Automatic gas-locking feeder

A technology of automatic lock and feeder, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., to achieve the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

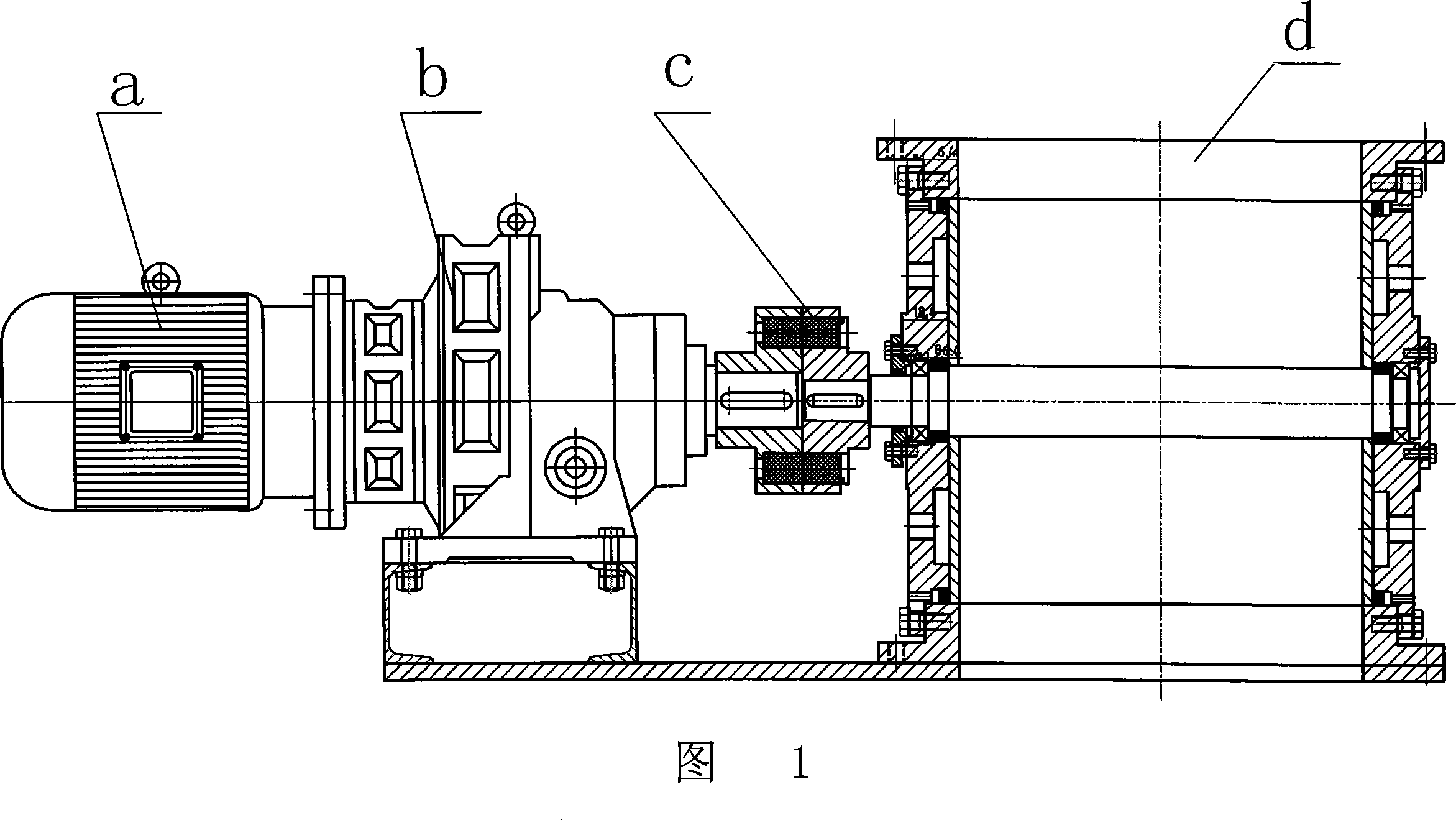

[0022] As shown in Figure 1, the overall structure is: a 4 kW variable frequency speed regulating motor with adjustable speed to meet the PLC control of different working systems; Resistance; c coupling adopts nylon column pin connection; d automatic air lock feeder, which is the core technology of the present invention.

