Patents

Literature

57results about How to "Realize upgrading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

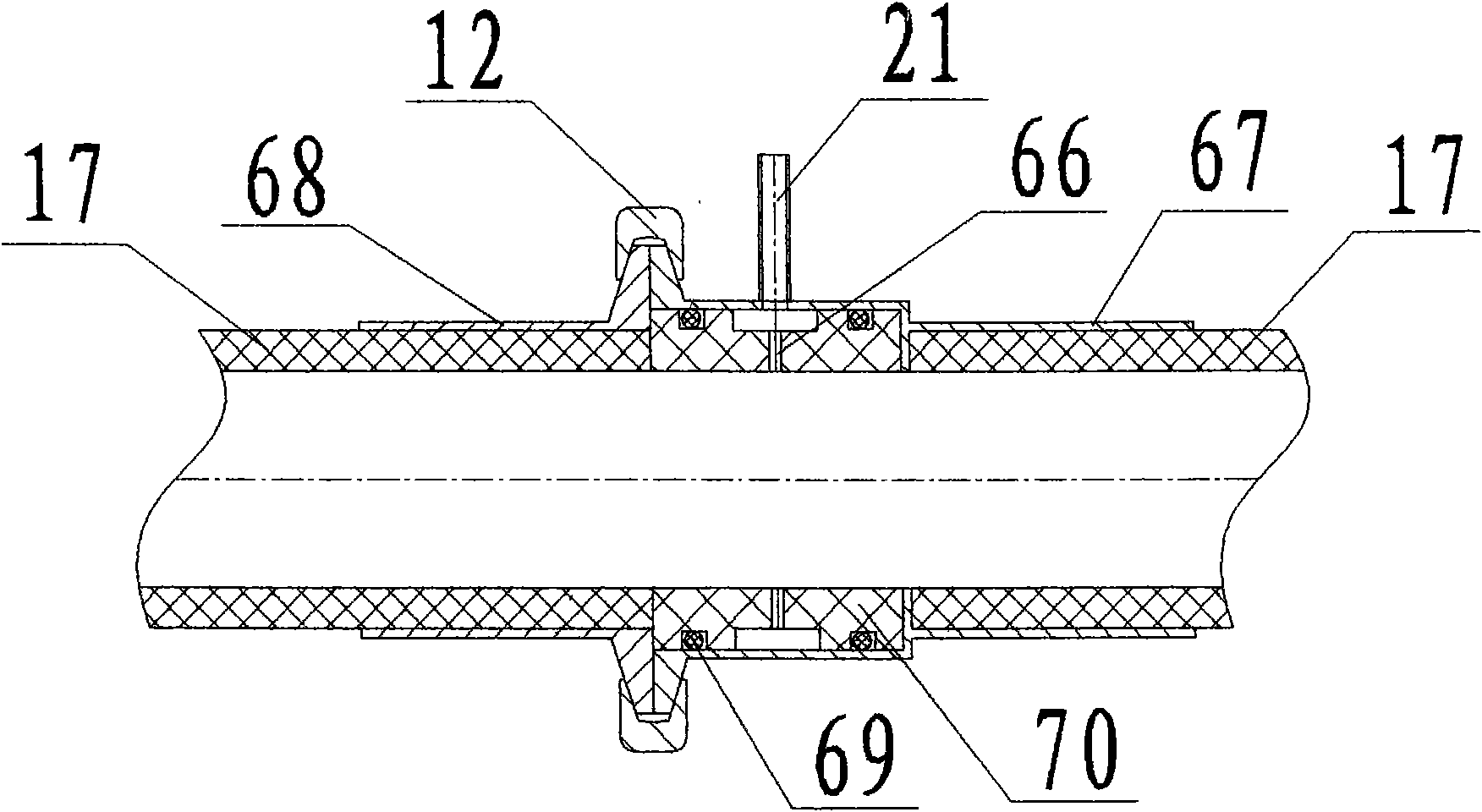

Wet spraying machine of concrete drier

InactiveCN101614128AImprove sealingReduce air and dust leakageUnderground chambersTunnel liningPulp and paper industryWater pressure

The invention relates to a wet spraying machine of concrete drier, which comprises a spraying machine, a water pressure booster and a powdered accelerator adder. The wet spraying machine of concrete drier integrates the advantages of a dry spraying machine and a wet spraying machine, achieves the upgrade of the concrete spraying technology, improves the sealing performance and reduces the dust generation and the pipe plugging times. The water pressure booster is designed to enable the water pressure to be higher than the wind pressure; water is added into a concrete conveying rubber pipe, so that water and concrete are effectively mixed to achieve the operating process of wet spraying of dry material. The invention has simple operation and can achieve the effects of low rebound and less power. The powdered accelerator adder enables the powdered accelerator to be quantitatively, uniformly and continuously added in the wet spraying process.

Owner:周德祥

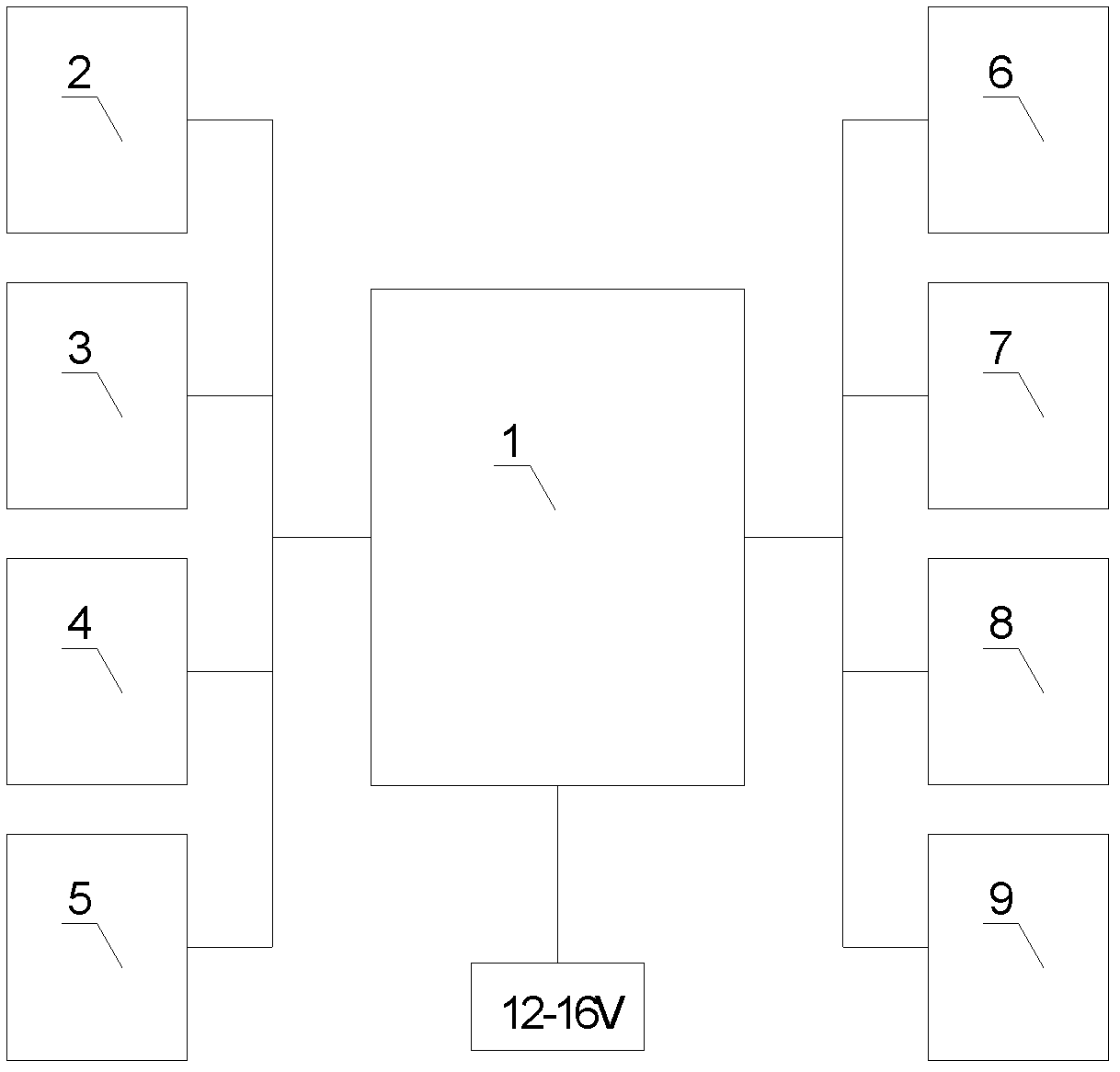

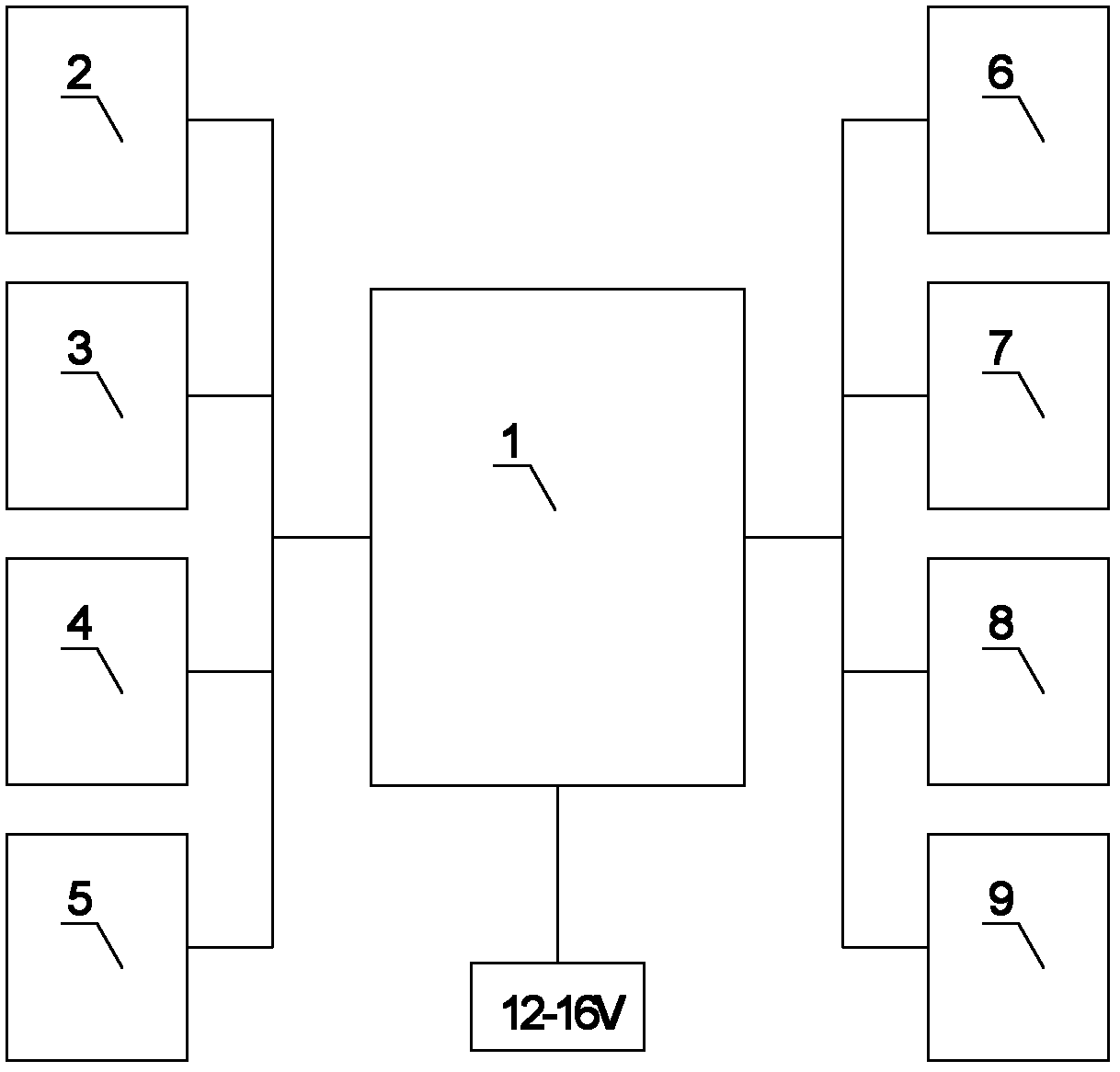

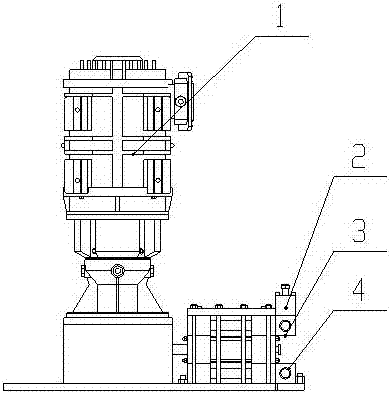

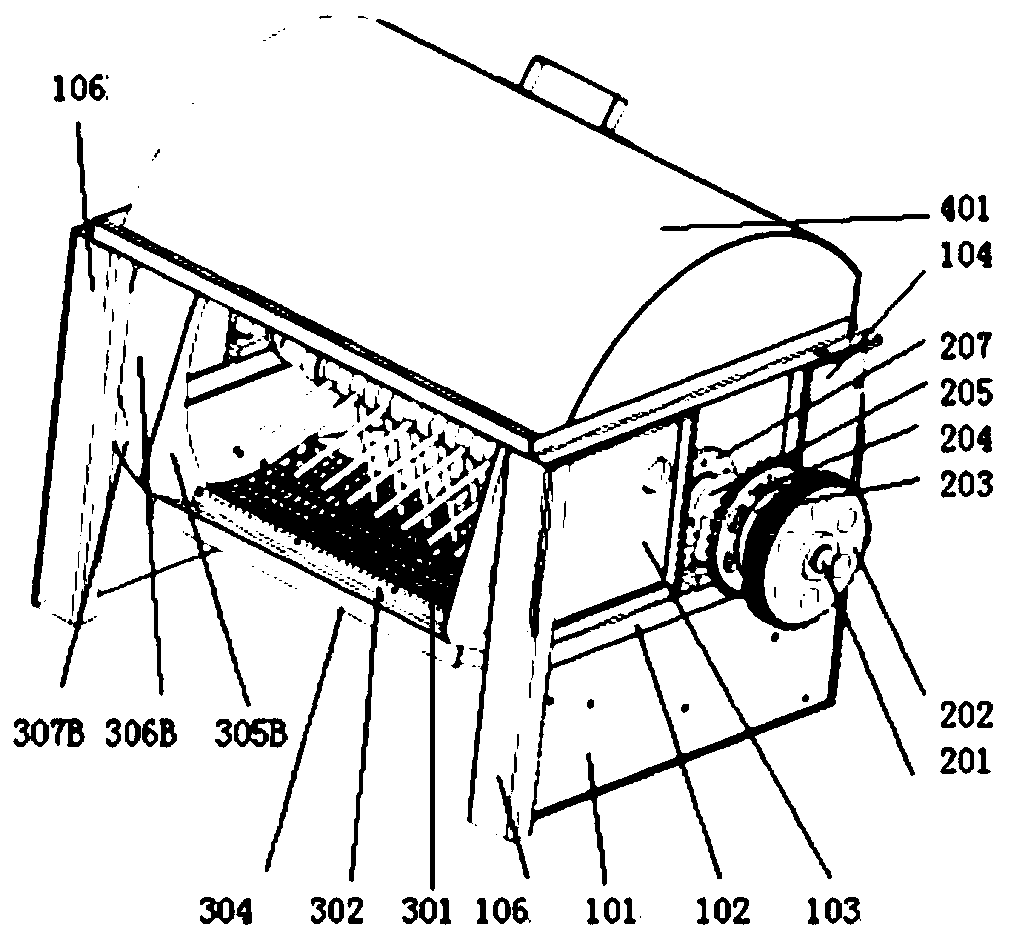

Automatic control system for large-sized cotton picking machine

InactiveCN102354195ARealize upgradingRealize digital collectionPicking devicesProgramme total factory controlArea networkAutomatic control

The invention discloses an automatic control system for a large-sized cotton picking machine. The automatic control system comprises a vehicle-mounted electronic control unit (1) of the cotton picking machine and is characterized in that: the vehicle-mounted electronic control unit (1) is connected with an engine assembly signal acquisition module (2), a complete vehicle state switch signal acquisition module (3), a cotton picking head state signal acquisition module (4) and an automatic line aligning sensor signal acquisition module (5) respectively and is used for receiving data of the engine assembly signal acquisition module (2), the complete vehicle state switch signal acquisition module (3), the cotton picking head state signal acquisition module (4) and the automatic line aligning sensor signal acquisition module (5); and the vehicle-mounted electronic control unit (1) is connected with an instrument and meter display module (6), a complete vehicle state indicator light control module (7), a cotton picking head control module (8) and an automatic line aligning device control module (9) respectively and is used for sending control signals of the instrument and meter display module (6), the complete vehicle state indicator light control module (7), the cotton picking head control module (8) and the automatic line aligning device control module (9). In the invention, controller area network (CAN) transmission is realized by embedded equipment, and a general automatic control platform is provided for the cotton picking machine; and a field bus technology is applied to control of the cotton picking machine so as to complete digital transmission of system data and the data acquisition and control of all monitoring points of the cotton picking machine.

Owner:GUIYANG KING TECH SCI & TECH

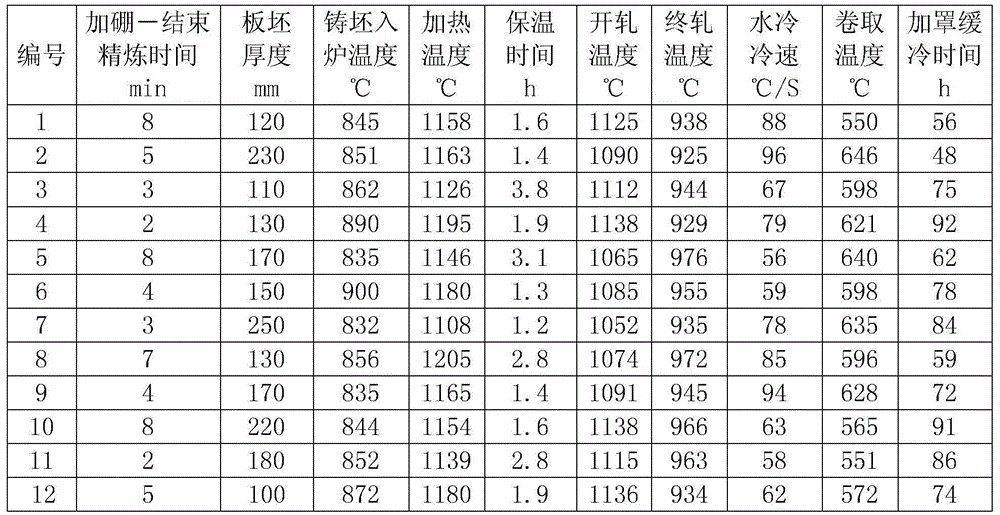

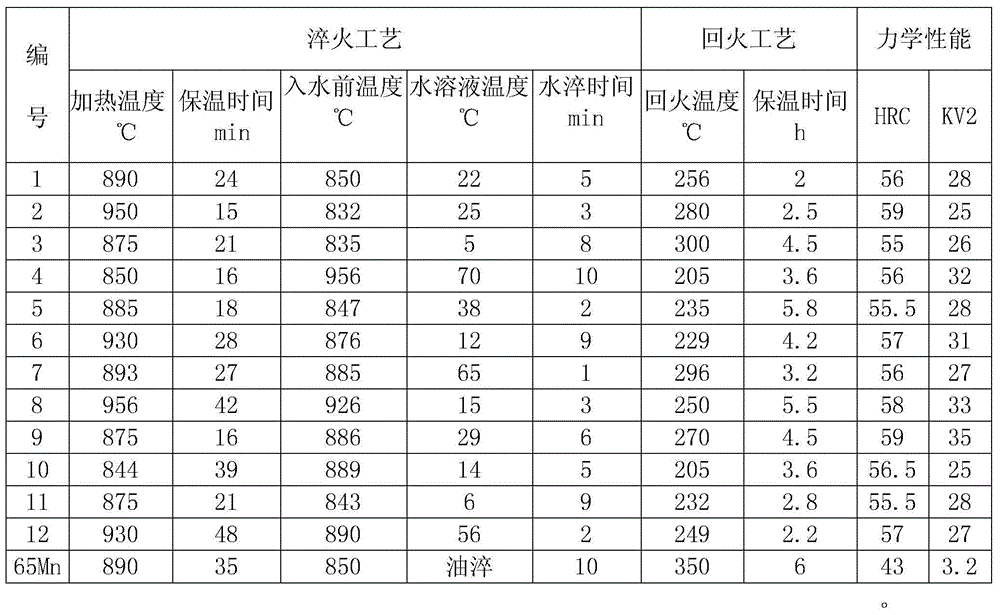

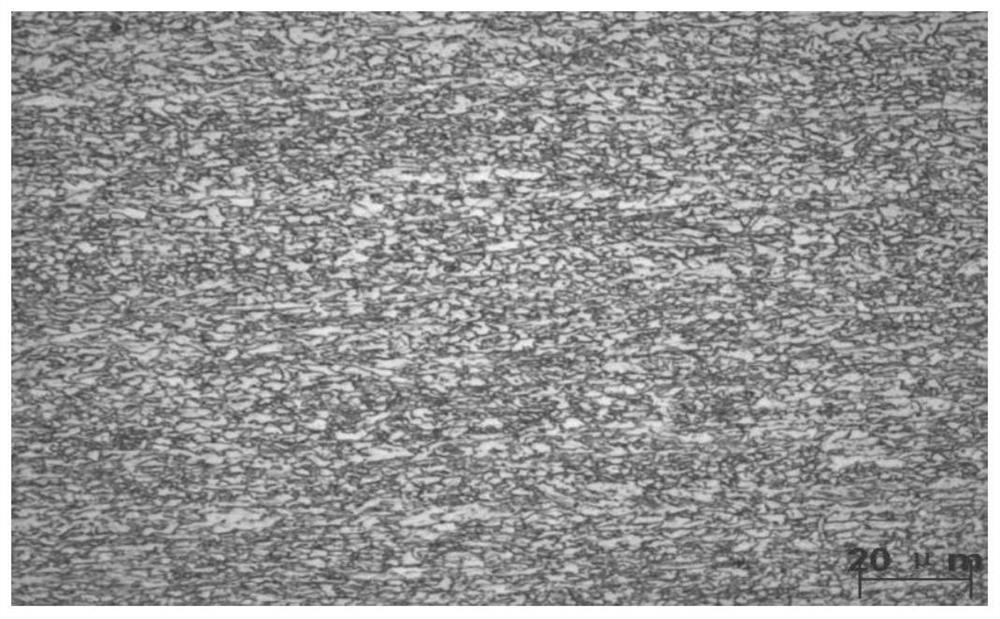

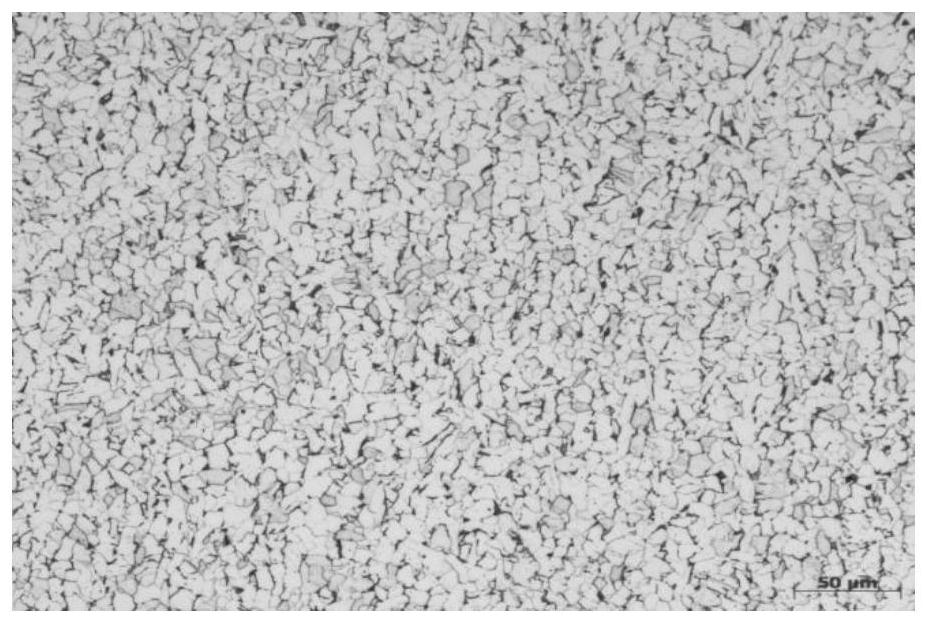

Steel for disk blade, production method and disk blade treatment method

ActiveCN105296866AImprove hardenabilityExtended service lifeTemperature control deviceWork treatment devicesChemical compositionHardness

The invention provides steel for a disk blade, a production method and a disk blade treatment method. The steel includes chemical components of, by weight, 0.25% to 0.35% of C, 0.1% to 0.40% of Si, 1.0% to 1.5% of Mn, not larger than 0.5% of Cr, 0.01% to 0.05% of Al, 0.015% to 0.06% of Ti, 0.001% to 0.006% of B, not larger than 0.0070% N, not larger than 0.020% of P, not larger than 0.015% of S and the balance Fe and impurities, wherein the inequation 4<=(Ti+Al) / N<=20 is satisfied. Continuous casting and rolling is adopted, the cast blank furnace entry temperature is larger than 830 DEG C, the heating temperature ranges from 1100 DEG C to 1200 DEG C, and the temperature is kept for 1 h to 4 h; and the rough rolling and finish rolling temperature ranges from 920 DEG C to 980 DEG C. After finish rolling is finished, the steel is cooled to the temperature ranging from 550 DEG C to 650 DEG C at the cooling speed of 50-100 DEG C / s and then coiled, and the steel is covered with a hood and slowly cooled for over 48 h. The heating temperature of a disk blade blank ranges from 800 DEG C to 1000 DEG C and the temperature is kept for 15 min to 50 min. The pre-quenching temperature is larger than or equal to 830 DEG C, water quenching is performed for 1 min to 10 min, and the water temperature at which the steel is away from water is smaller than or equal to 200 DEG C. The tempering temperature ranges from 200 DEG C to 300 DEG C and the temperature is kept for 2 h to 6 h. The hardness of the disk blade is larger than 55 HRC, the ballistic work is larger than 25 J, abrasive resistance, toughness and plasticity are good, and the service life is longer than that of a 65 Mn steel disk blade.

