Graphite sheet electrical heating component and manufacturing method thereof

A graphite sheet and electric heating technology, which is applied in the direction of electrical components, ohmic resistance heating, electric heating devices, etc., can solve the problems of difficulty in controlling the uniformity of graphite slurry, unfavorable large-scale promotion, aging and failure of adhesive materials, etc., and achieve comprehensive The effect of industrial upgrading, simple and reliable manufacturing process, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

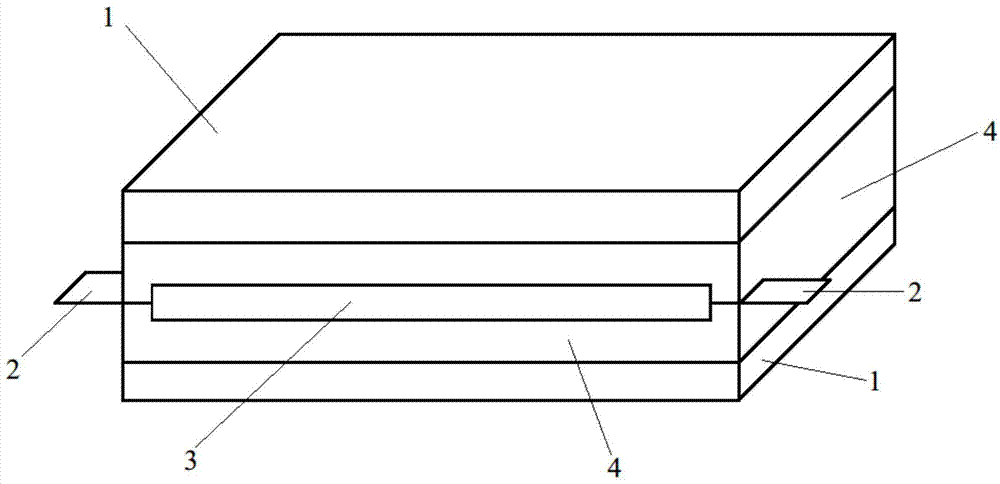

[0022] Such as figure 1 As shown, this embodiment includes: an insulating layer 1, a flexible graphite sheet 3 disposed between the insulating layers 1, copper foil electrodes 2 at both ends, and a sealant 4 between the graphite sheet and the insulating layer.

[0023] The insulating layer 1 adopts different materials according to the heating temperature, wherein:

[0024] 1) When the heating temperature is below 100°C, it is a low temperature heater. At this time, the insulating layer is made of polycarbonate film, and the sealant is made of insulating and heat-conducting glue with a temperature resistance of about 150°C. Polycarbonate film can withstand a temperature of about 130°C, and has good insulation and mechanical strength. While insulating the graphite sheet, it strengthens the strength of the entire heater.

[0025] 2) When the heating temperature is between 100 and 400°C, it is a medium temperature heater. At this time, the insulating layer is made of polyimide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com