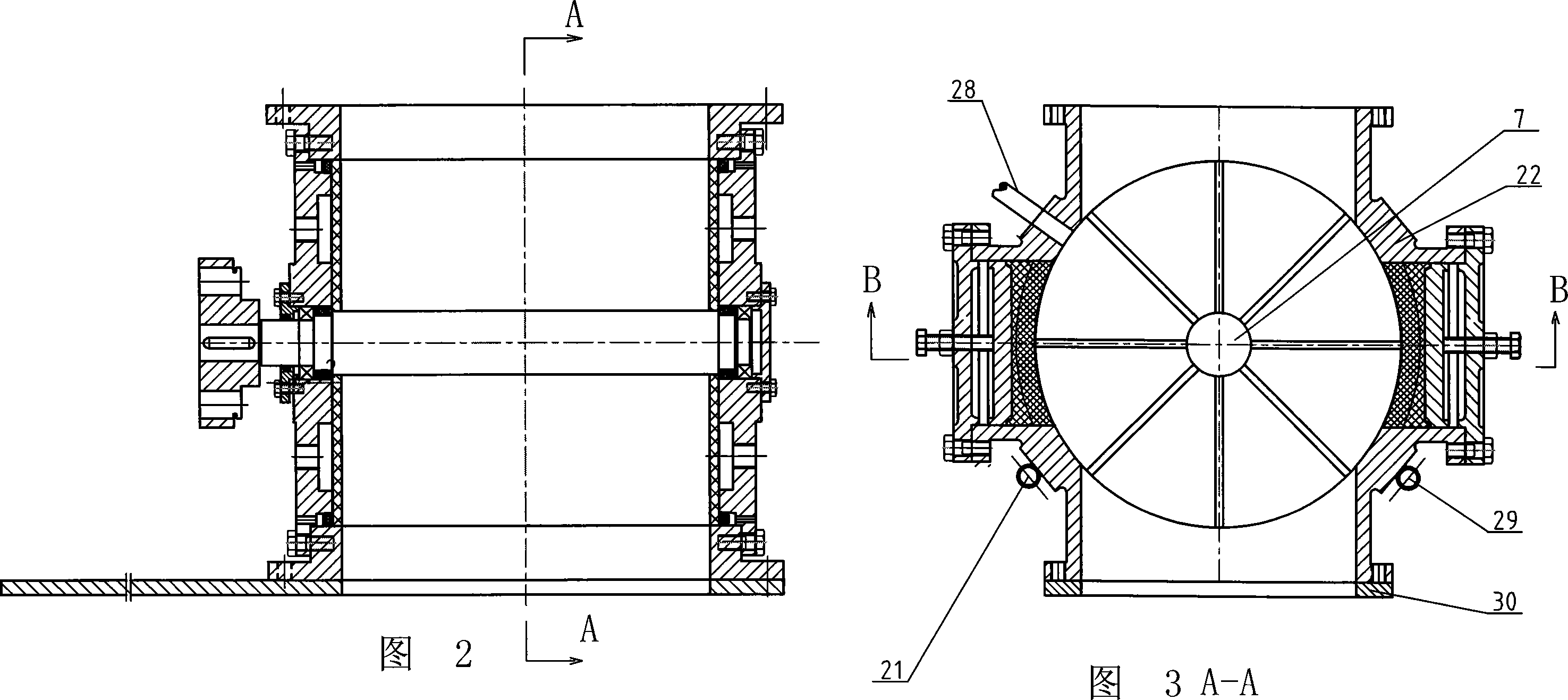

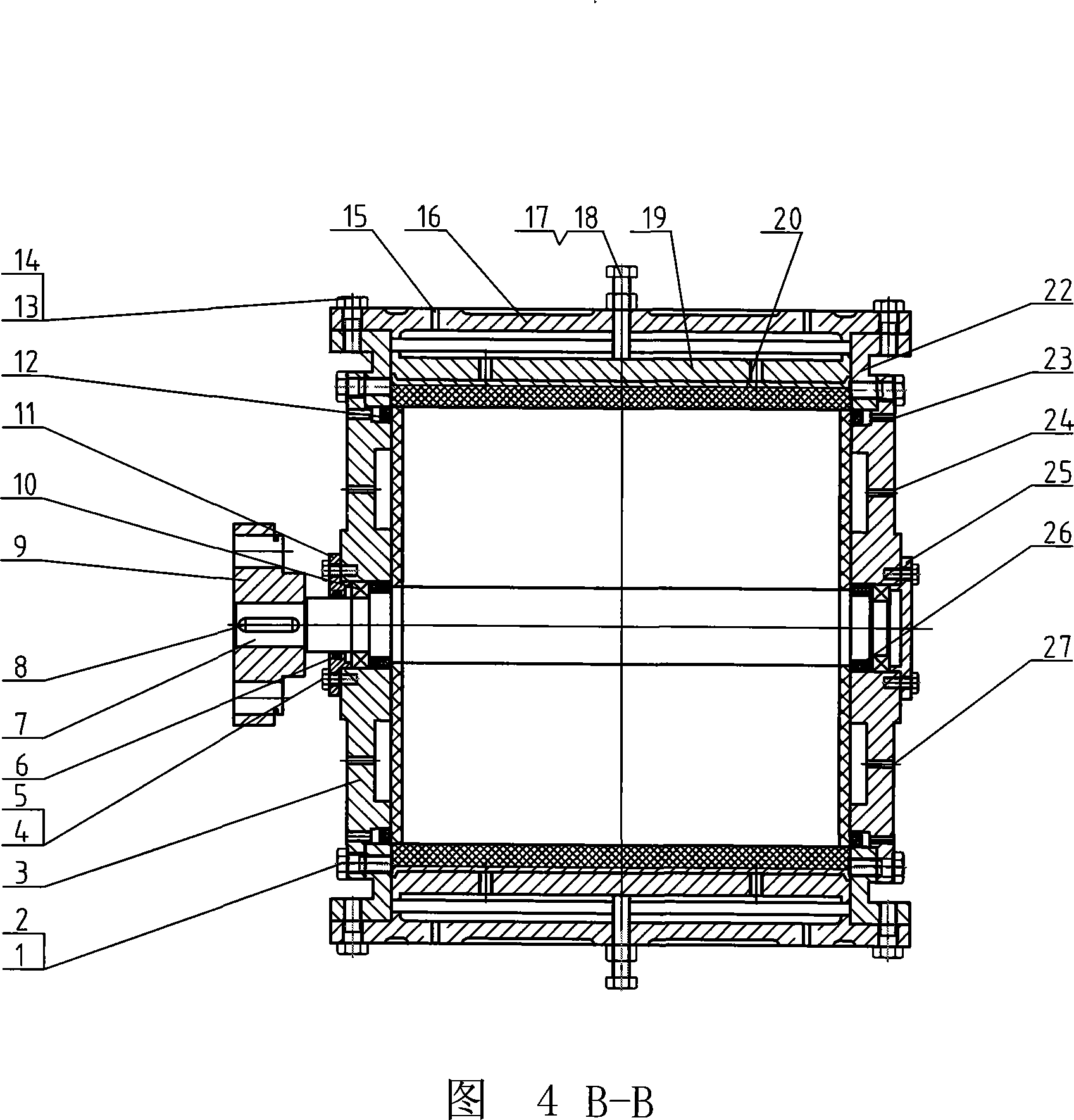

[0023] The product of the present invention will be further described in detail below in conjunction with the accompanying drawings. The half-coupling 9 is connected with the nylon pin of the half-coupling of the cycloidal pinwheel reducer. This figure has been omitted. The shaft 9 is connected, the two ends of the bearing 10 are provided with seals, the inner side of the transparent cover 11 is the bearing frame oil seal 6, the inner side of the bearing 10 is a carbon fiber packing seal 26, the bearing seat is supported by two round end faces 3, and the bolts 1 and 2 connect the round The connection between the end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com