Owner:ANGANG STEEL CO LTD

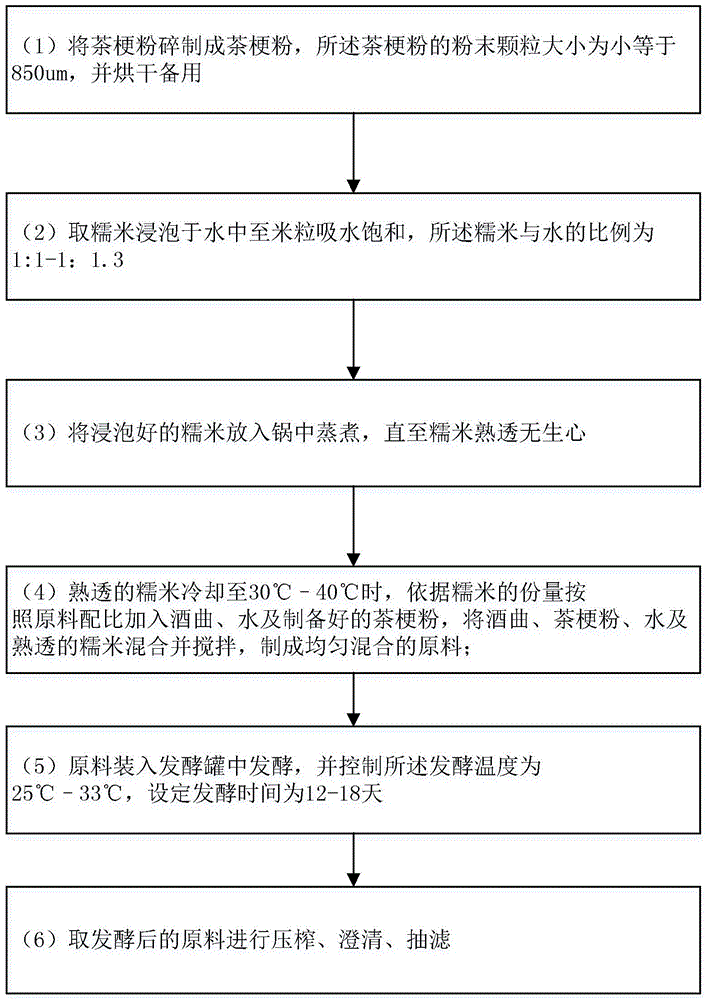

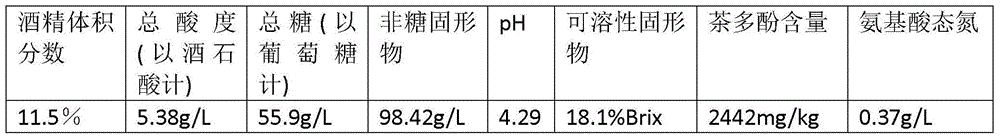

Pure fermentation tea liquor and method for brewing same

InactiveCN105039073ARealize upgradingImprove efficiencyAlcoholic beverage preparationYeastGreen Tea Polyphenols

The invention provides pure fermentation tea liquor. The pure fermentation tea liquor comprises (by weight) 8-10 parts of tea stems, 35-45 parts of glutinous rice, 0.29-0.38 part of distiller's yeast and 70-105 parts of water. The invention further discloses a method for brewing the pure fermentation tea liquor. The pure fermentation tea liquor and the method have the advantages that the content of tea polyphenols in the pure fermentation tea liquor which is brewed by the aid of the method according to raw material proportions is dozens of times the content of tea polyphenols in tea liquor brewed by the aid of common technological manufacturing procedures, and accordingly excellent healthcare effects can be realized by the pure fermentation tea liquor.

Owner:武夷学院

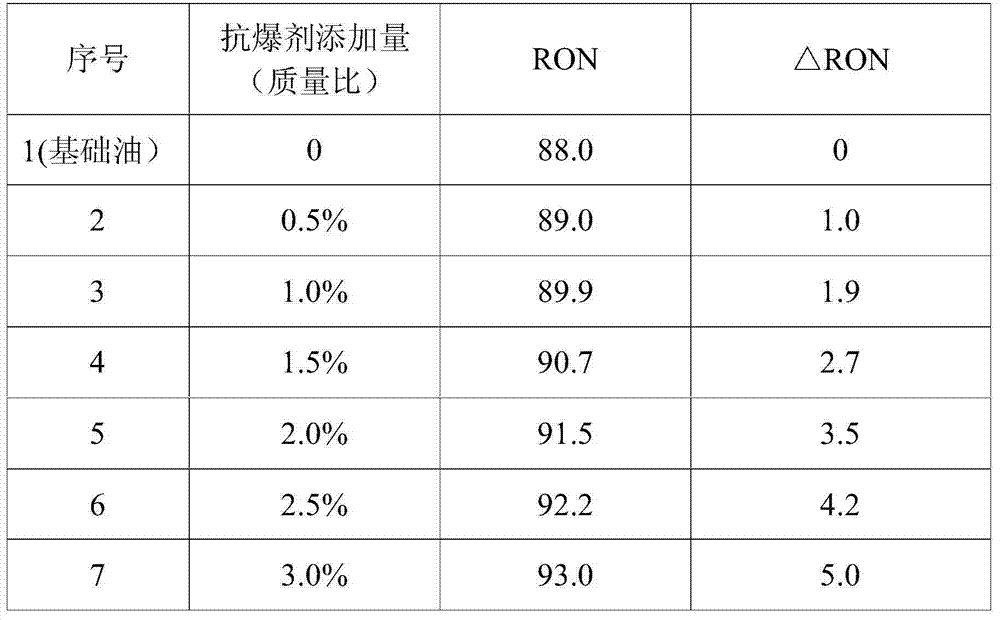

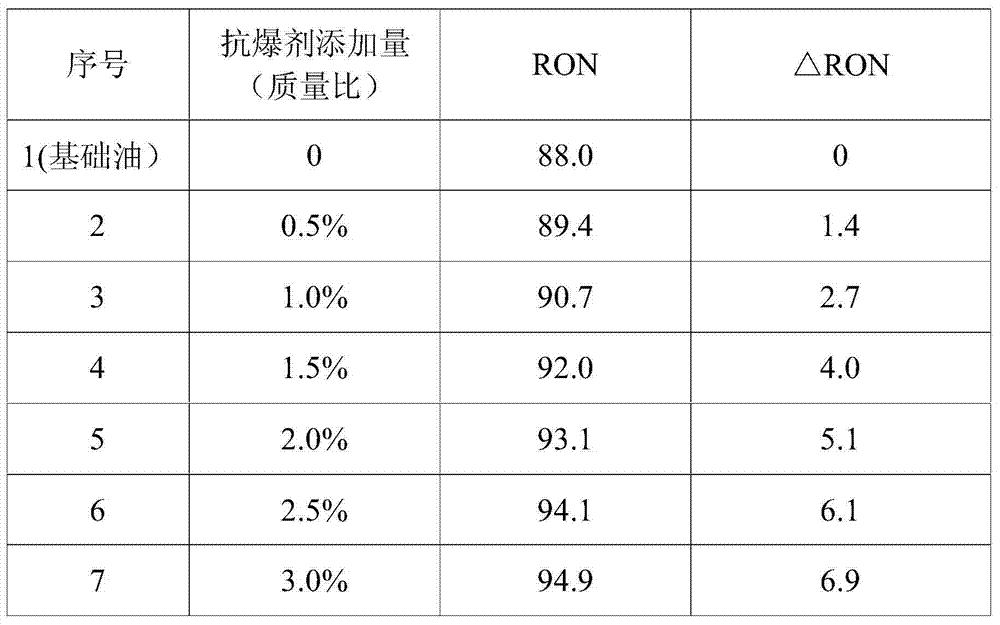

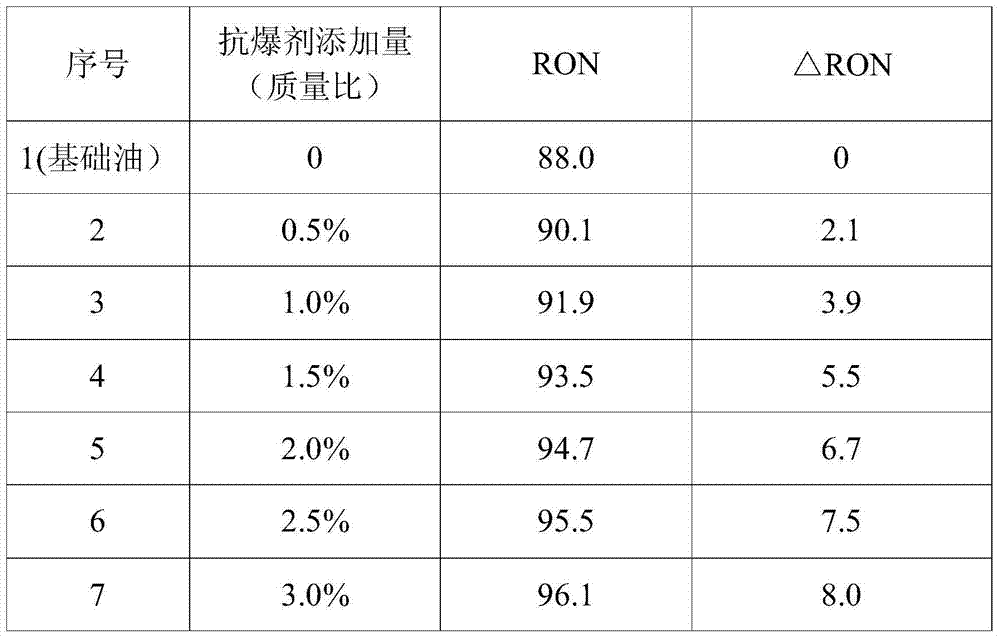

Nonmetallic gasoline antiknock

ActiveCN104711049AReduced knock intensityBoost octaneLiquid carbonaceous fuelsFuel additivesChemistryPetrochemical

The invention relates to the technical field of petrochemical engineering, in particular to a novel nonmetallic gasoline antiknock. The nonmetallic gasoline antiknock consists of the following components in parts by weight; 20 to 50 parts of an oxygen-containing arylamine compound, 50 to 80 parts of an ester compound and 0.01 to 1 part of a phenolic compound, and does not contain any metallic component. An experimental result of the antiknock shows that the octane value of gasoline can be increased by 1.0 to 8.0 units after 0.5 to 3 weight percent of the novel nonmetallic gasoline antiknock is added into gasoline and high antiknock performance is achieved; in addition, the novel nonmetallic gasoline antiknock has the advantages of low raw material cost, performance indexes consistent with a national V gasoline standard, no bad influence on a spark plug engine, capability of effectively reducing environmental hazards, and the like, and has high application value and good economic benefits.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

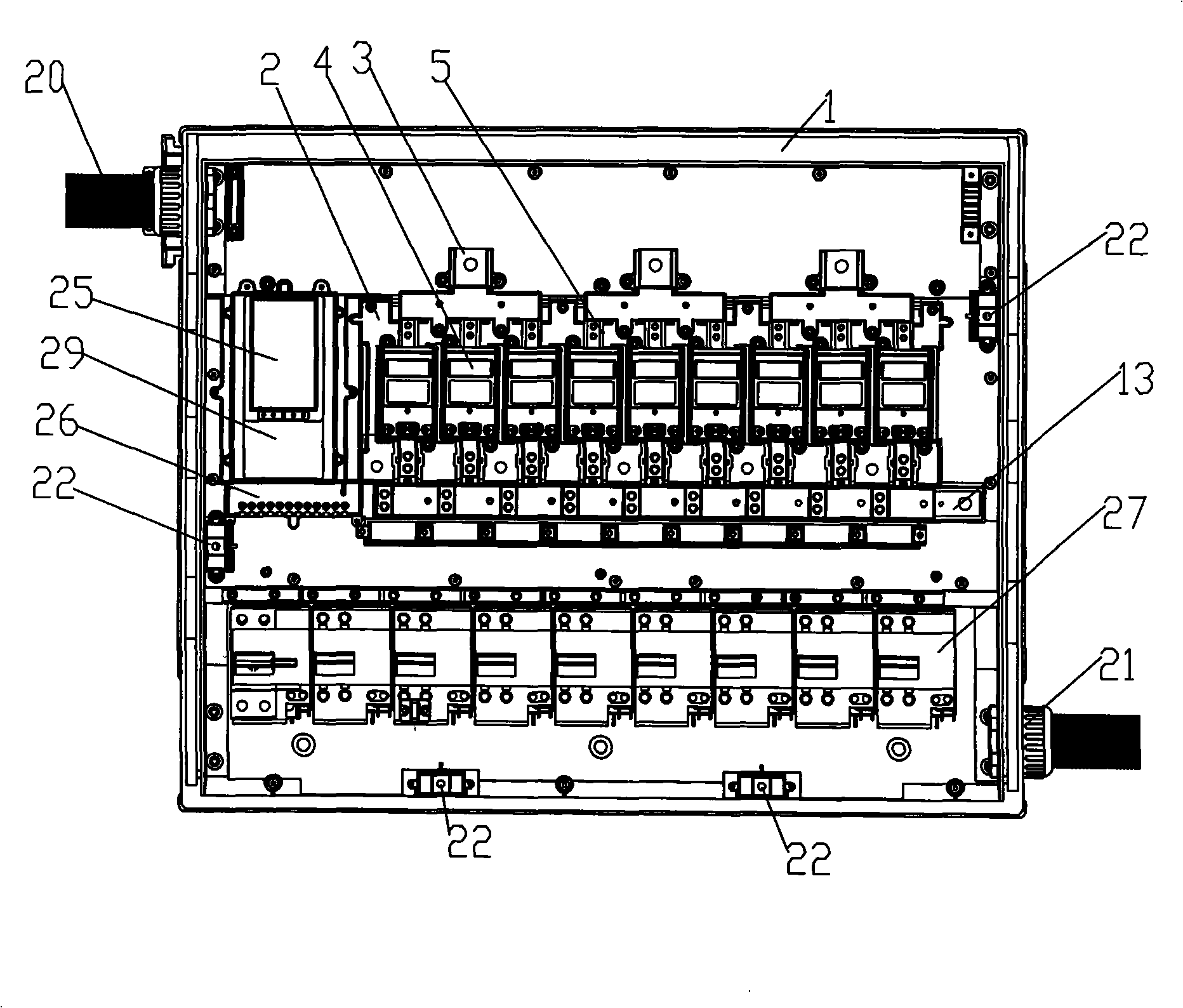

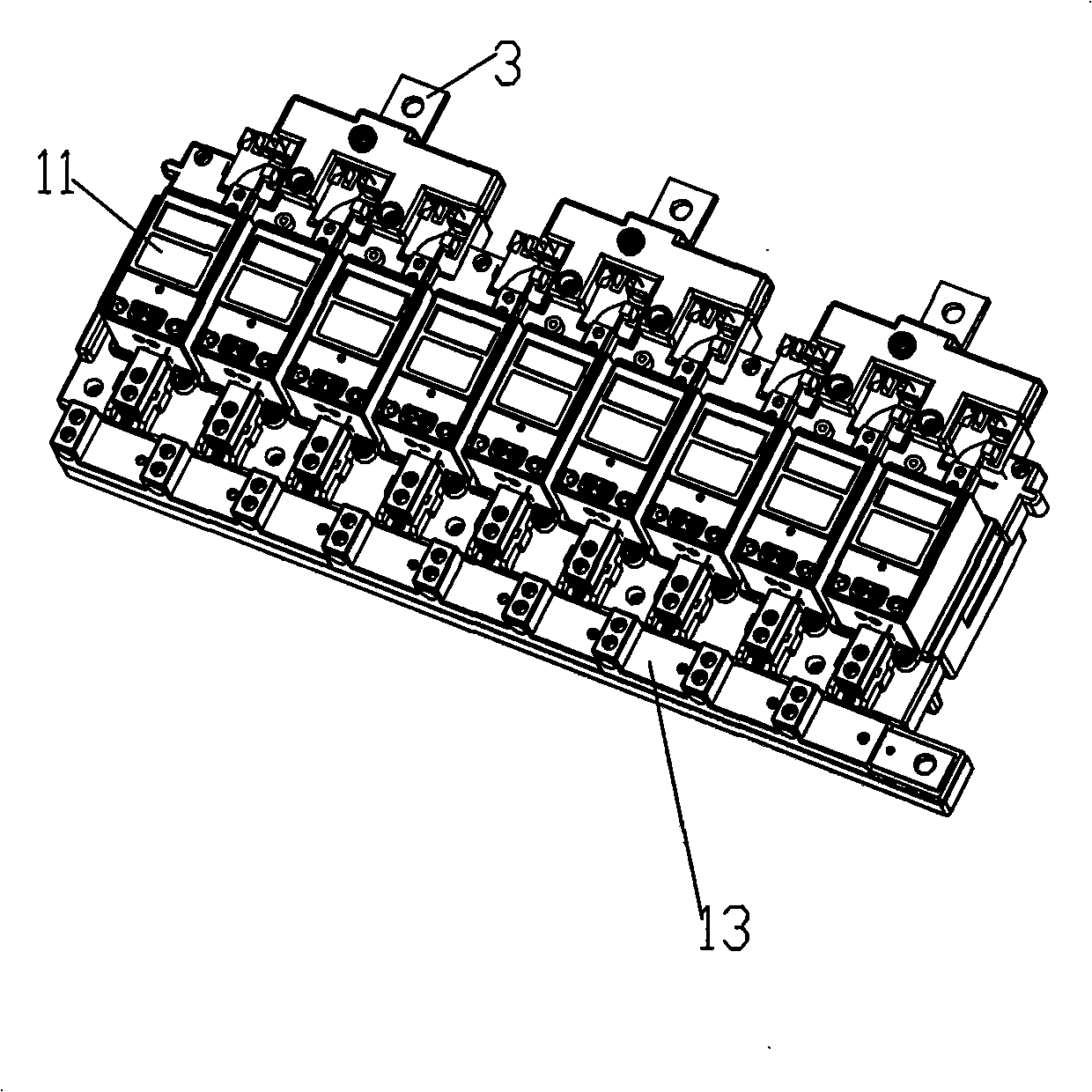

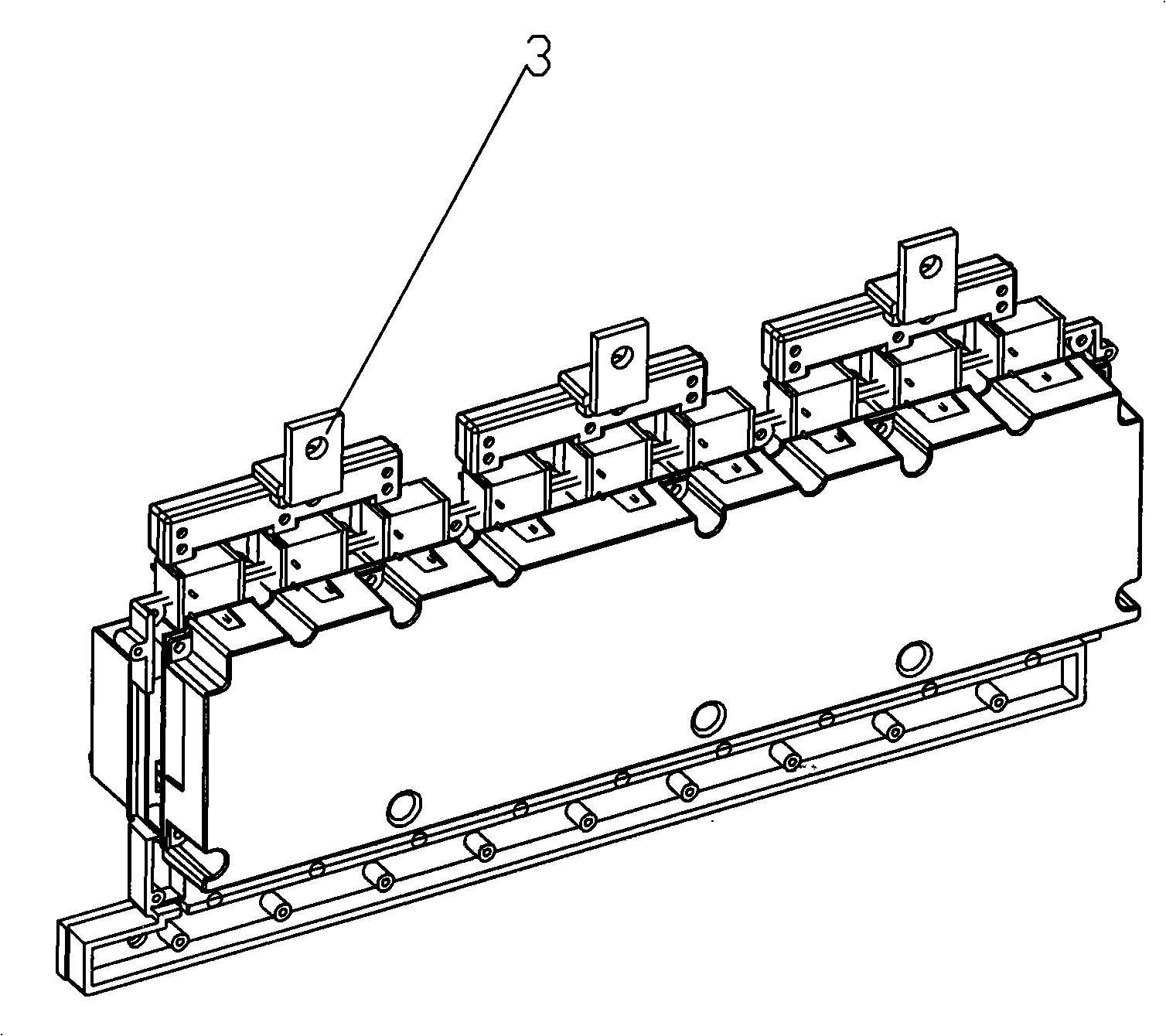

Multi-meter position electric energy metering device

InactiveCN101329368AReduce manufacturing costReduce metering equipment costsSpecial tariff metersModularityEngineering

The invention discloses a multi-epi position electric energy measuring device, comprising a box body and a module centralization-typed measuring device which is arranged inside the box body; the multi-epi position electric energy measuring device is characterized in that the module centralization-typed measuring device comprises a separation panel and at least two measuring modules; the separation panel is connected with a power supply; each output terminal of the separation panel is respectively connected directly with the input terminal of the power supply of each measuring module; each measuring module is provided with a signal output terminal and a power output terminal; the power input terminal and the power output terminal on the measuring module are metal conductive parts. All parts of the invention realize modularization, require no complex conductive wire connection, and shorten the volume to the utmost extent. The multi-epi position electric energy measuring device facilitates the product to unify the standard, and realizes large-scale production and standardized management, thus reducing the cost of the production enterprises and the cost of the power supply departments. The multi-epi position electric energy measuring device can realize the separate display of a single-measuring module and the centralized display and remote management of multi-measuring modules, realize the functions of displaying, measuring, pre-paying and querying, etc., can conveniently replace the modules so as to update, and realize the centralized and scientific management of the power supply.

