Method utilizing ammonium fluoride solution to treat electron transmission layer of perovskite cell

An electron transport layer and perovskite cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as affecting the electron transport efficiency of electrons through the transport layer, accelerating film degradation, and complicated processes, and improving electron extraction efficiency. , reduce the preparation cost and improve the effect of the contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take a certain amount of titanium tetraisopropoxide and slowly drop it into 4mL of isopropanol, and stir for 10min. Prepare a 50 mM hydrochloric acid solution with isopropanol as a solvent, and slowly add it dropwise to the newly prepared titanium tetraisopropoxide solution. The entire dropping process is controlled at about 10 minutes, and stirred for 30 minutes. The obtained solution was filtered with a 0.45mm PVDF syringe filter to obtain 0.25mmol / L, 0.33mmol / L, 0.42mmol / L and 0.5mmol / L titanium dioxide precursor solutions.

Embodiment 2

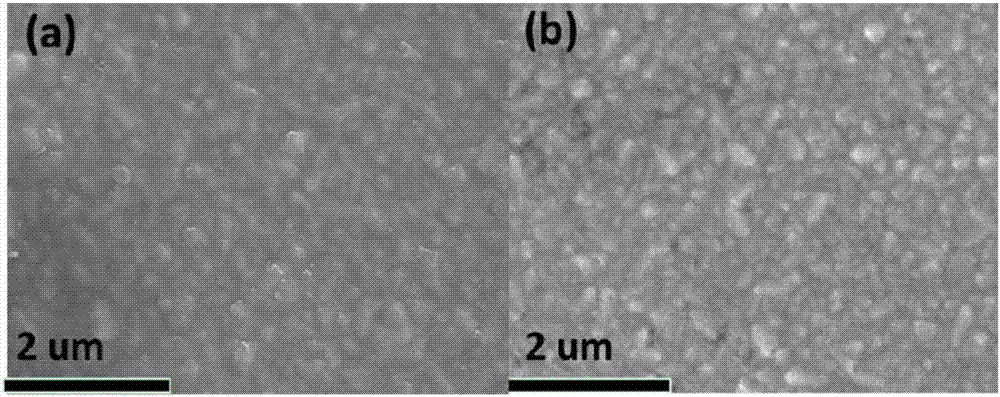

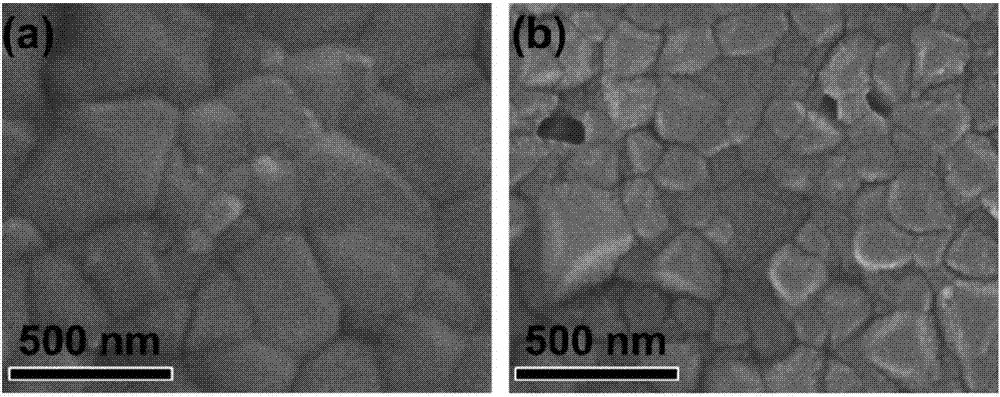

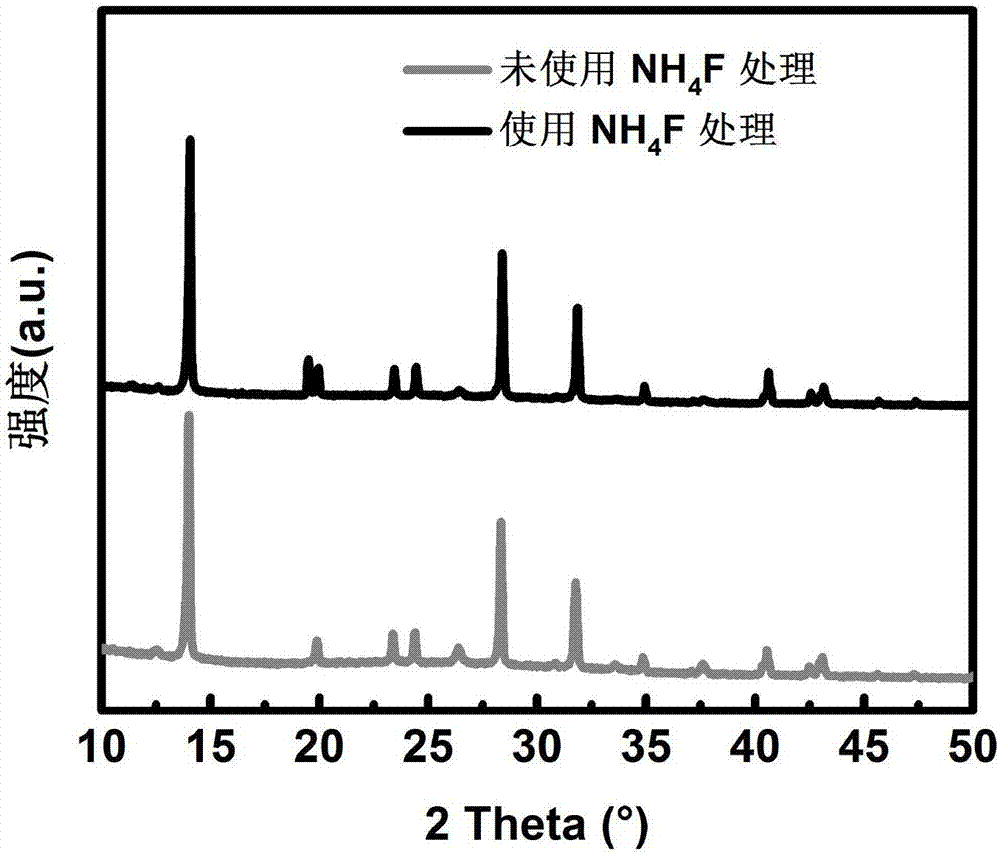

[0033]First cut the FTO conductive glass into a size of 1.5cm×2.0cm, use zinc powder and 2mol / L hydrochloric acid solution to etch a 0.5cm×1.5cm strip of FTO conductive glass, and use cleaning agent and deionized glass respectively for the etched glass Water, isopropanol and acetone were ultrasonically cleaned for 20 minutes, the cleaned glass was dried in an oven at 100°C for 30 minutes, and the dried glass was treated in a UV-ozone