Formula of ultra-high molecular weight polyethylene canvas surface modified rubber cement for rubber conveying belt

An ultra-high molecular weight, surface modification technology, applied in the field of industrial textiles, can solve problems such as inability to bond rubber, inert chemical properties, and low reactivity, and achieve good impact resistance, high strength, and low elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

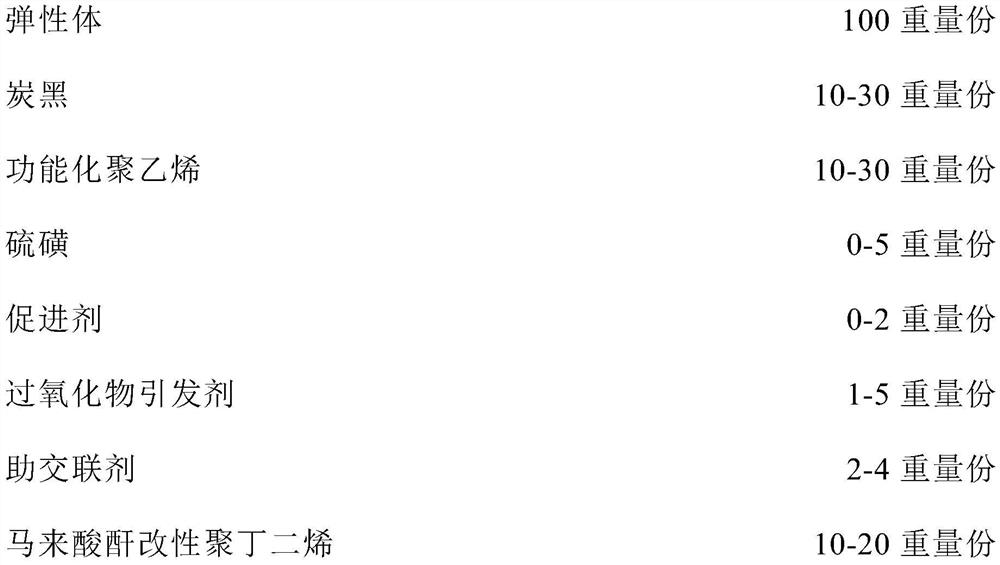

Method used

Image

Examples

Embodiment Construction

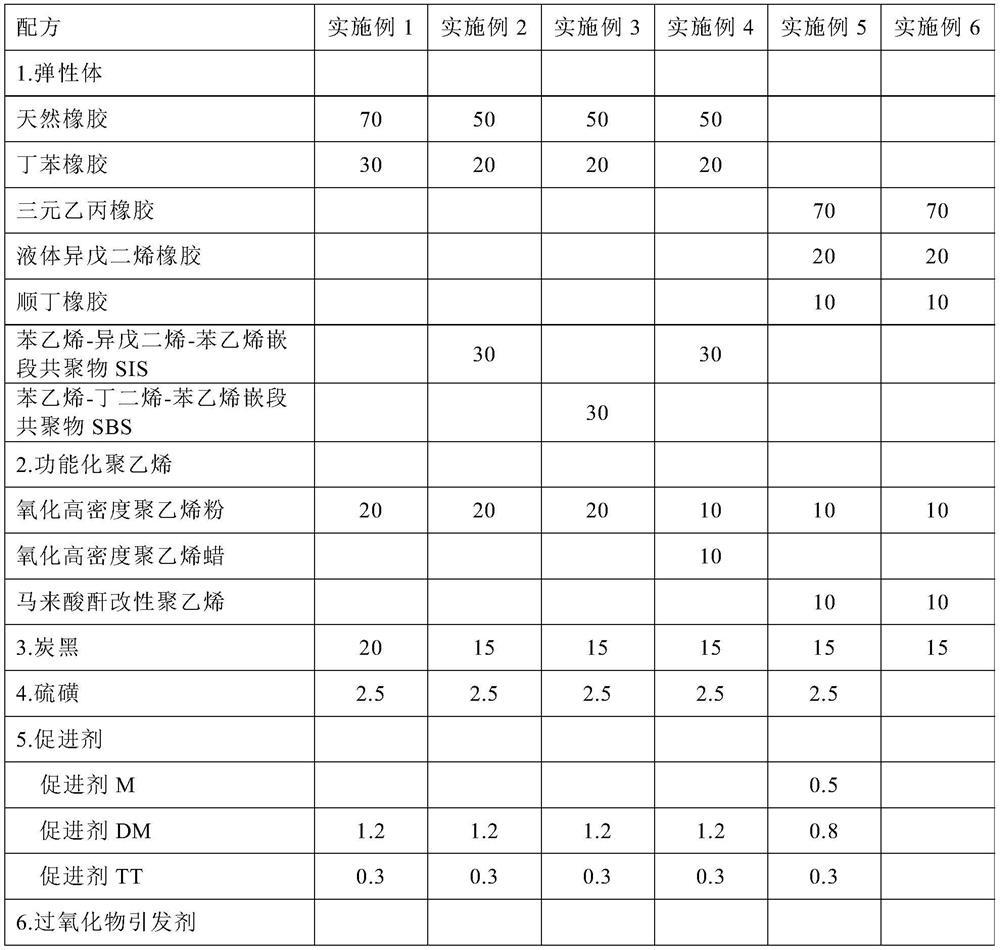

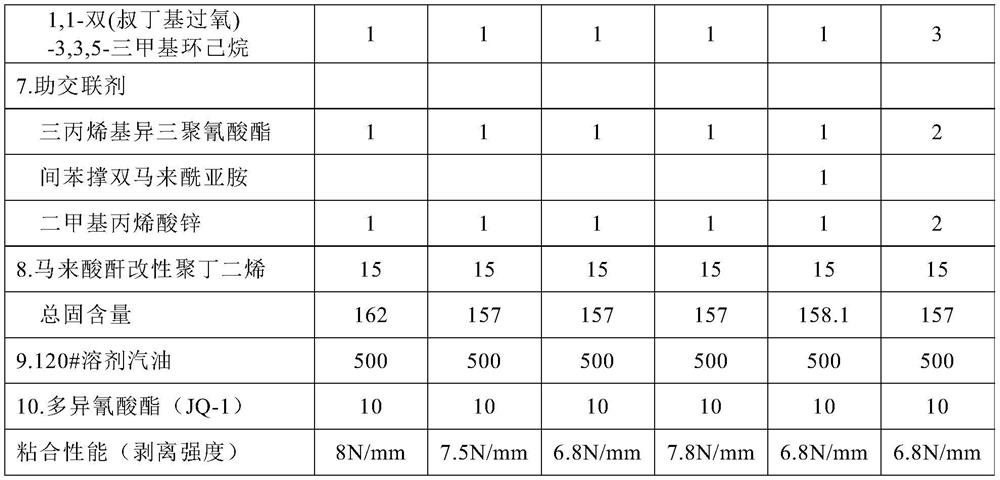

[0013] The principles and features of the present invention are described below through specific examples, which are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0014] The high-modulus, low-elongation ultra-high-molecular-weight polyethylene dipped canvas used in the rubber conveyor belt described in the ultra-high-molecular-weight polyethylene of the present invention adopts ultra-high-molecular-weight polyethylene filaments or ultra-high-molecular-weight polyethylene filaments The yarn mixed with silk and para-aramid filament is used as the longitudinal force-bearing material, and nylon 66 or nylon 6 is the woven canvas in which the auxiliary warp and weft yarns are interwoven. After glue coating, it is used to produce high-strength rubber conveyor.

[0015] The possible reaction process of the present invention is: the oxidized polyethylene or maleic anhydride-modified polyethylene contained in the glue use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com