Owner:HUBEI SHENGJIA ELECTRIC EQUIP +1

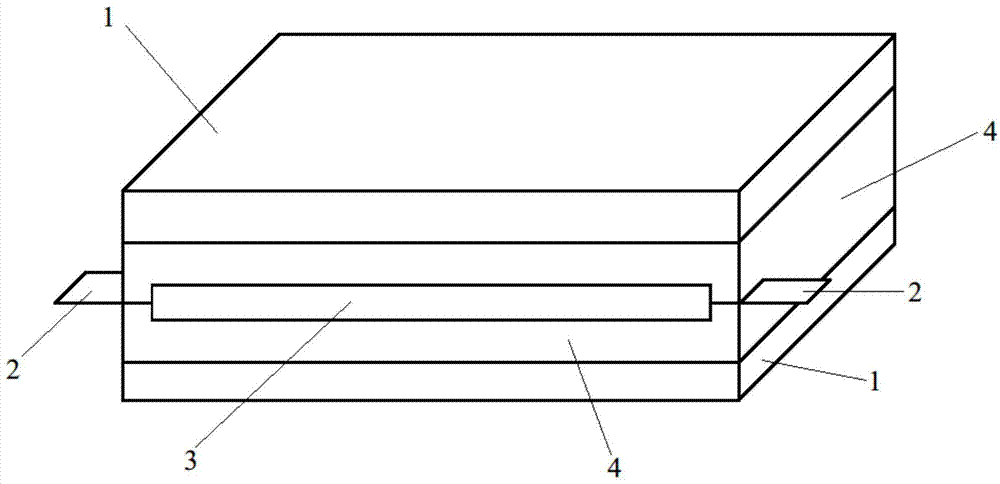

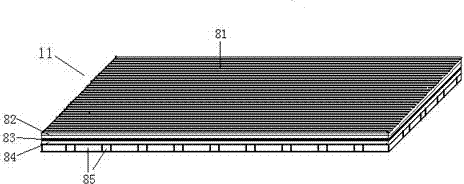

Graphite sheet electrical heating component and manufacturing method thereof

InactiveCN104768243ARealize upgradingThe preparation process is simple and reliableOhmic-resistance heatingHigh energyMaterials science

The invention relates to a graphite sheet electrical heating component. An ultrathin flexible graphite sheet which is 0.01-1 mm thick is adopted as the electrical heating component and used for heating an object after being packaged by insulating layers. The electrical heating component can be suitable for a low-temperature electric heating field, a medium-temperature electric heating field, a high-temperature electric heating field, an ultrahigh-temperature electric heating field and other various electric heating fields by adopting different insulating layer materials. The insulating layer materials wrapping the graphite sheet can insulate the graphite sheet and improve the strength of the graphite sheet. The technology has the advantages of being stable, durable, high in applicability, low in cost, simple in manufacturing process and the like and is suitable for mass industrial production and design and manufacturing of high-energy heaters for labs. The graphite sheet electrical heating component can be used as electric heating equipment in daily life and used in the high-temperature and ultrahigh-temperature heating fields in industrial production.

Owner:SHANGHAI JIAO TONG UNIV

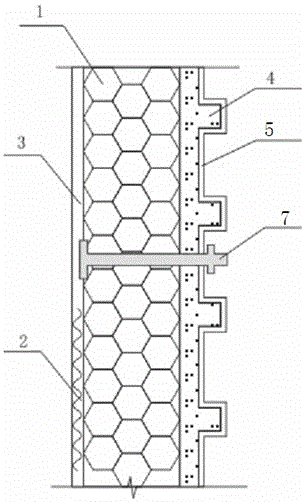

Polystyrene foamed plastic and preparation method thereof, and composite board prepared from polystyrene foamed plastic

InactiveCN105670150ALow costLow thermal conductivityHeat proofingSound proofingPolystyrene beadComposite plate

The invention discloses a polystyrene foamed plastic and a preparation method thereof, and a composite board prepared from the polystyrene foamed plastic. The invention is characterized in that the polystyrene foamed plastic is prepared by carrying out uniform mixing and steam pressurization or mold extrusion or high-pressure permeation polymerization on the following raw materials in parts by weight: 20-40 parts of expandable polystyrene material and 2-6 parts of inorganic MUEC colloidal liquid. The preparation method comprises the following steps: adding the expandable polystyrene beads into a prefoaming machine, prefoaming, drying, forming by coating drying and steam pressurization polymerization or coating and mold extrusion polymerization or steam pressurization and high-pressure permeation polymerization, and cutting the formed block into boards with various sizes by a cutting apparatus. An outer side protective layer (2) is attached to one surface of the polystyrene foamed plastic board, and a finishing coat (3) is attached to the outer side protective layer (2), thereby constituting the composite board; and the composite board is manufactured by one step in the factory. The board and composite board have the advantages of low inflammability, high heat resistance, high compression strength, low apparent density, low water absorptivity, favorable dimensional stability, sound insulation, aging resistance and environment friendliness.

Owner:王惠波

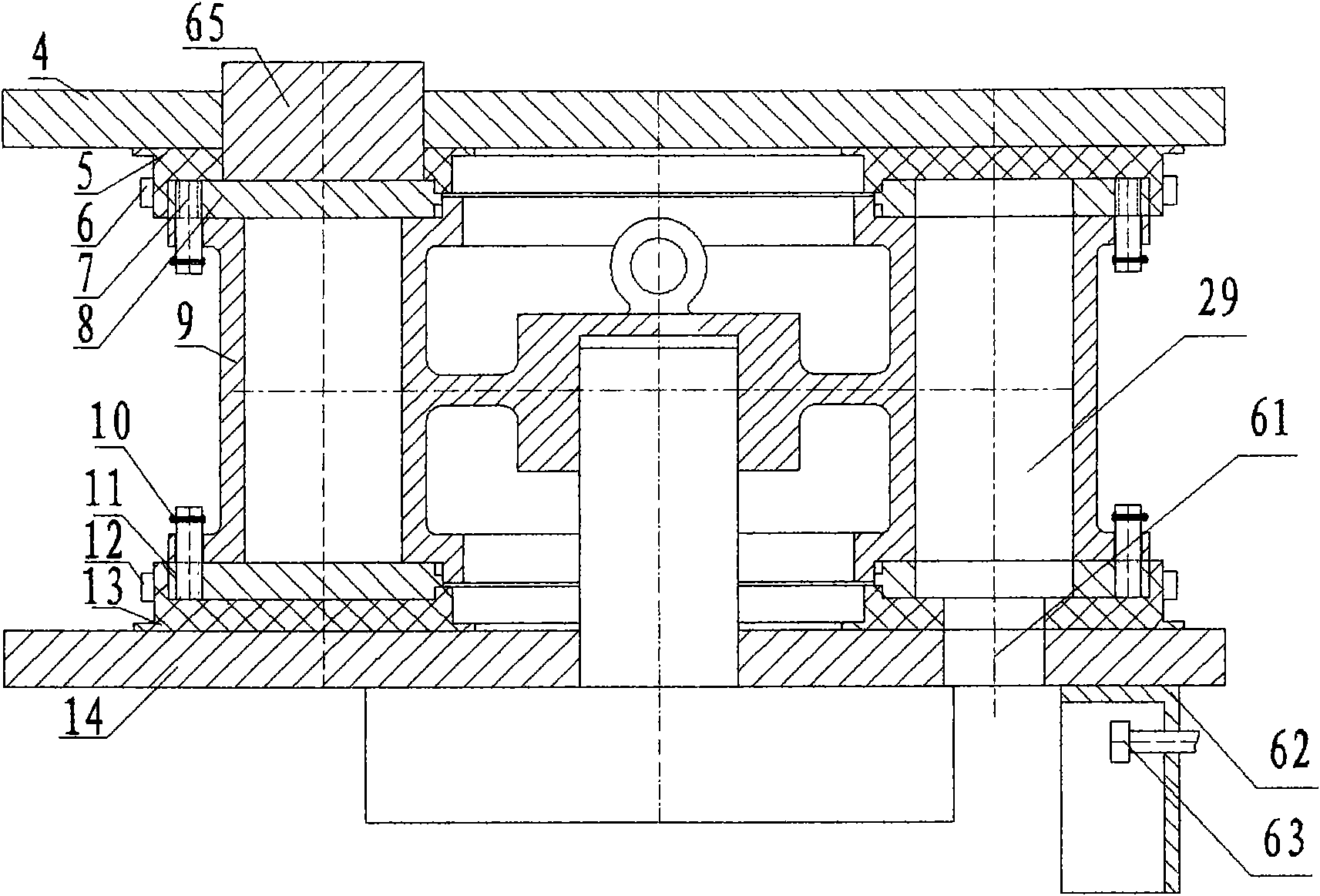

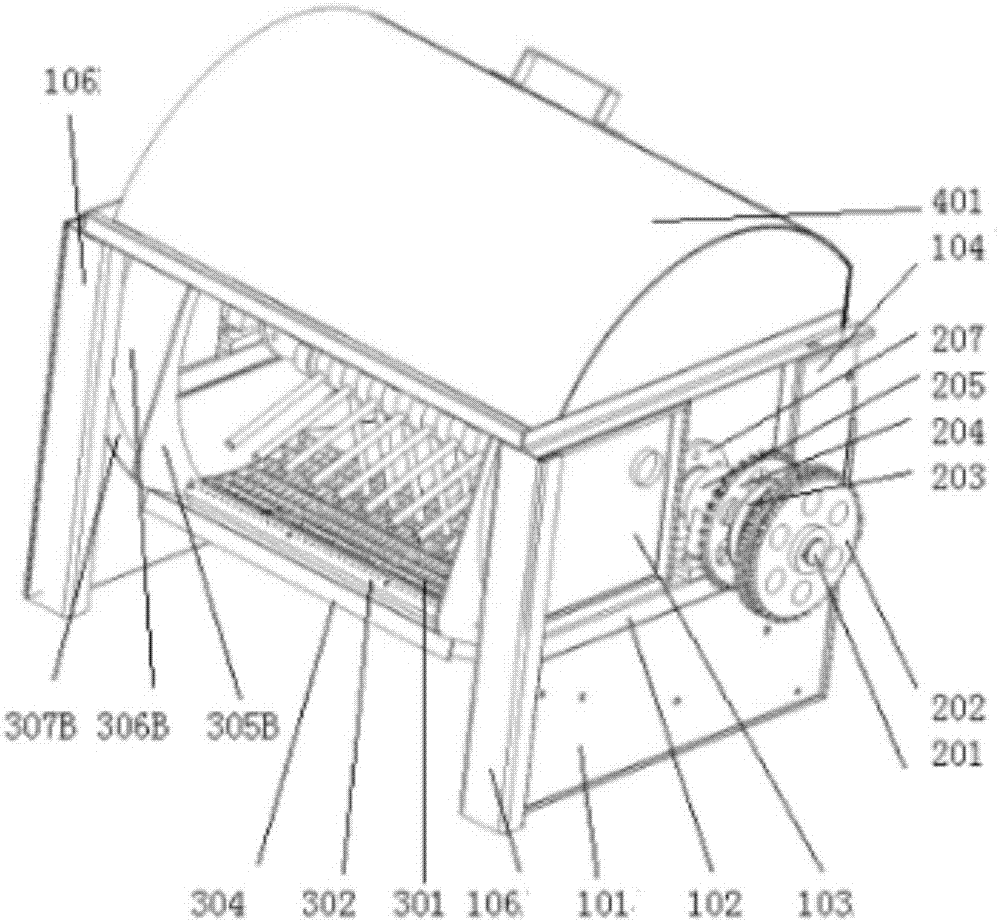

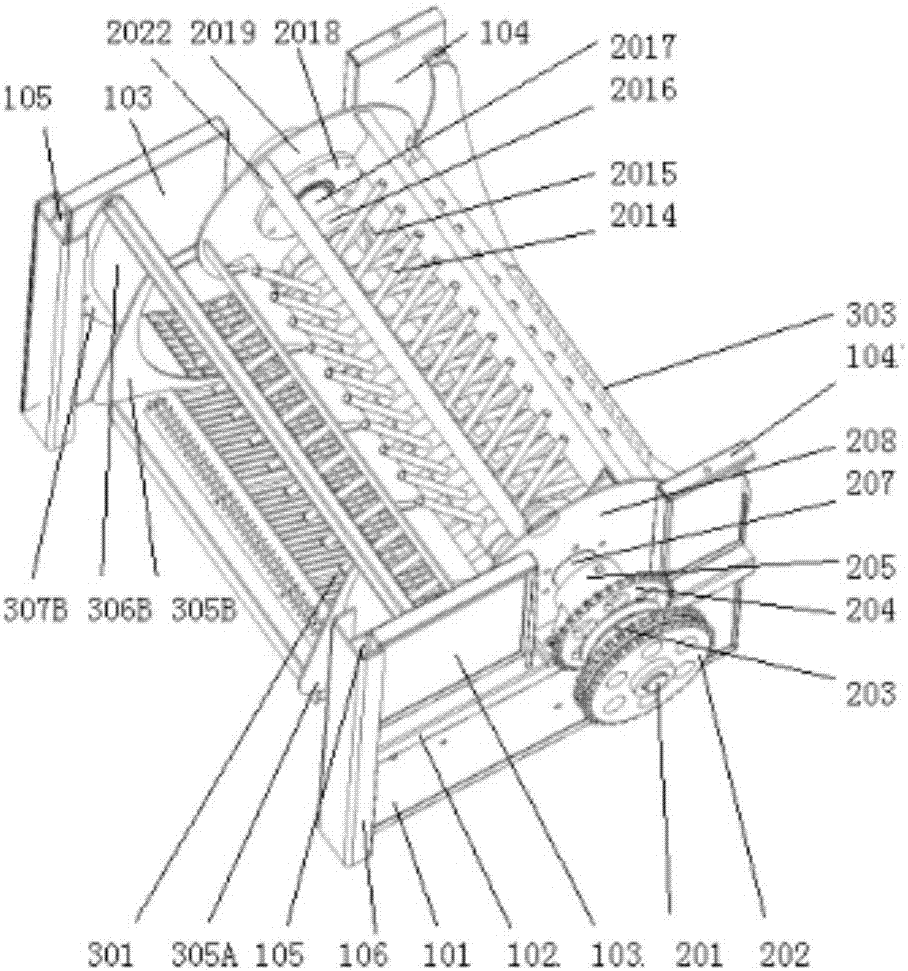

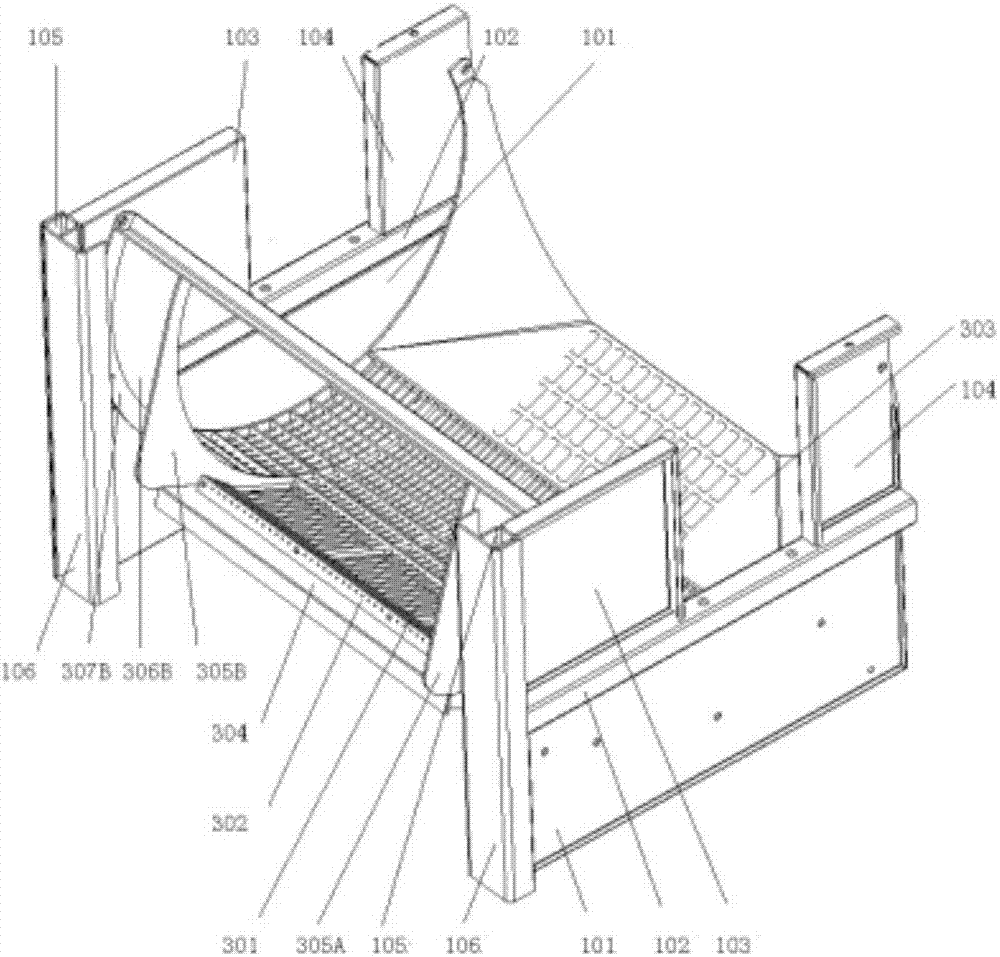

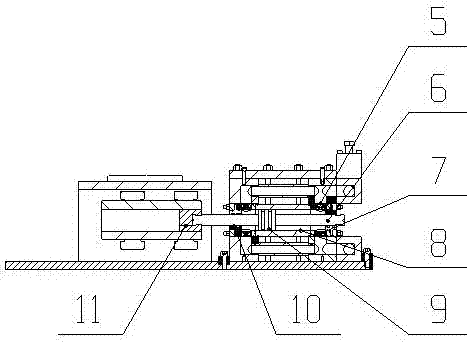

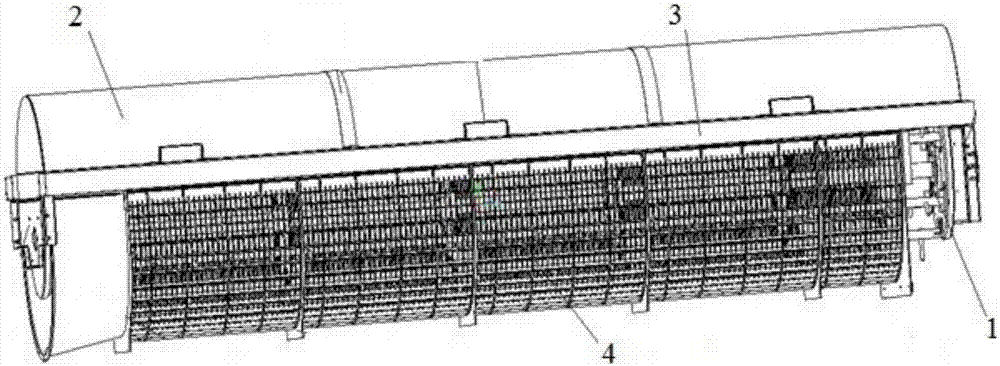

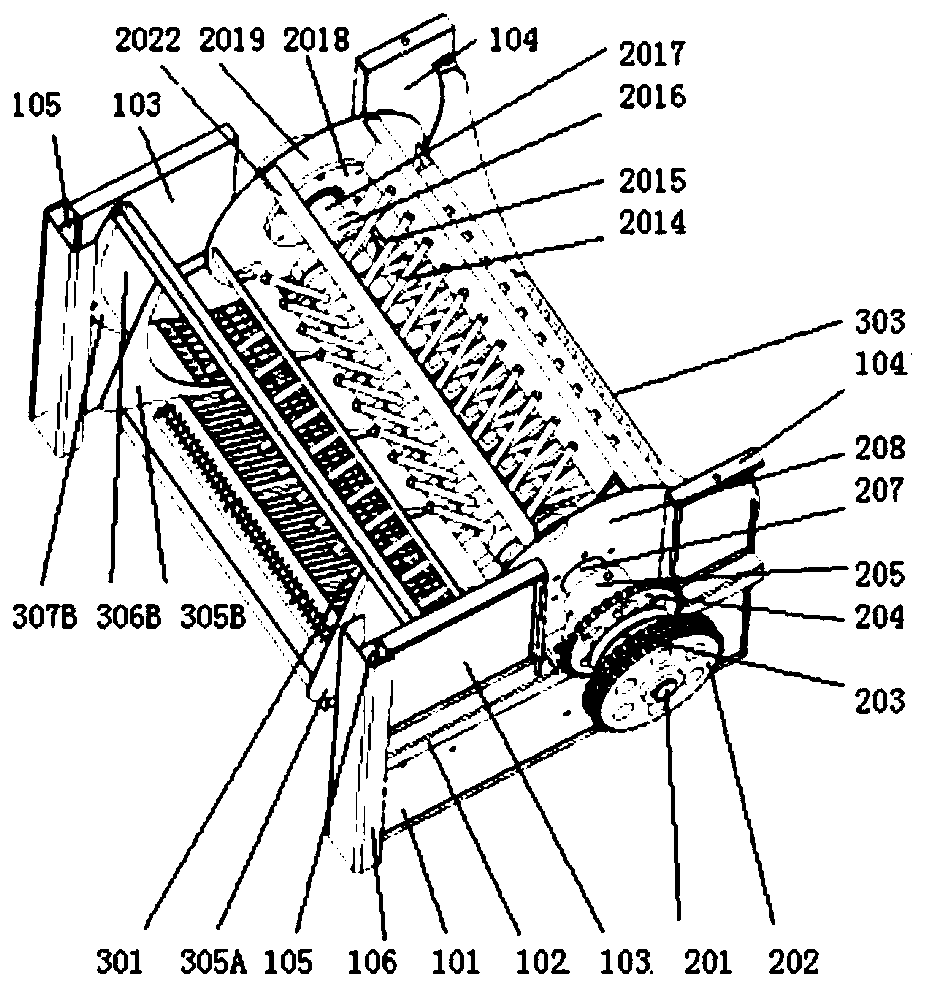

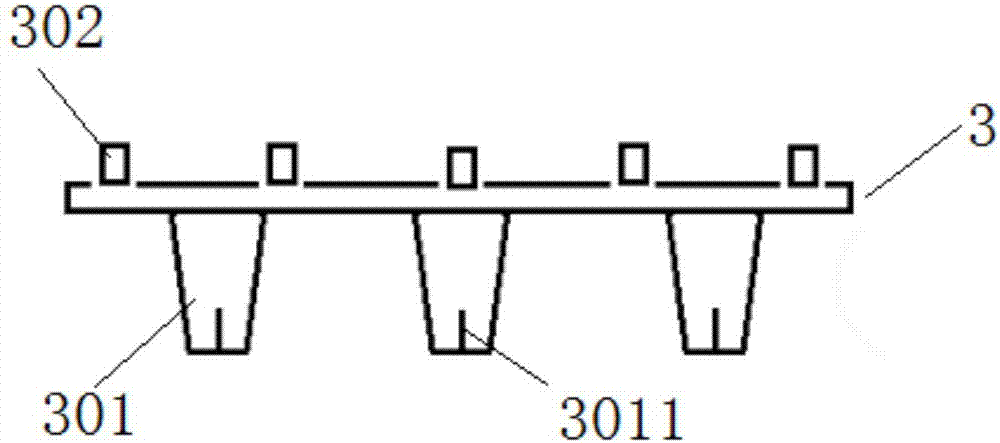

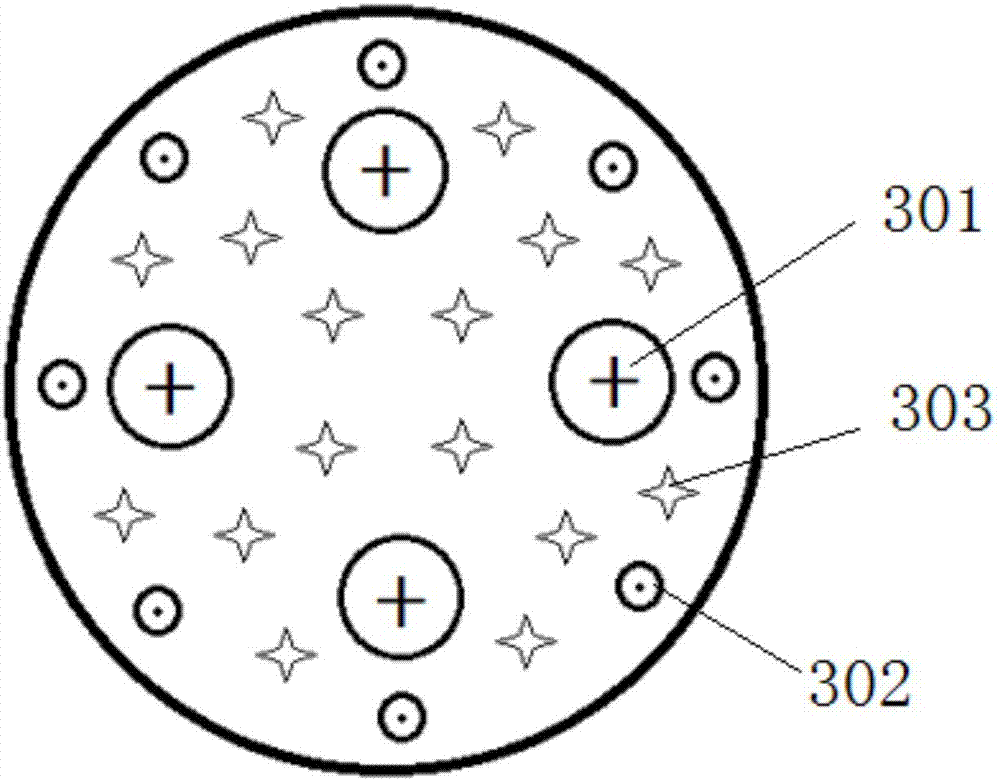

Eccentric tangential-flow primary threshing and separating device of rice combination harvester

ActiveCN107241971AReduce carrybackImprove the initial separation rateThreshersWork performanceEngineering

The invention provides an eccentric tangential-flow primary threshing and separating device of a rice combination harvester. A tangential-flow threshing roller, a concave plate sieve and a top cover are installed on a rack; a support shaft and transmission shaft of the tangential-flow threshing roller penetrate through a left plate and a right plate respectively, an eccentric shaft is located between the left plate and the right plate, and the two ends of the eccentric shaft are connected with the transmission shaft and the support shaft respectively; the center of the transmission shaft and the center of the support shaft both coincide with the rotating center of the threshing roller, so that a certain eccentricity exists between the center of the eccentric shaft and the rotating center of the threshing roller, and a certain angle exists between the horizontal plane and the connecting line of the two centers. When the threshing roller works, a threshing element begins to stretch out above a feeding opening of the tangential-flow threshing roller and draws back into the threshing roller near a longitudinal axial flow feeding opening, back-drawing of rice by the threshing element is effectively reduced, and the problem of unsmooth feeding at the intersection place between tangential flow and longitudinal flow is solved; meanwhile, the partial resistance torque produced by materials is balanced by the torque produced by the centre-of-gravity shift of the tangential-flow roller, the vibration of the tangential-flow threshing roller is reduced, the work performance is improved, and the service life is prolonged.

