Edge-cutting double-sided transmission tooth-shaped tight-up belt

A combined belt, double-sided technology, used in transmission belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of limited use range, large structure, large volume, large belt deformation, etc., to achieve good promotion and adaptability performance, high transmission efficiency, and low elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

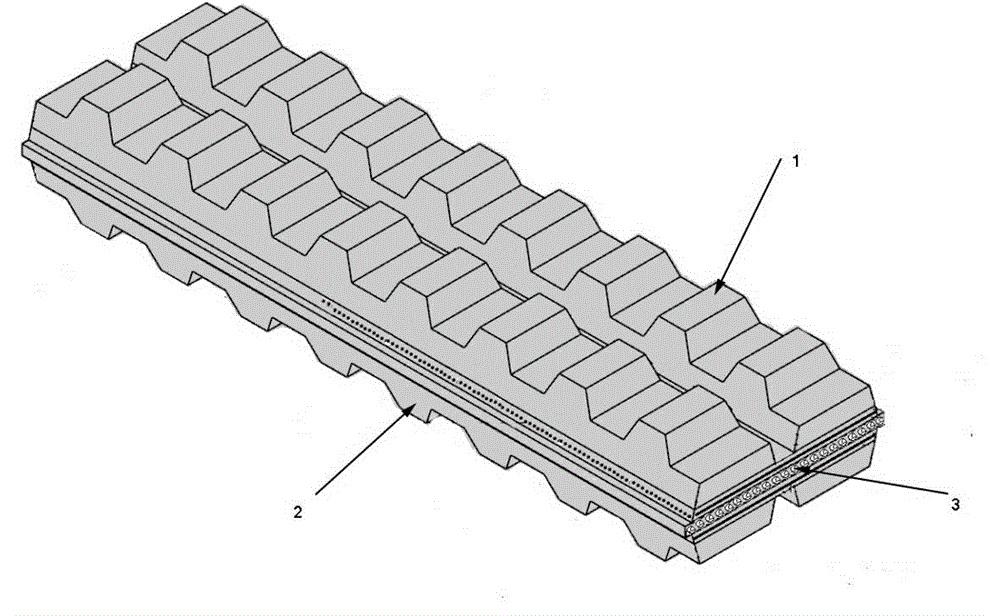

[0030] Such as figure 1 As shown, the edge-cut double-sided transmission toothed combined belt structure provided by the present invention includes a top cloth 1 , a bottom glue 2 and a transverse connecting core rope 3 . The main improvement point of the present invention is to improve the mechanical properties of the combined belt by improving the formula of the primer and transversely connecting the core rope through two dippings, and obtain better technical effects.

[0031] Specifically for this embodiment, in terms of parts by mass, the specific formulation of the raw materials for preparing the primer includes:

[0032] 100 parts of rubber-plastic alloy hydrogenated nitrile rubber, as the main material of the joint belt; the rubber-plastic alloy hydrogenated nitrile rubber is 80 parts by mass of hydrogenated nitrile and 20 parts by mass of polyvinyl chloride at 230 ° C The blended product under heat refining;

[0033] 18 parts of poly-p-phenylene terephthalamide pulp ...

Embodiment 2

[0059] Structure is with embodiment 1. Specifically for this embodiment, in terms of parts by mass, the specific formulation of the raw materials for preparing the primer includes:

[0060] 100 parts of rubber-plastic alloy hydrogenated nitrile rubber, as the main material of the joint belt;

[0061] 15 parts of poly-p-phenylene terephthalamide pulp fiber, used as the filling material of the primer, to enhance the lateral stiffness of the combined belt;

[0062] 8 parts of carboxyl liquid nitrile rubber, used as a softener to improve the processing performance and low temperature resistance of the rubber;

[0063] 13 parts fumed silica (SiO 2 ), further improve the structural performance of vulcanized rubber, improve the flex resistance of the transmission belt, the adhesion performance with the skeleton material, and improve the chemical resistance, heat resistance and weather resistance of the product;

[0064] 45 parts of high wear-resistant carbon black (N330), 15 parts...

Embodiment 3

[0077] Structure is with embodiment 1. Specifically for this embodiment, in terms of parts by mass, the specific formulation of the raw materials for preparing the primer includes:

[0078] 100 parts of rubber-plastic alloy hydrogenated nitrile rubber, as the main material of the joint belt;

[0079] 22 parts of poly-p-phenylene terephthalamide pulp fiber, used as the filling material of the primer, to enhance the lateral stiffness of the combined belt;

[0080] 10 parts of carboxyl liquid nitrile rubber, used as a softener to improve the processing performance and low temperature resistance of the rubber compound;

[0081] 15 parts fumed silica (SiO 2 ), further improve the structural performance of vulcanized rubber, improve the flex resistance of the transmission belt, the adhesion performance with the skeleton material, and improve the chemical resistance, heat resistance and weather resistance of the product;

[0082] 40 parts of high wear-resistant carbon black (N330)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com