Steel for disk blade, production method and disk blade treatment method

A technology of production method and treatment method, which is applied in the direction of heat treatment furnace, heat treatment equipment, workpiece surface treatment equipment, etc., can solve the problems of poor toughness and plasticity of steel plate, low production efficiency, high carbon content, etc., and achieve excellent wear resistance and toughness and plasticity , excellent performance, and the effect of improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

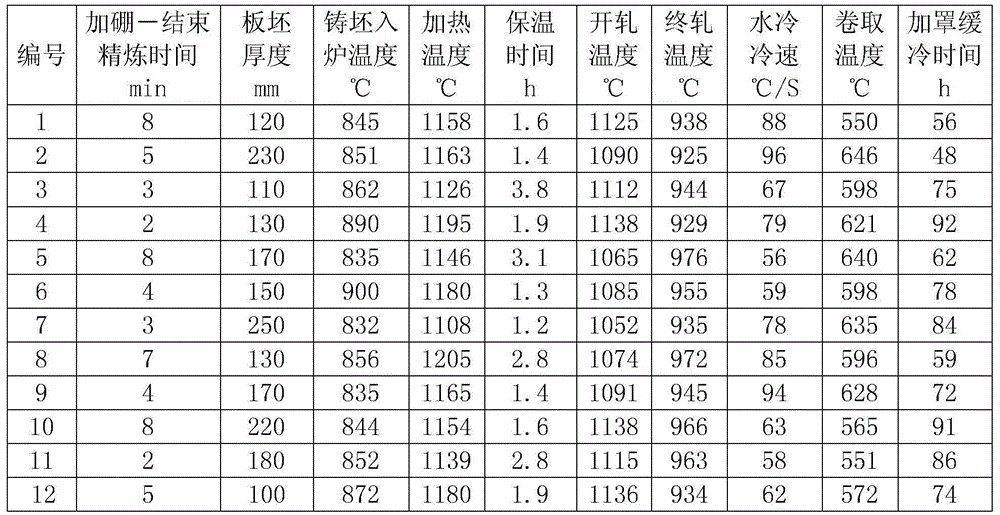

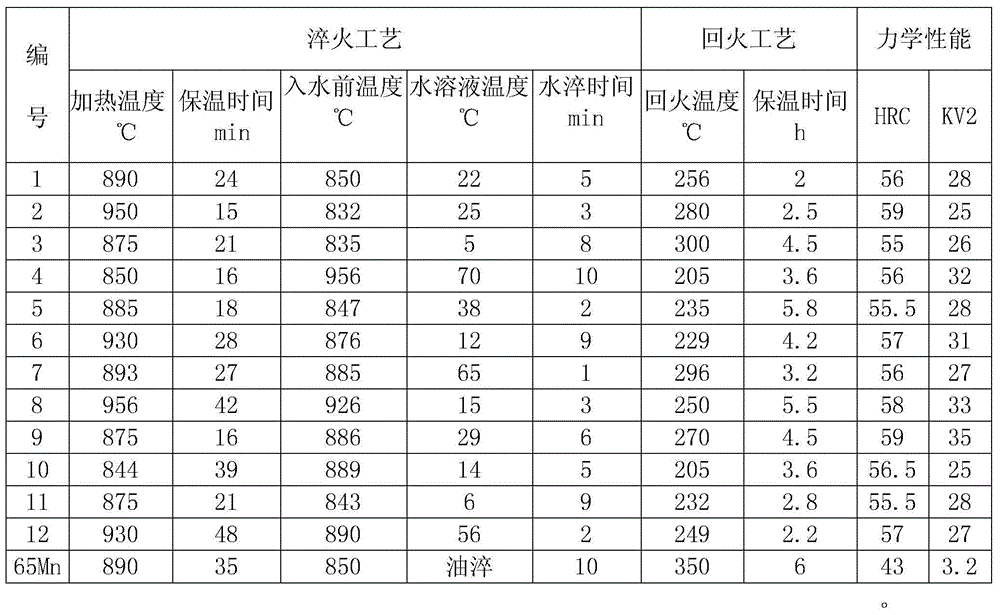

[0041] The present invention will be further described below in conjunction with embodiment.

[0042] Table 1 is the chemical composition wt% content list of the steel used for rake blades in Examples 1-12.

[0043] Table 1 Embodiment 1~12 steel chemical composition wt% content table for rake sheet

[0044] Numbering

C

Si

mn

P

S

B

Cr

Al

Ti

O

N

(Ti+Al) / N

1

0.25

0.25

1.48

0.015

0.005

0.0047

0.22

0.035

0.041

0.0015

0.0065

10.3

2

0.33

0.37

1.32

0.004

0.009

0.0024

0.45

0.022

0.058

0.0019

0.0062

16.5

3

0.32

0.05

1.01

0.008

0.002

0.0058

0.10

0.015

0.029

0.0012

0.0028

19.3

4

0.27

0.16

1.25

0.010

0.008

0.0045

0.04

0.042

0.015

0.0014

0.0035

18.9

5

0.30

0.30

1.20

0.018

0.004

0.0027

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com