Owner:JIANGSU UNIV

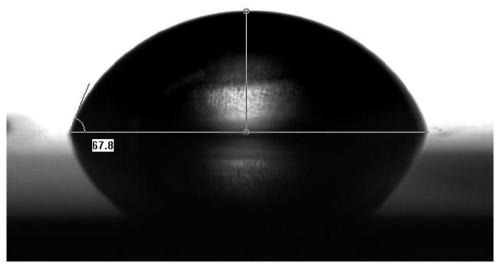

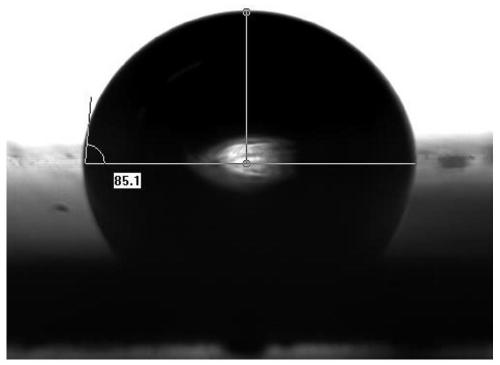

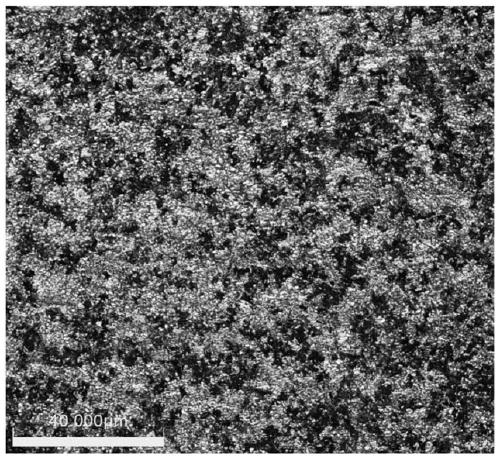

Multilayer high-frequency printed circuit board copper foil surface coarsening solution and using method thereof

ActiveCN110241422AImprove processing efficiencyReduce roughnessInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentPhosphoric acidCopper foil

The invention provides a multilayer high-frequency printed circuit board copper foil surface coarsening solution and a coarsening method thereof, and belongs to the technical field of printed circuit manufacturing. The copper foil coarsening solution comprises the components of hydrogen peroxide, sulfuric acid, phosphoric acid, a copper coordination agent, a corrosion inhibitor and the like, wherein the phosphoric acid, the copper coordination agent and the corrosion inhibitor form a reaction adjusting system, the oxidation reduction and the dissolution precipitation are skillfully fused together by adding a reaction regulator, and a layer of substance benzotriazole with strong affinity with resin is generated on the surface of the treated copper foil, so that organic consideration of surface coarsening and interlayer binding force of the copper foil is realized. Due to the fact that the copper reaction activity of the phosphoric acid system is low, air plasma activation is added before coarsening of the surface of the copper foil, high-activity particles such as electrons, positive ions, neutral particles and the like existing in the air plasma are utilized to activate copper, and then the treatment efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

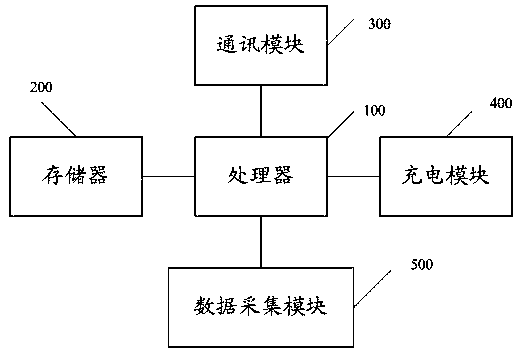

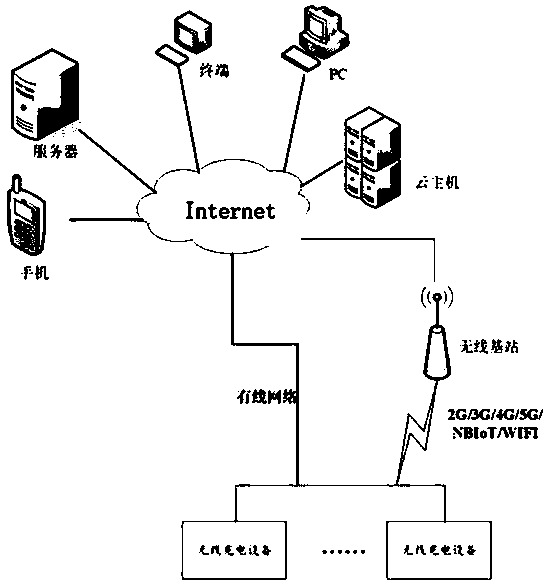

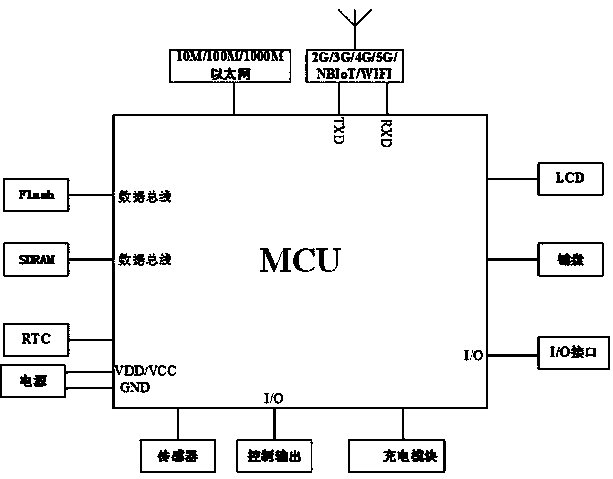

A wireless charging device and a control method

InactiveCN108958777ARealize upgradingImplement automatic updatesCircuit arrangementsSoftware deploymentSoftware systemComputer module

The invention discloses a wireless charging device and a control method. The wireless charging device comprises a communication module, a charging module, a processor and a memory. The communication module, the charging module and the memory are all connected with the processor. When the wireless charging device is in an upgrading mode, the processor is connected with the server through the communication module and obtains the corresponding upgrading package. The software system of the wireless charging device is upgraded by analyzing and installing the upgrading package so as to realize remote upgrading. The invention realizes automatic updating of wireless charging technology and a wireless charging communication protocol through remote automatic detection of upgrading packages and automatic downloading of program upgrading packages, and ensures compatibility of new wireless charging products.

Owner:广州云海智联科技有限公司

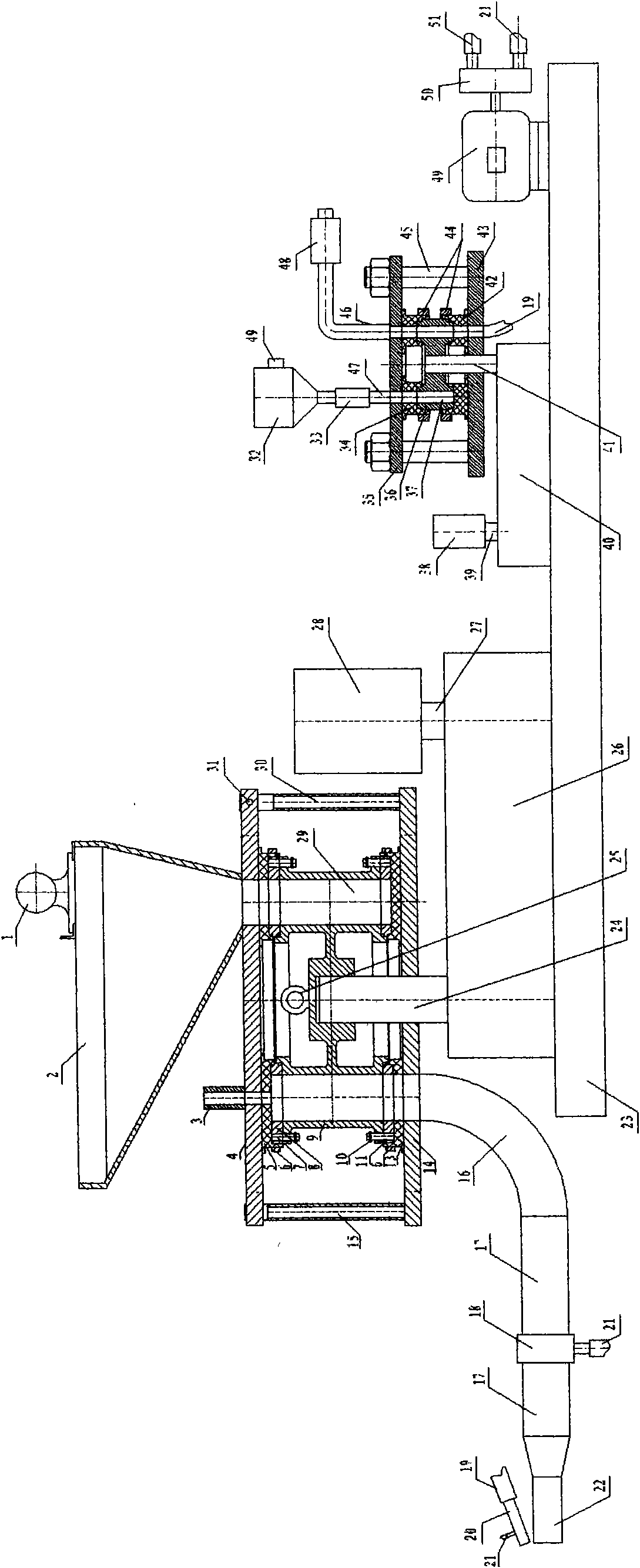

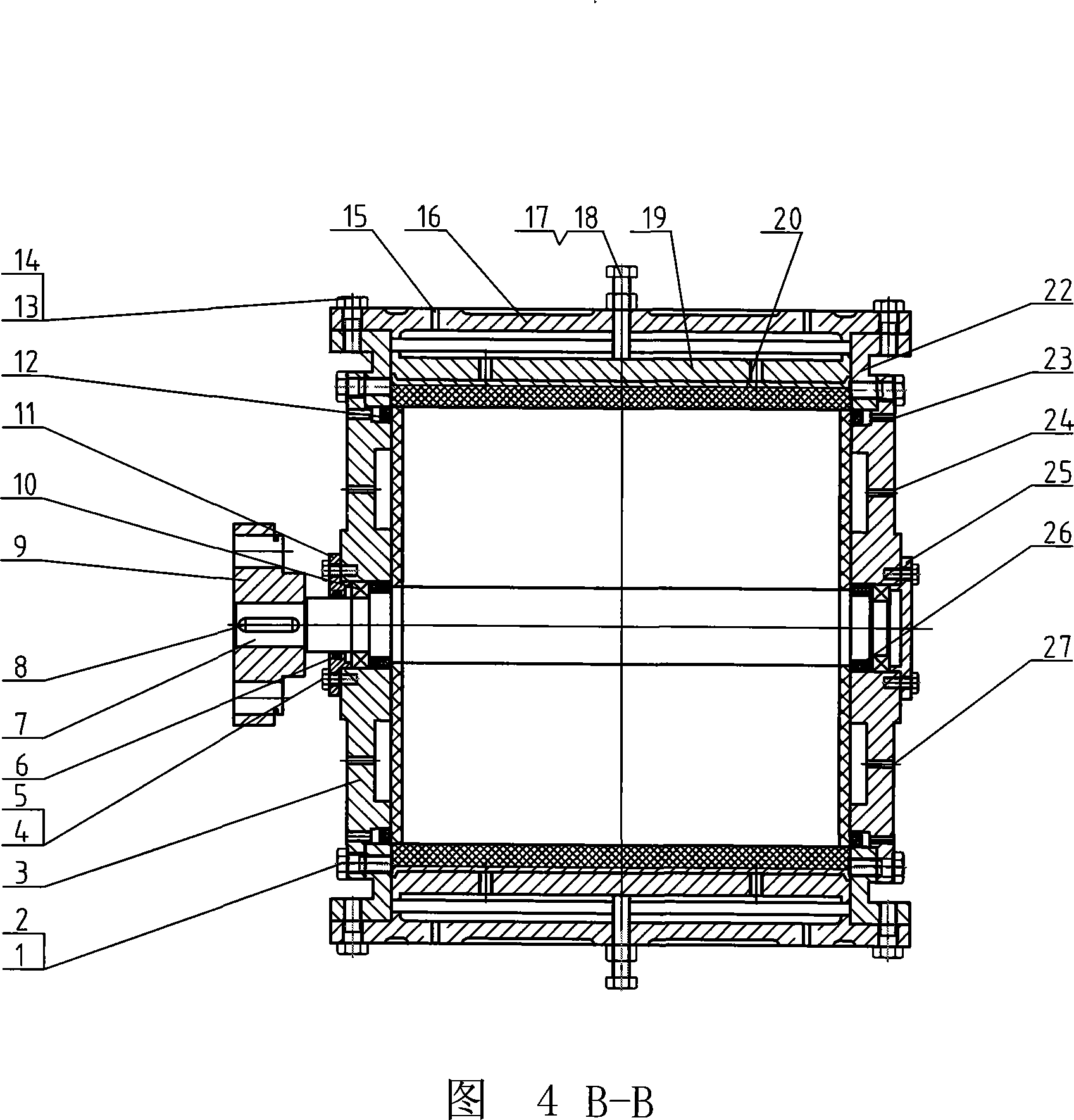

Automatic gas-locking feeder

InactiveCN101168414AAchieve continuous sealingRealize automatic air lock compensationBulk conveyorsFiberWork period

The invention relates to an automatic gas lock feeder which can transmit powder pneumatically, wherein eight rectangle bin blades form a blade wheel as a feeding transmitter, two circumferences and two axial side faces of the blade wheel are respectively sealed externally via a blade wheel end face sealing ring and a blade wheel axial face sealing pile, two end faces of the bearing use oil seal via a carbon fiber wheel and a skeleton, to externally seal the blade at six directions. The invention uses external seal technique to provide forward compensation spaces to all seals, and arranges a compression air room at the back of the seals, uses pressure balance under the constant pressure of external compressed air to realize automatic compensation. The seal material mainly uses modified F4, to realize abrasion-resistant dynamic seal under different conditions, while the pressure resistance of the chamber of the blade wheel can reach 0.25MPa. The automatic gas lock feeder can be engaged with any one of six pneumatic transmission methods as dense-phase, dilute-phase or the like, with compact structure, small volume, high efficiency, gas-lock transmission, strong output force, long service life, and low operation and maintenance costs.

Owner:冯晓

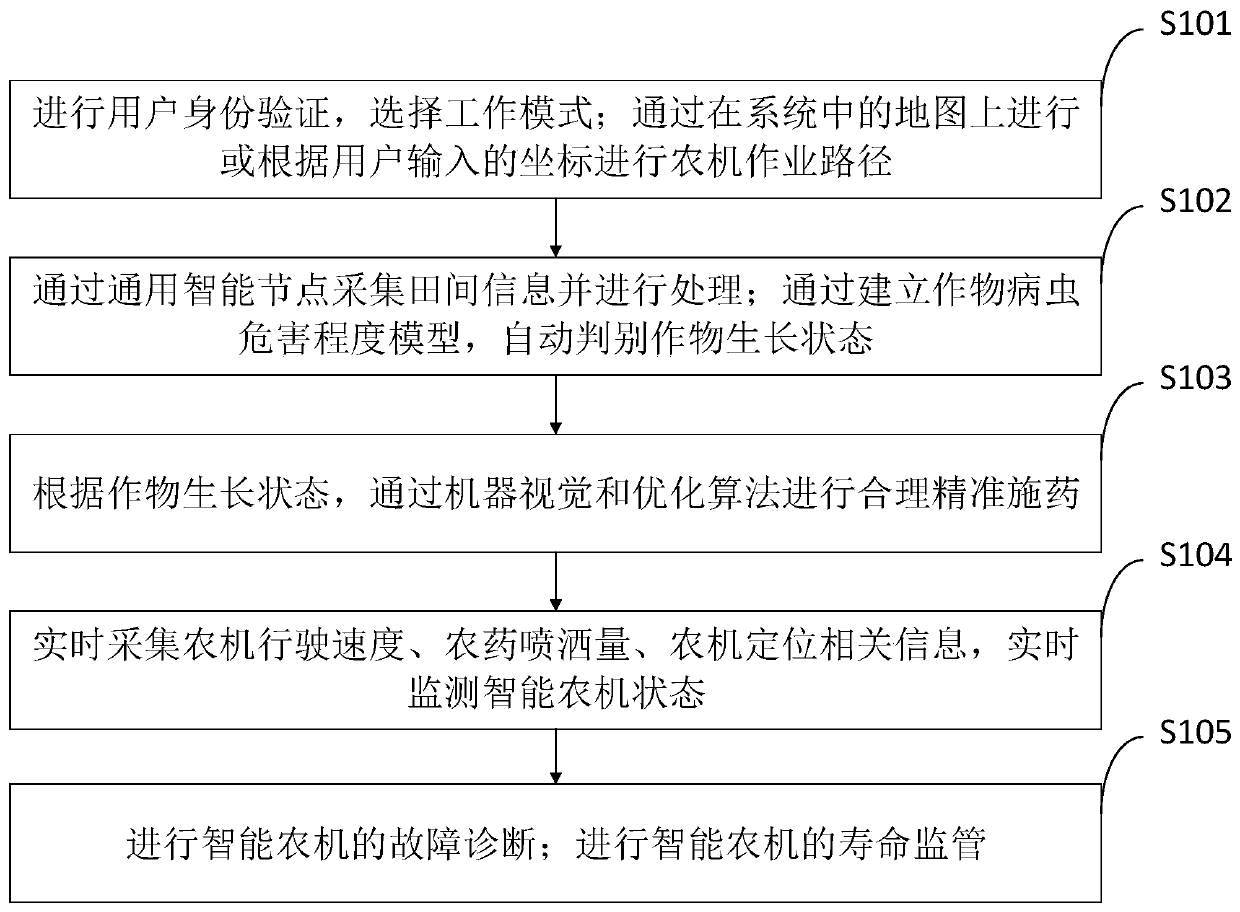

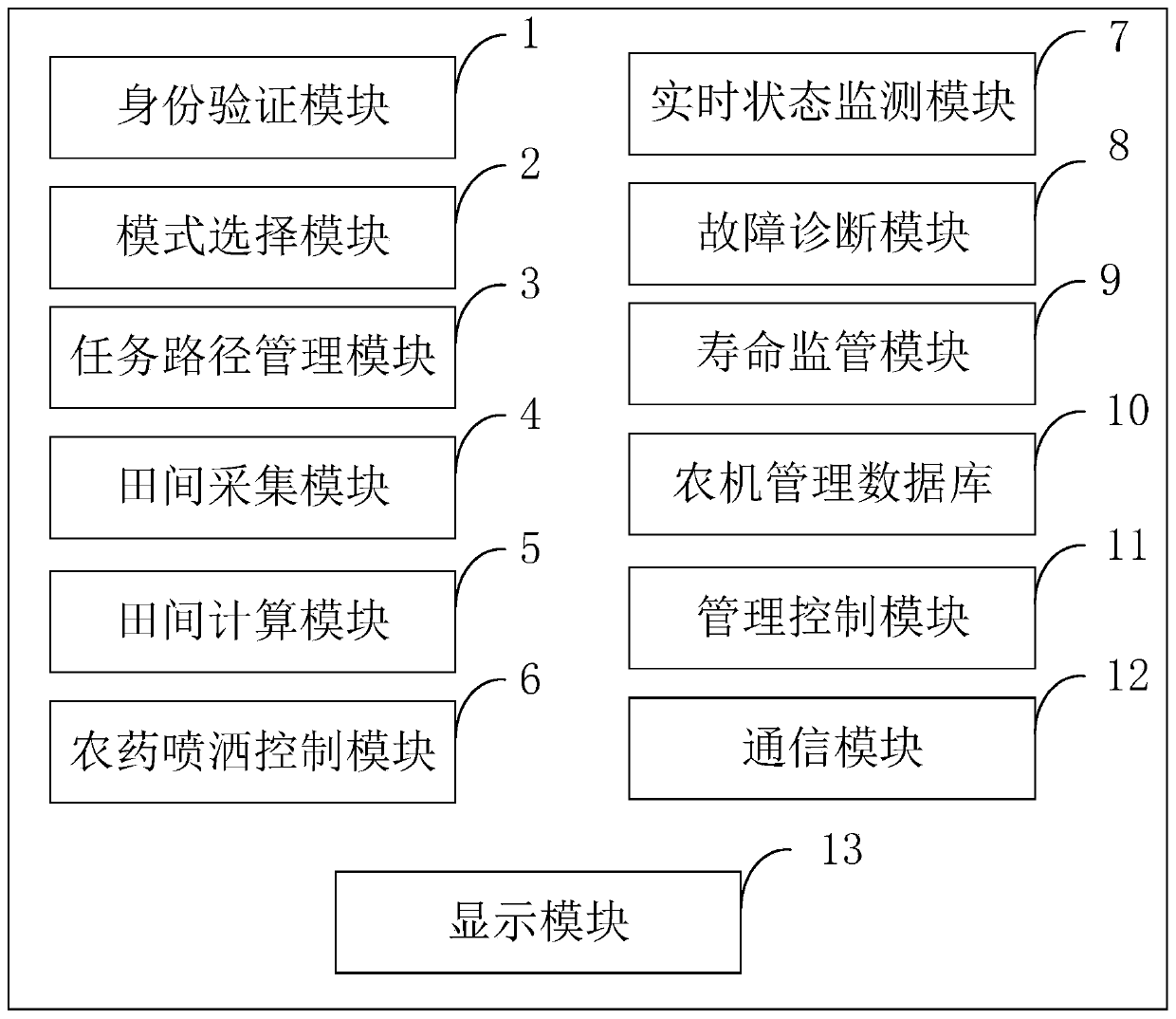

Intelligent agricultural machinery operation method and operation system for spraying pesticide

