Light gasoline catalytic rectification etherification device and technique

A catalytic rectification and light gasoline technology, which is applied in the fields of multi-stage series refining process, petroleum industry, and hydrocarbon oil treatment, and can solve the problems affecting the oxygen stability index of gasoline, automobile exhaust pollution, and affecting the full combustion of gasoline, etc. , to achieve the effect of reducing olefin content, reducing raw material consumption and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

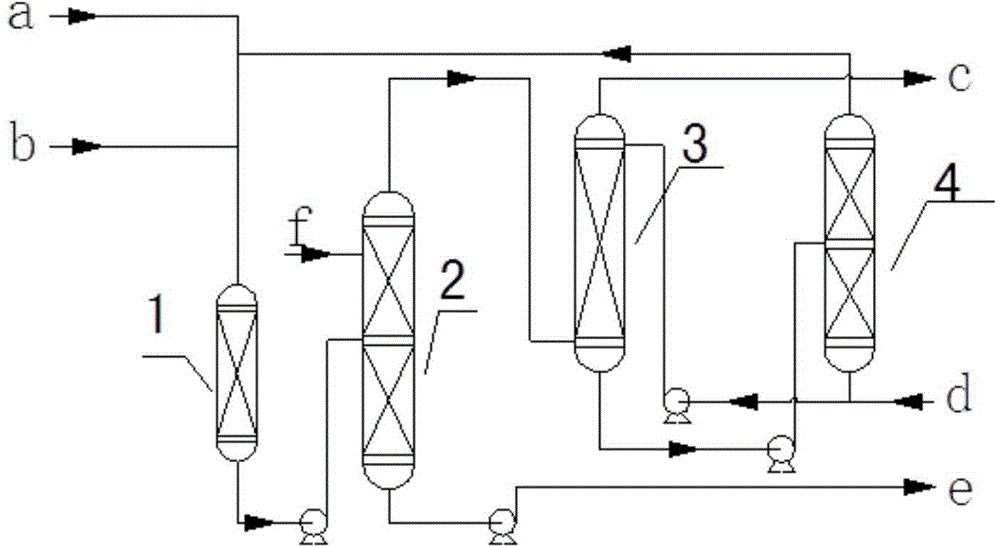

[0033] A light gasoline catalytic rectification etherification device, including a pre-reactor, a catalytic reaction rectification tower, a methanol extraction tower and a methanol refining tower;

[0034] The top of the prereactor is provided with a prereactor feed port, and the bottom end is provided with a prereactor discharge port;

[0035] The top of the catalytic reaction rectification tower is provided with a discharge port at the top of the catalytic reaction rectification tower, the upper part is provided with the methanol feed port of the catalytic reaction rectification tower and the feed port of the catalytic reaction rectification tower, and the bottom of the tower is provided with an etherification Rear product outlet;

