Elastic sealing device of sludge filter press

A sludge filter press, elastic sealing technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

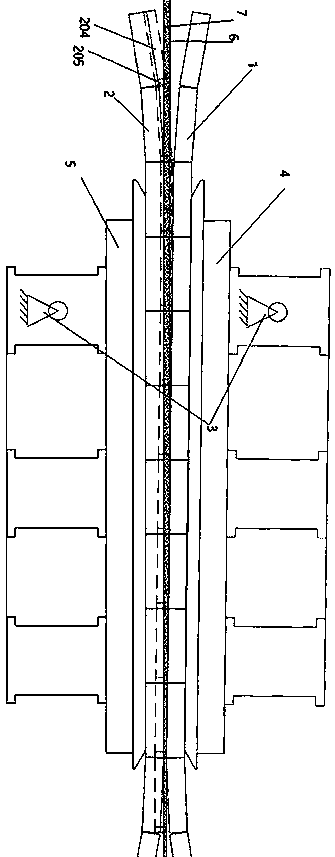

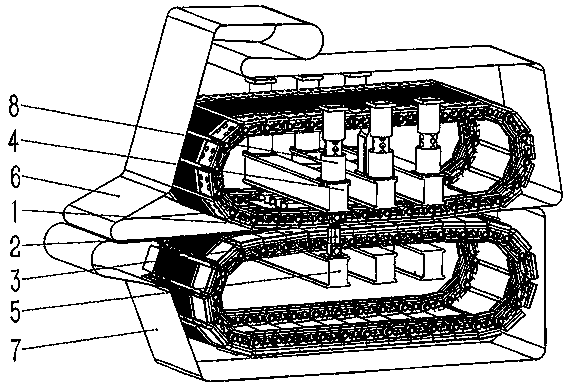

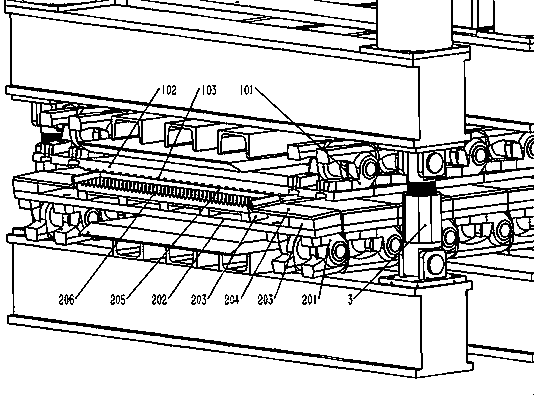

[0028] Embodiment: an elastic sealing device of a sludge filter press adopts a modular design, specifically including an upper plate chain circulation chain 1, a lower plate chain circulation chain 2, a hinged distance adjustment module 3, an upper pressure frame module 4, a lower pressure The frame module 5, the upper filter cloth circulating chain 6 and the lower filter cloth circulating chain 7, the upper pressing frame module 4 and the lower pressing frame module are respectively fixed on the outer frame, and the upper plate chain circulating chain 1 circulates on the upper pressing frame module 1 Outside, the lower plate chain circulating chain 2 circulates outside the lower press frame module 5, the upper filter cloth circulating chain 6 circulates outside the upper plate chain circulating chain 1, and the lower filter cloth circulating chain 7 circulates outside the lower plate chain circulating chain 2 Externally, the sludge is clamped on the opposite side of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com