InactiveCN110973102ARealize upgradingRealize real-time status monitoringData processing applicationsTransmissionEnvironmental resource managementMachine vision

The invention belongs to the technical field of agriculture, and discloses an intelligent agricultural machinery operation method and an operation system for spraying pesticide. The intelligent agricultural machinery operation method comprises steps of identifying authentication of a user, selecting a working mode; carries out an agricultural machinery operation path through a map in the system orcoordinates input by the user; collecting and processing field information through general intelligent nodes; automatically determining crop growth status by establishing a crop disease and pest hazard severity model; reasonably and accurately applying the pesticide by machine vision and optimized algorithms based on the crop growth status; collecting agricultural machinery driving speed, pesticide dosage and agricultural machinery positioning related information in real time, and monitoring status of an intelligent agricultural machinery in real time; and performing fault diagnosis and lifemonitoring for the intelligent agricultural machinery. The intelligent agricultural machinery operation method of the present invention can control the agricultural machinery to accurately drive alongthe planned operation path, so that an agricultural machinery operator can get rid of long-term fatigue driving and improve quality and efficiency of field operation.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

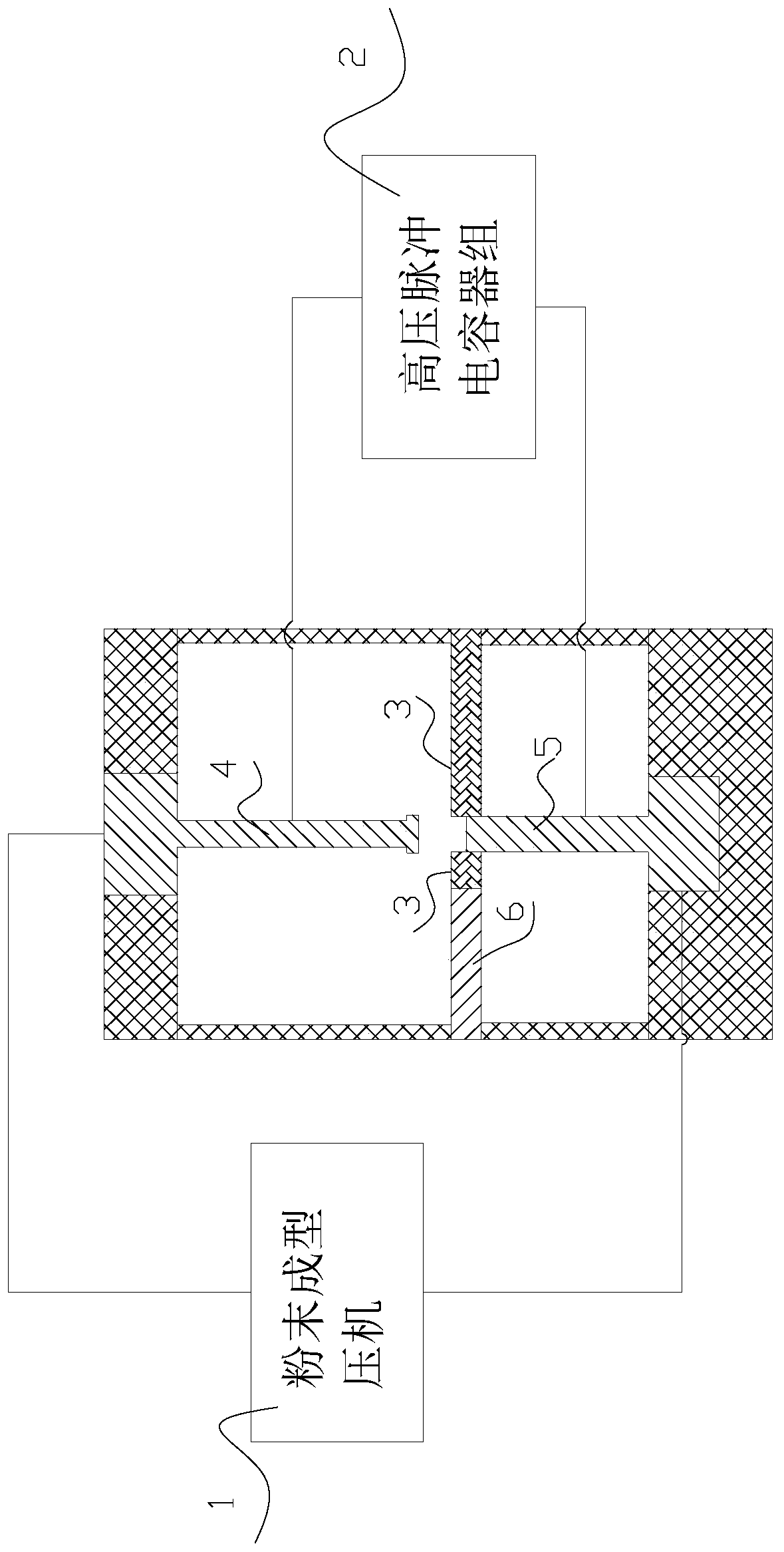

Pulse discharge flash sintering metal-based part near-net forming technology method

InactiveCN109894615ASimple processHigh energy consumptionAdditive manufacturing apparatusPorosityMetal powder

The invention discloses a pulse discharge flash sintering metal-based part near-net forming technology method, and belongs to the technical field of powder metallurgy. The problems that a traditionalpowder metallurgy part production process is high in power consumption, tedious and complex in process flow and low in production efficiency are solved. The method mainly comprises the steps of pushing metal powder into a mold, and forming the metal powder through stamping; enabling the inner wall, making contact with the metal powder, of the mold to have the insulation property; and enabling stamping to serve as an electrode of a pulse discharge body, and enabling stamping to synchronously carry out pulse discharge in the metal powder forming process. According to the method, the process flowis greatly simplified, large-scale industrialized application is easily achieved, the near-net forming advantage is achieved, the product quality is high, porosity adjusting control is convenient, practicality is high, and the method has the important significance in the powder metallurgy industry manufacturing field.

Owner:YANGZHOUSSHINE POWDER METALLURGY

Basic framework of building LED light-emitting apparatus by standard pieces

PendingCN107339618AReduce volumeReduce weightLighting support devicesElongate light sourcesElectricitySupporting system

The invention relates to a basic framework of building an LED light-emitting apparatus by standard pieces with different shapes, structures, types and functions and the basic framework is randomly assembled by light-emitting modules of standard pieces, a power supply connecting module and a supporting system. Each of the light-emitting module is composed of an LED light source integrating a chip and heat dissipation, a color temperature adjusting module and an optical lens; the power supply connecting module is formed by connecting a plurality of light source modules with different voltage output interfaces, light source bases where the light-emitting modules are assembled, power supply connectors connecting the power supply bases and the power supply modules and circuit connectors electrically connecting two adjacent light source bases. The supporting system is formed by a plurality of connecting blocks of building block type connecting structures and rib parts. The heat conducting efficiency of the LED light-emitting apparatus manufactured thereby is enhanced by 4-6 times, the volume and weight of the product are reduced by 70%, and the cost is lowered by 60%. The application diversification of the product is met, and the basic framework is simple to mount and maintain, and the sizing standard of the product is extremely simplified.

Owner:HUNAN YUEGANG MOOKRAY IND CO LTD

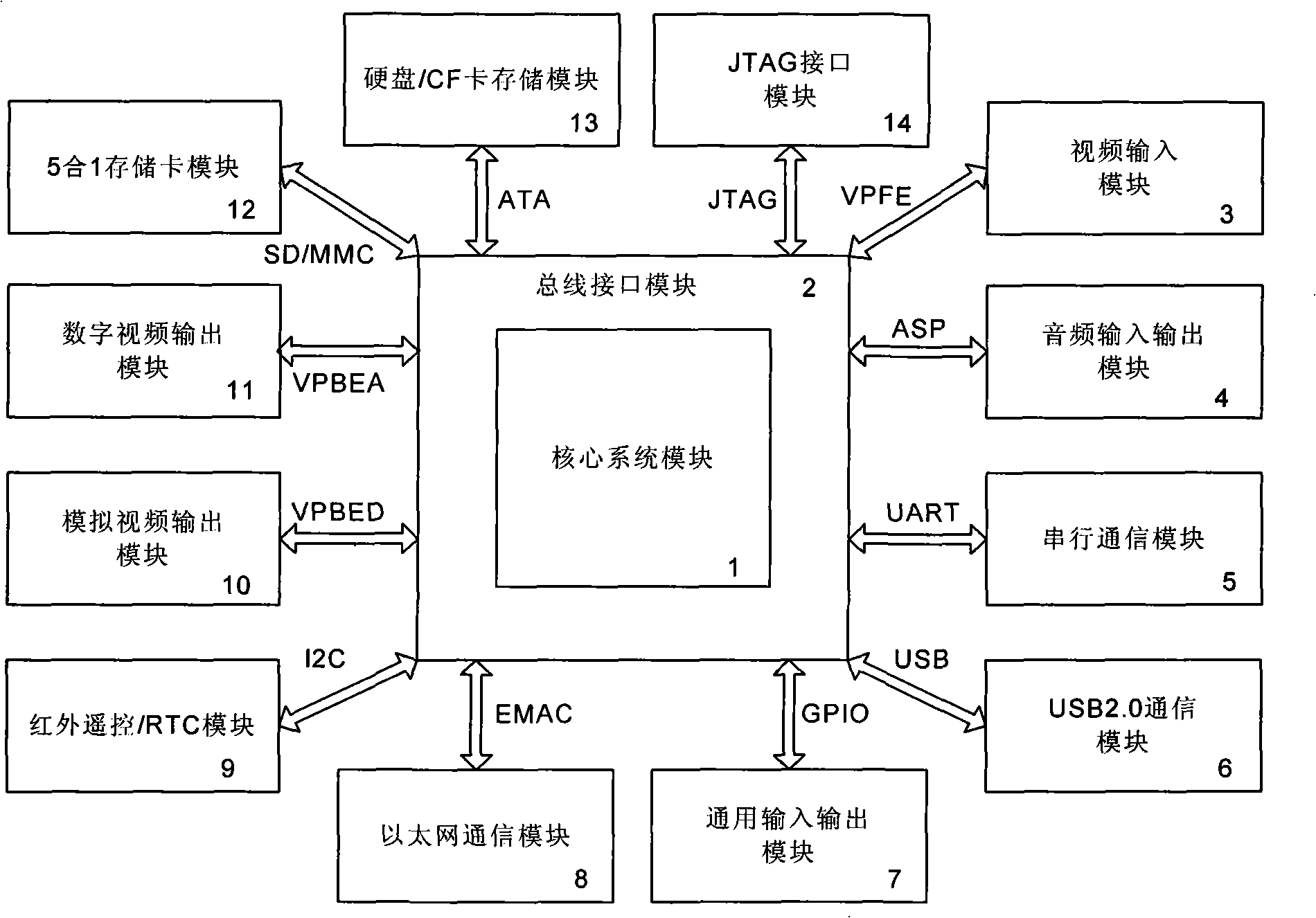

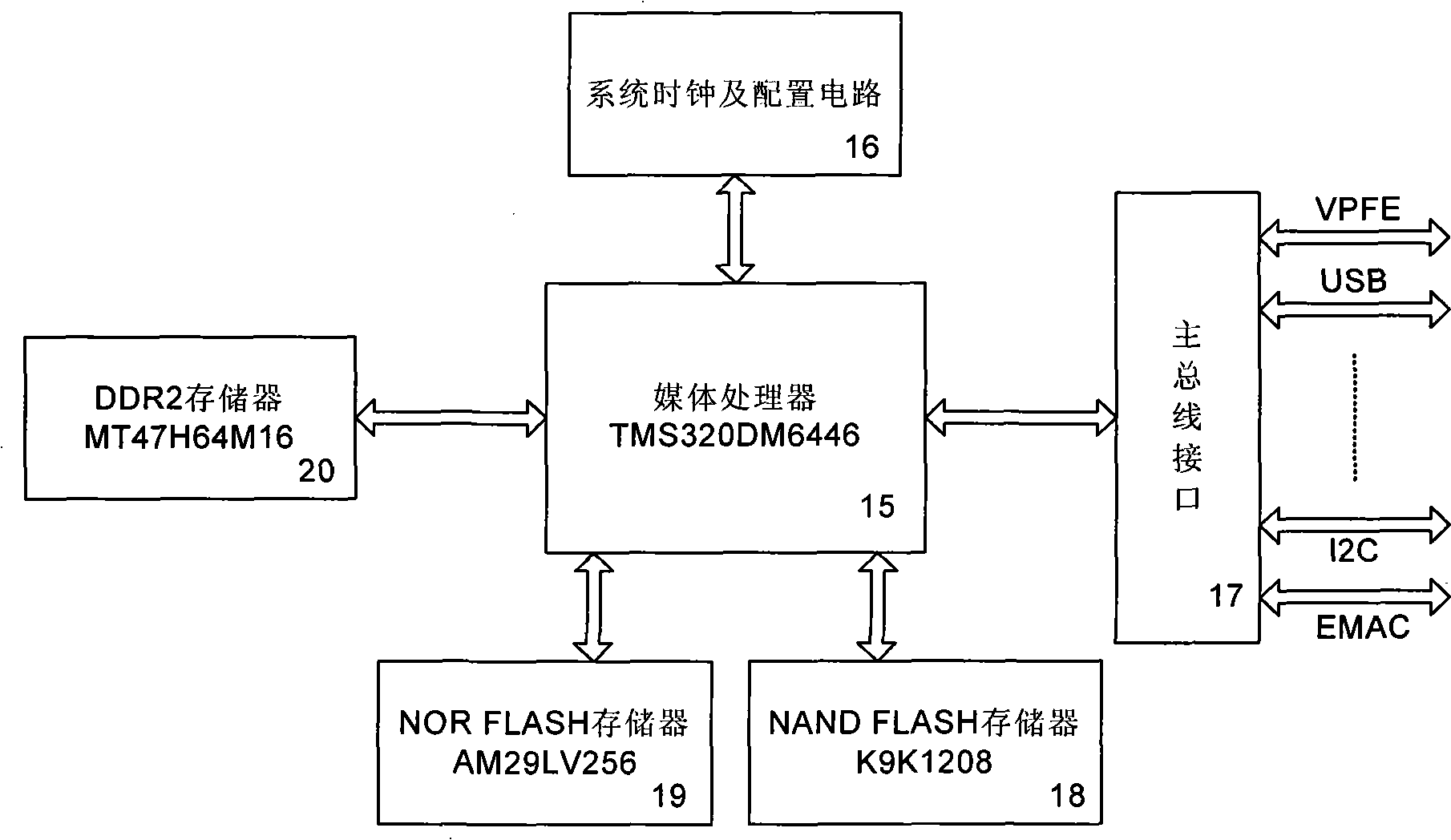

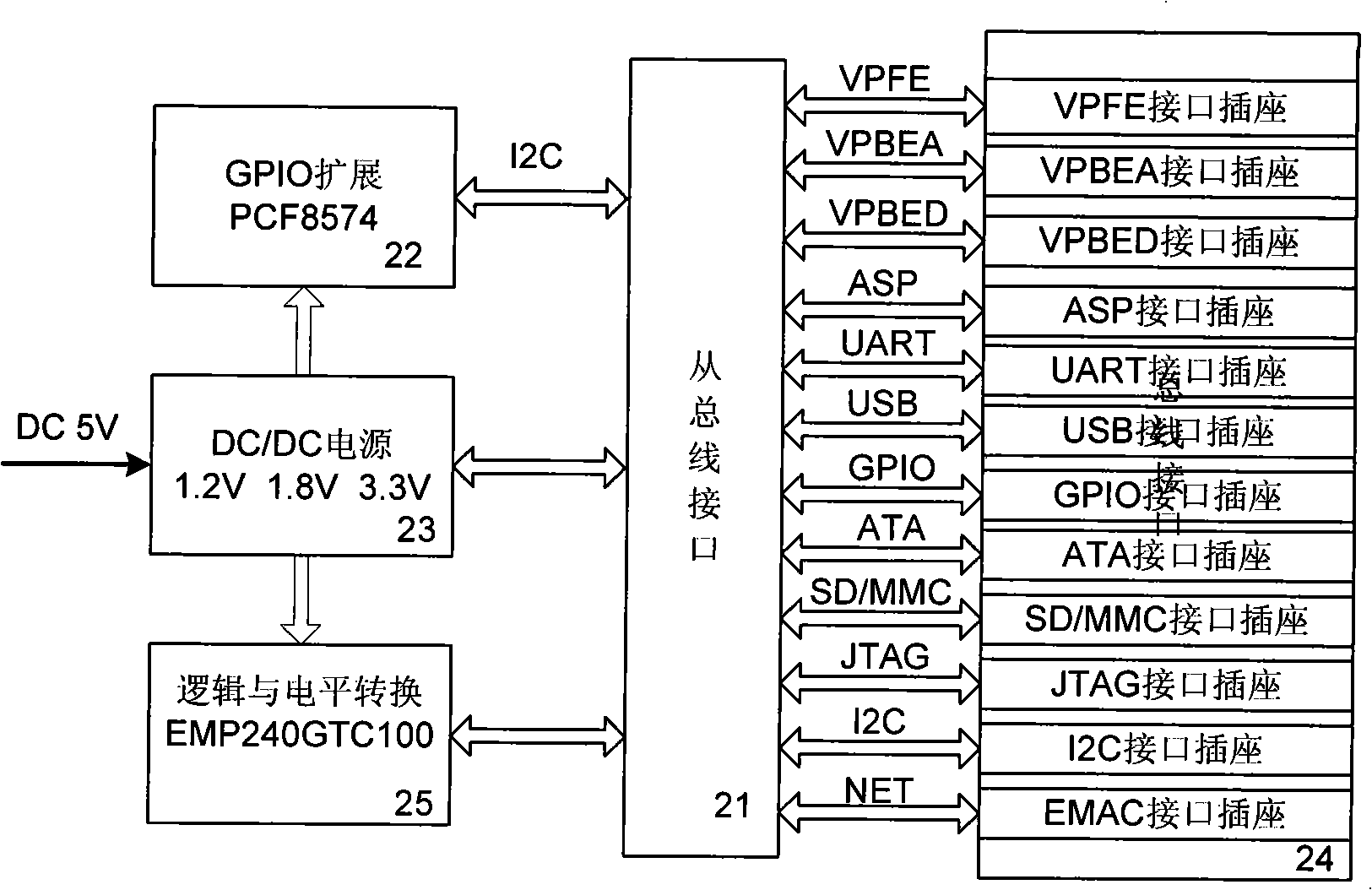

Modularized multifunctional embedded audio/video encoding/decoding device

InactiveCN101404718ASimple designReduce testingTelevision system detailsPulse modulation television signal transmissionBus interfaceEmbedded system

The invention relates to a modular multi-function embedded audio and video coding and decoding device, and belongs to the technical field of high-speed data processing devices. The modular multi-function embedded audio and video coding and decoding device consists of a bus interface module (2), a core system module (1) respectively interconnected with the bus interface module (2) by a line interface and a peripheral system module. Compared with the existing devices, the device has the advantages of reusing the hardware module, effectively shortening the development period, promoting product upgrade and benefiting fault isolation and diagnosis. The modular multi-function embedded audio and video coding and decoding device can be widely applied to digital monitoring systems, DVB / IP set top boxes, KTV set top boxes and multimedia information issuing terminals. The reusability of the same hardware module can be used for rapidly customizing new products.

Owner:YUNNAN UNIV

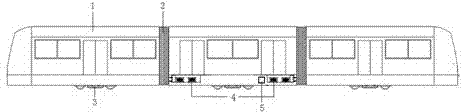

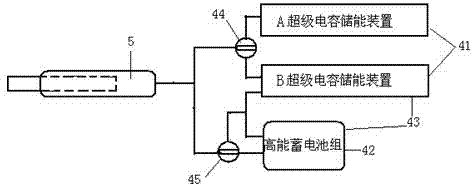

New energy power-driven rail bus group

ActiveCN102730012AStrong power sourceReduce power consumptionRailway braking systemsElectric locomotivesBogieNew energy

The invention relates to a new energy power-driven rail bus group. According to the bus group, an electric power-driven system is vehicle-mounted super capacitance energy storage devices, and is provided with an electric power receiving arm; compartments of the bus group are light-weight integral bearing compartments, and the height of a floor of a short-section thin bottom frame away from a rail is between 780 and 350 millimeters; and light-weight small-wheel diameter S-shaped plate wheels and steering frames are arranged on lower sides of the compartments. The power-driven rail bus group has the advantages of large carrying capacity, quick running, high efficiency, time reliability, comfort, no pollution discharge and the like and can be compared favorably with subways, light railways and modern super streetcars, and the manufacturing cost is about 1 / 3 of that of the subways and about 1 / 2 of that of the light railways and the modern super streetcars. The new energy power-driven rail bus group is an important component of a new energy rail transit operation system (ERT) and supports the comprehensive implementation of the ERT effectively, so that the system is in the optimum operating state.

Owner:中辆新能源轨道交通装备有限公司

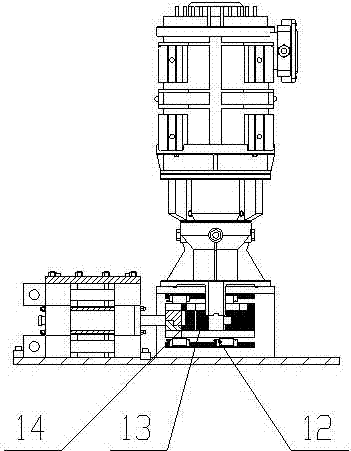

Energy-saving type reciprocating high-pressure plunger pump

InactiveCN107503900AAdvanced technologyNovel structurePositive displacement pump componentsPositive-displacement liquid enginesInlet channelSand blasting

An energy-saving type reciprocating high-pressure plunger pump is a novel reciprocating high-pressure plunger pump composed of a planetary gear reduction variable-frequency motor, a pressure adjusting valve, a water outlet channel assembly, a water inlet channel assembly, forcing valves, a piston rod, intake valves, cylinder blocks, a piston, cylinder block glands, a piston rod clamp, a guide rail, a sector gear and racks. Compared with the prior art, the energy-saving type reciprocating high-pressure plunger pump has the advantages of saving energy, being environmentally friendly, advanced in technology, novel in structure, convenient to install and low in manufacturing cost and use cost. The energy-saving type reciprocating high-pressure plunger pump is a upgraded and updated novel product and can be widely applied to conveyance of high-pressure liquid, high-pressure scale removal of metallurgy and rolling mills and scale removal of the building industry, the chemical engineering industry, the shipbuilding industry, the papermaking industry and the like, high-pressure long-distance fire extinguishment of fire fighting trucks and high-pressure pumps of wet sand blasting machines.

