A rice combine harvester eccentric cutting flow primary separation device

A combine harvester and separation device technology, applied in threshing equipment, agricultural machinery and implements, agriculture, etc., can solve the problems of reducing the belt-back effect of threshing components, so as to improve the working performance and service life, improve the initial separation rate, The effect of reducing shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

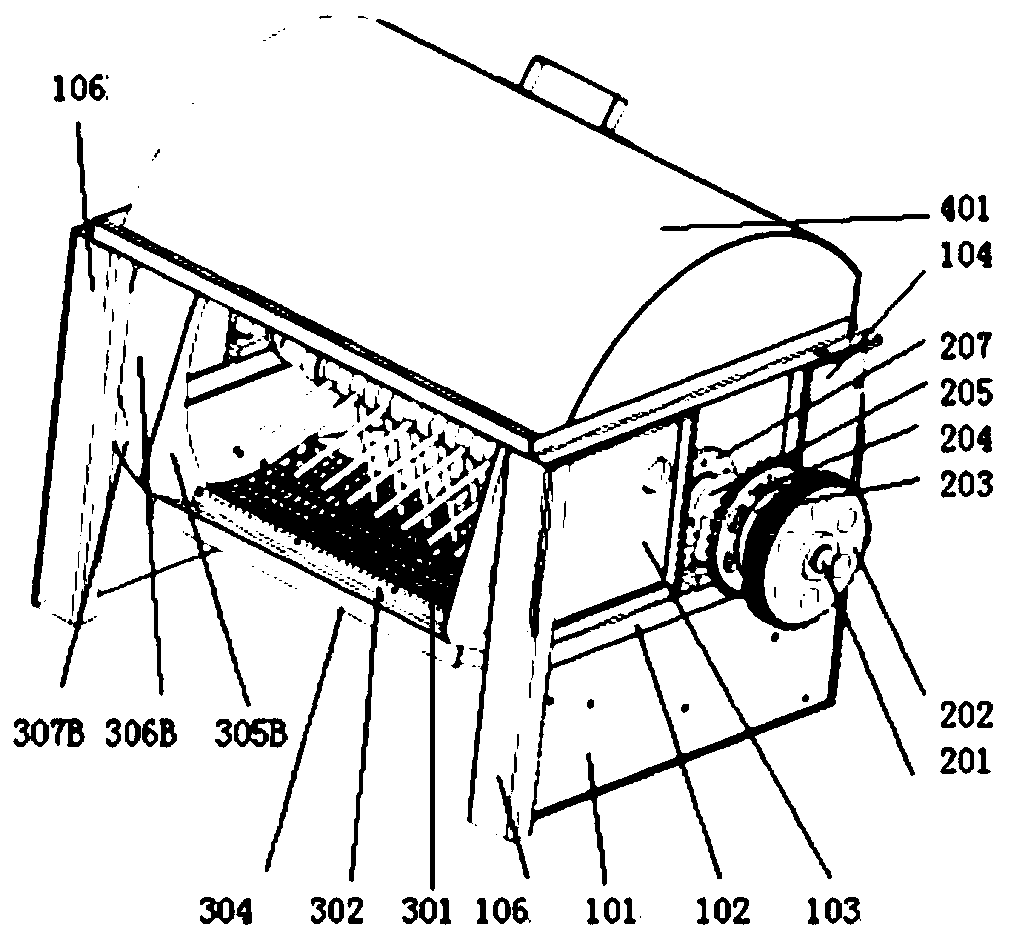

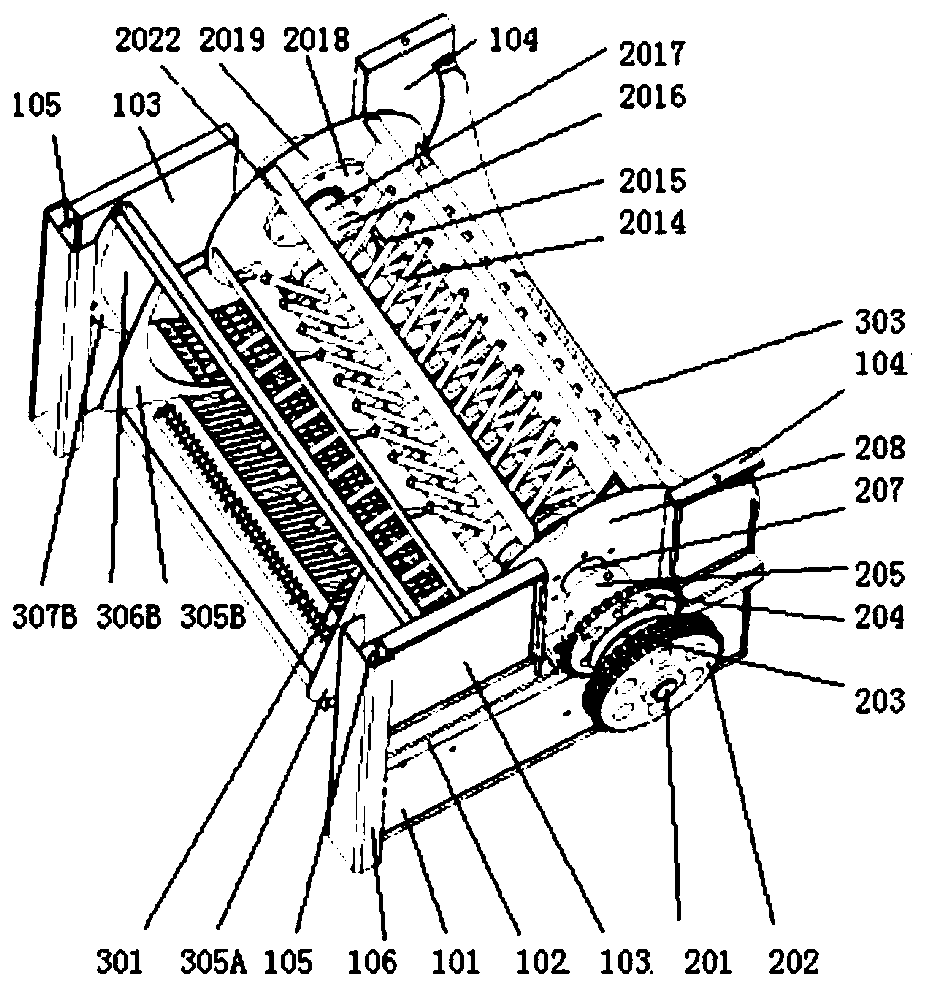

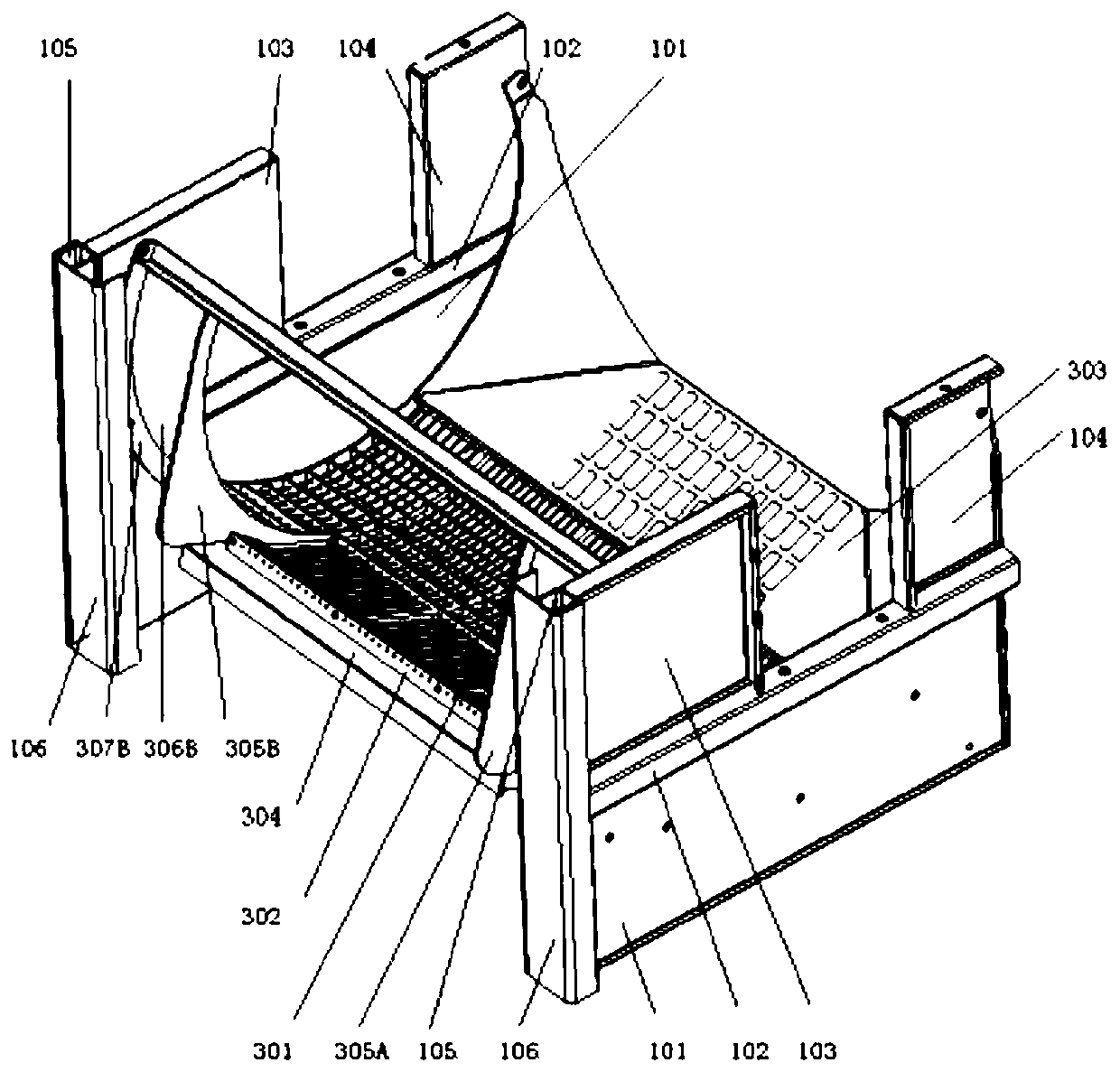

[0040] Such as figure 1 , figure 2 As shown, the rice combine harvester eccentric cutting flow separation device of the present invention comprises a frame, a cutting flow threshing cylinder, a concave plate screen and a top cover; the cutting flow threshing cylinder is installed on the frame, and the concave plate The sieve is located under the cutting flow threshing drum, and its two ends are fixed on the frame. The top cover is located above the cutting flow threshing drum, and its lower end is connected with the frame.

[0041] Described frame comprises baffle plate 101, beam 102, front sealing plate 103, rear sealing plate 104, first groove bar 105 and second groove bar 106, and described baffle plate 101 is installed below cross beam 102, and front sealing plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com