Automatic filling system and method for single-component polyurethane sealing gum

A polyurethane sealant, automatic filling technology, applied in barrel/barrel filling, liquid filling, etc., can solve the problems of affecting the storage period of sealant, low work efficiency, premature crusting, curing, etc., to reduce sealant Opportunities for contact with air, effects on solving waste and large maintenance, stabilizing quality and shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

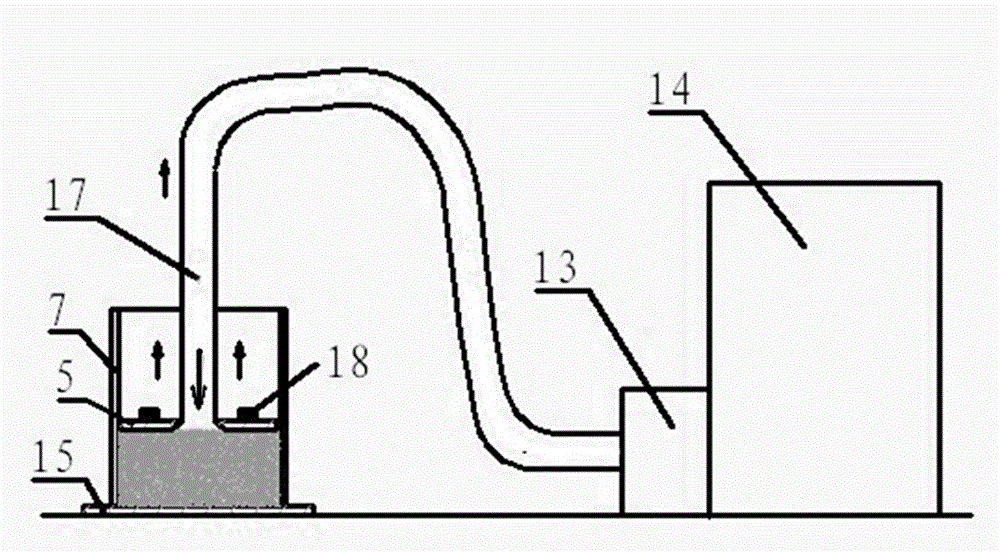

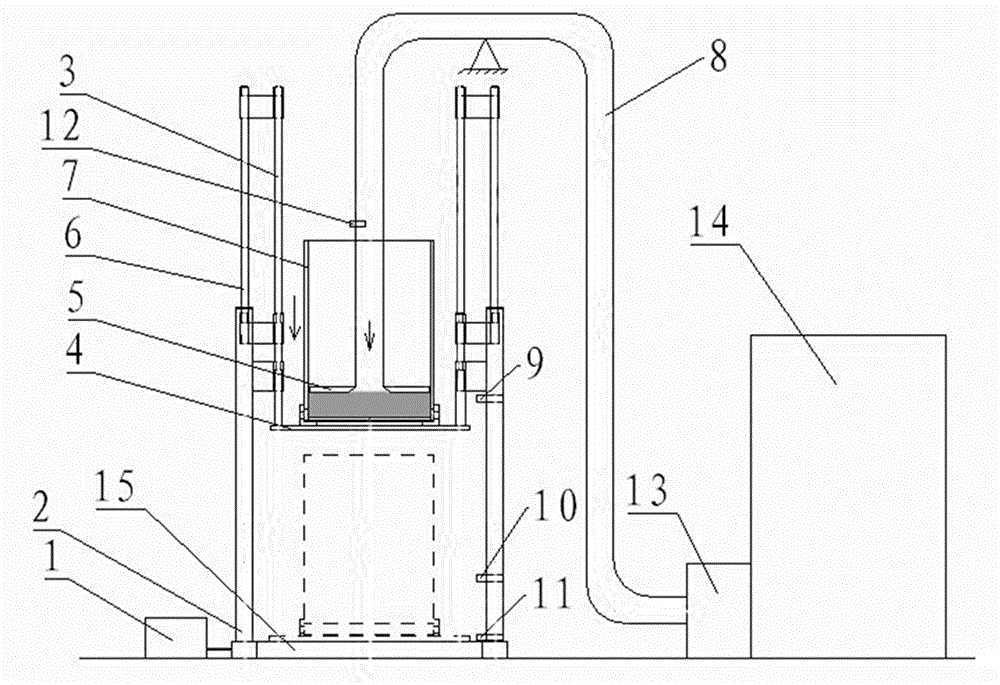

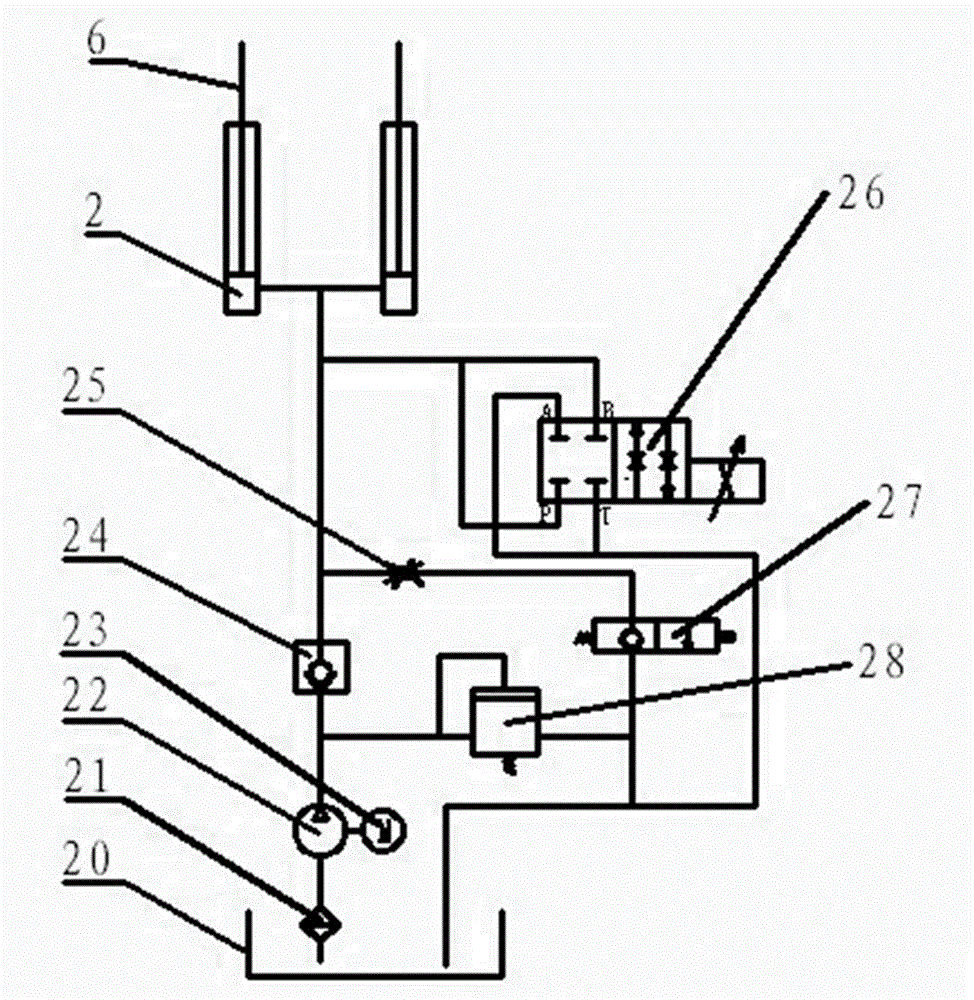

[0032] like figure 2 As shown, the structural principle diagram of the one-component polyurethane sealant automatic filling system of the present invention is provided, which includes a glue making machine 14, a glue pump 13, a rubber hose 8, a pressure plate 5, a tray 4, a guide rod 3, The hydraulic cylinder 2, the fixed base 15, the hydraulic control system 1 and the control circuit part, the glue making machine 14 shown is used to complete the production of one-component polyurethane sealant, and the glue pump 13 is used to pump out the prepared sealant. The rubber hose 8 is an inverted U shape. One end of the rubber hose 8 is connected to the output end of the rubber pump 13, and the other end is connected to the pressure plate 5. The rubber hose 8 is made of stainless steel to solve the problem caused by the fragility of the rubber hose. Problems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com