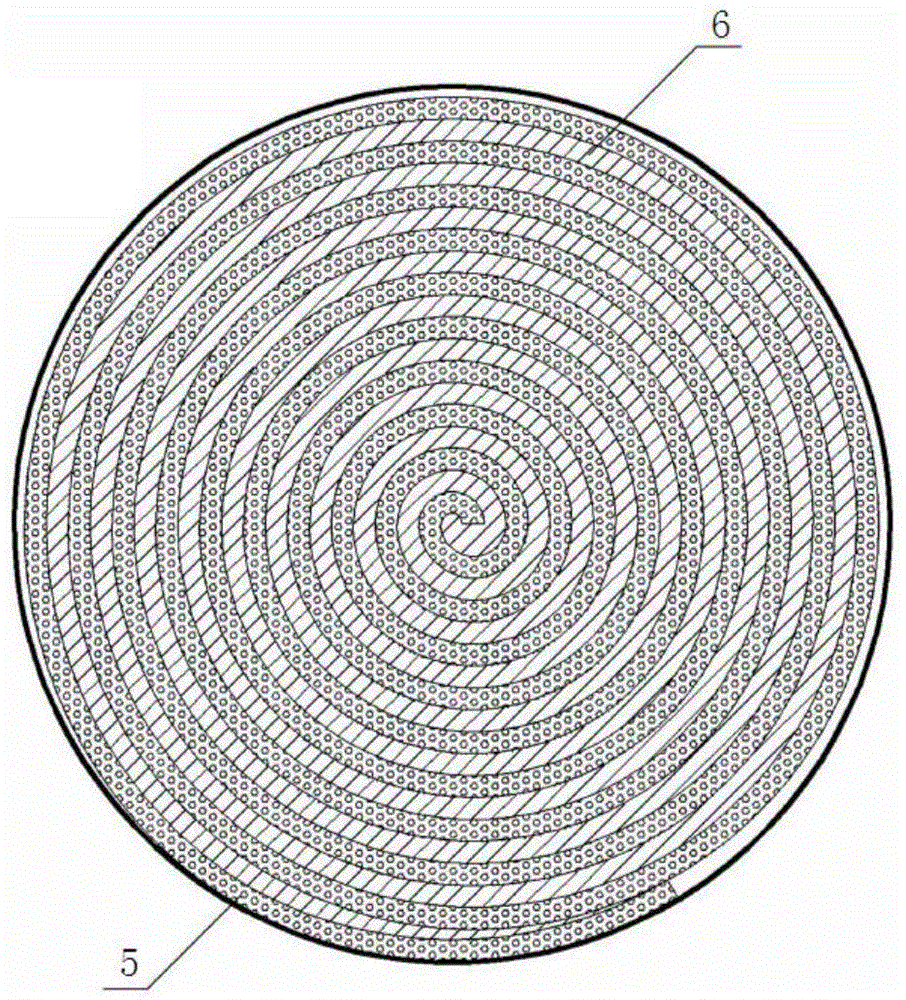

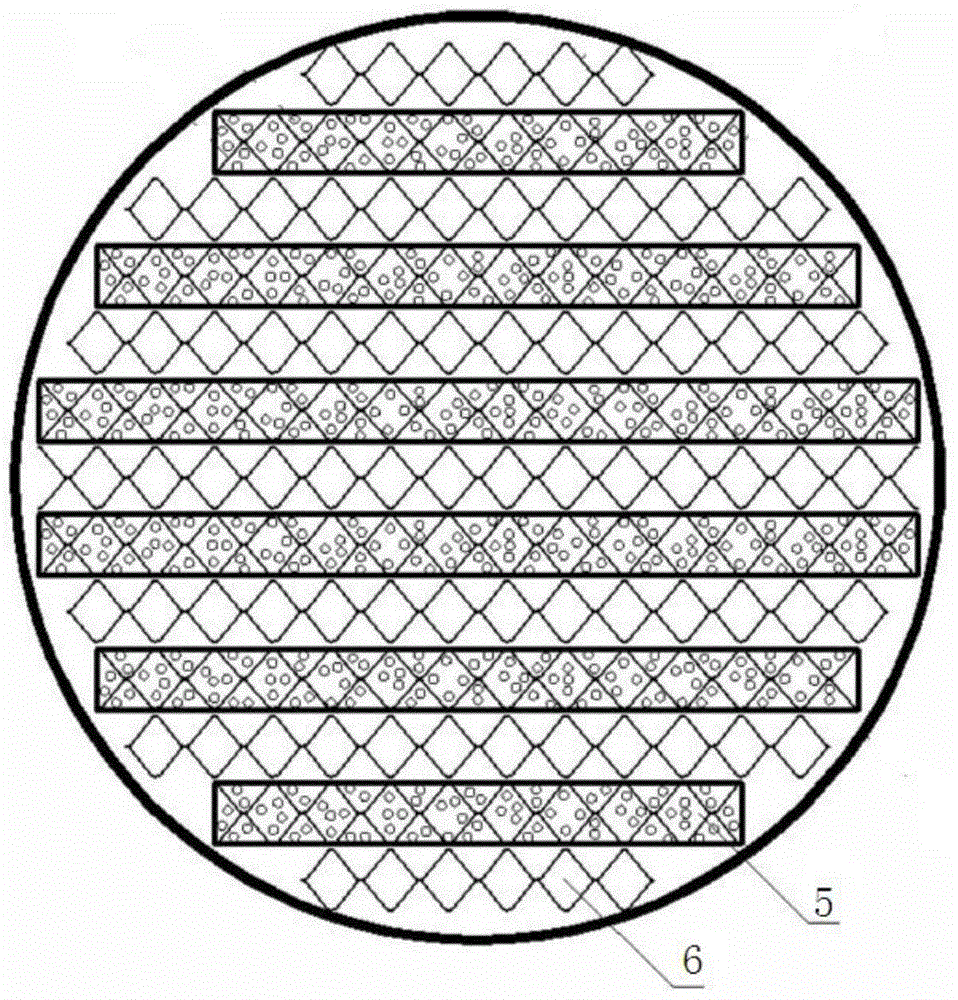

[0036] The rectification section and the etherification reaction section of the catalytic reaction rectification tower adopt window-opening flow-guiding structured packing, and each packing layer contains two different structures of component A a...

Embodiment 2

[0058] The light gasoline catalytic rectification etherification device adopted in the present embodiment is the same as that in Embodiment 1.

[0059] In this embodiment, the process steps of using the above-mentioned device to carry out the etherification of light gasoline by catalytic rectification are:

[0060] 1.1, the light gasoline raw material and methanol containing active olefins (mainly composed of 2-methyl-1-butene, 2-methyl-2-butene) enter the prereactor from the feed port of the prereactor for preliminary The etherification reaction generates TAME, wherein: the feed flow rate of methanol to the prereactor is 6.44×10 3 kg / h, the feed flow rate of light gasoline to the prereactor is 5.00×10 4 kg / h, the temperature of the pre-reactor is 60°C, the operating pressure of the pre-reactor is 0.1 MPa, and the reacted mixture is taken out from the outlet of the pre-reactor.

[0061] 1.2. Enter the mixture produced in step 1.1 and newly supplemented methanol into the cata...

Embodiment 3

[0074] The light gasoline catalytic rectification etherification device adopted in the present embodiment is the same as that in Embodiment 1.

[0075] In this embodiment, the process steps of using the above-mentioned device to carry out the etherification of light gasoline by catalytic rectification are:

[0076] 1.1, the light gasoline raw material and methanol containing active olefins (mainly composed of 2-methyl-1-butene, 2-methyl-2-butene) enter the prereactor from the feed port of the prereactor for preliminary The etherification reaction generates TAME, wherein: the feed flow rate of methanol to the prereactor is 9.06×10 3 kg / h, the feed flow rate of light gasoline to the prereactor is 6.00×10 4 kg / h, the temperature of the pre-reactor is 45°C, the operating pressure of the pre-reactor is 0.1 MPa, and the reacted mixture is taken out from the outlet of the pre-reactor.

[0077] 1.2. Enter the mixture produced in step 1.1 and newly supplemented methanol into the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com