Nonmetallic gasoline antiknock

A gasoline antiknock agent, non-metallic technology, applied in the field of new non-metallic gasoline antiknock agents, can solve the problems of three-way catalytic converter damage, reduce gasoline combustion speed, research stagnation, etc., achieve high application value and economic benefits, reduce Environmental hazards, excellent anti-knock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 80g of ester compound (methyl acetate, dimethyl malonate mixture, mass ratio is 2:1), 20g of oxygen-containing arylamine compound (p-ethoxyaniline, 4-methyl Oxygen-N-methylaniline mixture (mass ratio: 1:1) and 0.1g of 2,6-di-tert-butyl-p-cresol, mixed and stirred evenly to obtain a light yellow transparent liquid, which is a non-metallic gasoline antiknock agent;

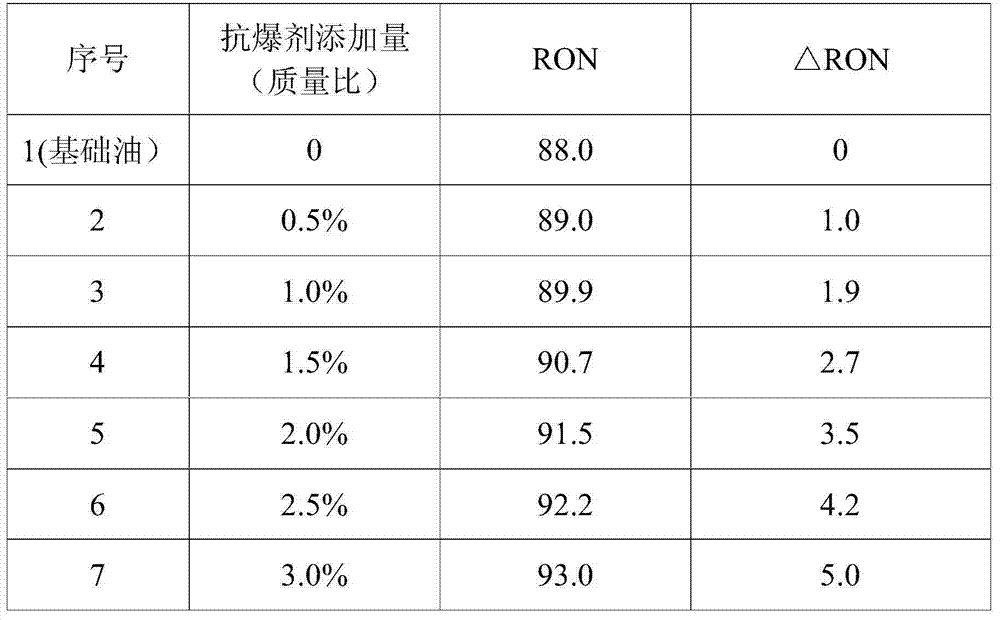

[0028] Add the new non-metallic gasoline antiknock agent into 88# FCC gasoline according to different masses, and measure the gasoline octane number promotion value. The measurement results are shown in the following table:

[0029]

Embodiment 2

[0031]Into the 250ml four-necked flask, add 70g ester compound (ethyl acetate, dimethyl malonate mixture, mass ratio is 2:1), 30g oxygen-containing arylamine compound (p-methoxyaniline, 4-methoxyaniline, Oxygen-N-methylaniline mixture, mass ratio is 1:1) and 0.1g2-tert-butyl-p-cresol, mix and stir, obtain light yellow transparent liquid, be non-metallic gasoline antiknock agent; (in order to be with Corresponding to our preferred substance, I replaced some substances in this example)

