Preparation method of fluoride-free single-crystal TiO2 nanometer thin film

A nano-thin film and single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of passivating surface activity, reducing photocatalytic performance and photoelectric conversion performance, and achieve high controllability , high photocatalytic performance and photoelectric conversion performance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

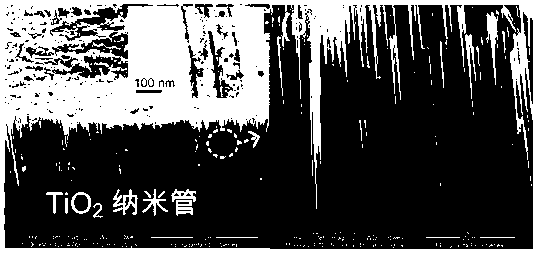

[0021] 1) Amorphous TiO was obtained by anodizing metal titanium sheets in fluorine-containing organic electrolyte (294 ml ethylene glycol, 6 ml water and 1 g ammonium fluoride). 2 Nanotube array films as precursors. It looks like figure 1 As shown, the length of the nanotube array can be controlled by adjusting parameters such as voltage and oxidation time;

[0022] 2) The obtained amorphous TiO 2 The nanotube array film precursor is soaked in an aqueous ammonium fluoride solution with a concentration of 0.1% by mass for 5 minutes, and taken out to dry for later use;

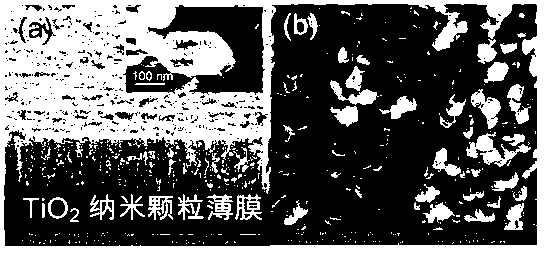

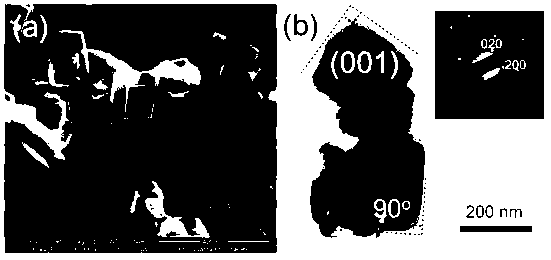

[0023] 3) The TiO treated in step 2) 2 The nanotube array film was placed in a closed container and calcined at 450 °C for 2 hours to obtain a single crystal anatase type (001) exposed TiO with fluorine on the surface 2 nano film. The SEM morphology of the film is shown in figure 2 As shown, the single-crystal anatase (001) exposed TiO contained 2 The particle size distribution of nanoparticles can be c...

Embodiment 2

[0026] 1) Using the method of anodizing metal titanium sheets, in the fluorine-containing organic electrolyte, obtain amorphous TiO 2 Nanotube array films as precursors;

[0027] 2) The obtained amorphous TiO 2 The nanotube array film precursor is soaked in an aqueous ammonium fluoride solution with a mass percent concentration of 0.5% for 5 minutes, and taken out to dry for later use;

[0028] 3) The TiO treated in step 2) 2 The nanotube array film is placed in a closed container and calcined at 500 ° C for 2 hours to obtain a single-crystal anatase (001) surface-exposed TiO with fluorine on the surface 2 nano film;

[0029] 4) TiO exposed on the fluorine-containing single crystal anatase (001) surface obtained in step 3) 2 Nano-film, further calcined in air at 500 ° C for 3 hours for defluorination treatment, that is, TiO with fluorine-free single crystal anatase (001) surface exposed 2 nano film.

Embodiment 3

[0031] 1) Using the method of anodizing metal titanium sheets, in the fluorine-containing organic electrolyte, obtain amorphous TiO 2 Nanotube array films as precursors;

[0032] 2) The obtained amorphous TiO 2 The nanotube array film precursor is soaked in an aqueous ammonium fluoride solution with a mass percent concentration of 1.0% for 4 minutes, and taken out to dry for later use;

[0033] 3) The TiO treated in step 2) 2The nanotube array film is placed in a closed container and calcined at 550 ° C for 1 hour to obtain a single-crystal anatase (001) surface-exposed TiO with fluorine on the surface 2 nano film;

[0034] 4) TiO exposed on the fluorine-containing single crystal anatase (001) surface obtained in step 3) 2 Nano-film, further calcined in air at 550 ° C for 2 hours for defluorination treatment, that is, TiO with fluorine-free single crystal anatase (001) surface exposed 2 nano film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com