Owner:肖宏伟

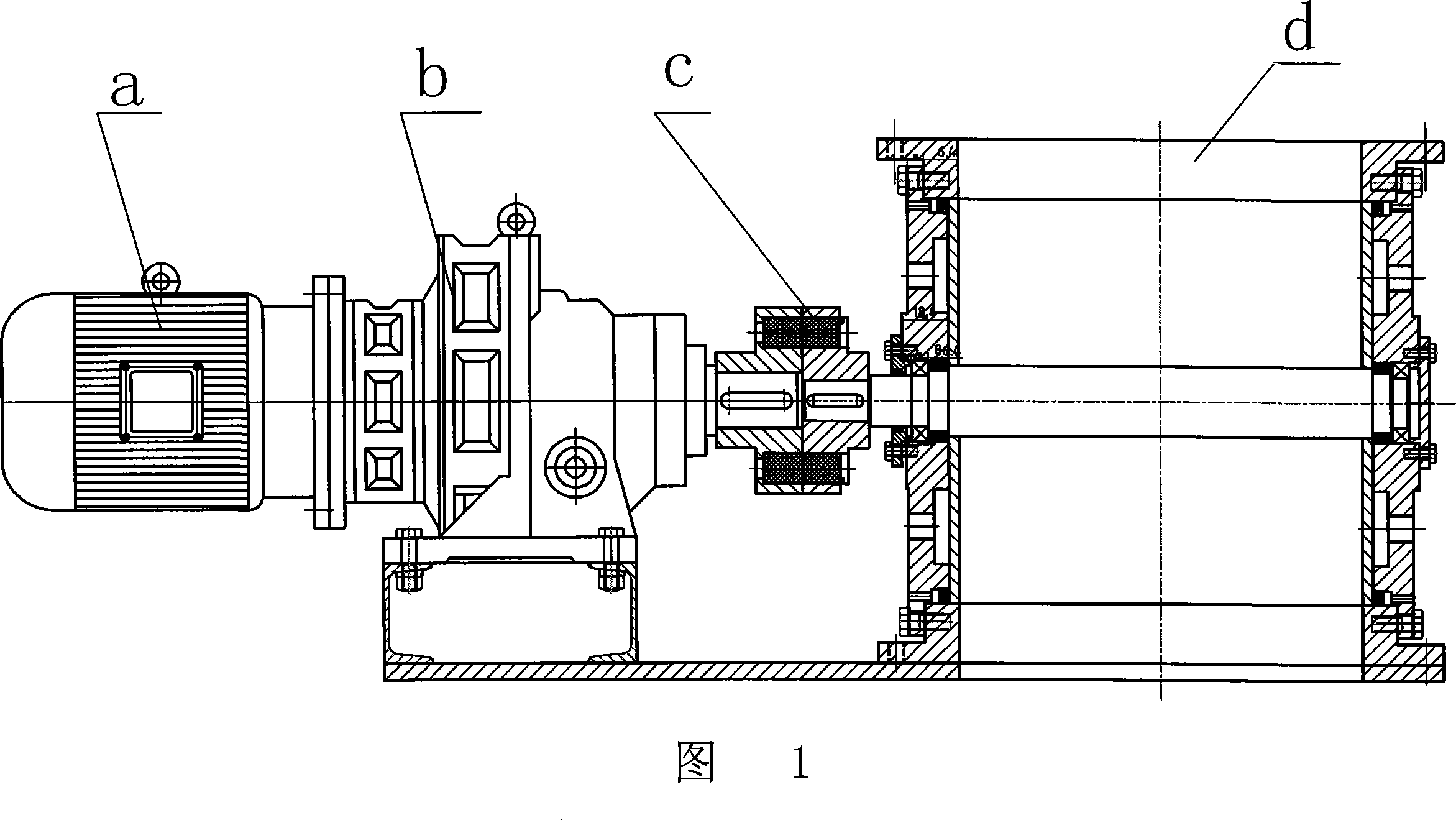

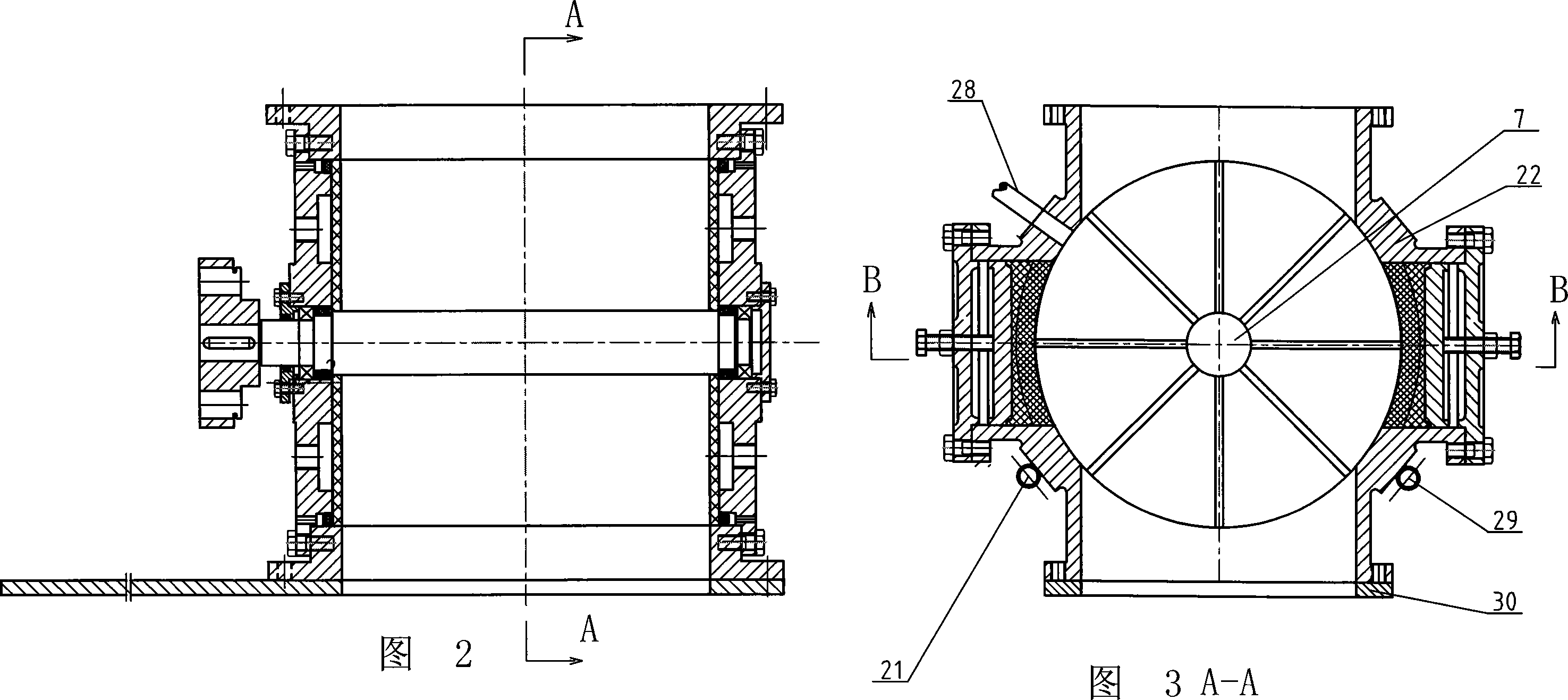

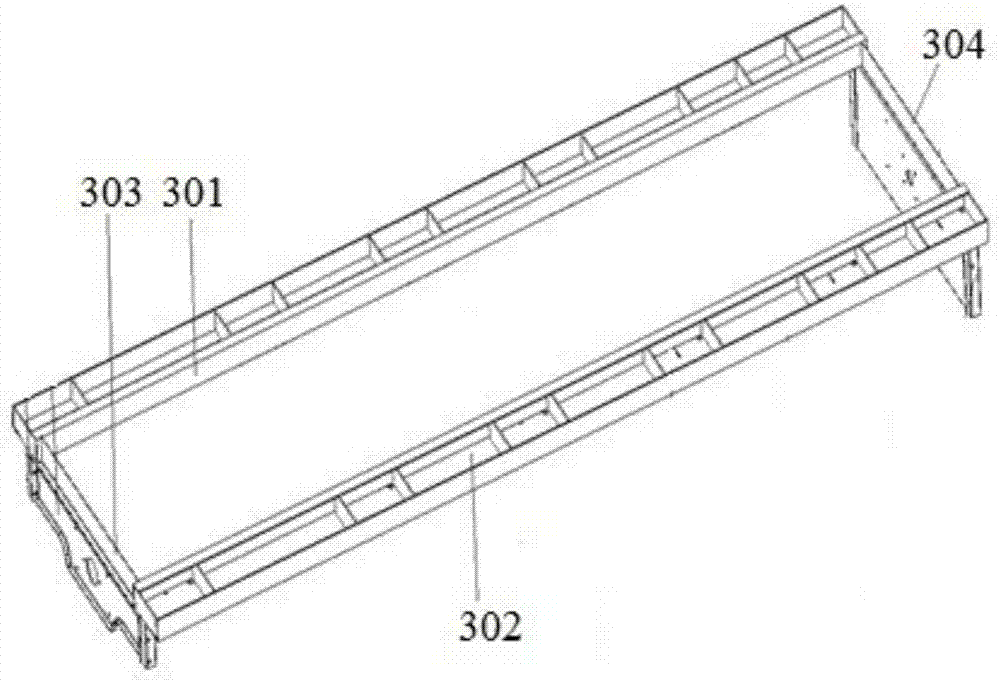

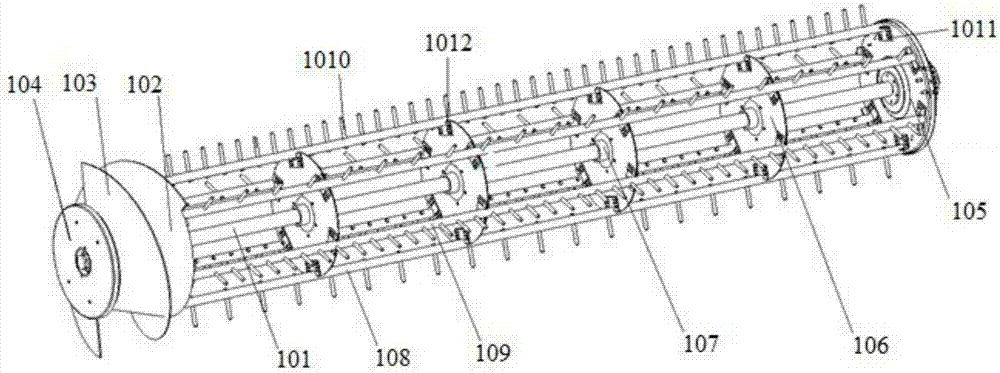

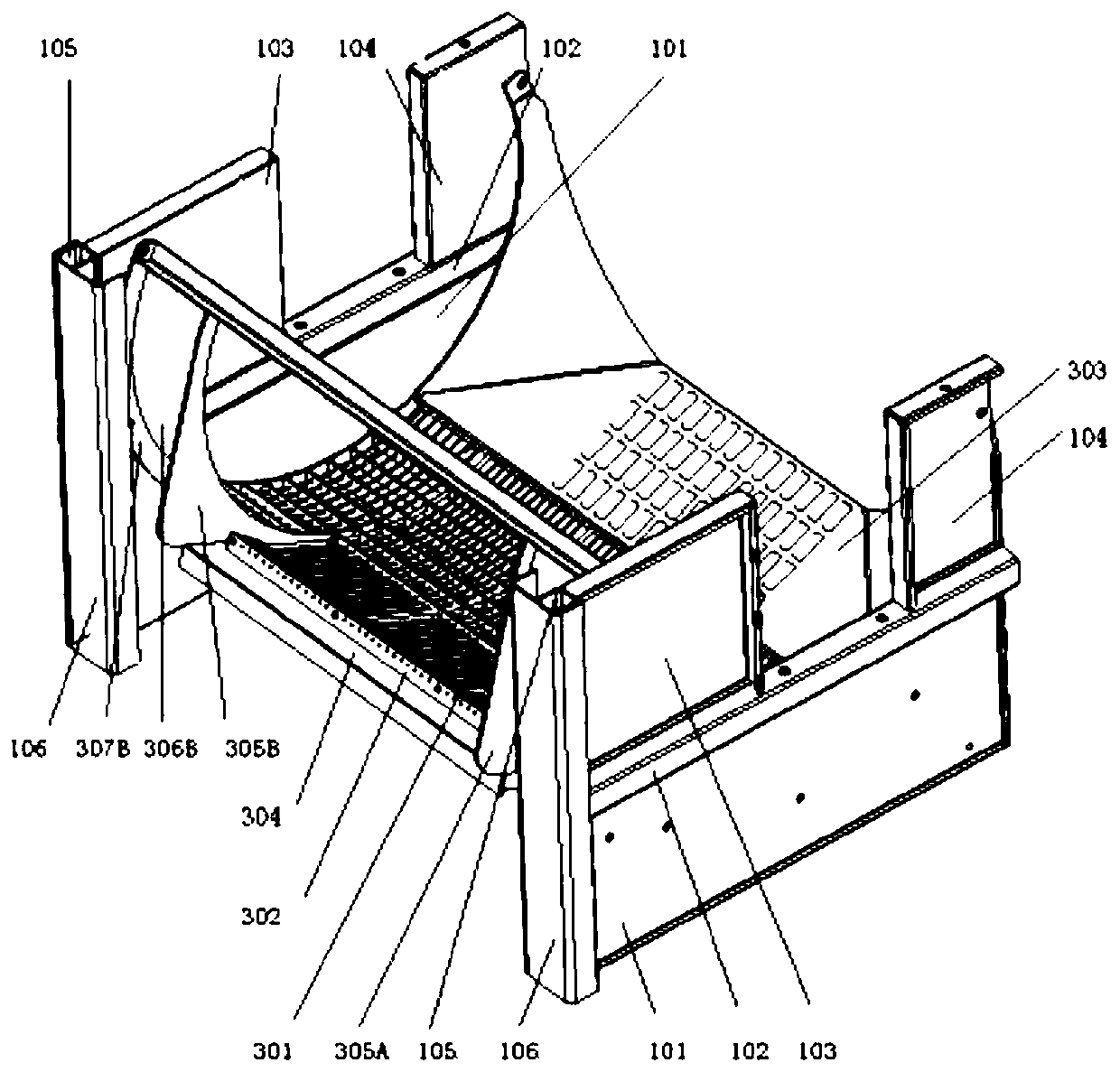

Negative-stiffness and longitudinal-axial-flow threshing cylinder of combined harvester

InactiveCN107455096AAvoid vibrationImproved threshing and separation capabilitiesThreshersEngineeringSpoke

The invention provides a negative-stiffness and longitudinal-axial-flow threshing cylinder of a combined harvester. The negative-stiffness and longitudinal-axial-flow threshing cylinder structurally comprises a longitudinal-axial-flow and negative-stiffness cylinder body, a cylinder top cover, a threshing rack, a concave grid and the like and is characterized in that spoke disc positioning sleeves on the longitudinal-axial-flow and negative-stiffness cylinder body are positioned on a cylinder shaft through key grooves, a middle spoke disc and a tail spoke disc are positioned on the spoke disc positioning sleeves through corresponding holes, and then spokes are welded and fixed to a middle positioning plate and a tail positioning plate and form bow shapes along an axial direction to allow the longitudinal-axial-flow cylinder to have a negative-stiffness feature. The negative-stiffness and longitudinal-axial-flow threshing cylinder has the advantages that the negative-stiffness and longitudinal-axial-flow threshing cylinder is applicable to various longitudinal-axial-flow paddy rice combined harvesters and can satisfy the efficient threshing requirements of paddy rice with different features; by the longitudinal-axial-flow and negative-stiffness cylinder body, the tangential stress of the cylinder spokes and spoke bending and deformation during paddy rice threshing can be balanced, and the difficulty of random dynamic load vibration, caused by stalks, of the cylinder during threshing can be solved effectively.

Owner:JIANGSU UNIV

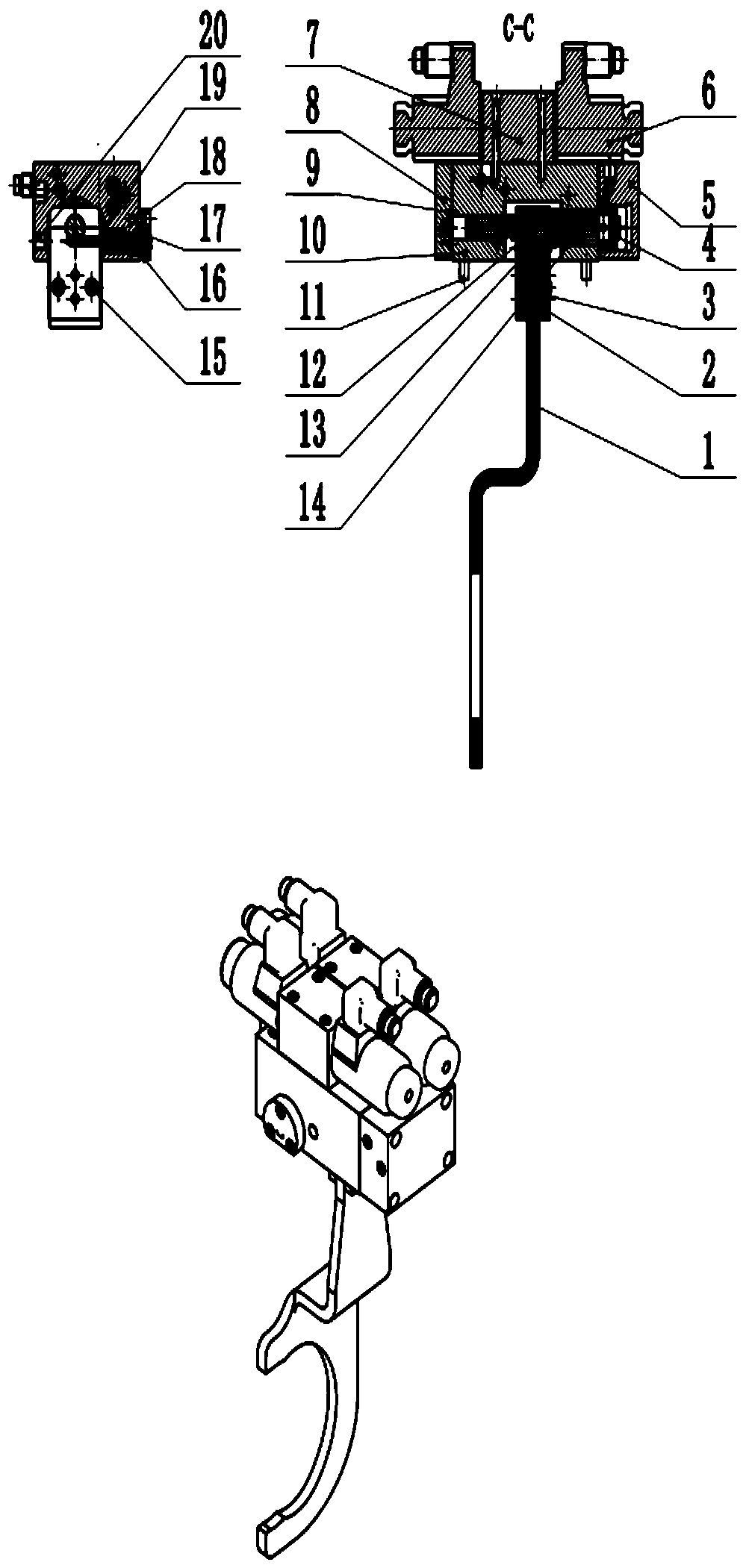

Electrohydraulic control gearshift device for tractor

InactiveCN108488374ASimple structureIncrease the cost of useControlled membersGearing controlElectricityRemote control

The invention discloses an electrohydraulic control gearshift device for a tractor. The electrohydraulic control gearshift device for the tractor comprises a shifting fork and is simple in structure.The electrohydraulic control gearshift device for the tractor is applied to solving the executing part of gearshift. In China, tractors commonly use mechanical gearshift mechanisms. If power gearshiftmechanisms at abroad are used, the conventional tractor structure will lose the original characteristics, and high price tractors will bring huge using cost to national economy. The research key point is how to control the conventional tractors by means of comprehensive characteristics of machinery, electricity and hydraulicity to fully complement shortcomings of machinery, electricity and hydraulicity effectively. The device is a novel product researched without changing the structure of the conventional tractor. Conventional shifting fork, shifting fork shaft, lever and the like are replaced by the electrohydraulic control gearshift mechanism, so that power gearshift can be achieved. Tractors can be updated by additionally mounting data detection, operation and remote control units, sothat automation and intelligence are achieved.

