Variable-cross-section gradient foam core cylinder anti-explosion structure

A technology of explosion-proof structure and variable cross-section, which is applied in the direction of blasting, protective clothing, protective equipment, etc., can solve the problems of inconvenient to carry, high-quality explosion-proof structure, etc., and achieve the effect of improving anti-blast performance, simple structure, and reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

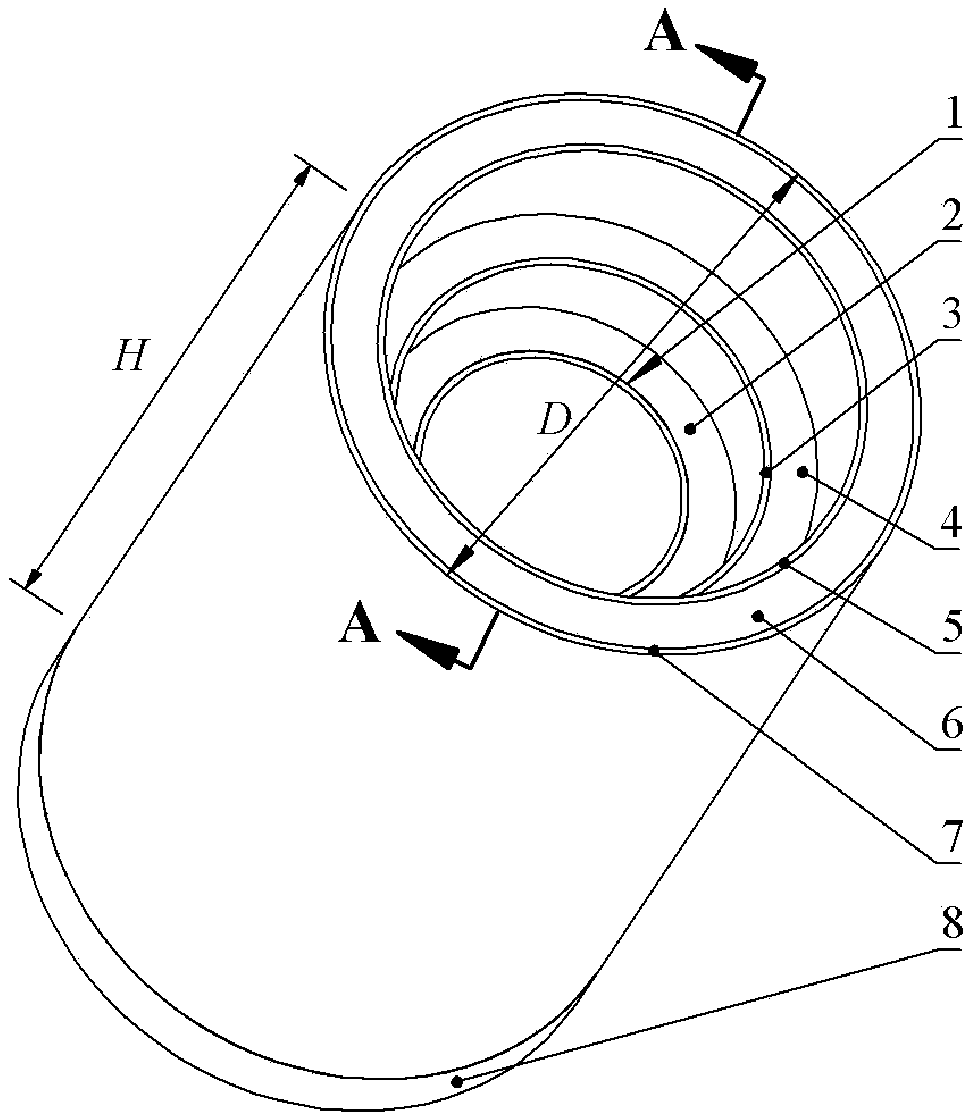

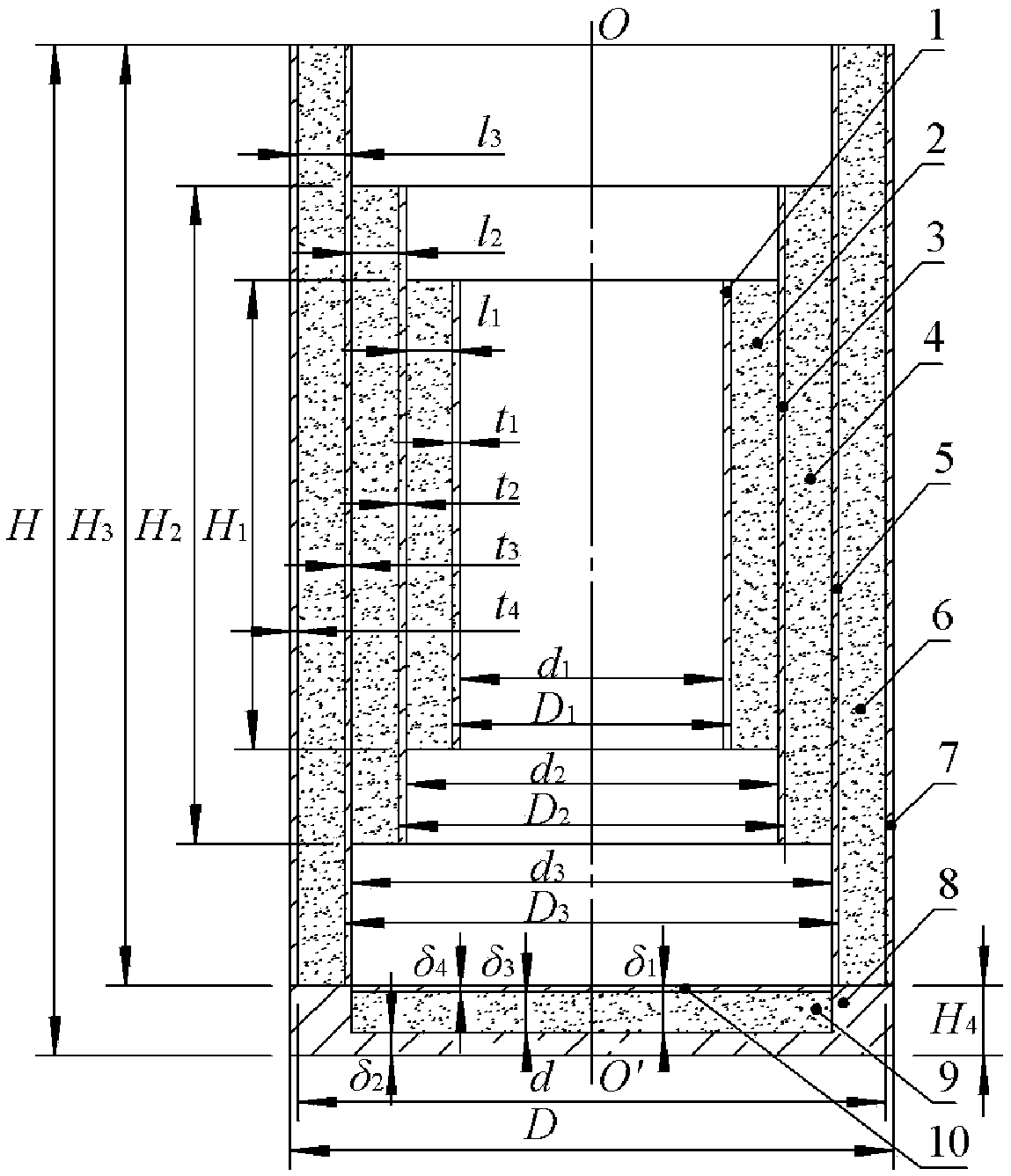

[0025] Such as figure 1 As shown, the explosion-proof structure of the variable cross-section gradient foam sandwich cylinder of the present invention is cylindrical as a whole, consisting of an inner panel 1, an inner core 2, a middle panel 3, a middle core 4, an outer panel 5, an outer core 6, and a shell 7. The bottom cover 8, the bottom core 9 and the bottom panel 10 are composed. The outer diameter of the present invention is D, and D is determined according to the antiknock requirement, satisfying 0.1m<D<2m, and the height is H, satisfying D<H<2D.

[0026] Such as figure 2 As shown, the inner panel 1, the inner core 2, the middle panel 3, the middle core 4, the outer panel 5, the outer core 6, and the shell 7 are coaxially assembled from inside to outside, and the bottom cover 8 is welded on the outer panel 5, the outer Core body 6 and housing 7 lower end faces, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com