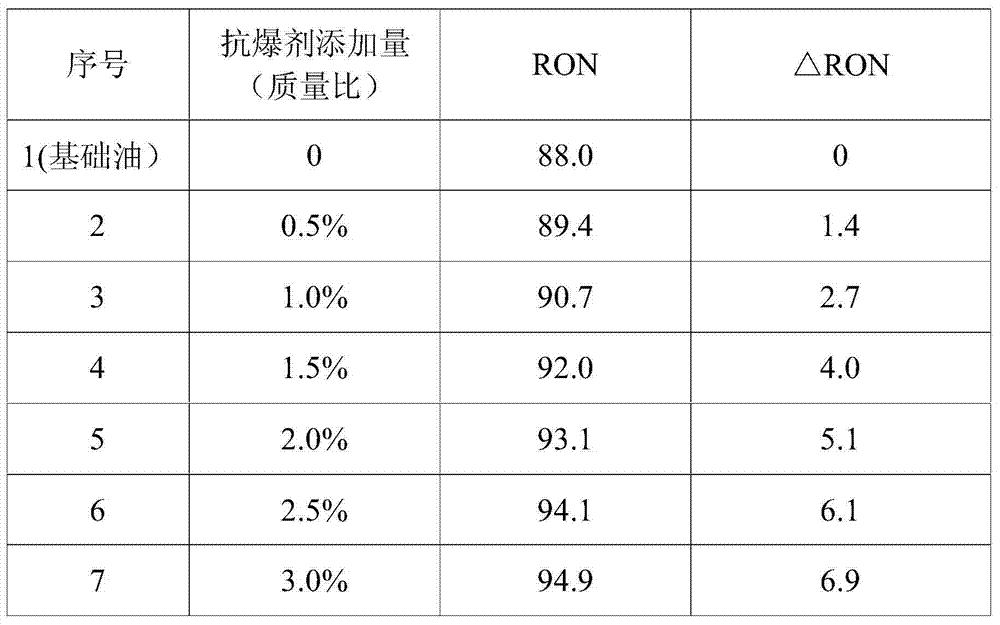

[0032] Add the new non-metallic gasoline antiknock agent into 88# FCC gasoline according to different masses, and measure the gasoline octane number promotion value. The measurement results are shown in the following table:

[0033]

Embodiment 3

[0035] Add 50g of ester compounds (methyl acetate, dimethyl malonate mixture, mass ratio is 2:1), 50g of oxygen-containing arylamine compounds (p-ethoxyaniline, 4-methoxyaniline, A mixture of oxy-N-methylaniline (mass ratio: 1:1) and 0.1g of 2,6-di-tert-butyl-p-cresol, mixed and stirred evenly to obtain a light yellow transparent liquid, which is a new type of non-metallic gasoline antiknock agent.

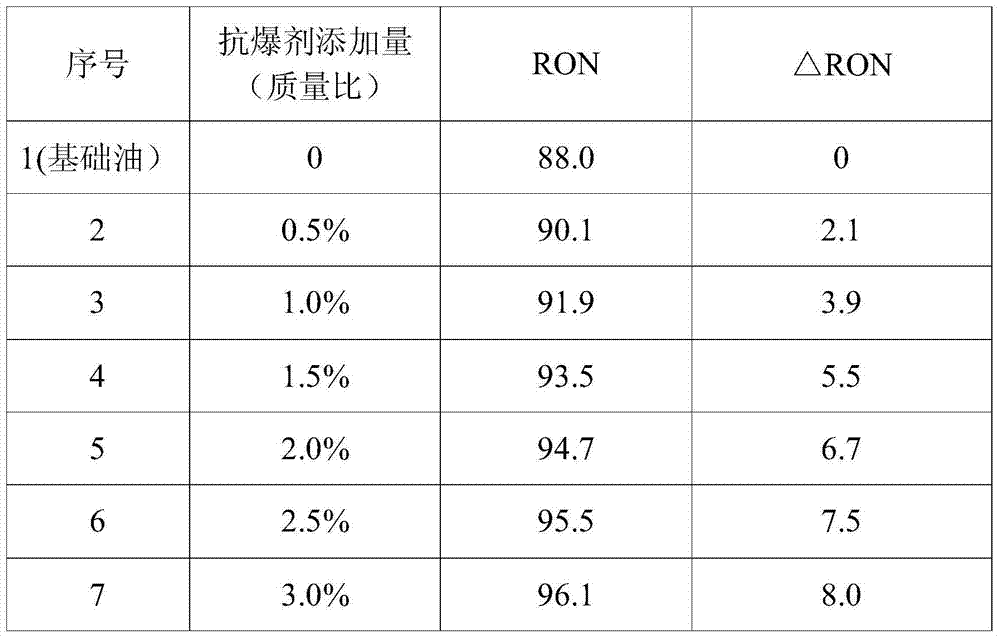

[0036] Add the new non-metallic gasoline antiknock agent into 88# FCC gasoline according to different masses, and measure the gasoline octane number promotion value. The measurement results are shown in the following table:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com