Combined process of catalytic gasoline selective hydrodesulfurization and light gasoline etherification

A catalytic cracking gasoline and combined process technology, applied in the field of catalytic cracking gasoline selective hydrodesulfurization and light gasoline etherification combined process, can solve the problems of increasing investment costs of enterprises, reduce olefin content, save equipment investment costs and production Operating cost, effect of increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

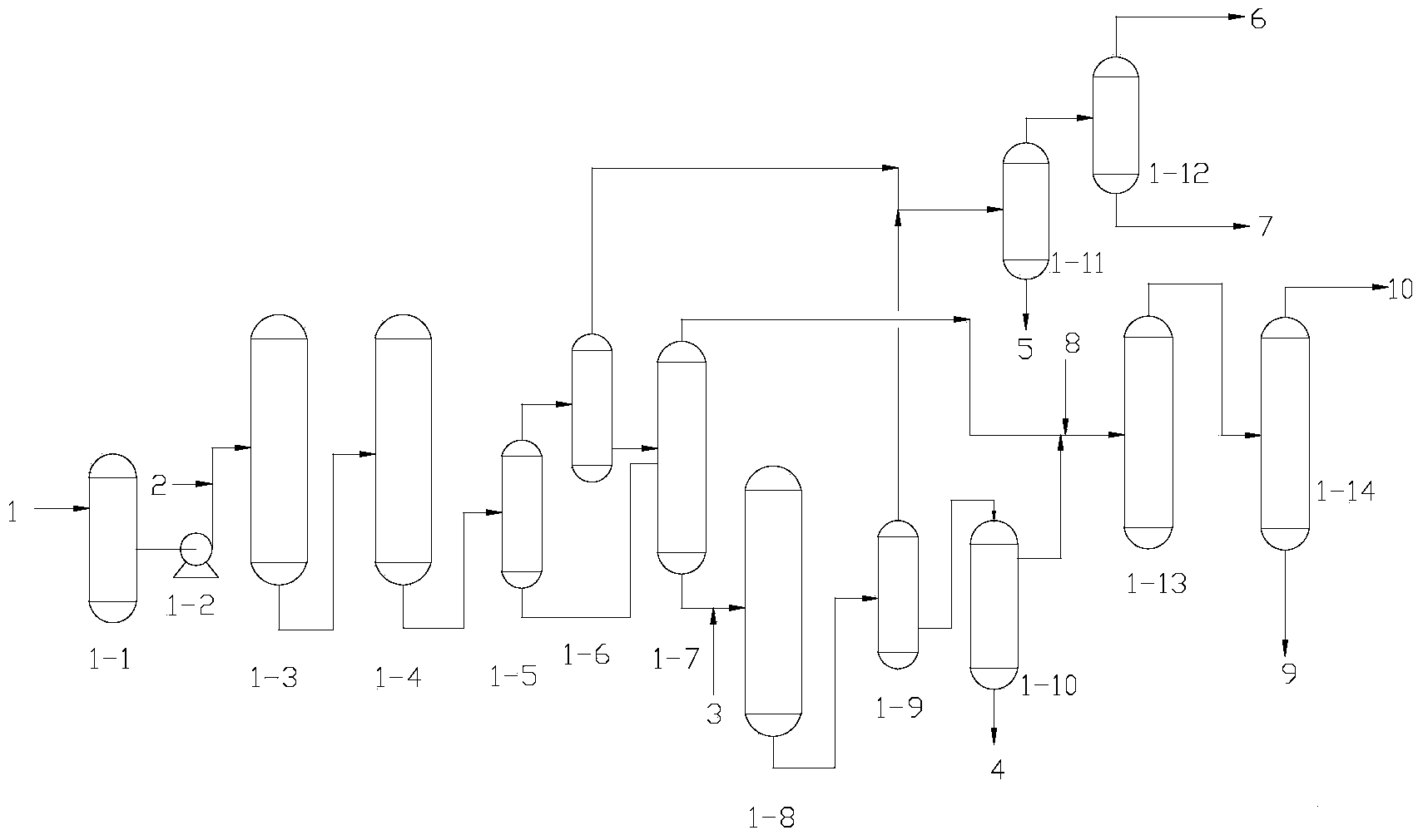

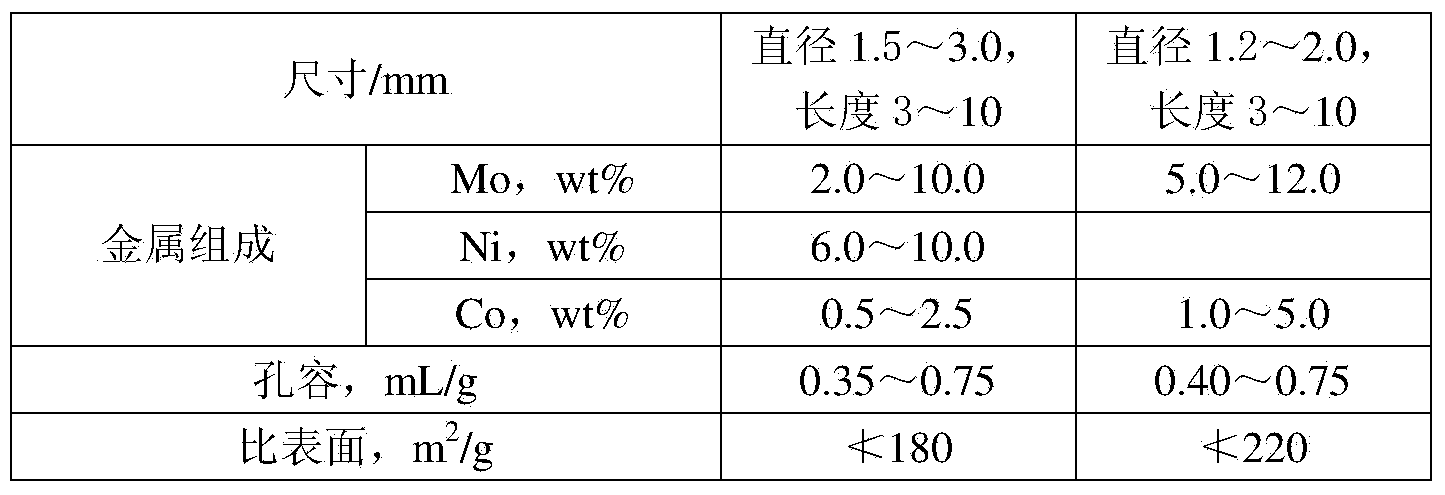

[0023] 1. The raw material oil (catalytic cracking gasoline 1) is first sent to the raw material buffer tank 1-1 after removing impurities and particles of 10 μm, and then boosted by the catalytic gasoline pump 1-2, mixed with hydrogen 2, and enters the selective In the hydrogenation reactor 1-3, and under the action of the commercially available hydrogenation catalyst FDJY-01 produced by Jiangsu Jiayuxin Co., Ltd., selective hydrogenation is carried out to remove dienes and colloid components in the raw oil, and make part of Hydrocarbons are isomerized. The operating conditions of the hydrogenation process are: hydrogen partial pressure 1.6MPa, inlet reaction temperature 120-180°C, liquid hourly space velocity 5-15h-1. Then enter the pre-desulfurization reactor 1-4, and remove active sulfur under the action of commercially available catalyst FDJZ-05. The reaction conditions are: reaction inlet temperature 230-260°C, outlet temperature 240-270°C, operating pressure 1.0 ~2.0MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com