Owner:LUOYANG SHIYING MACHINERY PRODION

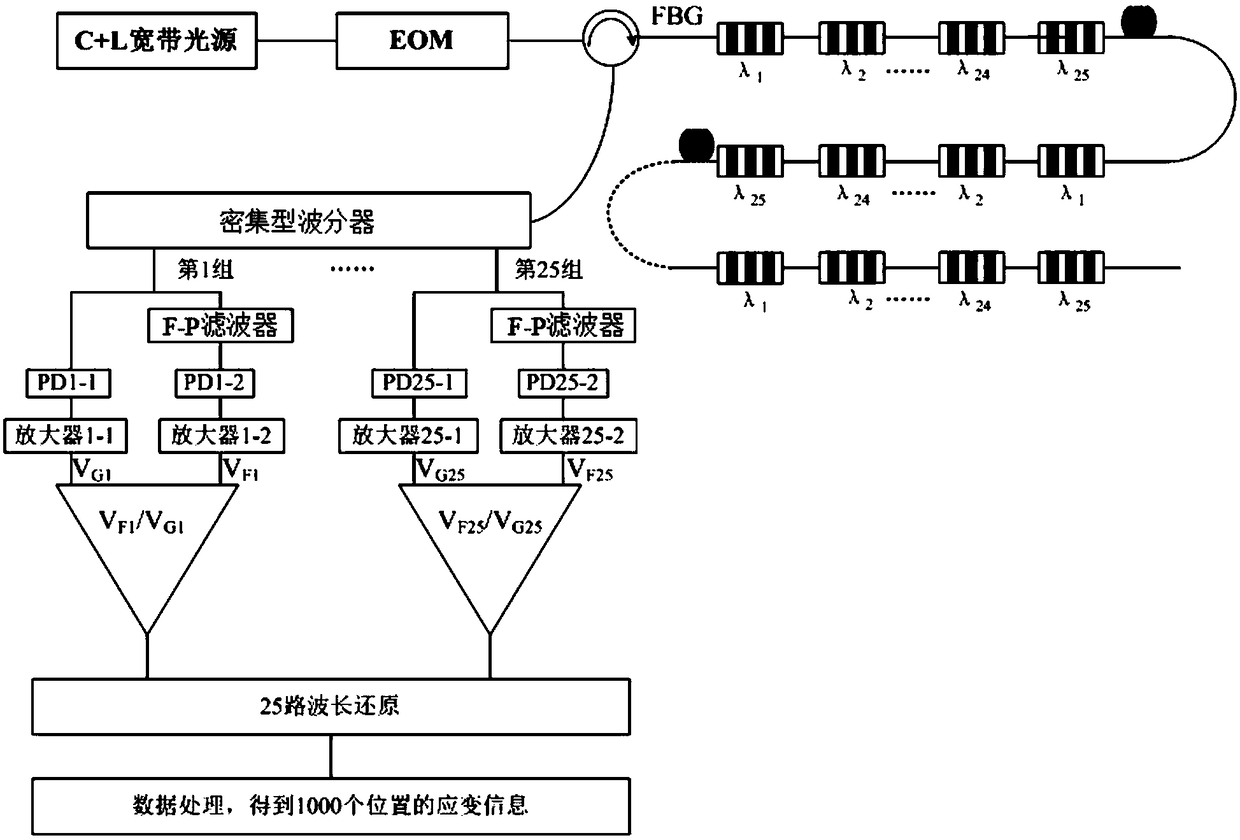

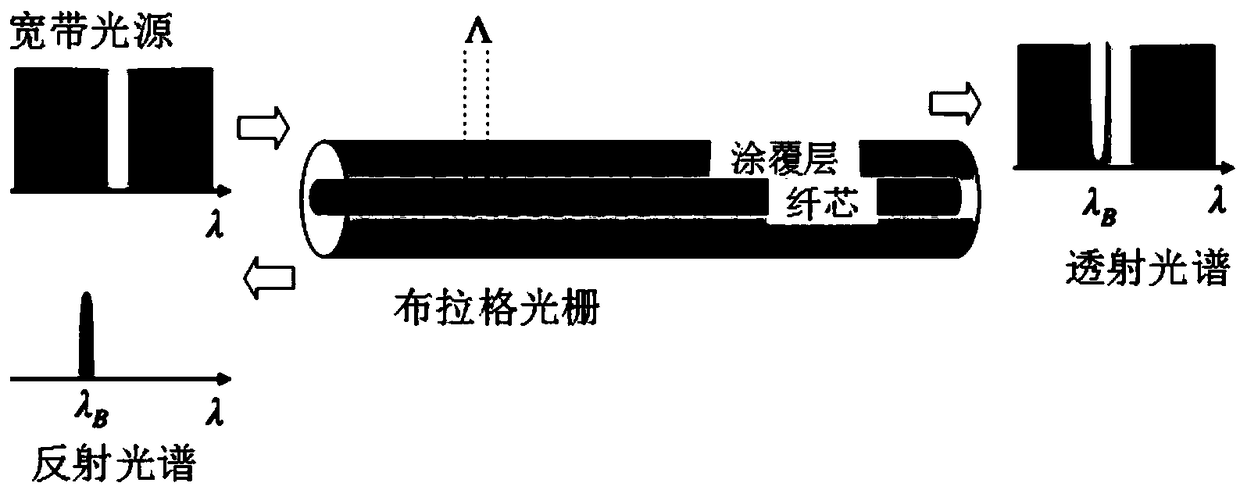

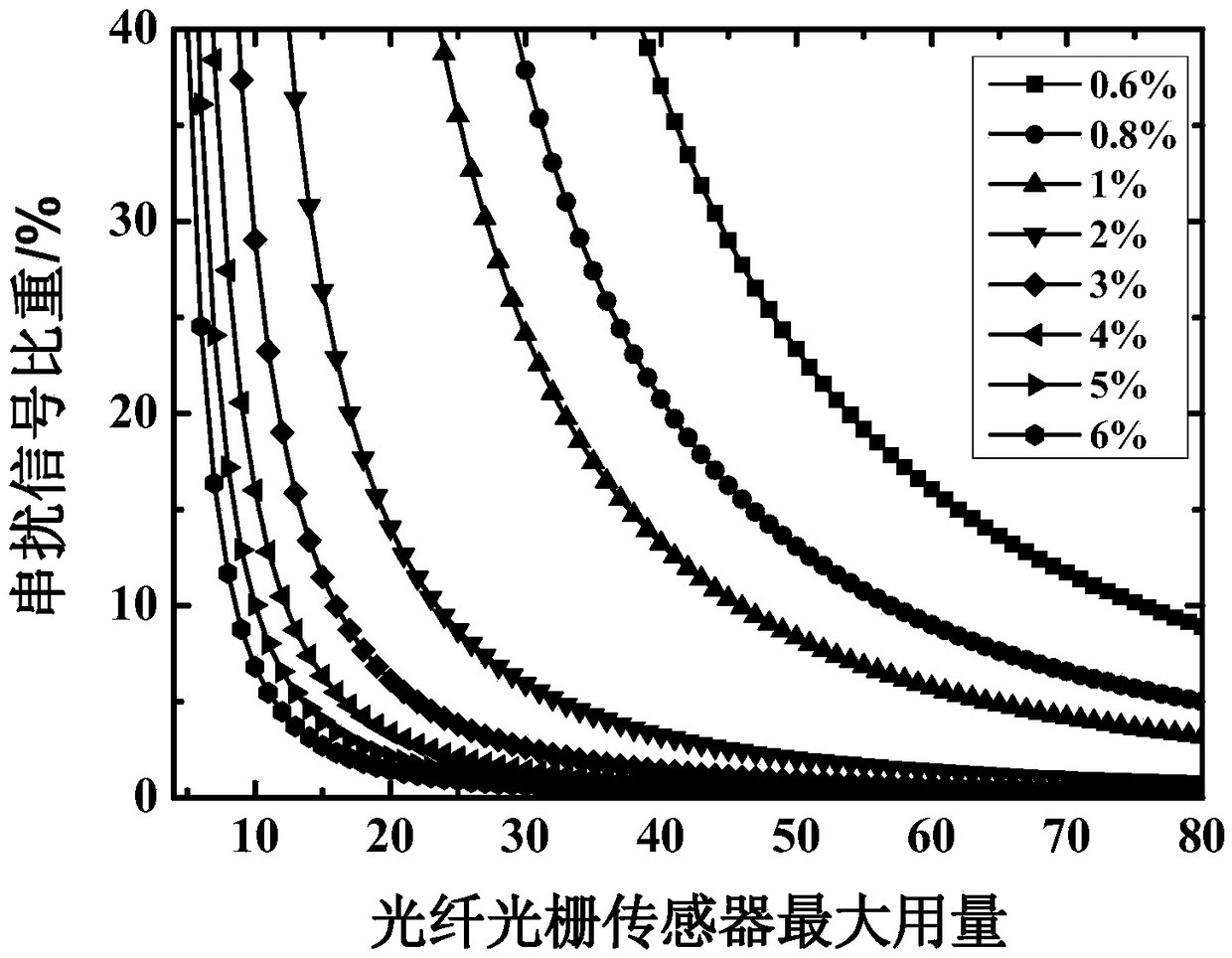

Large-capacity ultra-high-speed optical fiber sensing device for spacecraft strain monitoring

ActiveCN109470163AIncrease capacityMeet the needs of large-capacity optical fiber sensing and large area array detectionUsing optical meansGratingEngineering

The invention discloses a large-capacity ultra-high-speed optical fiber sensing device for spacecraft strain monitoring. The device solves the technical problem of simultaneously having 'large numberof sensors of single fiber' and 'ultra-fast demodulation rate'; a novel sensing framework is constructed, a 'dense splitting technology' and a 'low-reflectivity grating alternate use technology' are adopted to increase the capacity of the sensors on a single fiber, the number of the sensors of the single fiber is larger than one thousand, and the demands for large-area-array detection of the large-capacity optical fiber of a spacecraft are met; the ultra-high-speed demodulation of optical fiber sensing of the spacecraft is achieved through a non-mechanical strength adjustment principle, related research achieves upgrading of existing products, and great market value is brought.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

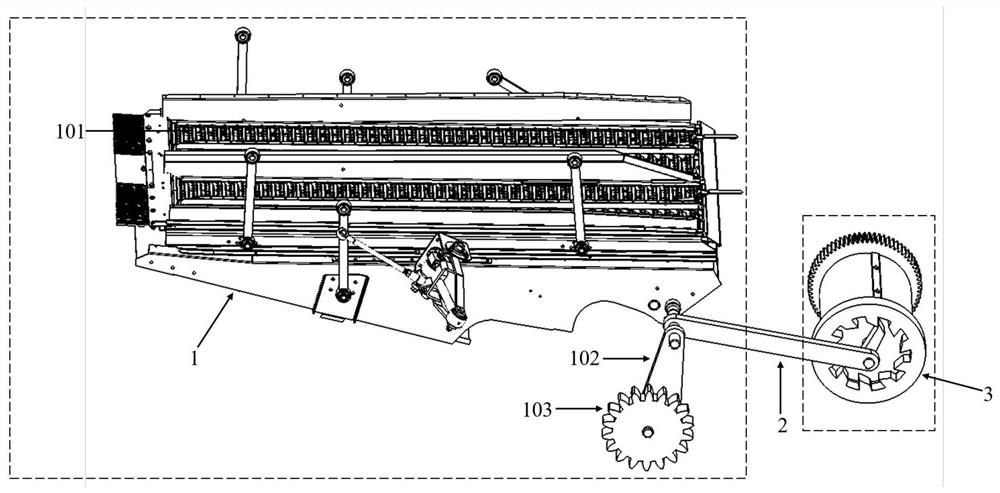

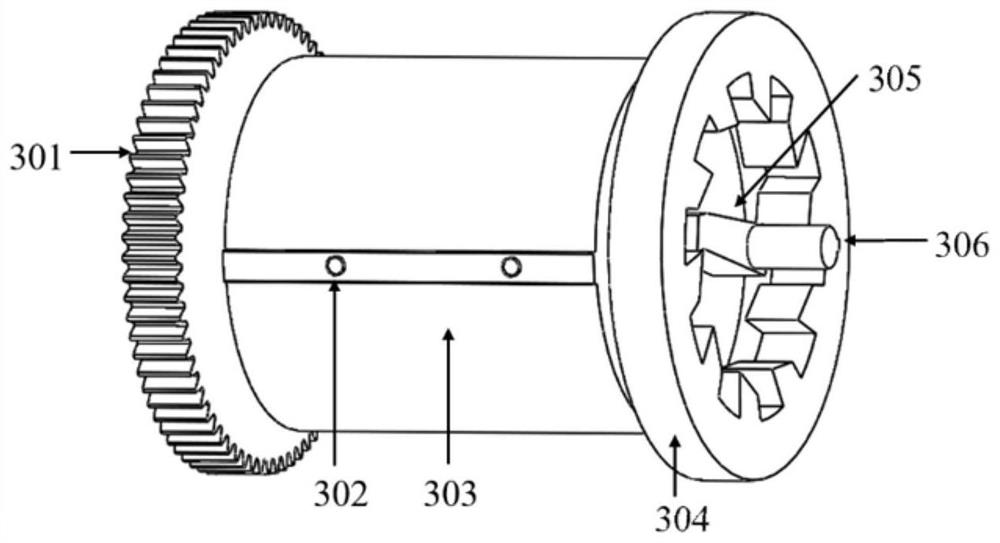

A rice combine harvester eccentric cutting flow primary separation device

ActiveCN107241971BReduce carrybackImprove the initial separation rateThreshersAgricultural engineeringStructural engineering

The invention provides an eccentric tangential-flow primary threshing and separating device of a rice combination harvester. A tangential-flow threshing roller, a concave plate sieve and a top cover are installed on a rack; a support shaft and transmission shaft of the tangential-flow threshing roller penetrate through a left plate and a right plate respectively, an eccentric shaft is located between the left plate and the right plate, and the two ends of the eccentric shaft are connected with the transmission shaft and the support shaft respectively; the center of the transmission shaft and the center of the support shaft both coincide with the rotating center of the threshing roller, so that a certain eccentricity exists between the center of the eccentric shaft and the rotating center of the threshing roller, and a certain angle exists between the horizontal plane and the connecting line of the two centers. When the threshing roller works, a threshing element begins to stretch out above a feeding opening of the tangential-flow threshing roller and draws back into the threshing roller near a longitudinal axial flow feeding opening, back-drawing of rice by the threshing element is effectively reduced, and the problem of unsmooth feeding at the intersection place between tangential flow and longitudinal flow is solved; meanwhile, the partial resistance torque produced by materials is balanced by the torque produced by the centre-of-gravity shift of the tangential-flow roller, the vibration of the tangential-flow threshing roller is reduced, the work performance is improved, and the service life is prolonged.

Owner:JIANGSU UNIV

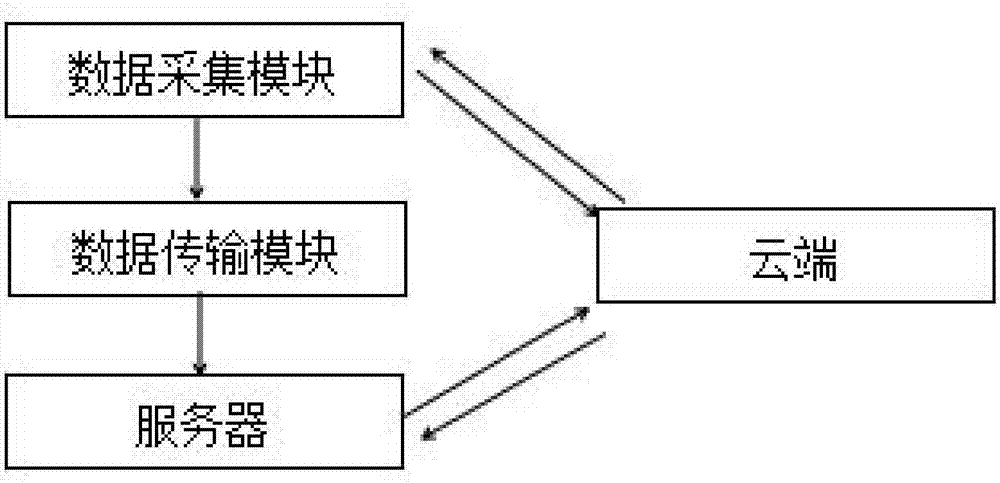

Stone internet-of-things handset system and management method thereof

InactiveCN107256489ASimplify the management processRealize upgradingBuying/selling/leasing transactionsManagement efficiencyClient-side

The invention discloses a stone internet-of-things handset system and a management method thereof. The system comprises a cloud end, a data collection module, a data transmission module and a server, wherein the data collection module is used for collecting related data of stones; the data transmission module transmits the collected related data to the server; the server analyzes and judges whether the related data is abnormal or not, provides a solution, and prints and outputs the related data according to the demand of a client; and the cloud end is used for storing all the related data of the stones. Tags are arranged on the stones, the data collection module obtains the related data through the tags, then the data is transmitted to the server through the data transmission module, and the data is transmitted to the cloud end for storage; and the server receives and analyzes the data, transmits a result to the client and stores the result in the cloud end. The manual statistics, manual inspection and manual printing of production management are greatly improved and the purposes of reducing the cost and improving the management efficiency are achieved.

Owner:曹孝忠

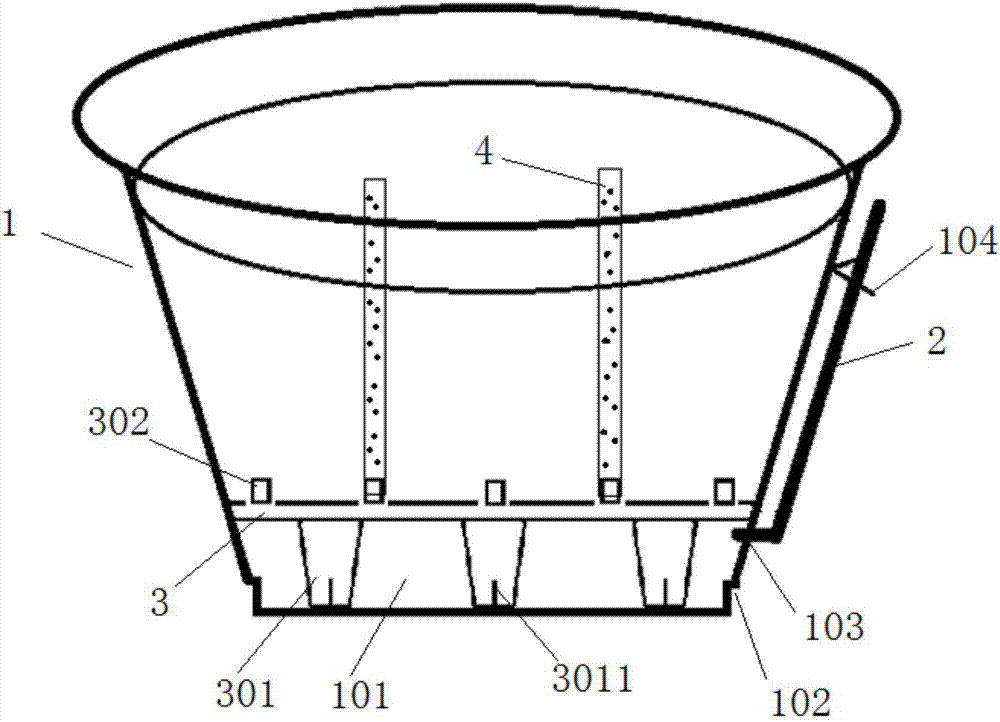

Gardening pot tower system

InactiveCN106912317AAvoid wastingSave waterSelf-acting watering devicesReceptacle cultivationSitting roomGreening

The invention provides a gardening pot tower system which comprises a flower pot portion and a support portion. The flower pot portion changes the existing design that air exhausting and water draining holes are arranged at the bottom of a flower pot, and a tray of the flower pot is prevented from being used. The whole pot tower system achieves the purpose of upgrading and updating household gardening, improves gardening ornamental value and practicability, effectively utilizes limited indoor space, greatly increases indoor greening area, reduces maintaining technology requirements and time at the same time and improves micro environmental climate of humidity, air quality and the like of living room microenviroment. The gardening pot tower system has the advantages of a simple technology, low cost and large practical value and market prospect.

Owner:高双喜

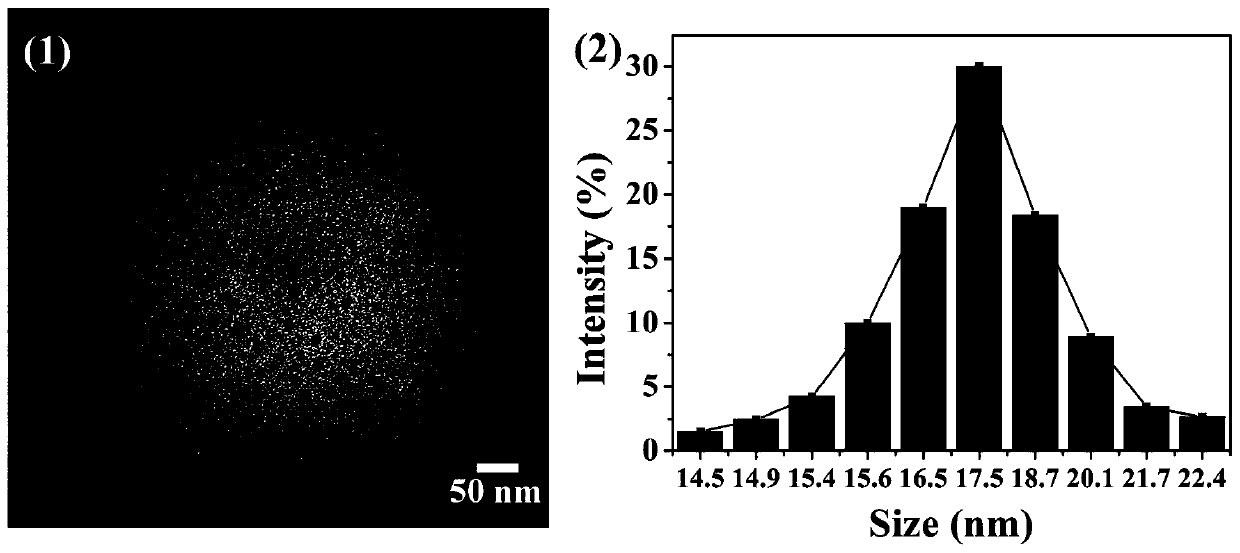

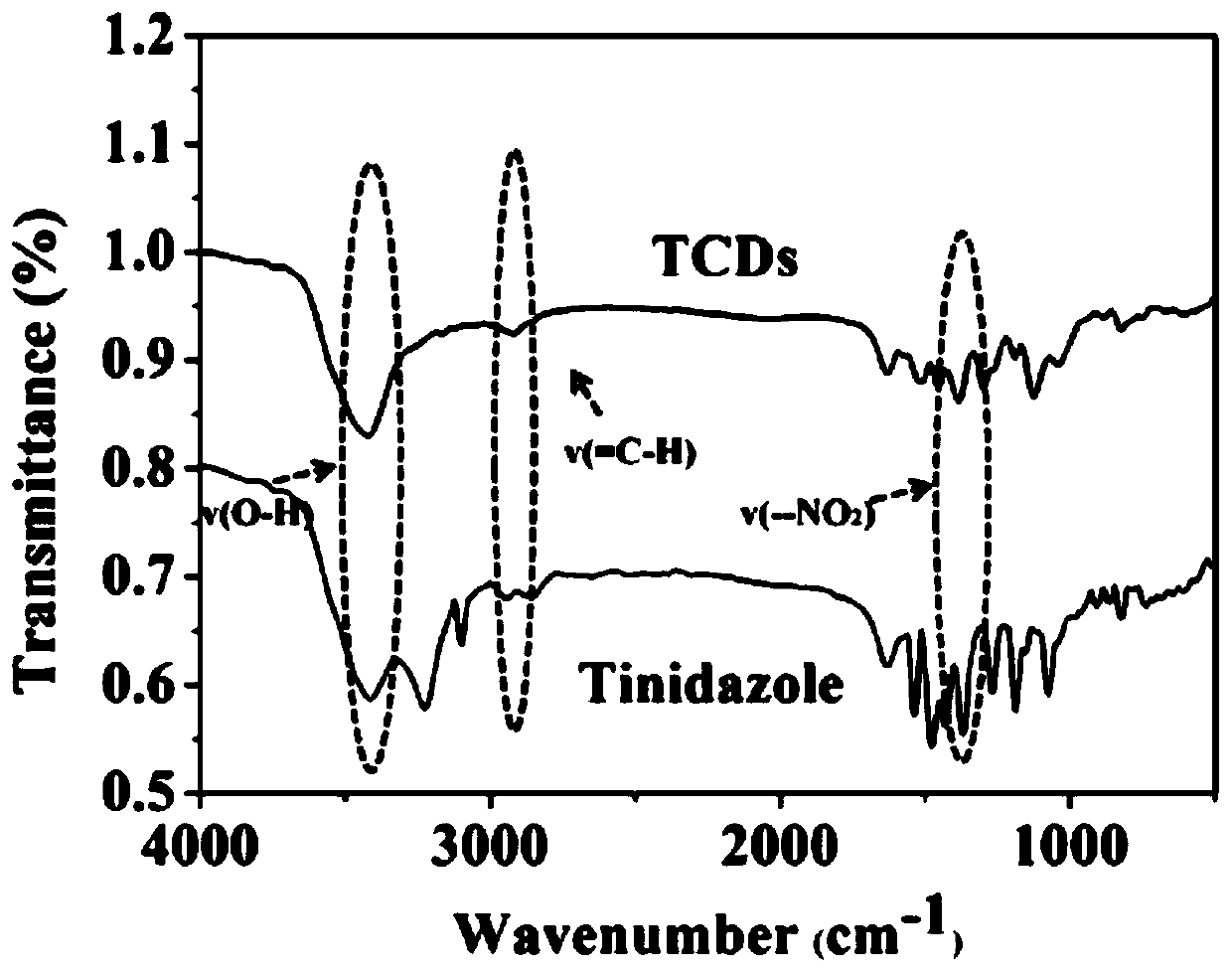

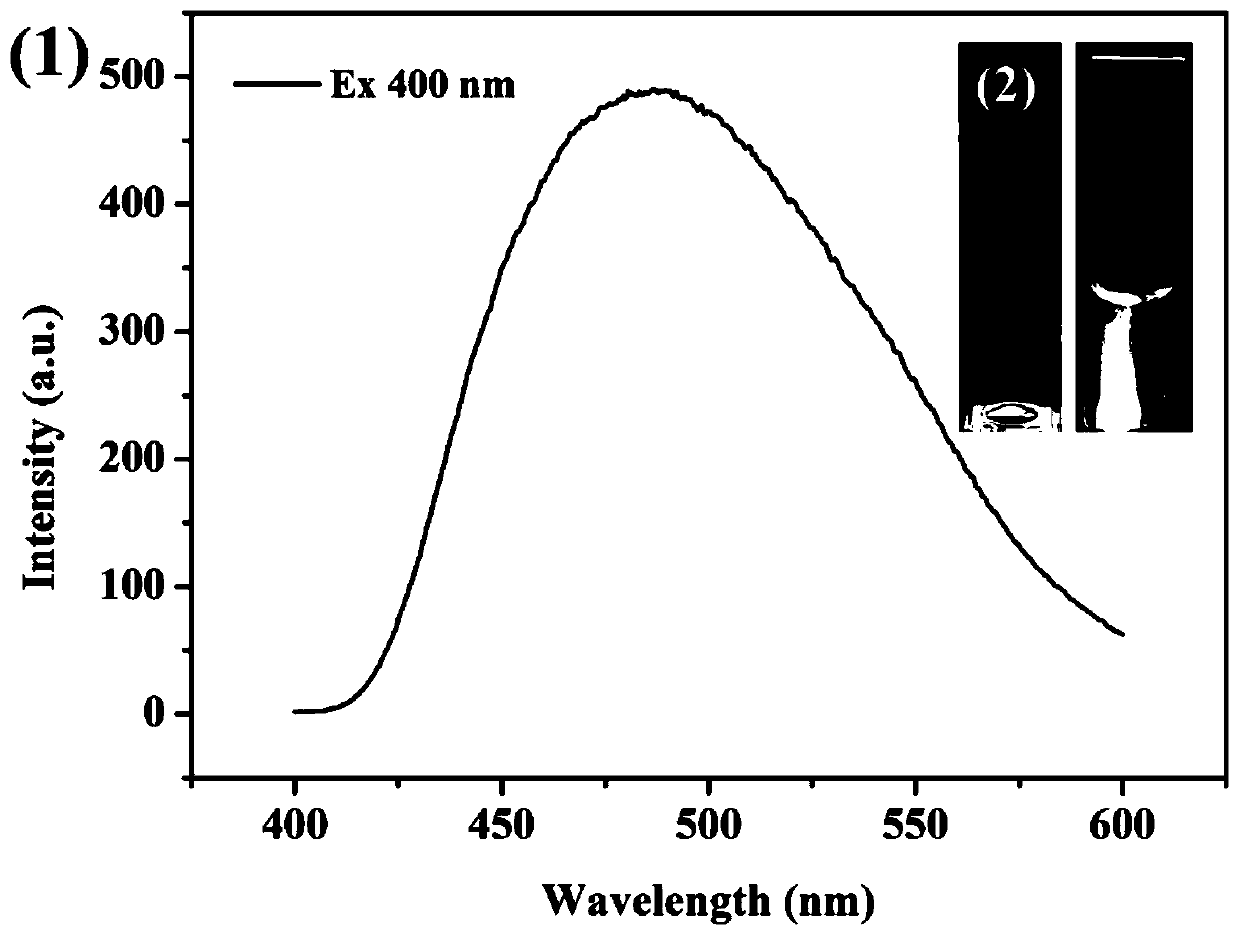

Nanometer tinidazole carbon point as well as preparation method and application thereof

InactiveCN110790258ARealize upgradingSimple processAntibacterial agentsDigestive systemTinidazoleObligate anaerobe

The invention discloses a nanometer tinidazole carbon point as well as a preparation method and application thereof and belongs to the technical field of medicines. The preparation method comprises the following steps: preparing a 0.1-0.3mol / L tinidazole solution, performing a hydrothermal reaction on the tinidazole solution at a temperature of 180-250 DEG C so as to obtain a crude product, filtering the crude product by using a membrane of which the aperture is 0.22[mu] m, performing dialysis by using a dialysis bag of which the molecular cutoff is 800Da, and performing drying, so as to obtain the nanometer tinidazole carbon point. Tinidazole is adopted as a predrug, the tinidazole medicine is prepared into a carbon point medicine through hydrothermal conditions, and the obtained tinidazole carbon point medicine has a small nanometer size and a tinidazole antibacterial function, meanwhile has selective antibacterial activity upon obligate anaerobes, and is capable of even penetratingbacterium biomembranes to achieve deep sterilization, so that the effect of the medicine can be maximized.

