Polystyrene foamed plastic and preparation method thereof, and composite board prepared from polystyrene foamed plastic

A polystyrene and foamed plastic technology, applied in building components, thermal insulation, sound insulation, etc., can solve the problems of high apparent density, hollow, air leakage, non-puncture, etc., and achieve good dimensional stability, high compressive strength, The effect of low apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

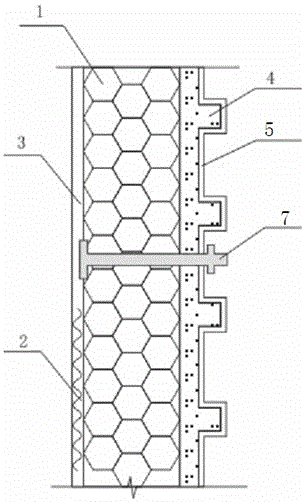

Image

Examples

Embodiment 1

[0026] Embodiment 1, accurately weigh 30 kg of expandable polystyrene material, which can be various polystyrene materials, such as expandable polystyrene beads, etc.; weigh 4 kg of inorganic MUEC glue , the inorganic MUEC glue is a mixture of AI2O3, TiO2, and SiO2, and the weight ratio of AI2O3:TiO2:SiO2 is 1:2.6:3.8. First, put the expandable polystyrene material into the pre-expanding machine, and control the amount of steam entering the pre-expanding machine and the temperature of the intake air through the steam and temperature regulating valve. The steam pressure is controlled at 3.5MPa, and the inside of the pre-expanding machine The temperature is controlled at 85°C, and the time is controlled at 4 minutes. After the raw materials in the standby are completely pre-expanded, the beads are discharged from the outlet of the pre-expanding machine, enter the drying bed for drying, and are transported to the silo through the conveying pipe; the pre-expanded The soaked polyst...

Embodiment 2

[0027]Embodiment 2, accurately weigh 40 kg of expandable polystyrene material, which can be various polystyrene materials, such as expandable polystyrene beads, etc.; weigh 6 kg of inorganic MUEC glue , the inorganic MUEC glue is a mixture of AI2O3, TiO2, and SiO2, and the weight ratio of AI2O3:TiO2:SiO2 is 1:2.6:3.8. First, put the expandable polystyrene beads into the pre-expanding machine, and control the amount of steam entering the pre-expanding machine and the temperature of the intake air through the steam and temperature regulating valve. The steam pressure is controlled at 4MPa, and the inside of the pre-expanding machine The temperature is controlled at 90°C, and the time is controlled at 3 minutes. After the raw materials in the standby are completely pre-expanded, the beads are discharged from the outlet of the pre-expanding machine, enter the drying bed for drying, and then are transported to the silo through the conveying pipe; the pre-expanded The soaked polysty...

Embodiment 3

[0028] Embodiment 3, accurately weigh 20 kg of expandable polystyrene material, which can be various polystyrene materials, such as expandable polystyrene beads, etc.; weigh 2 kg of inorganic MUEC glue , the inorganic MUEC glue is a mixture of AI2O3, TiO2, and SiO2, and the weight ratio of AI2O3:TiO2:SiO2 is 1:2.6:3.8. First, put the expandable polystyrene beads into the pre-expanding machine, and control the amount of steam entering the pre-expanding machine and the temperature of the intake air through the steam and temperature regulating valve. The steam pressure is controlled at 3MPa, and the inside of the pre-expanding machine The temperature is controlled at 80°C, and the time is controlled at 5 minutes. After the raw materials in the standby are completely pre-expanded, the beads are discharged from the outlet of the pre-expanding machine, enter the drying bed for drying, and are transported to the silo through the conveying pipe; the pre-expanded The soaked polystyrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com