cleaning machine for 15 minutes to remove residual organic matter on the surface to obtain a cleaner surface. The configured 0.25mmol / L, 0.33mmol / L, 0.42mmol / L and 0.5mmol / L titanium dioxide precursor solutions were spin-coated on the conductive glass at a spin-coating speed of 3000rpm and a spin-coating time of 30s. The spin-coated film was transferred to a muffle furnace for sintering at 500°C for 30min with a heating rate of 2°C / min. After the procedure is over, cool to room temperature and take out for later use. Prepare a 0.2M ammonium fluor...

Embodiment 3

[0036] First cut the FTO conductive glass into a size of 1.5cm×2.0cm, use zinc powder and 2mol / L hydrochloric acid solution to etch a 0.5cm×1.5cm strip of FTO conductive glass, and use cleaning agent and deionized glass respectively for the etched glass Water, isopropanol and acetone were ultrasonically cleaned for 20 minutes, the cleaned glass was dried in an oven at 100°C for 30 minutes, and the dried glass was treated in a UV-ozone cleaning machine for 15 minutes to remove residual organic matter on the surface to obtain a cleaner surface. The configured 0.25mmol / L, 0.33mmol / L, 0.42mmol / L and 0.5mmol / L titanium dioxide precursor solutions were spin-coated on the conductive glass at a spin-coating speed of 3000rpm and a spin-coating time of 30s. The spin-coated film was transferred to a muffle furnace for sintering at 500°C for 30min with a heating rate of 2°C / min. After the procedure is over, cool to room temperature and take out for later use. Prepare a 0.4M ammonium fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com