Owner:HENAN UNIV OF SCI & TECH

Characterization method of coke oven vertical flue temperature

ActiveCN110377939AChange the temperature representation mode a bitRealize upgradingEnergy inputDesign optimisation/simulationIrregular matrixEngineering

The invention provides a characterization method of a coke oven vertical flue temperature, which comprises the following steps: acquiring a coke oven vertical flue thermal image by a thermal imager, meshing the thermal image, removing a circumferential irregular matrix and uniformly dividing the thermal image into a plurality of groups of matrixes to obtain characterization parameters of the maximum temperature of a vertical flue, the average temperature of the vertical flue and the temperature range of the vertical flue. According to the characterization method, the temperature and distribution of the coke oven vertical flue can be comprehensively characterized, the characterization mode of one-point temperature of an original coke oven vertical flue is thoroughly changed, and upgrading and updating of coke oven heating management can be achieved.

Owner:南京智宝节能环保科技有限公司

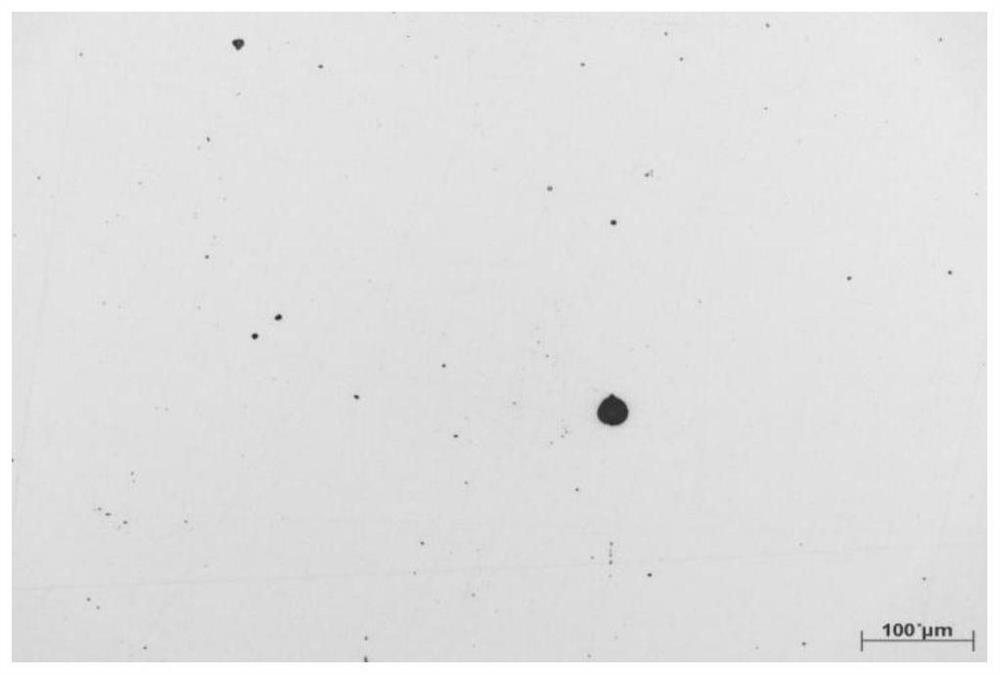

Steel for corrosion-resistant automobile concrete mixing tank and preparation method thereof

ActiveCN113737098BImprove corrosion resistanceImprove wear resistanceSteelmakingChemical composition

The invention provides a steel for an anti-corrosion automobile concrete mixing tank and a preparation method thereof. The chemical composition and mass percentage of the steel are: C: 0.15-0.20%; Si≤0.01%; Mn≤1.50%; S≤0.001%; P≤0.010%; Al: 0.01-0.06%; O: 0.0010-0.0020%; N: 0.0010-0.0030%; Ca: 0.0020-0.0040%; Cr: 0.50-1.50%; Ti: 0.20-0.40%; ~0.35%; Cu: 0.19~0.40%, the rest is Fe and other unavoidable impurities. The preparation method includes S1, steelmaking; S1.1, smelting; S1.2, LF ladle furnace refining; S1.3, continuous casting; S2, hot rolling; S2.1, heating; S2.2, controlled rolling; S2 .3, layer cooling; S2.4, coiling.

Owner:BENGANG STEEL PLATES

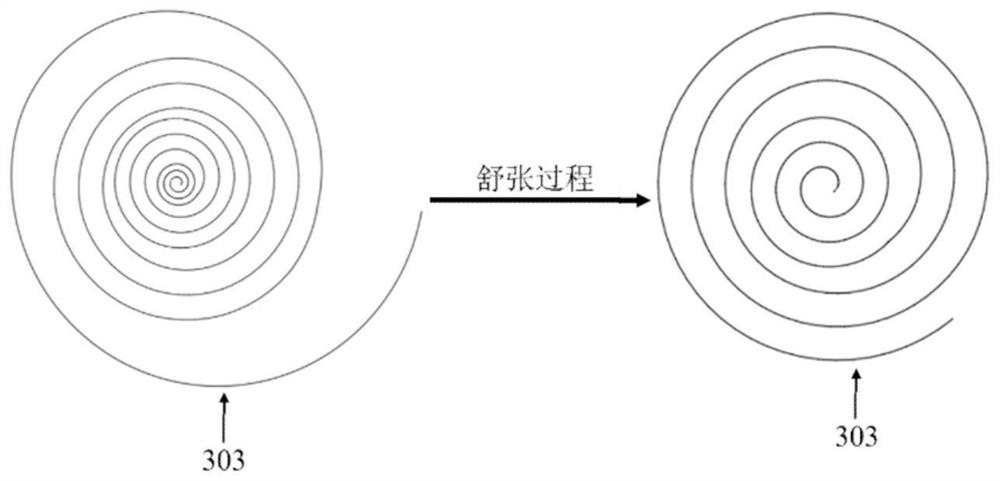

Energy recovery and cyclic utilization system for balancing load fluctuation of vibrating screen of combine harvester

ActiveCN113940188AImprove capacity utilizationOptimize working modelMowersSaving energy measuresRatchetElectric generator

The invention provides an energy recovery and cyclic utilization system for balancing load fluctuation of a vibrating screen of a combine harvester. The energy recovery and cyclic utilization system comprises the vibrating screen, a connecting rod, an energy storage device and a power supply device; one end of the vibrating screen reciprocates through an eccentric device; the eccentric device is connected with the energy storage device through the connecting rod; the energy storage device comprises a transmission gear, a volute spiral spring, a ratchet wheel, a pawl and an energy storage spring shaft; one end of the volute spiral spring is connected with the energy storage spring shaft, and the other end of the volute spiral spring is fixed on a sleeve; the volute spiral spring is connected with the transmission gear, the sleeve is in transmission connection with the connecting rod, the ratchet wheel is arranged at one end of the sleeve, the pawl is installed on the energy storage spring shaft, the pawl is matched with the ratchet wheel, and the ratchet wheel drives the pawl to rotate in a one-way mode; the power supply device comprises a generator and a battery pack; and the transmission gear is in transmission connection with the generator. According to the energy recovery and cyclic utilization system, excess energy generated by the vibrating screen due to load fluctuation can be recovered, and energy cyclic utilization of the vibrating screen under high load can be achieved.

Owner:JIANGSU UNIV

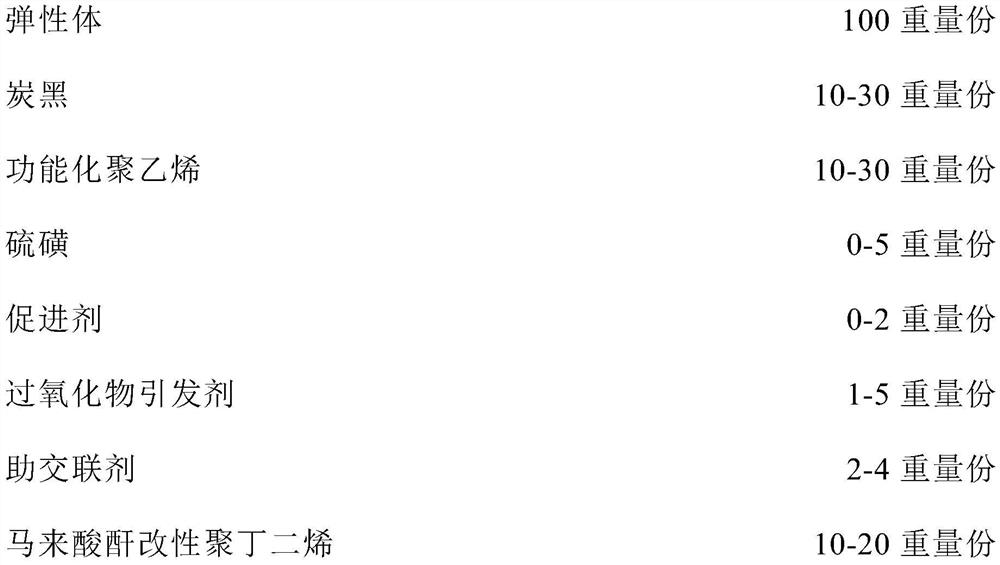

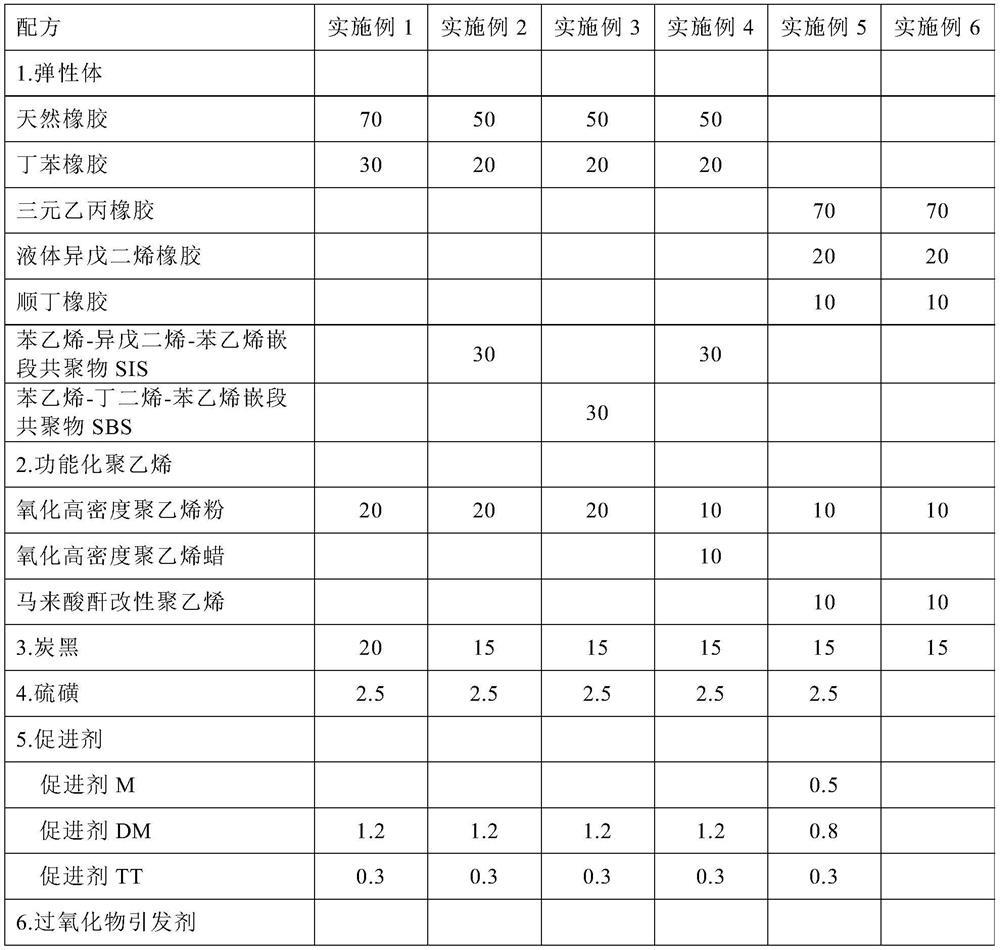

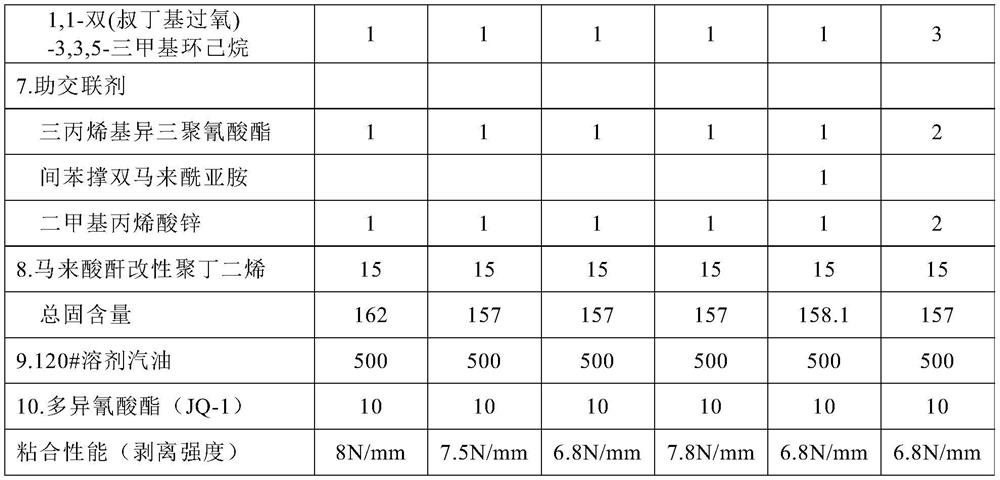

Formula of ultra-high molecular weight polyethylene canvas surface modified rubber cement for rubber conveying belt

The invention relates to a formula of ultra-high molecular weight polyethylene canvas surface modified rubber cement for a rubber conveying belt. The formula comprises the following components in parts by weight: 100 parts of elastomer, 10-30 parts of functionalized polyethylene, 10-30 parts of carbon black, 0-5 parts of sulfur, 0-2 parts of accelerant, 1-5 parts of peroxide initiator, 2-4 parts of assistant crosslinker, 10-20 part of maleic anhydride modified polybutadiene, and 5-10 parts of polyisocyanate or polyisocyanates. The ultra-high molecular weight polyethylene canvas can be bonded with the rubber conveying belt through the adhesive cement prepared according to the formula, and the rubber conveying belt produced by adopting the ultra-high molecular weight polyethylene fiber impregnated canvas coated with the adhesive cement has the characteristics of small elongation, good impact resistance, tear resistance, energy conservation and high strength; a steel wire rope can be replaced, and upgrading and updating of conveying belt framework materials are achieved.

Owner:无锡宝强工业织造有限公司 +1

Balance oscillating dyeing machine

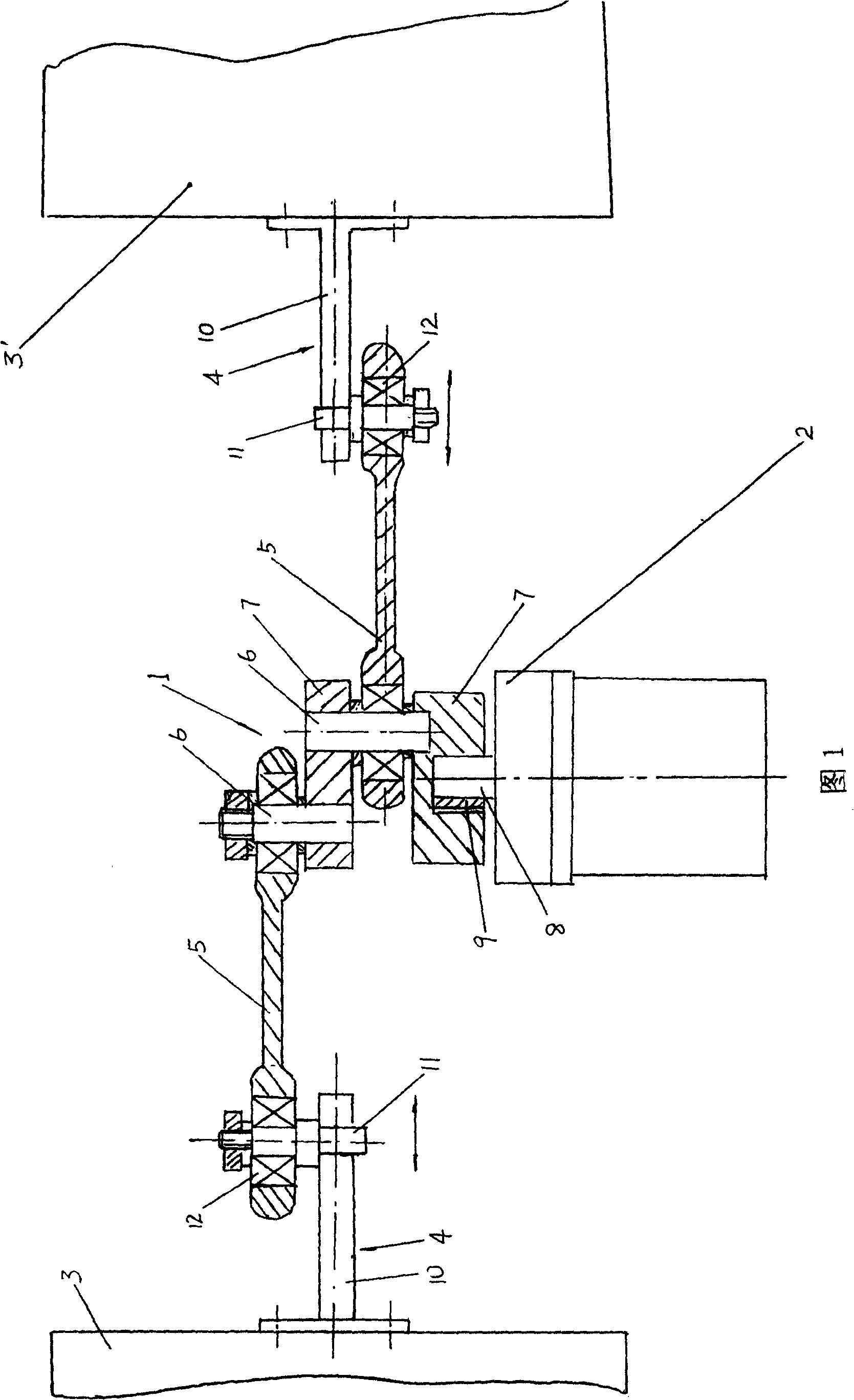

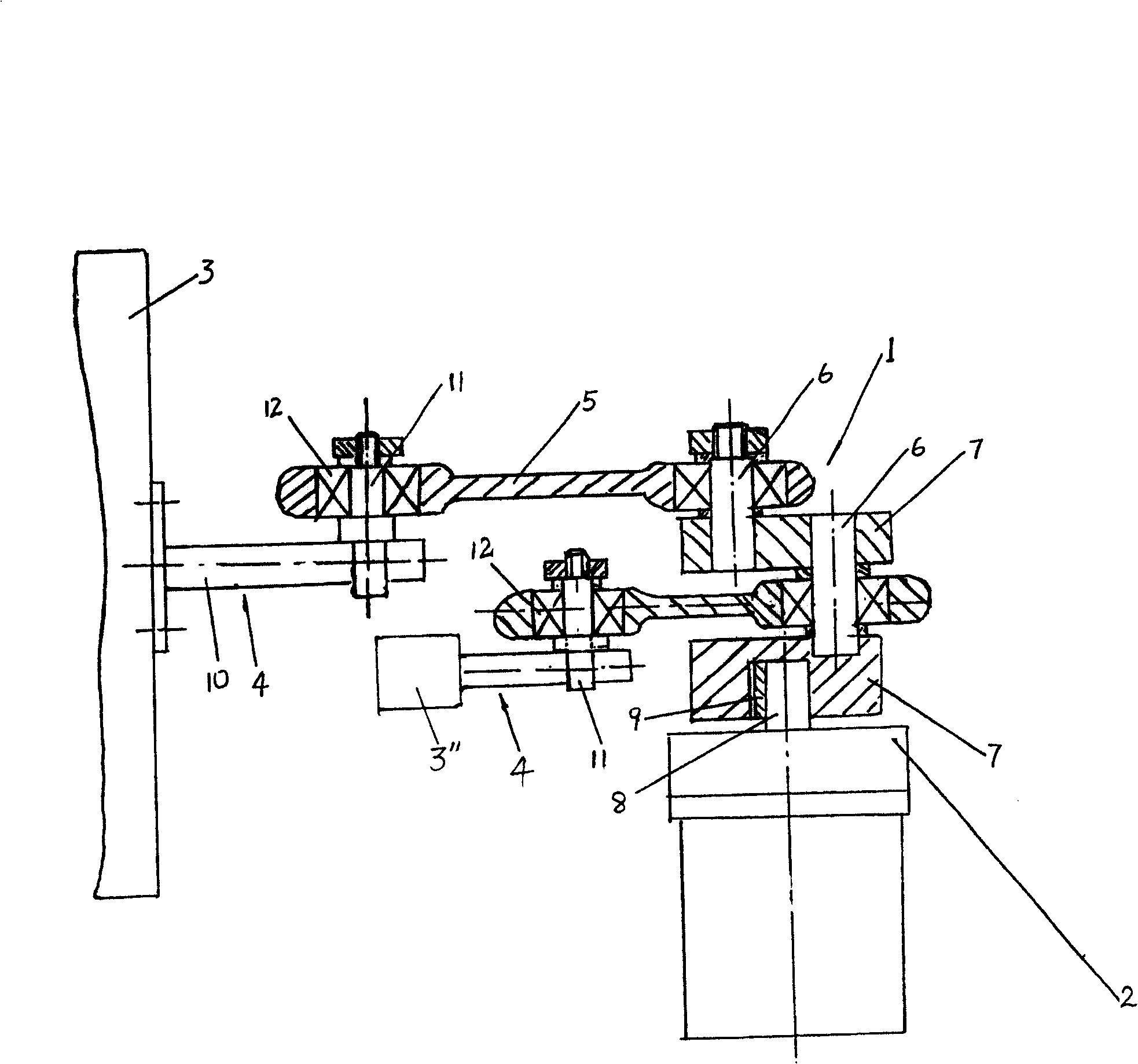

InactiveCN100451209CReduce noiseStable jobTextile treatment dyeing devicesVibration treatmentEngineeringWork time

This invention discloses a kind of balanced concussion coloring machine which can keep the apparent force almost in balance when the crank mechanical linkage is working which can drive the concussing box moving. So the vibration is small while the jar is low and the abrade is small. As a result, we can substantially elongate the machine's non-accident working time and using life length. It includes the crank mechanical linkage (1), concussion box(3), and (3) whose reciprocation is driven by (1) is linked with (1) and is fixed on one side of (1). The invention's characters are that not only does (1 has (3) on its side, but also it has another concussion box(3`) or (3``)on the other side to balance the apparent force of (1). (3),(3') and (3``) are linked with one end of the connection bar(5) of (1), while the other end is linked with the crank(6) corresponding to (1).

Owner:张同生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com