Energy-saving type reciprocating high-pressure plunger pump

A high-pressure plunger pump, energy-saving technology, applied in variable capacity pump components, pumps, multi-cylinder pumps, etc., can solve problems such as difficulty in meeting actual needs, high cost, and high noise, and achieve low production costs and low operating costs The effect of low cost and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

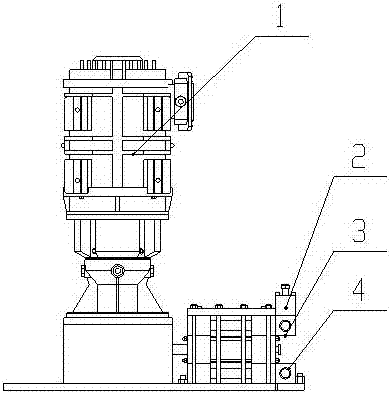

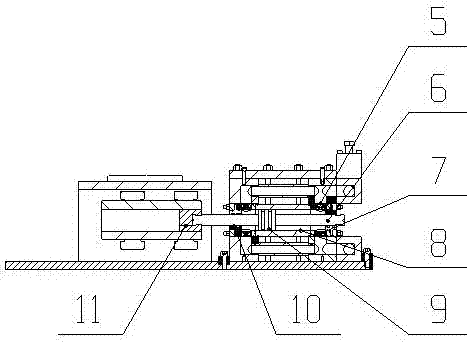

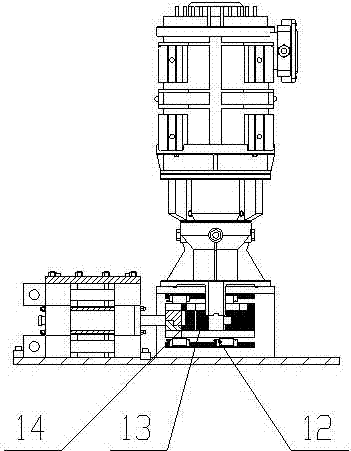

[0020] Figure 1-3 Middle: 1-planetary gear reduction frequency conversion motor, 2-pressure regulating valve, 3-water outlet assembly, 4-water inlet assembly, 5-extrusion valve, 6-piston rod, 7-suction valve, 8-cylinder, 9 -piston, 10-cylinder gland, 11-piston rod clamp, 12-guide rail, 13-sector gear, 14-rack.

[0021] With reference to the drawings, the specific implementation plan is: an energy-saving plunger-type high-pressure plunger pump is composed of a planetary gear reduction frequency conversion motor 1, a pressure regulating valve 2, a water outlet group 3, a water inlet assembly 4, an extruding valve 5, a piston Rod 6, suction valve 7, cylinder body 8, piston 9, cylinder body gland 10, piston rod clamp 11, guide rail 12, sector gear 13, rack 14; it is characterized in that when the planetary gear reduction frequency conversion motor 1 starts, Drive the sector gear 13 to run. When the sector gear 13 rotates for one cycle, it d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com