in step (2) is subjected to hot isostatic pressing; the hot isostatic pressing (HIP) process is a process of applying high air pressure to a heated casting in a specially constructed pressure vessel, It eliminates porosity inside the casting and increases elongation. In the hot isostatic pressing process, after the pinhole defects are eliminated, the unit load area of the material increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com